Construction thermal insulation decorative system

A thermal insulation and construction technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of multiple layers of thermal insulation systems, heavy building load-bearing, large overall thickness, etc., to achieve less quality control links, low thermal conductivity, dry The effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

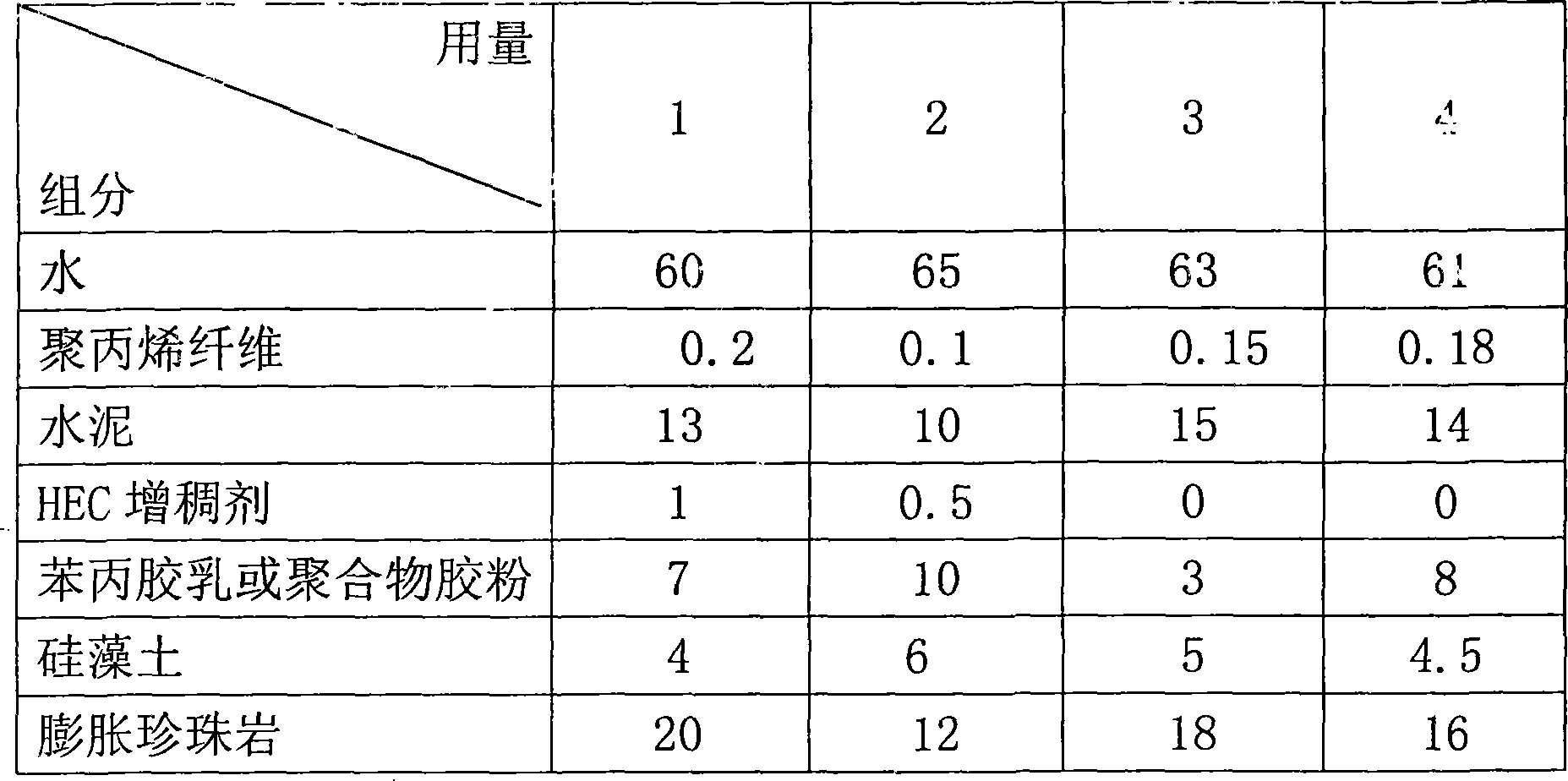

[0018] The base wall of this example is the inner and outer parts of the concrete wall of the building. The formula of the thermal insulation slurry layer is as follows: weight kg

[0019]

[0020] This example selects Group 1 in the formula.

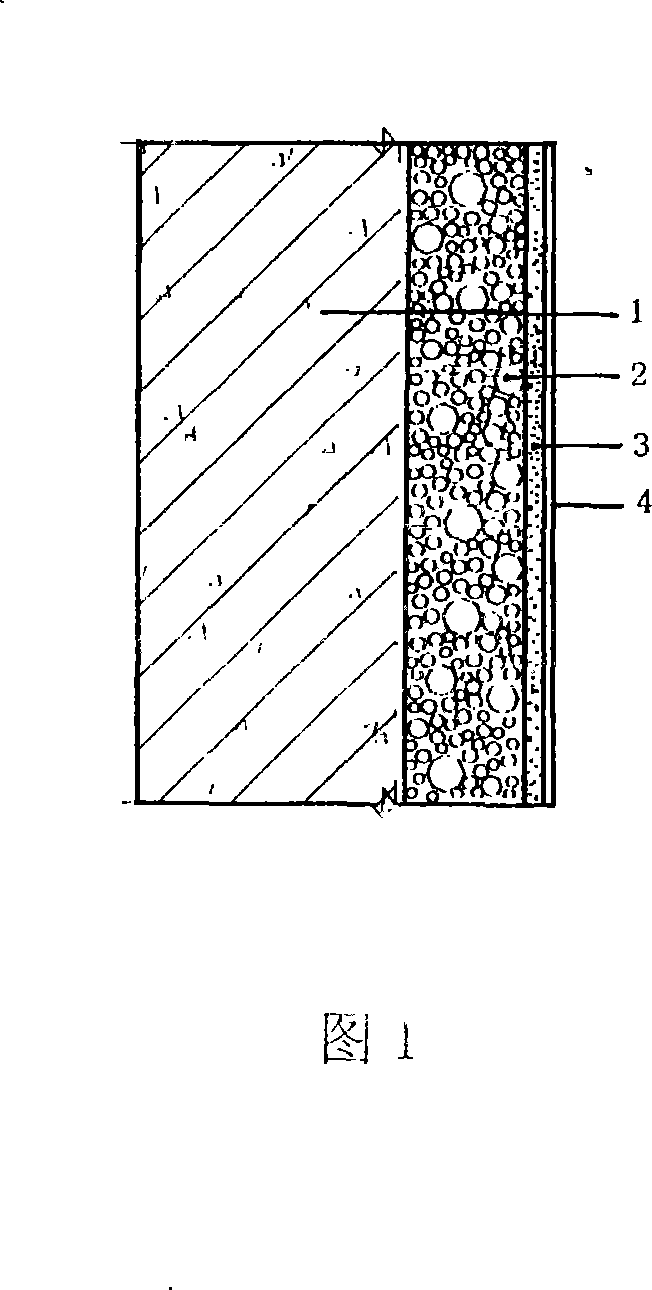

[0021] Stir the components in the first group of formulations into a slurry. Apply directly on the surface of the base wall, and the thickness of each application is 10mm. The thickness of the thermal insulation slurry layer after drying is determined by the design, usually 20-40mm. In this example, choose 30mm to dry and then apply the building flexible putty layer. After the flexible putty layer is dried and polished, apply the architectural paint layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com