Titanium alloy investment cast precision part wax mold assembly tool

A precision casting and titanium alloy technology, applied in the field of wax pattern splicing tooling, can solve the problems of insufficient dimensional accuracy and deformation of wax pattern splicing, achieve the effects of shortening the production cycle, reducing the scrap rate, and improving the integrity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

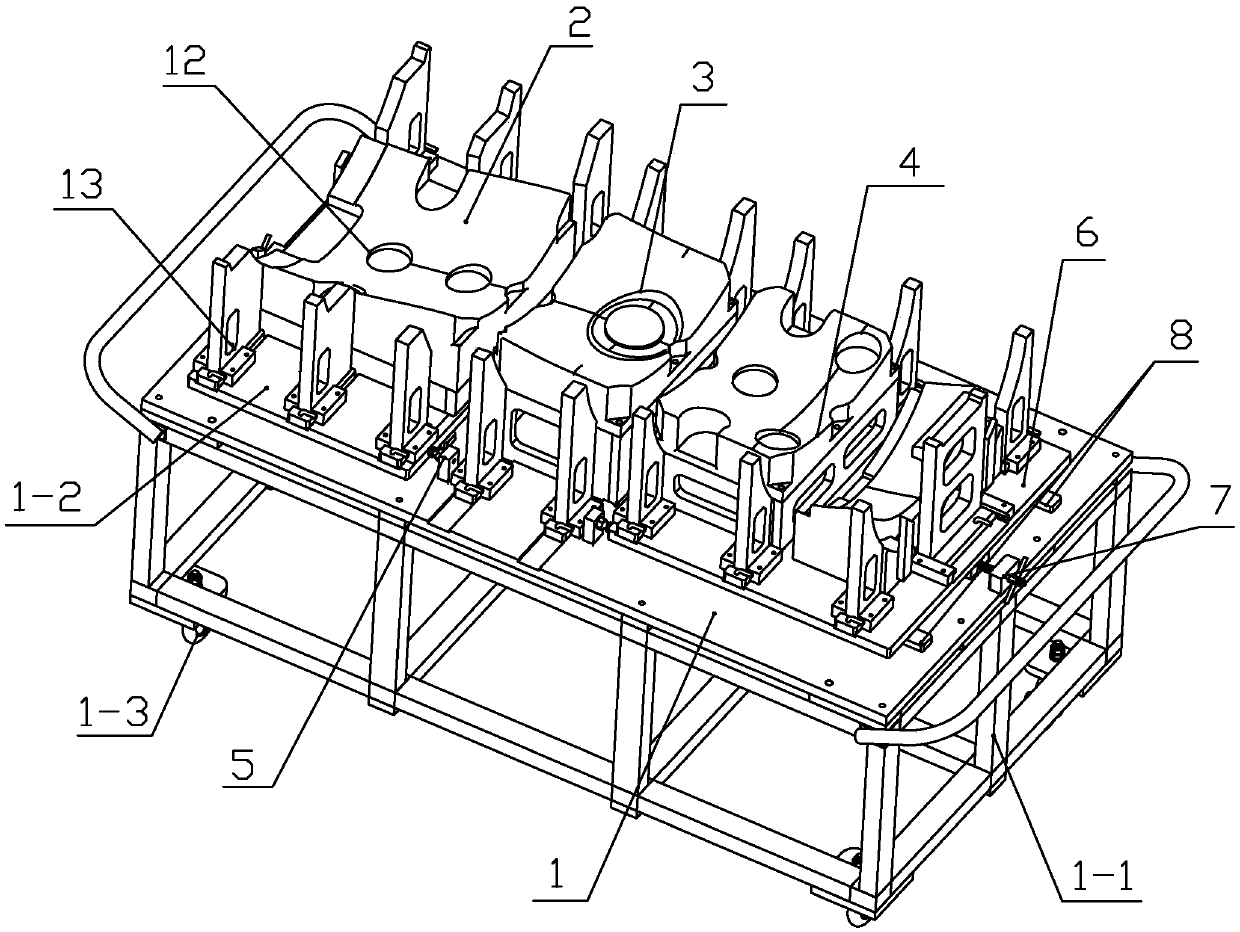

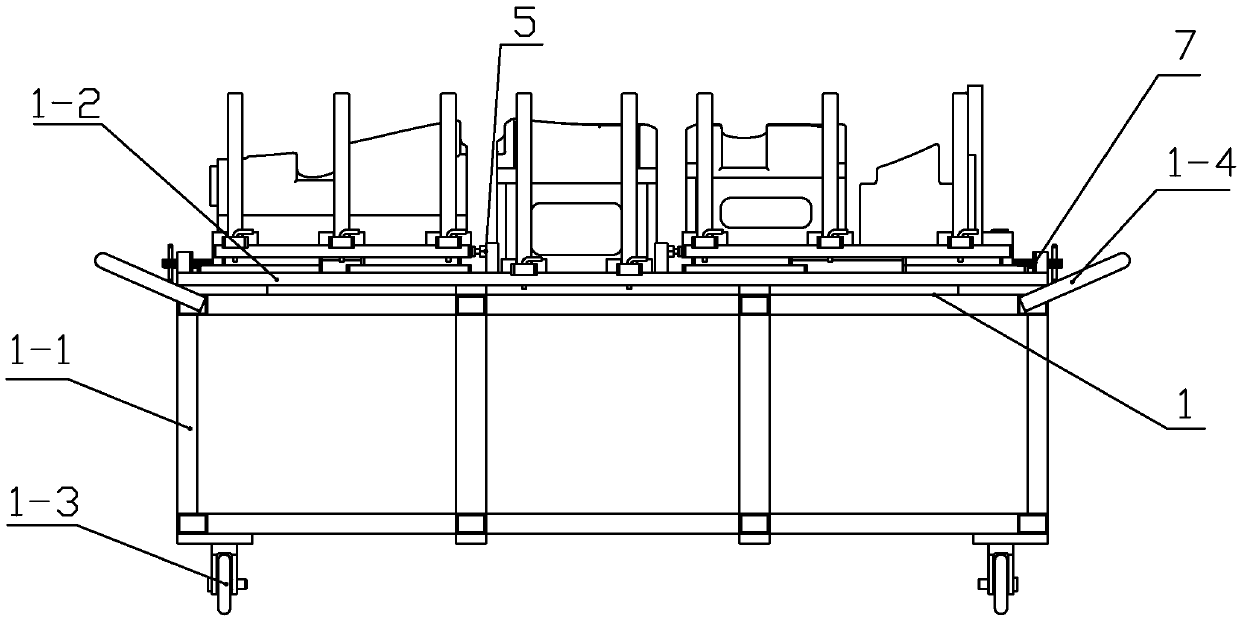

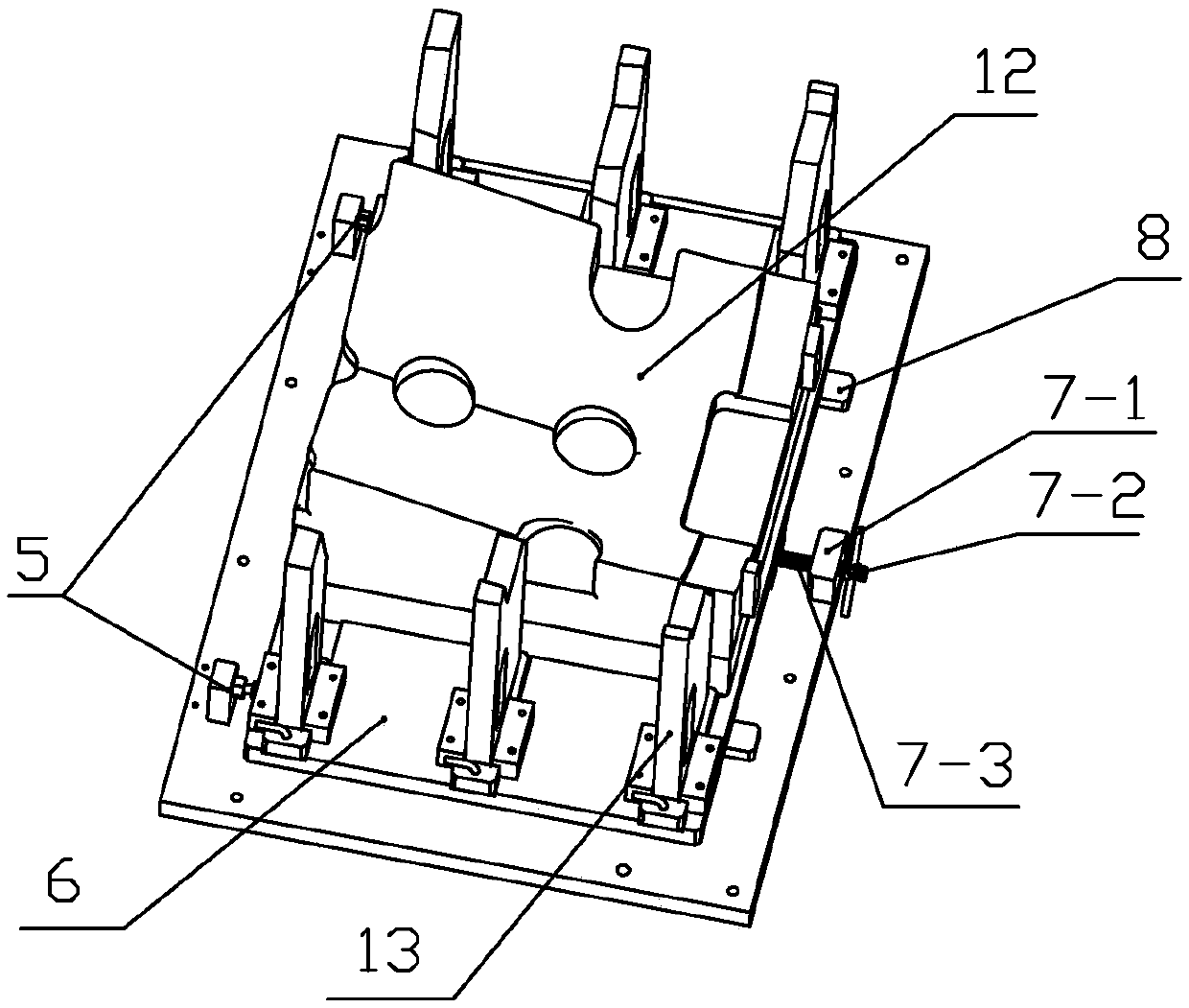

[0024] Specific implementation mode one: combine Figure 1-7 Describe this embodiment, a wax pattern splicing tool for titanium alloy investment investment castings, which includes a workbench 1, first to third position adjustment parts arranged above the workbench 1, and several limit assemblies 5, wherein The second position adjusting part 3 is fixedly connected with the workbench 1, the first position adjusting part 2 and the third position adjusting part 4 are respectively located on the left and right sides of the second position adjusting part 3, and the first position adjusting part 2 and the third position adjusting part The adjustment parts 4 are all slid and set on the workbench 1 along the left and right directions. The three wax models to be spliced are placed one by one on the three position adjustment parts. The same, and the size of the top surface of each position adjustment member is the theoretical shape size of the wax model, and several limit components 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com