Material cutting machine

A material cutting machine and material technology, applied in the direction of casting molding equipment, metal processing, etc., can solve problems such as wasting time, achieve the effect of improving precision, improving cast iron quality, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

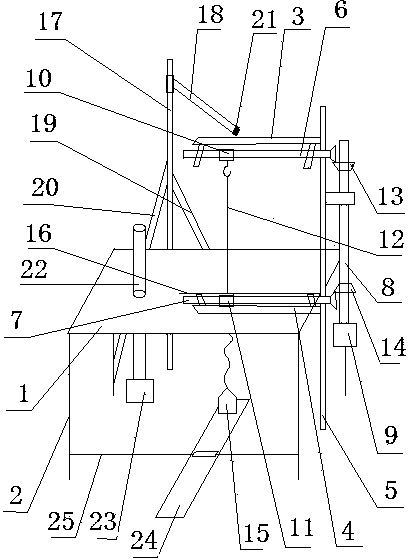

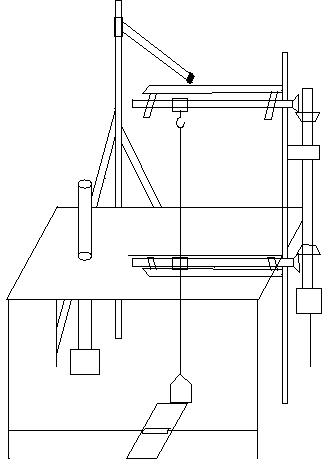

[0022] see figure 1 , the material cutting machine, including:

[0023] Operating platform assembly: including operating platform 1 and operating platform feet 2, the operating platform feet 2 are fixed on the operating platform 1, and the operating platform feet include two front operating platform feet and two rear operating platform feet;

[0024] Bracket assembly: including the bracket upper cross arm 3, the bracket lower cross arm 4 and the bracket rod 5, the bracket upper cross arm 3 and the bracket lower cross arm 4 are all vertically fixed on the bracket rod 5, the bracket upper cross arm 3 is located above the operating table 1, and the lower cross arm 4 of the bracket is located below the operating table 1;

[0025] Cutting assembly: including upper screw mandrel 6, lower screw mandrel 7, transmission shaft 8, first motor 9, upper slider 10, lower slider 11, shredded wire 12, said upper screw mandrel 6 and lower screw mandrel 7 pass through the umbrella Shaped gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com