Small ultrathin flaky magnetic core and production process thereof

A production process, ultra-thin sheet technology, applied in the direction of magnetic core/yoke, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of poor production effect of ultra-thin magnetic cores, improve appearance and simplify operation Process, the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

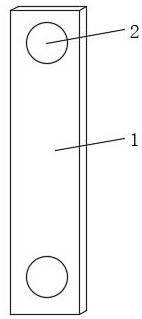

[0035] Such as Figure 1-2 As shown, the embodiment of the present invention provides a small ultra-thin chip core, which includes an ultra-thin chip core body 1 , and through holes 2 are provided at the upper and lower ends of the ultra-thin chip core body 1 .

[0036] A production process of a small ultra-thin sheet magnetic core, comprising the following production process steps:

[0037] S1. Carry out storage inspection of iron, manganese, zinc oxide particles and their salt particles, and check the specific gravity of iron, manganese, zinc oxide particles and their salt particles, particle water content, particle fluidity, particle Particle size distribution is tested;

[0038] S2. After the inspection is completed, use a mixer to uniformly mix iron, manganese, zinc oxide particles and their salt particles. During the mixing process, add a certain amount of additives to improve the adhesion of the mixture;

[0039] S3. After the mixing is completed, the mixed granular m...

Embodiment 2

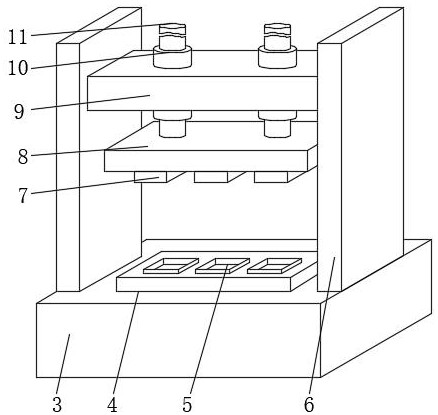

[0047] The die device in S4 includes a support body 3, the upper middle part of the support body 3 is provided with a lower mold 4, the upper end of the lower mold 4 is provided with a mold groove 5, and the mold groove 5 is provided with multiple and arranged at equal intervals. Ultra-thin sheet magnetic cores 1 of different sizes are required to replace the lower mold 4, so as to facilitate the effective pressing of the green body;

[0048] Both sides of the upper end of the support body 3 are fixedly connected with a support frame 6, and the inner side of the upper end of the support frame 6 is fixedly connected with a limit frame 9, and the two sides of the limit frame 9 are provided with a cylinder 10, and the upper end of the cylinder 10 is provided with an air guide 11. The lower end of the cylinder 10 is extended with a telescopic rod and one end of the telescopic rod is fixedly connected with a fixed frame 8 relative to the bottom of the limit frame 9, and the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com