Method for preparing wax mold of monocrystal spiral crystal selector

A spiral crystal selector and spiral crystal selection technology, applied in the field of investment precision casting, can solve the problems of spiral crystal selector mold complexity, high metal mold price, cumbersome preparation process, etc., achieve small capital investment, save time and Economic cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

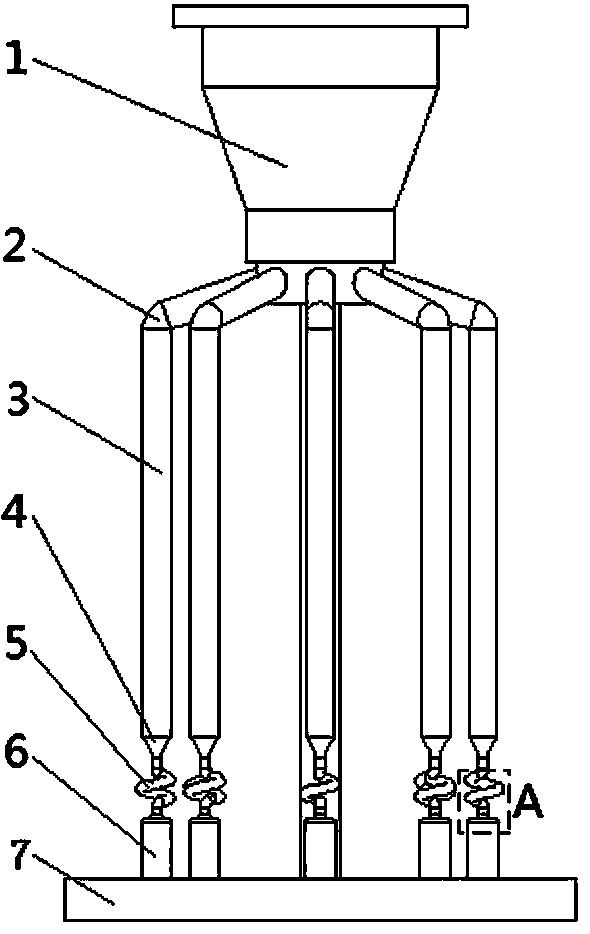

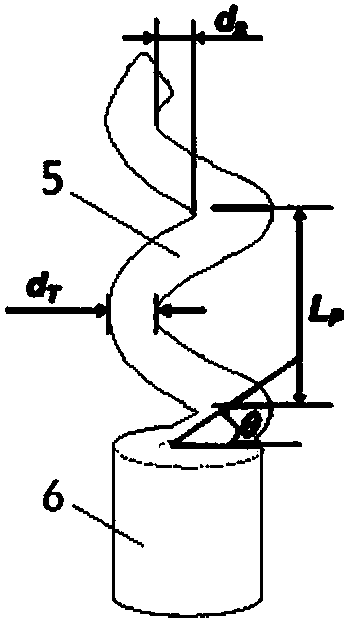

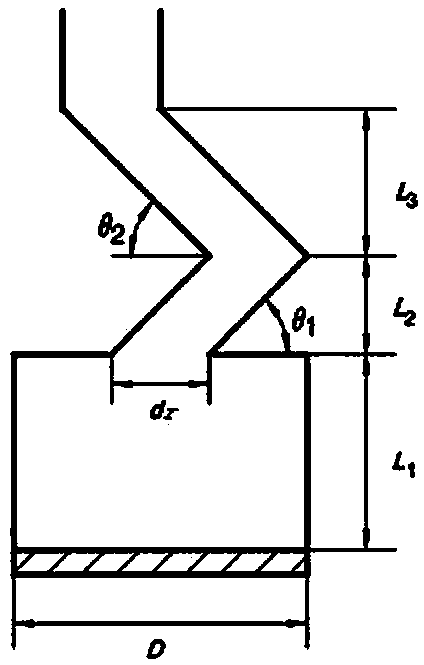

[0027] Such as Figure 1~4 As shown, the wax pattern of the single crystal spiral crystal selector of the present invention includes the wax pattern 6 of the seeding segment, the wax pattern 5 of the spiral crystal selection segment and the wax pattern 4 of the transition segment connected in sequence from bottom to top. In this specific embodiment: it is necessary to use bonding wax heated to 130° C. to assemble the components 1 to 7 into a wax model tree. Firstly, sprue wax mold 2, wax mold sample 3, spiral selection section wax mold 5, seeding section wax mold 6 and transition section wax mold 4 are bonded in turn for later use; then the gate is fixed with an iron stand The cup wax model 1 and the bottom plate wax model 7 are two parts; finally press all parts figure 1 The structures shown are glued together to form the wax model tree for the spiral crystal selector.

[0028] The present invention mainly provides a method for rapidly preparing a single crystal spiral crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com