Method for preventing deformation of refined casting casing wax model

A wax mold and precision casting technology, which is applied in casting and molding equipment, etc., to simplify the operation process, reduce risks, and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

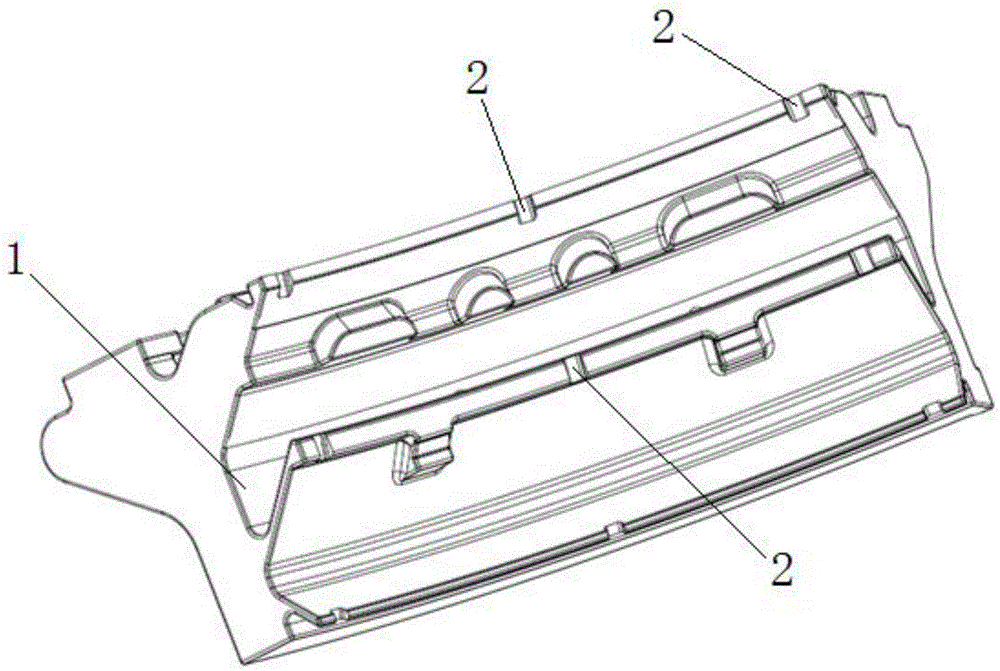

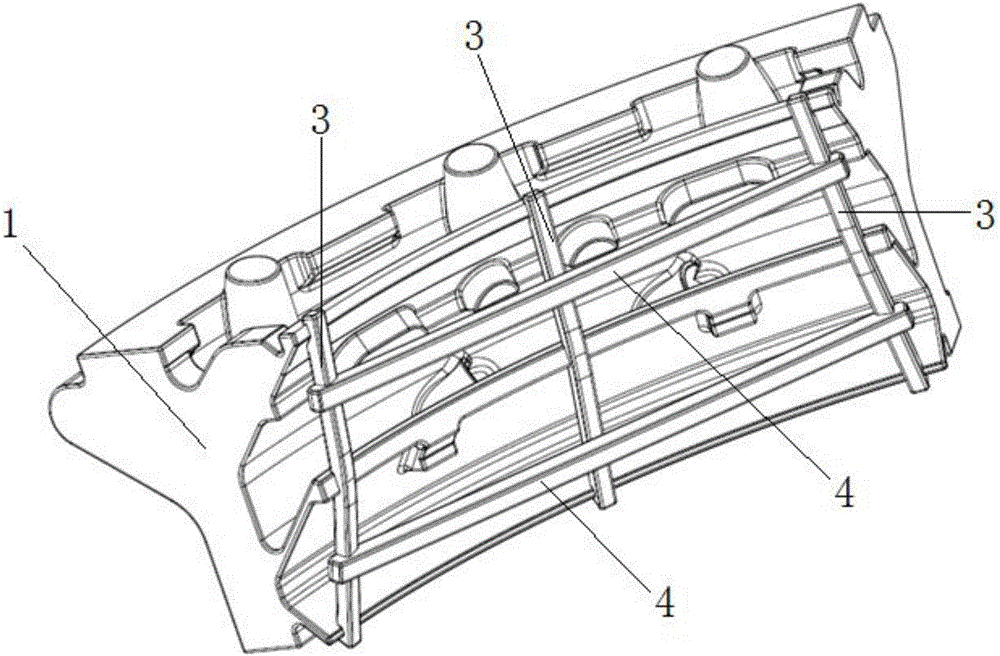

[0034] This embodiment is used for the precision casting of the C-type gas turbine bearing casing. It is composed of a 1 / 6 circle combination. The casing wall thickness varies greatly, and the wall thickness in some areas is only 3 to 4 mm. It is very easy to open and deform during production. Determine the molding process of the wax mold 1 according to the shape of the casing, and then determine the shape of the mold according to the shape of the wax mold 1 and make the mold. During production, a plurality of positioning blocks 2 for clamping the ribs 3 are opened on the mold. 2 Depressed on the surface of the mold, and then perform wax pressing operation on the mold to obtain a wax mold 1. The wax mold 1 also has a positioning block 2 adapted to the shape, position and size of the mold. After the wax mold 1 is cooled, the upper mold and the mold Remove each part of the live block separately, embed the reinforcement ribs 3 between the positioning blocks 2 of the wax mold 1 to c...

Embodiment 2

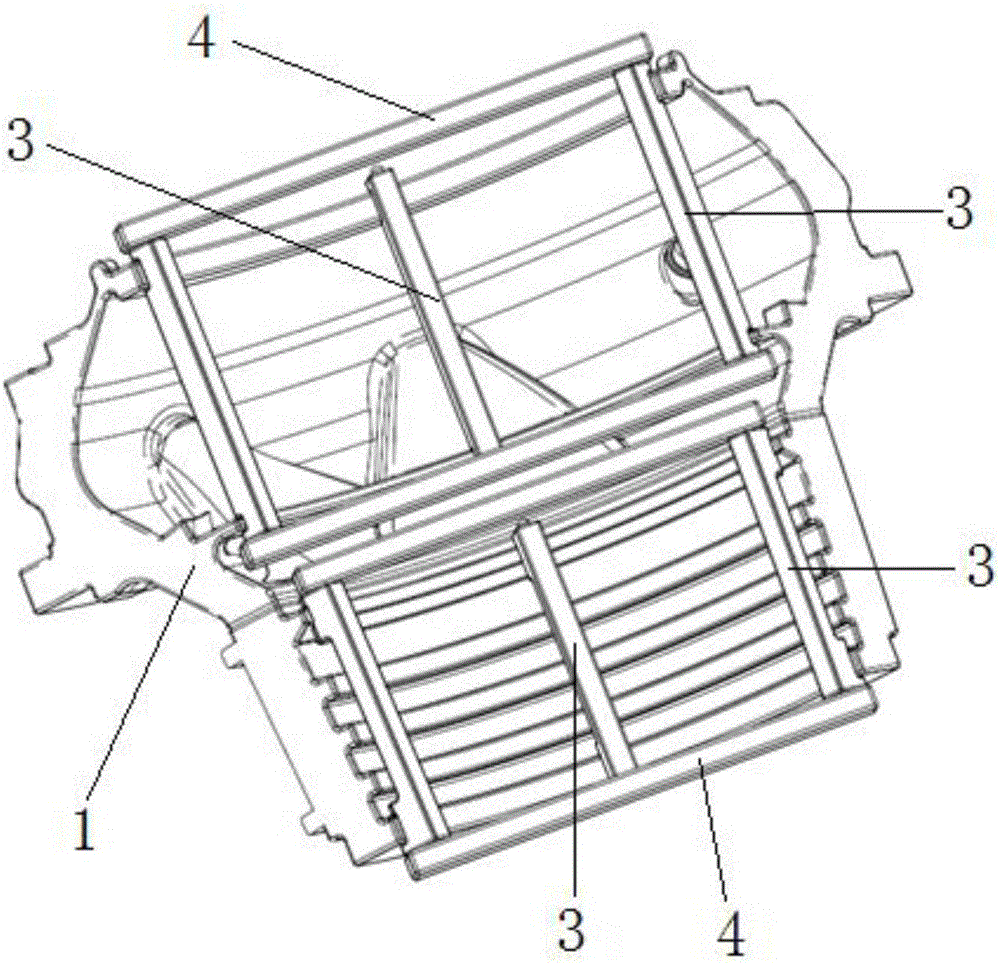

[0037] This embodiment is used for precision casting of the C-type gas turbine bearing casing, which is composed of a quarter circle combination, which is extremely easy to deform during production. Using the same processing method as in Example 1, the combined schematic diagram after the reinforcement rib 3 and the reinforcement rod 4 are embedded in the positioning block 2 of the wax mold 1 is as follows: image 3 As shown, the reinforcing rib 3 and the reinforcing rod 4 effectively prevent the deformation of the wax mold, and the final produced castings are tested by three-coordinate and reverse scanning, and the dimensional accuracy fully meets the design requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com