Synthesis and preparation process for high-silicon-molybdenum ductile iron material

A preparation process, high-silicon-molybdenum technology, applied in the field of metal materials, can solve the problems of high-silicon-molybdenum ductile iron impact toughness requirements, high production costs, unqualified, etc., to improve mechanical properties, prevent oxidation burning loss, promote melting and Diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The mass percent content of each component of the high silicon molybdenum ductile iron material in this embodiment is C: 3.495%; Si: 2.73%; Mo: 0.408%%; P: <0.03%; S: <0.015%; Mn: 0.266%; Mg: 0.0401%, Sb: 0.001%, and the rest is Fe.

[0027] The synthetic preparation process of the high silicon molybdenum ductile iron material of the present embodiment comprises the following steps:

[0028] Step 1: Prepare raw materials with the following mass percentages: steel scrap 68%; pig iron 28%; ferrosilicon 1%, ferromolybdenum 1.0%; recarburizer 2%. Step 2: Smelting: During the melting process of raw materials, the furnace charge is added in batches: the first batch adds all the pig iron and 1 / 3 of the quality of scrap steel; after the furnace charge is melted, add the second batch of furnace charge: 5 / 11 of the quality Carburizer and 1 / 3 of the quality of steel scrap, in which the scrap steel is pressed on the surface of the carburizer and added by carbon pressing, that is, ...

Embodiment 2

[0035]The difference between this embodiment and embodiment 1 mainly lies in the following aspects:

[0036] The composition of the high silicon molybdenum ductile iron material in the present embodiment is:

[0037] C: 3.48%; Si: 2.73%; Mo: 0.423%; P: <0.03%; S: <0.015%; Mn: 0.251%;

[0038] The quality ratio of raw materials is: scrap steel 61%; pig iron 26%; ferrosilicon 1.2%, ferromolybdenum 1.3%; recarburizer 2.5%.

[0039] Table 3 shows the test results of the mechanical properties of the test block after the material of this embodiment was smelted and poured.

[0040] table 3

[0041]

Embodiment 3

[0043] The difference between this embodiment and embodiment 1 mainly lies in the following aspects:

[0044] The composition of the high silicon molybdenum ductile iron material in the present embodiment is:

[0045] C: 3.4%; Si: 2.79%; Mo: 0.472%; P: <0.03%; S: <0.015%; Mn: 0.263%;

[0046] The quality ratio of raw materials is: scrap steel 61%; pig iron 30.4%; ferrosilicon 1.1%, ferromolybdenum 1.2%; recarburizer 2.3%.

[0047] The mechanical performance test results of the test block after the material smelting and pouring of the present embodiment are as described in Table 4

[0048] Table 4

[0049]

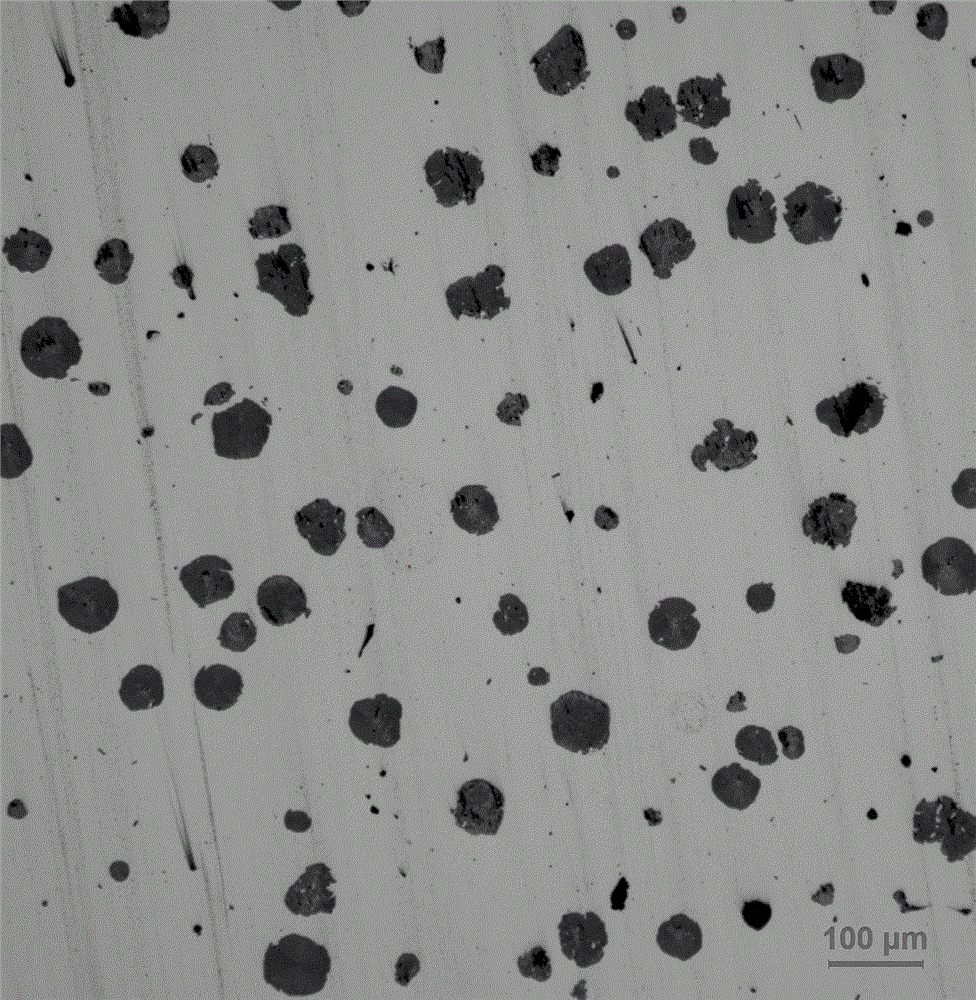

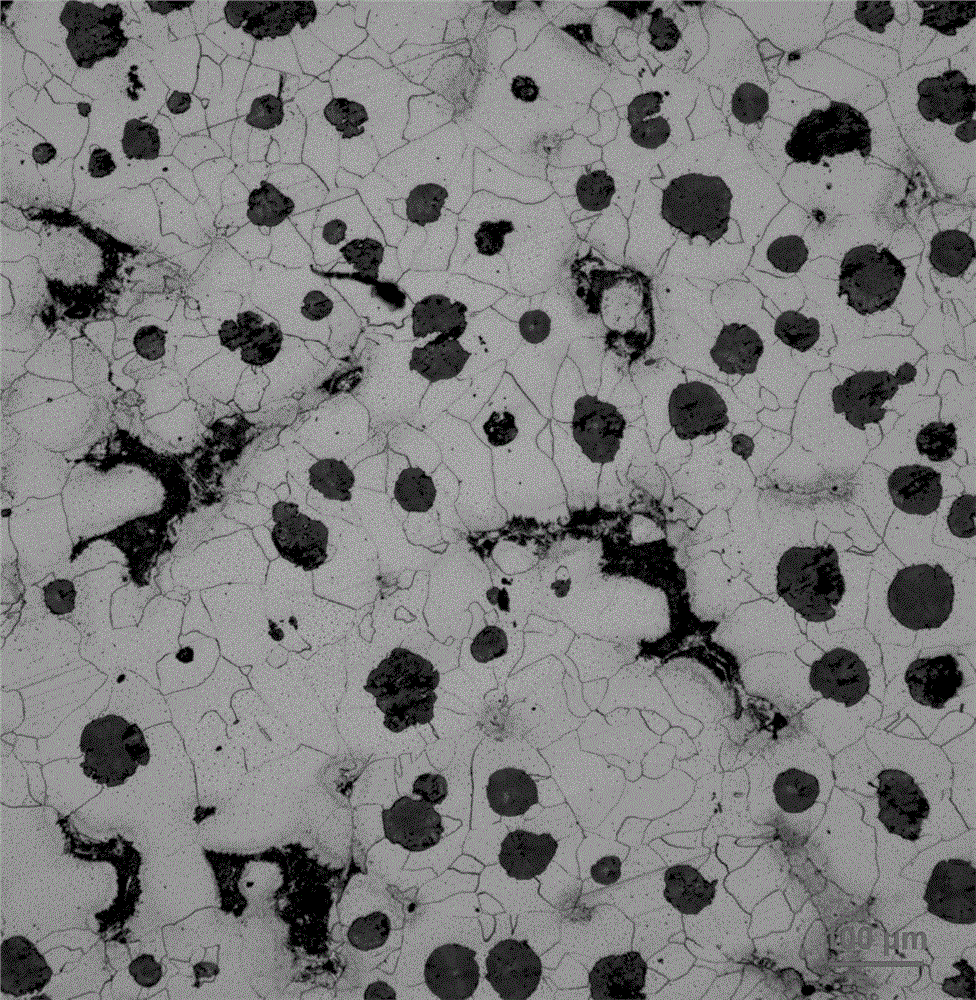

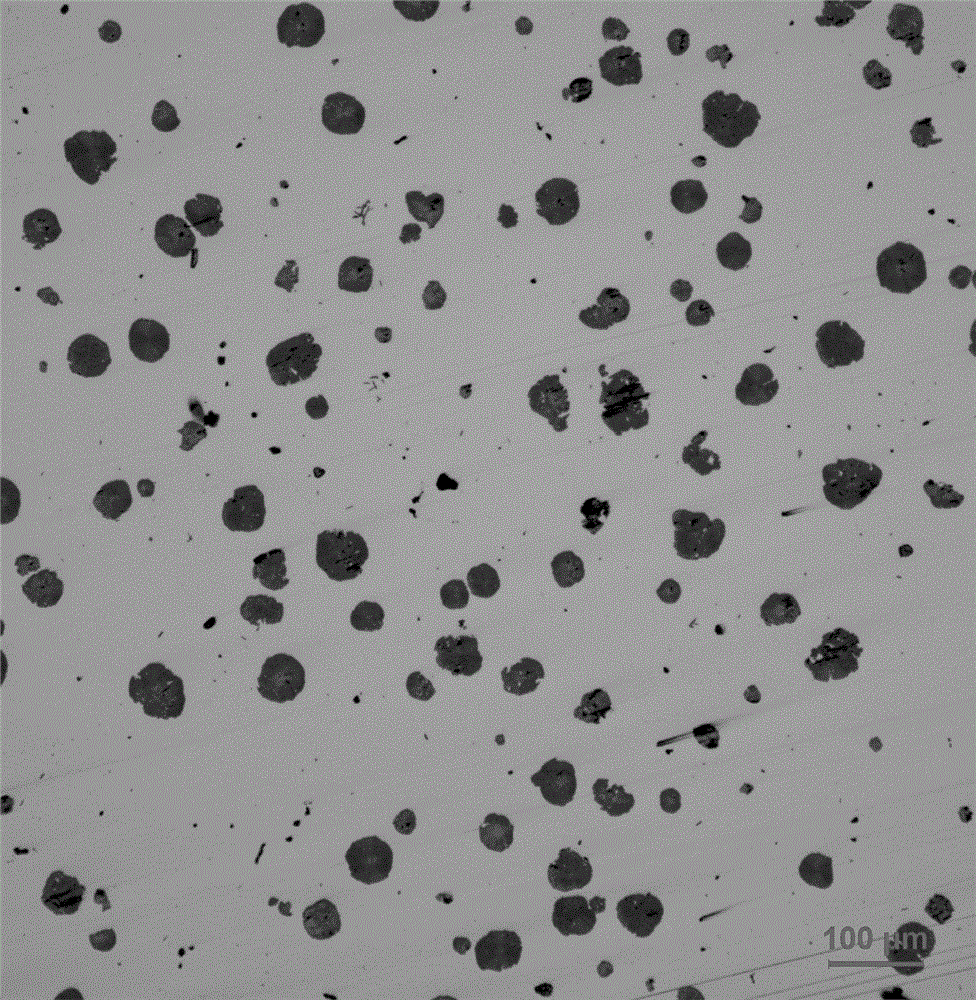

[0050] image 3 It is the nodularization rate figure of the high silicon molybdenum nodular iron material of the present embodiment, Figure 4 It is the metallographic structure diagram of the high silicon molybdenum ductile iron material of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com