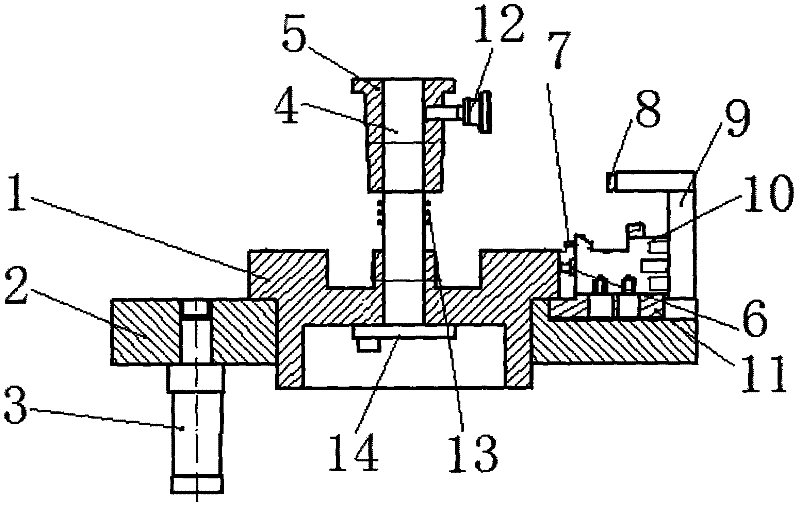

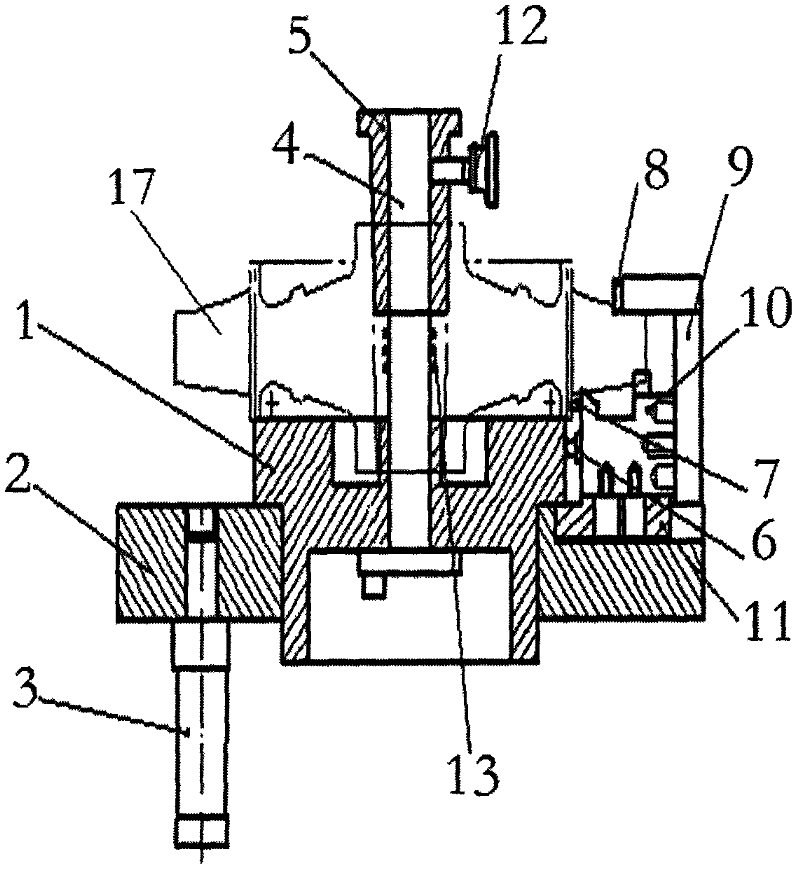

Manufacturing method and fixture of integral bladed-disk wax mold

A technology of integral blisks and manufacturing methods, which is applied in the direction of casting and molding equipment, can solve the problems of unguaranteed dimensional accuracy of disc rings, high precision requirements, and difficult processing, so as to avoid rework or even scrapping, improve dimensional accuracy, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

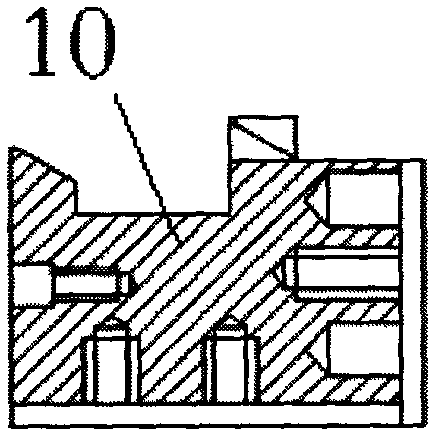

Method used

Image

Examples

Embodiment 1

[0040] This embodiment is a method of using MPI55-50 wax press machine to manufacture the overall wax mold of a turbine rotor blisk. The number of single-blade wax molds produced is consistent with the number of turbine disk blades. In this embodiment, the turbine disk The number of blades was 43. Its specific process includes the following steps:

[0041] Step 1, pressing the single blade wax model. The mold is placed on the wax press machine, and the temperature of the upper template and the lower template of the wax press machine is 35°C. The clamping pressure is 50bar. Pour the wax into the mold. After injecting pressure into the mold, keep the pressure for 10s, and the injection time is 20s to obtain a molded single blade. The wax material is F28. The injection temperature of the wax material is 70° C., and the injection pressure is 18 bar to obtain a molded single-blade wax mold. Repeat the above process to make 43 single-blade wax models in total. After the press...

Embodiment 2

[0047] This embodiment is a method of using MPI55-50 wax press machine to manufacture the overall wax mold of a turbine rotor blisk. The number of single-blade wax molds produced is consistent with the number of turbine disk blades. In this embodiment, the turbine disk The number of blades was 23. Its specific process includes the following steps:

[0048] Step 1, pressing the single blade wax model. The mold is placed on the wax press machine, and the temperature of the upper template and the lower template of the wax press machine is 40°C. The clamping pressure is 40bar. Pour the wax into the mold. After injecting pressure into the mold, keep the pressure for 8s, and the injection time is 15s to obtain a molded single blade. The wax material is F28. The injection temperature of the wax material is 68° C., and the injection pressure is 15 bar to obtain a molded single-blade wax mold. Repeat the above process to make 23 single-blade wax models in total. After the presse...

Embodiment 3

[0054] This embodiment is a method of using MPI55-50 wax press machine to manufacture the overall wax mold of a turbine rotor blisk. The number of single-blade wax molds produced is consistent with the number of turbine disk blades. In this embodiment, the turbine disk The number of blades was 31. Its specific process includes the following steps:

[0055] Step 1, pressing the single blade wax model. The mold is placed on the wax press machine, and the temperature of the upper template and the lower template of the wax press machine is 38°C. The clamping pressure is 45bar. Pour the wax into the mold. After injecting pressure into the mold, keep the pressure for 9s, and the injection time is 18s to obtain a molded single blade. The wax material is F28. The injection temperature of the wax material is 75° C., and the injection pressure is 16 bar to obtain a molded single-blade wax mold. Repeat the above process to make 31 single-blade wax models in total. After the presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com