On-line monitoring method for failure state of metal and protection layer inter face

A technology of failure state and protective layer, applied in measuring devices, instruments, material analysis by electromagnetic means, etc., can solve the problems of lack of metal substrate and protective layer interface state change trend non-destructive, direct, advanced prediction, etc., to achieve advanced corrosion Monitoring performance, high sensitivity, predicting the effect of coating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

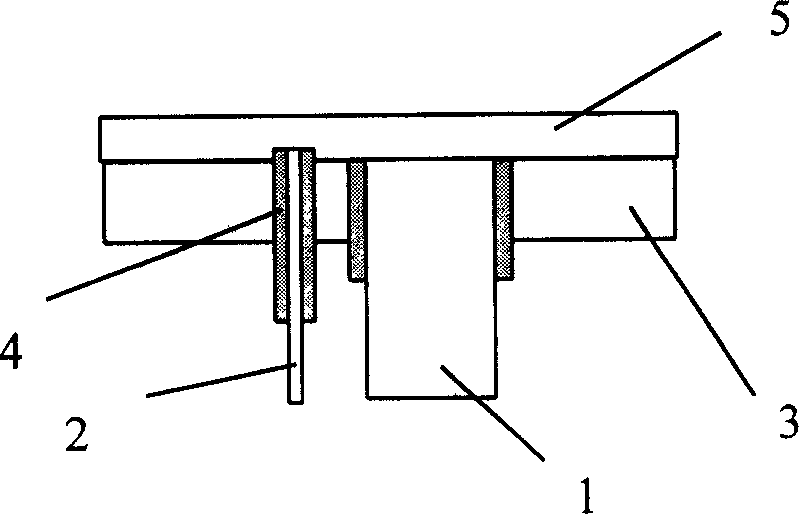

[0032]Example 1, a method for on-line corrosion monitoring of metal and protective layer interface failure, in the corrosion-sensitive part of the metal substrate of the mechanical equipment designed or manufactured, the probe for monitoring the state change of the interface is prefabricated, and the probe is used from the metal substrate of the equipment. The same material directly cut from the corrosion-sensitive part is processed into a probe and then inserted into the metal base of the mechanical equipment in situ. The probe and the metal base of the equipment are integrated and undergo the subsequent preparation and processing of the surface protection layer. The state of the interface between the probe and the protective layer is completely consistent with the state of the interface between the metal substrate and the protective layer of the mechanical equipment, so that the surface of the probe and the surface of the metal substrate of the device have exactly the same sta...

example 2

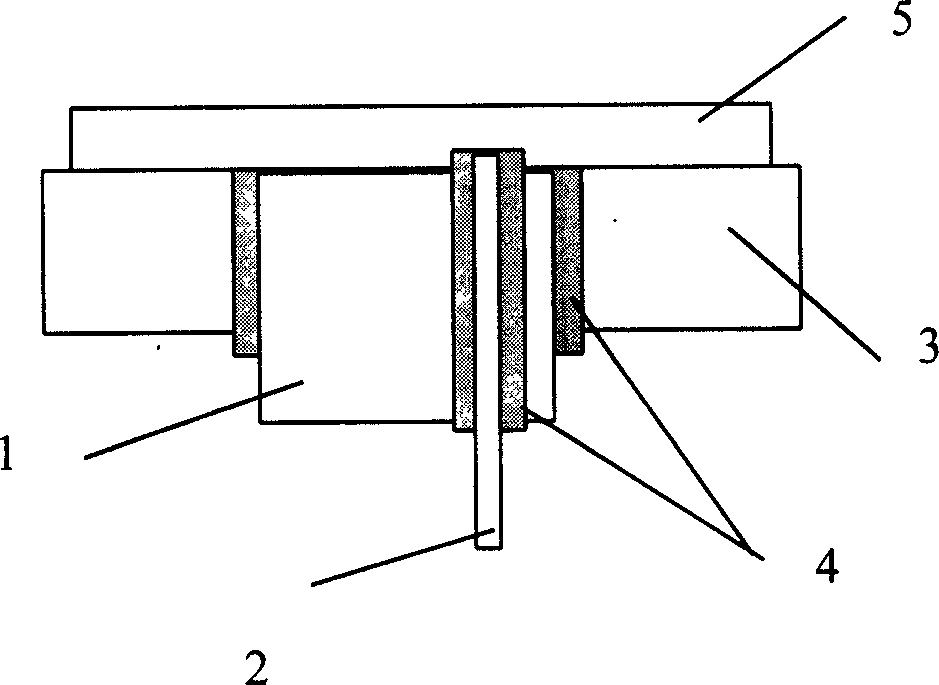

[0044] Example 2: A method for on-line monitoring of metal corrosion, in the same metal equipment design and manufacturing process as in Example 1, the structure of the probe is changed, figure 2 It is a structural schematic diagram of the probe in Example 2 of the present invention. The research electrode (1) and the reference electrode (2) are embedded into the metal device body at one time as a whole. If the protective coating (5) is organic, the collected information may include the coating's water absorption rate, porosity, and the rate of change and magnitude of the bonding force at the interface between the metal and the coating.

[0045] If the protective coating (5) is a thermally sprayed metallic material, the change in the state of adhesion between the metal substrate and the coating can be evaluated from the measured information.

[0046] The working environment of metal machinery can be a liquid strong corrosive medium, such as sea water, or the equipment in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com