Packing mold material used in investment precision casting

A technology of investment precision casting and mold materials, which is applied in the direction of casting molding equipment, etc., can solve the problem that it is difficult to meet the requirements of precision thin-walled or jewelry castings with increasingly higher dimensional accuracy and surface quality, and the adverse effects of surface quality, which are higher than 0.5 % and other issues to achieve the effect of meeting high surface quality, avoiding the danger of mold material swelling, and reducing linear shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

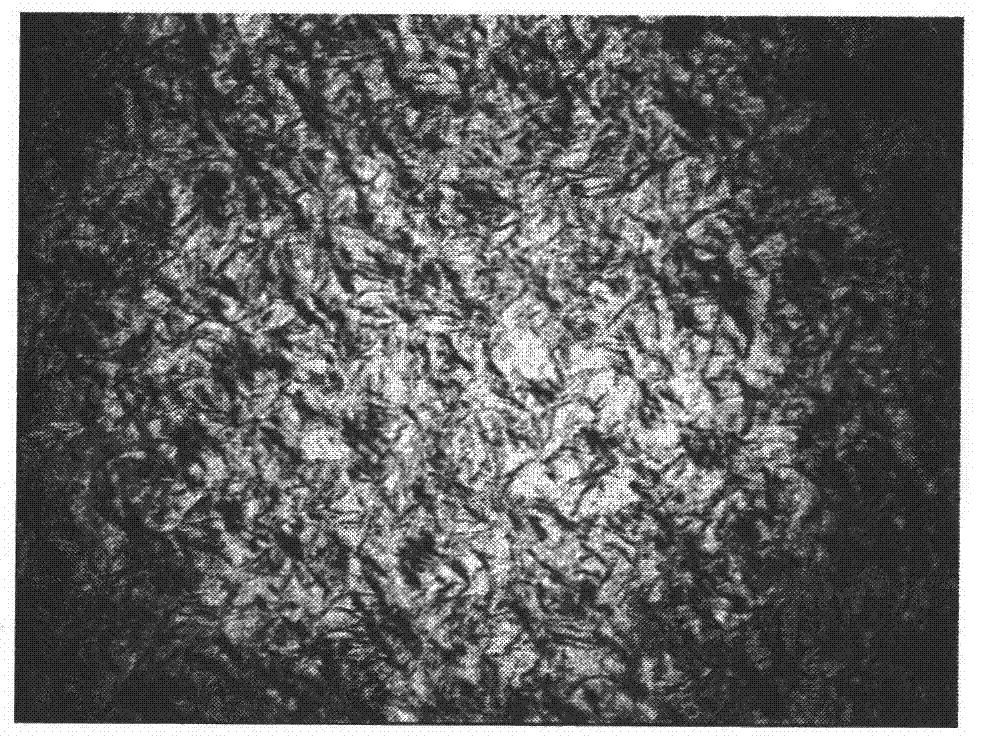

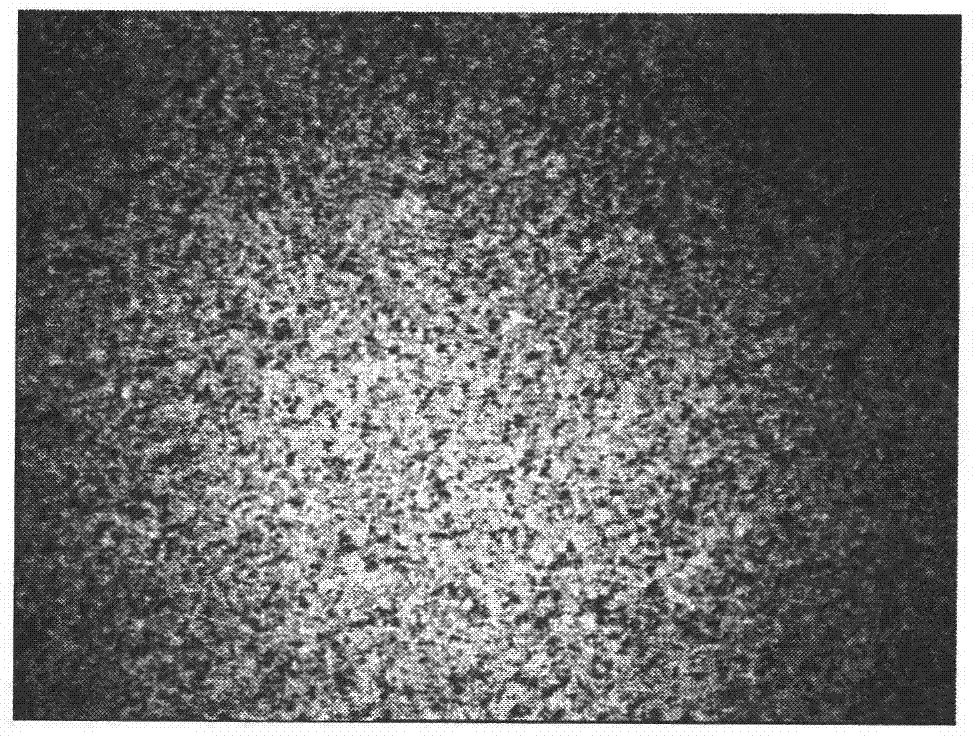

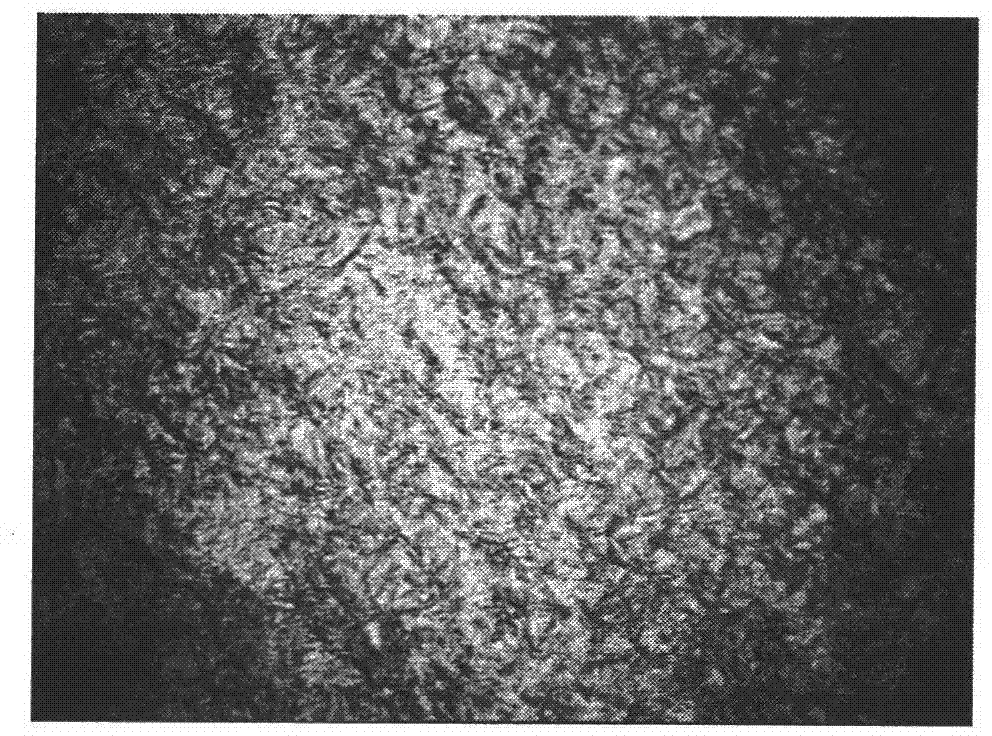

Image

Examples

Embodiment 1

[0068] 66# fully refined paraffin wax 10%

[0069] 64# fully refined paraffin wax 10%

[0070] 62# fully refined paraffin wax 15%

[0071] Hydrogenated Rosin, Highly Hydrogenated Grade 1 30%

[0072] EVA, melt index 50 5%

[0073] Tapioca Starch, Industrial Grade 15%

Embodiment 2

[0075] 62# semi-refined paraffin wax 42%

[0076] 115# polymerized rosin 40%

[0077] EVA, melt index 45 10%

[0078] Tapioca Starch, Technical Grade 8%

Embodiment 3

[0080] 64# fully refined paraffin wax 15%

[0081] 62# fully refined paraffin wax 35%

[0082] 140# polymerized rosin 10%

[0083] Hydrogenated Rosin, Ordinary Hydrogenated Grade 1 30%

[0084] PET, melt index 50 3%

[0085] EVA, melt index 35 5%

[0086] Tapioca Starch, Industrial Grade 12%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com