Casting die easy to strip

A casting mold and mold pouring technology, which is applied in casting and molding equipment and other directions, can solve the problems of wax mold size or shape defects, and the inability to guarantee the quality of wax molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

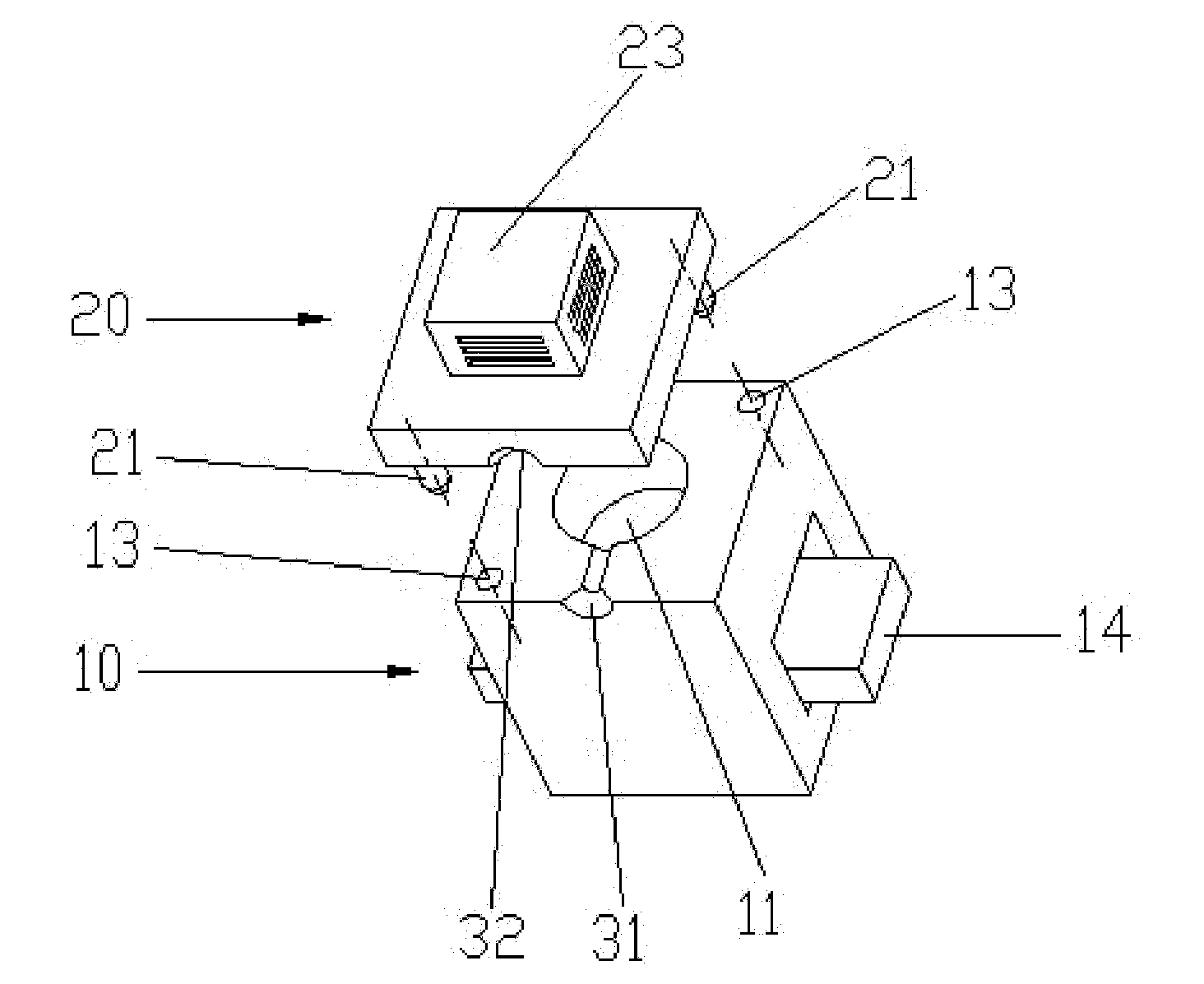

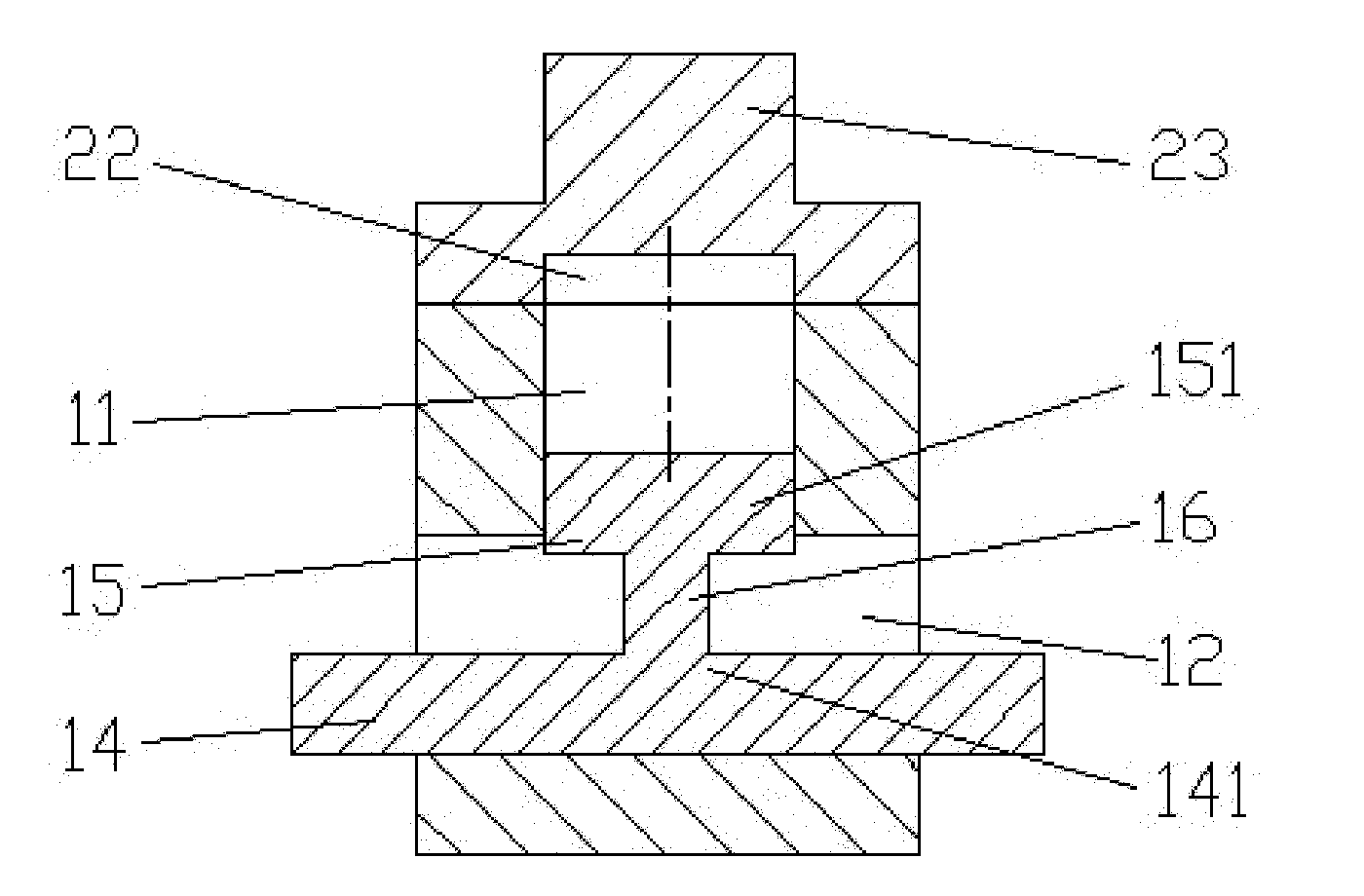

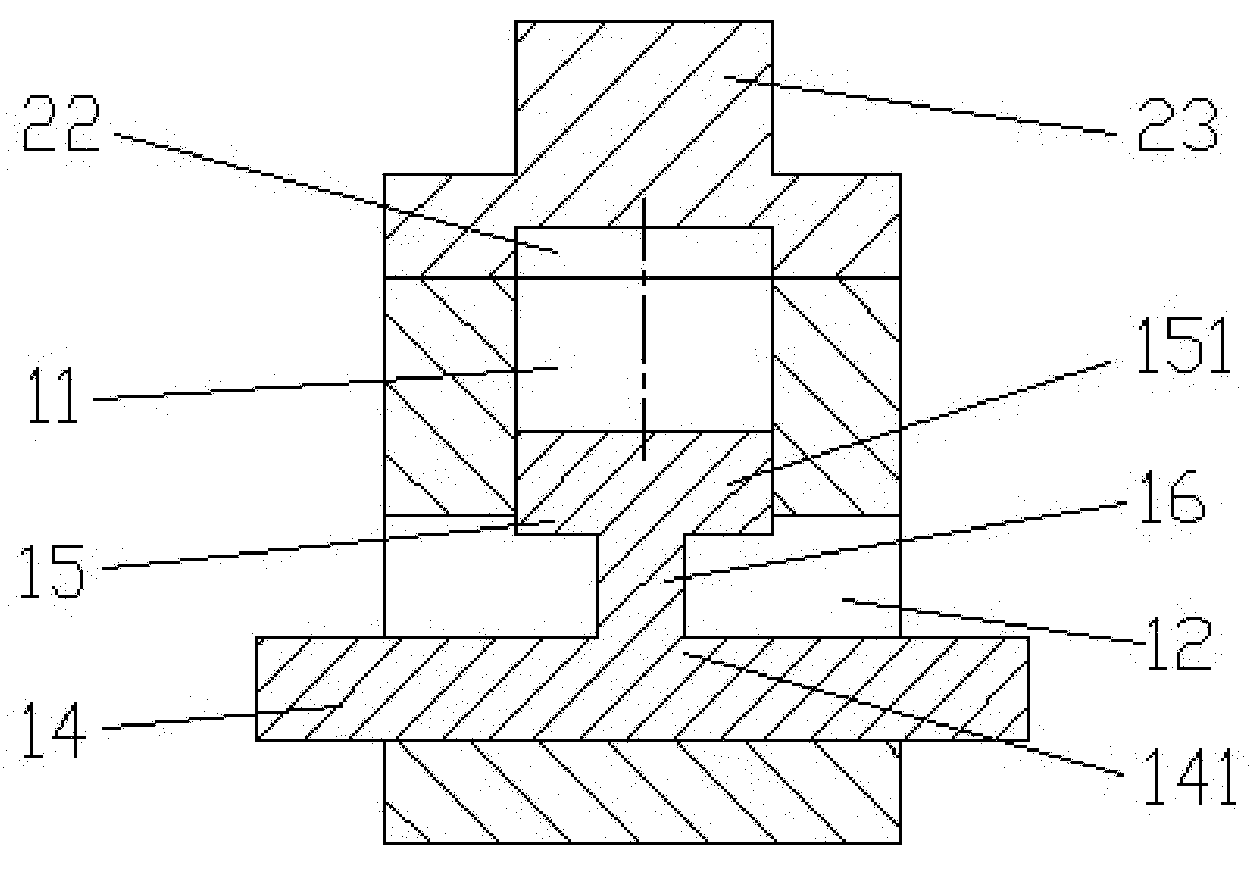

[0015] Refer to attached figure 1 To attach figure 2 , the casting mold in the present embodiment, it comprises lower mold 10, upper mold 20, lower mold sprue 31, upper mold sprue 32, it is characterized in that: lower mold 10 has the first through cavity 11 that vertically arranges and horizontal The provided second through cavity 12 communicated with the first through cavity 11, the first through cavity 11 is provided with a sliding block 15 matched with it, the second through cavity 12 is provided with a flat plate 14, and the two ends of the flat plate 14 Protrude from the second through cavity 12 and connect with the slider 15 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com