Rubber forming method and die for sheet metal frame parts with different-direction flanges

A technology for forming molds and sheet metal, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high cost, low unloading efficiency, and many molds, etc., to achieve low cost, high unloading efficiency, and number of molds. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

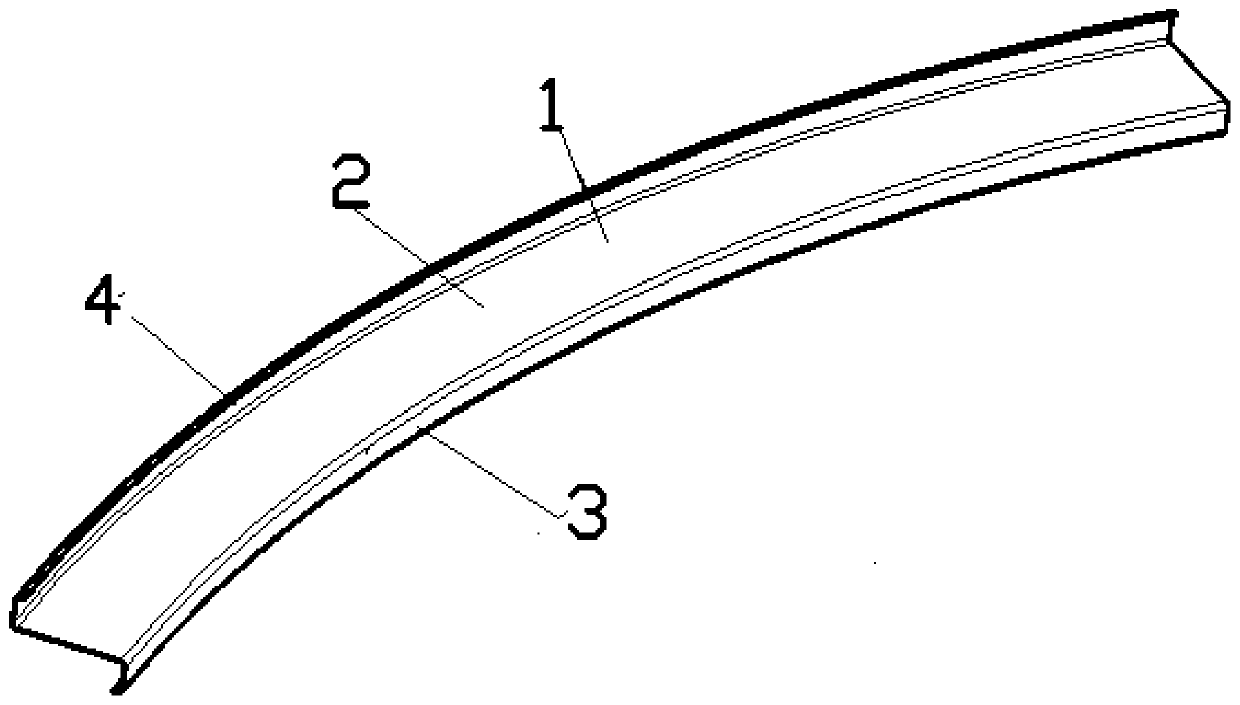

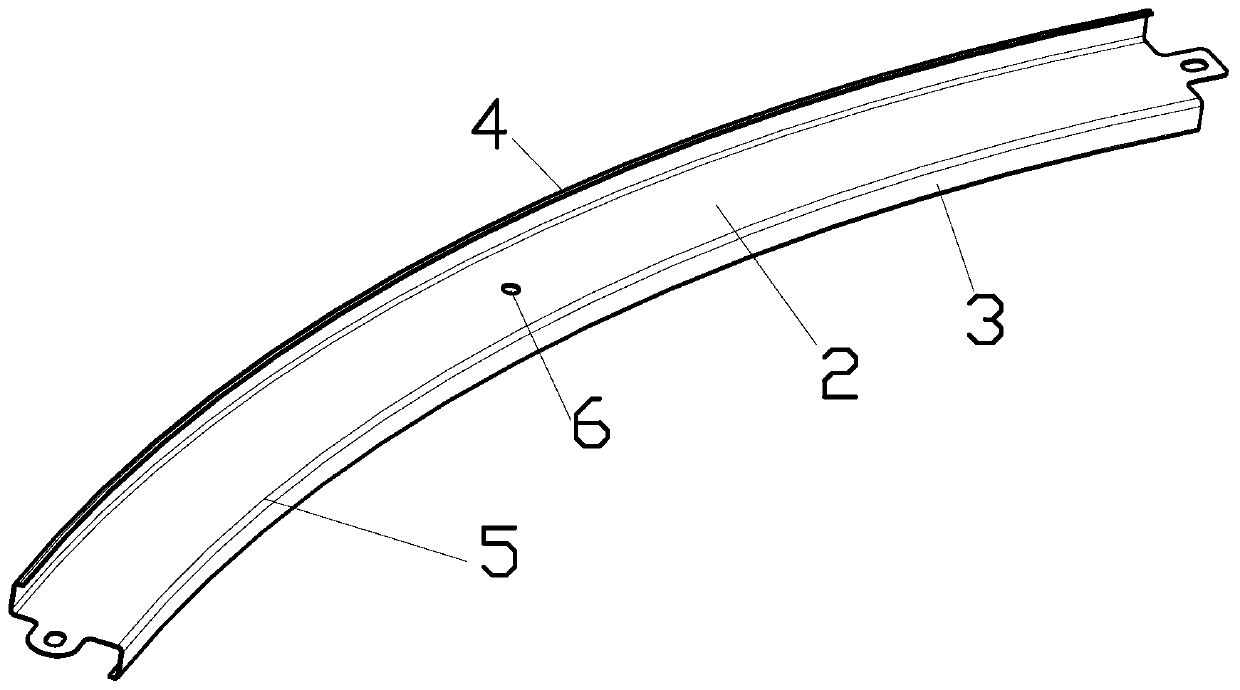

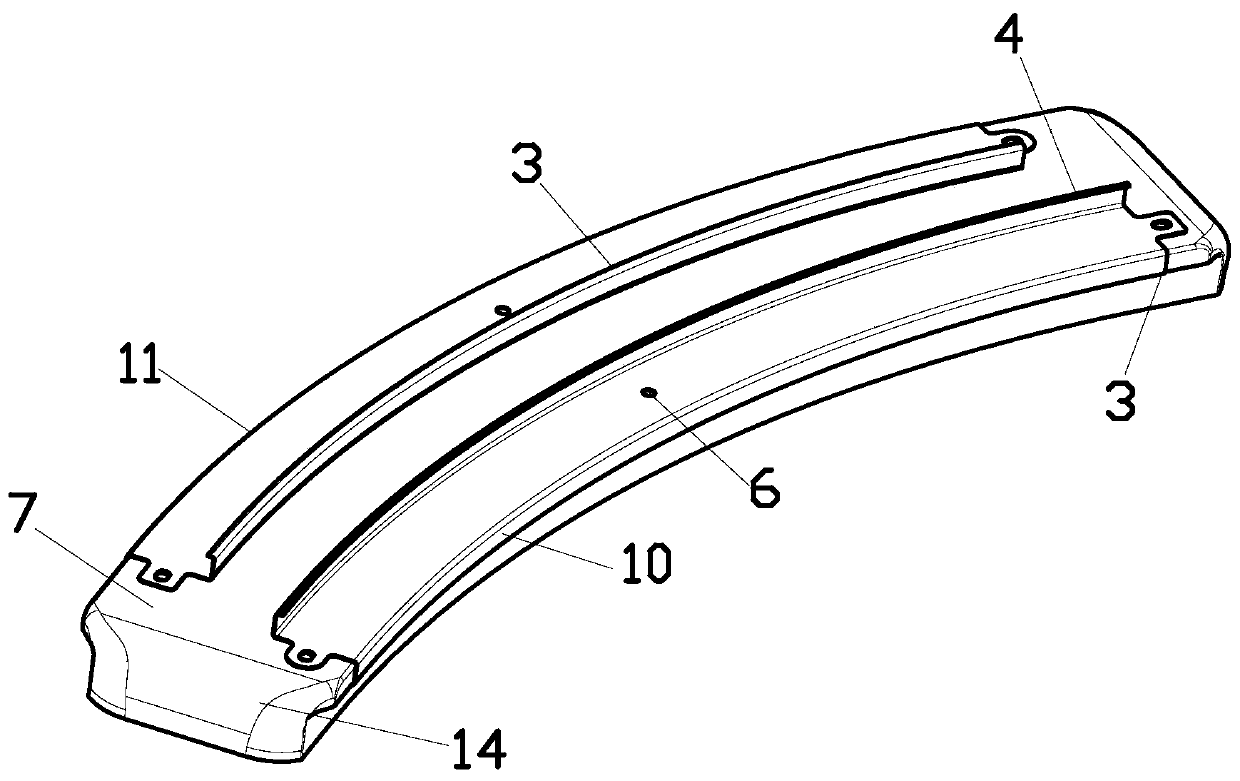

[0018] Referring to the accompanying drawings, the part model and process model of the sheet metal frame with different bending edges are firstly introduced.

[0019] Such as figure 1 As shown, the part model 1 of the sheet metal frame part with different curvatures includes an arc-shaped web 2 of equal curvature, a first flange 3, and a second flange 4, and the first flange 3 is located on the inner side of the arc-shaped web 2 For downward bending, the second flange 4 is located on the outer side of the arc-shaped web 2 and is bent upward. In order to solve the difficult positioning problem of the length change of sheet metal quenching, the process model 5 is designed according to the part model 1; the process model 5 is provided with a positioning hole 6 in the middle of the arc-shaped web 2, and protrusions are provided at both ends of the arc-shaped web The positioning lugs, the positioning holes on the positioning lugs are oblong. In actual operation, the relative disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com