Automatic wax injection press

A technology of wax pressing machine and worktable, applied in casting and molding equipment and other directions, can solve the problems of high labor intensity of workers, affect product quality, low production efficiency, etc., and achieve the effects of simple structure, long service life and fast mold change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

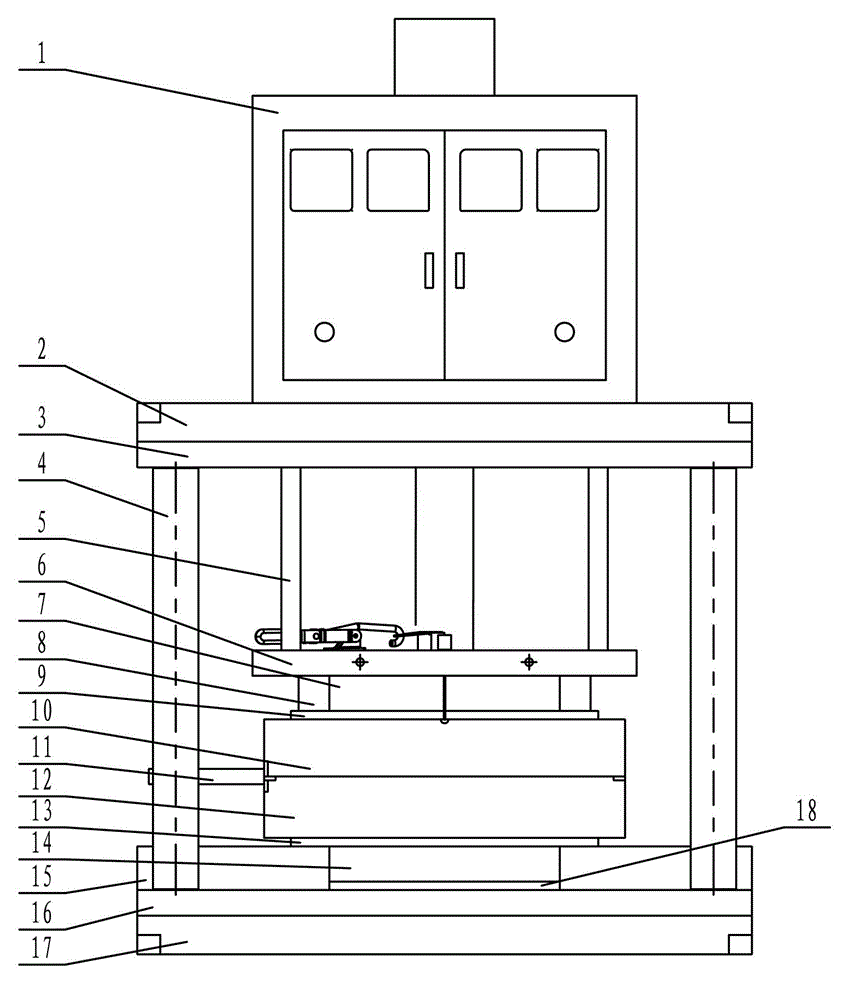

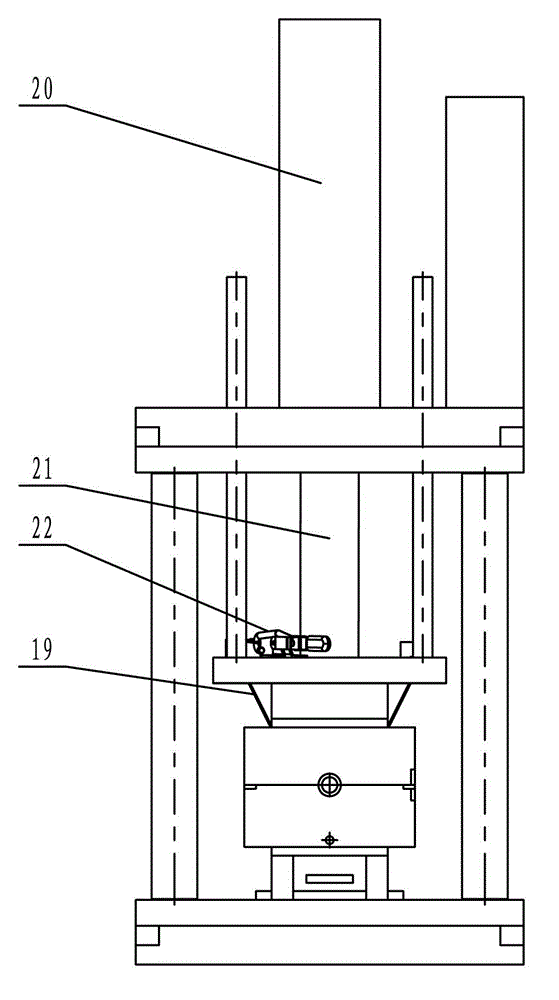

[0016] Such as Figure 1~2 As shown, the present invention mainly includes an electric cabinet 1, a reinforcing plate 2, a wax press cover plate 3, a support column 4, an upper workbench 6, a first magnetic sucker 7, an upper transition plate 9, an upper mold 10, a lower mold 12, Lower transition plate 13, second magnetic chuck 14, wax pressing machine base 16, magnetic chuck mounting plate 18, oil cylinder 20 and piston rod 21.

[0017] The four corners of the wax press base 16 are respectively connected with a support column 4 , the upper ends of the four support columns 4 are connected with the wax press cover 3 , and the wax press cover 3 is connected with the reinforcing plate 2 . The electric cabinet 1 is fixed at the front end of the reinforcing plate 2, and the oil cylinder 20 is fixed at the middle. The electric cabinet 1 controls the operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com