Precision casting wax granular molding material and preparation method and application of precision casting wax granular molding material

A technology of precision casting and wax particles, applied in the direction of casting molding equipment, etc., can solve the problems of wax mold surface quality influence, poor strength, high ash content, etc., and achieve the effect of broad market competitiveness, low melting point, convenient transportation and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

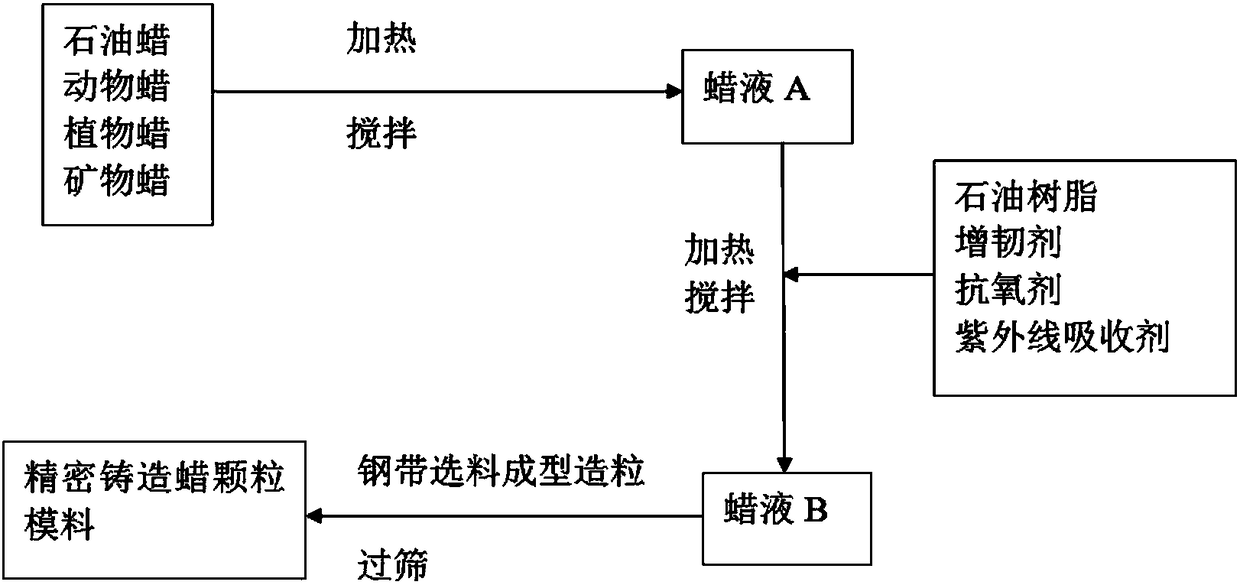

Method used

Image

Examples

Embodiment 1

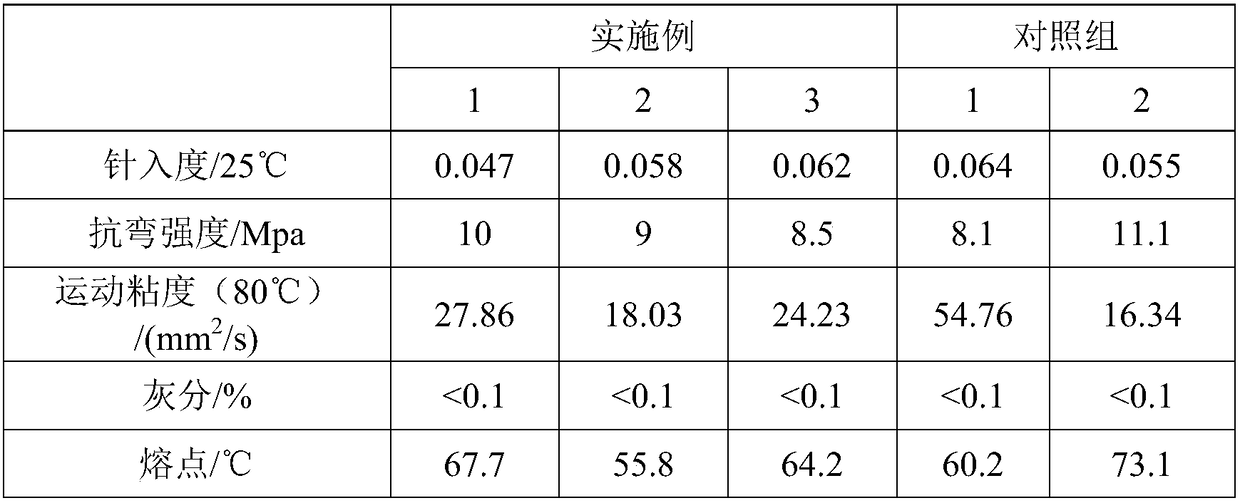

[0035] 70# microcrystalline wax (60%), montan wax (remainder, about 10%), palm wax (10%) are added in the reaction kettle, 95 ℃ of heating and stirring until all melting; Stirring then adds C5 petroleum resin (10%) %), EVA (10%), ultraviolet absorber uv-9 (5‰), antioxidant 1010 (5‰), continue to stir at constant temperature for 30min after melting completely, then transport the wax liquid to the dispenser, and the temperature of the dispenser is 95℃, and formed by steel belt material selection, the steel belt line speed is 4 ~ 5m / min; use cold air or cold water to cool the wax drop, the top of the steel belt is cooled by cold air, the temperature is 19℃, and the water cooling during the steel belt transmission is 2 Stage cooling, the cooling water in the front stage is normal temperature cooling water, and the rear stage is cooled by cooling water at 9°C, the granular wax is obtained in the receiver, and then sieved to obtain the investment casting wax granular mold material of...

Embodiment 2

[0038]Add 58# paraffin wax (remainder, about 60%), beeswax (10%), montan wax (10%), and palm wax (10%) into the reaction kettle, heat and stir at 95°C until all melted; then stir and add C5 Petroleum resin (10%), ultraviolet absorber uv-9 (4.5‰), antioxidant 1010 (4.5‰), continue to stir at constant temperature for 30 minutes after completely melting, and then transport the wax liquid to the dispenser, the temperature of the dispenser is 100°C , and formed by steel belt material selection, the steel belt line speed is 4 ~ 5m / min; use cold air or cold water to cool the wax drop, the top of the steel belt is cooled by cold air, the temperature is 19 ℃, and the water cooling is 2-stage cooling during the steel belt transmission process , the cooling water in the front section is normal temperature cooling water, and the rear section is cooled by cooling water at 9°C, the granular wax is obtained in the receiver, and then sieved to obtain the investment casting wax granular molding...

Embodiment 3

[0041] Add 58# paraffin wax (35%), 682# microcrystalline wax (35%), beeswax (5%), montan wax (balance, about 5%), ozokerite (10%), palm wax (5%) Put it in the reaction kettle, heat and stir at 95°C until it is completely melted; then add EVA (5%), ultraviolet absorber uv-9 (4.5‰) and antioxidant 1010 (4.5‰) with stirring, and continue to stir at constant temperature for 30 minutes after melting completely. Then the wax liquid is transported to the dispenser, the temperature of the dispenser is 100°C, and the material is selected and formed by the steel belt, the steel belt line speed is 4-5m / min; the wax drops are cooled by cold air or cold water, and the steel belt is cooled by cold air. The temperature is 19°C, and the water cooling in the steel strip conveying process is 2-stage cooling. The cooling water in the front stage is normal temperature cooling water, and the cooling water in the rear is 9°C. Granular wax is obtained in the receiver, and then sieved to obtain the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com