Wax pattern correcting tool

A correction device and wax pattern technology, which is applied in the direction of casting and molding equipment, can solve the problems of wax pattern accuracy deterioration and casting qualification rate drop, and achieve the effect of large adjustment range, high adjustment accuracy and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

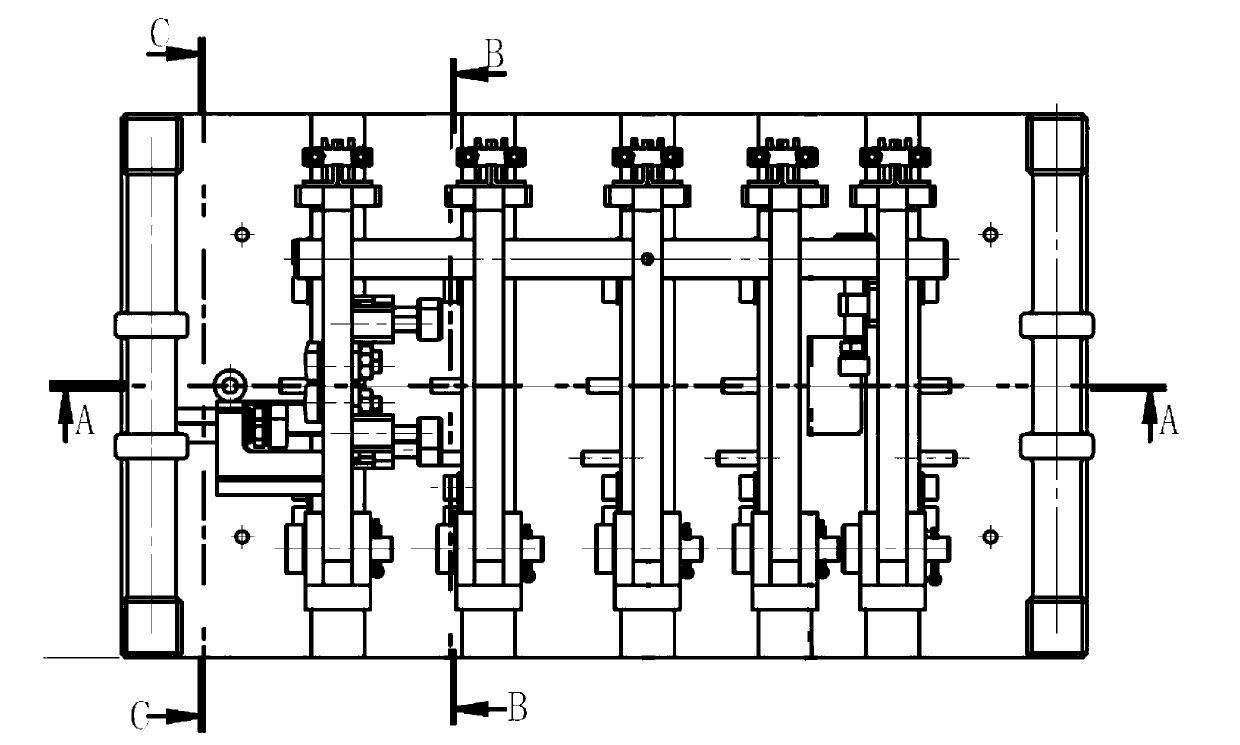

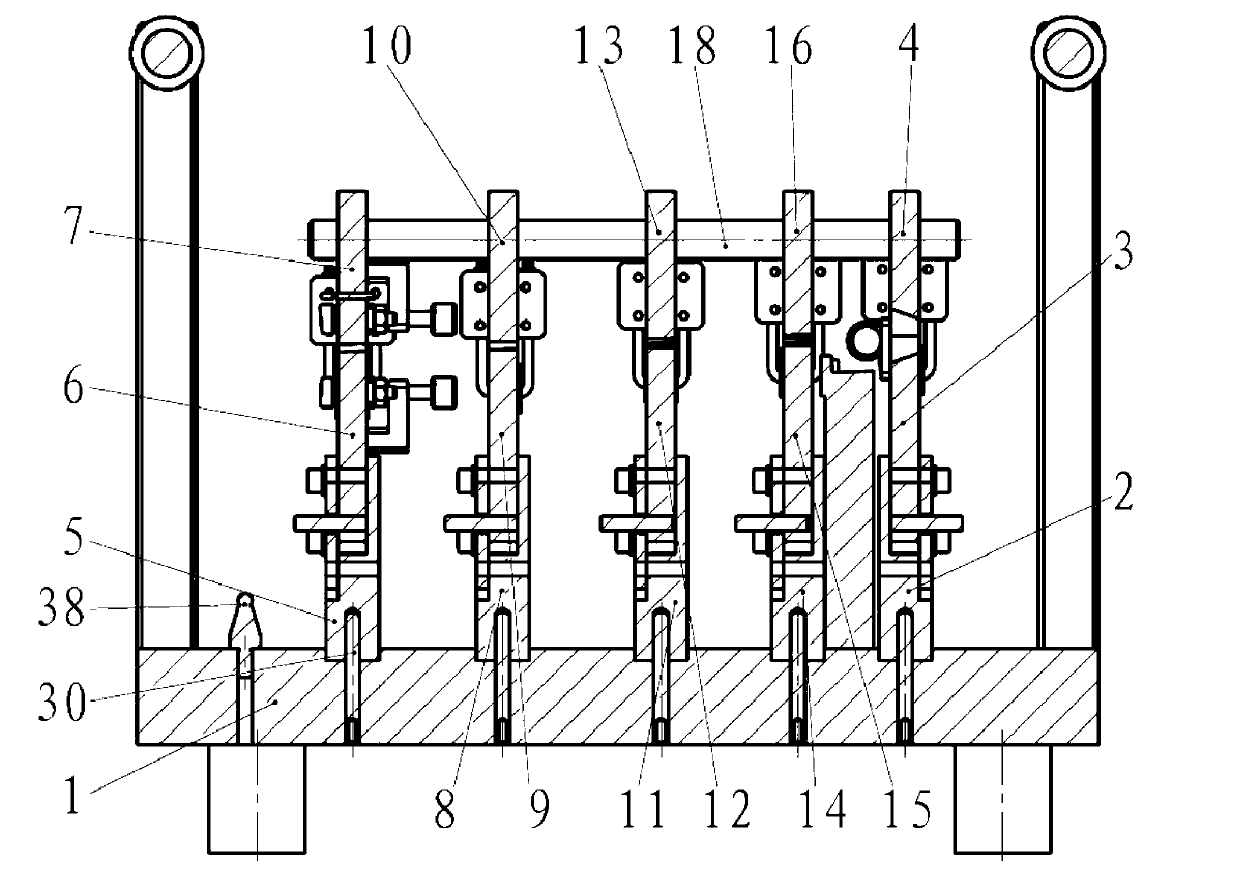

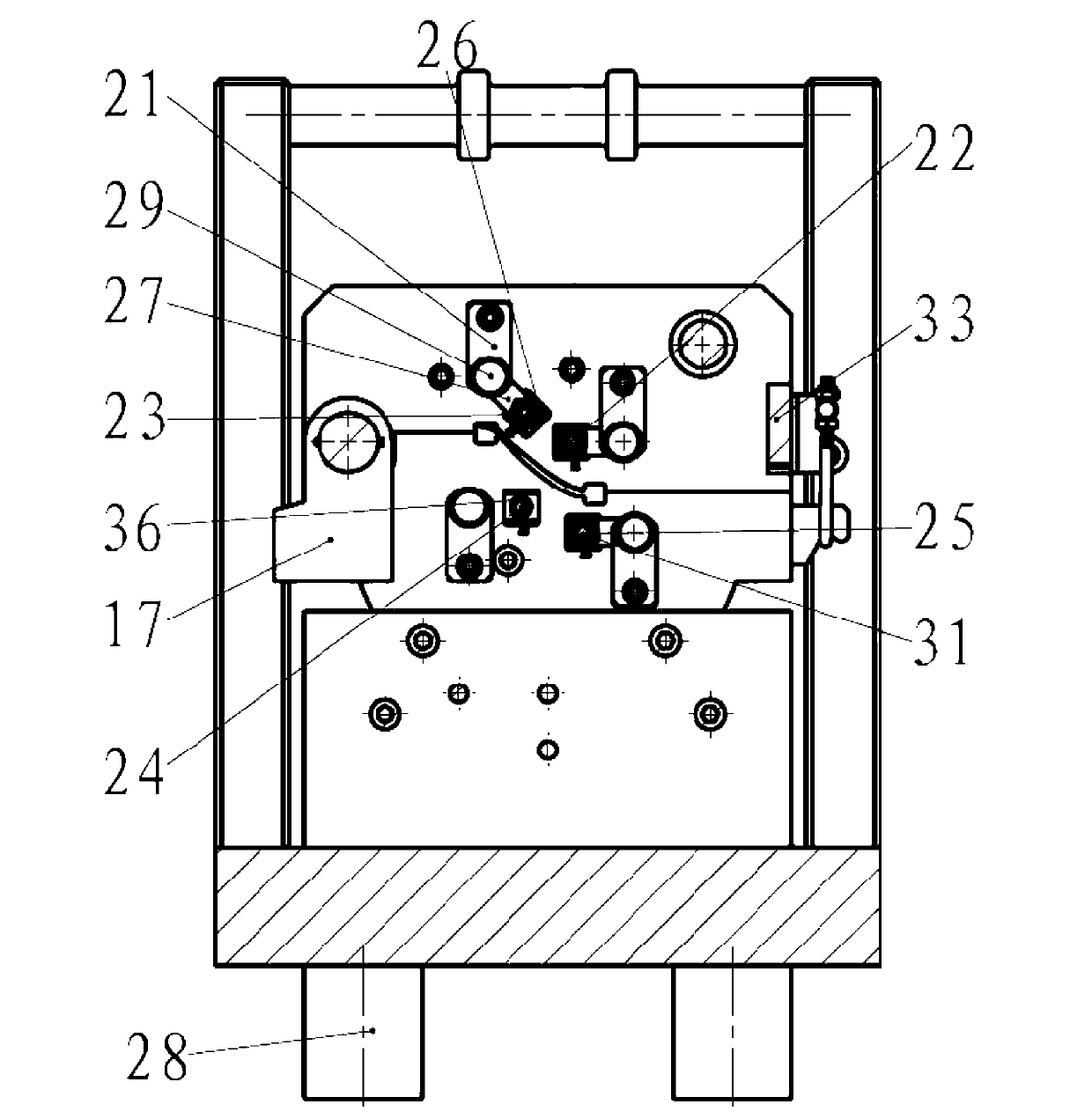

[0023] Figure 1 to Figure 4 A specific structure of the present invention is shown; as shown in the figure, the present invention includes: base plate 1, the first correction surface fixing plate 2, the first correction surface fixing frame I, the first correction surface fixing frame II, the second calibration surface Front fixing plate 5, second correction surface fixing frame I, second correction surface fixing frame II, third correction surface fixing plate 8, third correction surface fixing frame I, third correction surface fixing frame II, fourth correction surface fixing Plate 11, the fourth correction surface fixing frame I, the fourth correction surface fixing frame II, the fifth correction surface fixing plate 14, the fifth correction surface fixing frame I, the fifth correction surface fixing frame II, the connecting block 17, the connecting shaft 18 , five cover plates 19, the first crown compression block 20, the second crown compression block 21, the first crown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com