Double-laser cleaning device and method thereof

A cleaning device and dual-laser technology, applied in the field of laser cleaning, can solve the problems of inability to accurately guarantee cleaning effect, unsuitable for large-scale industrial applications, inability to clean, etc., so as to avoid ablation of the surface of the substrate, improve the surface quality of the substrate, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

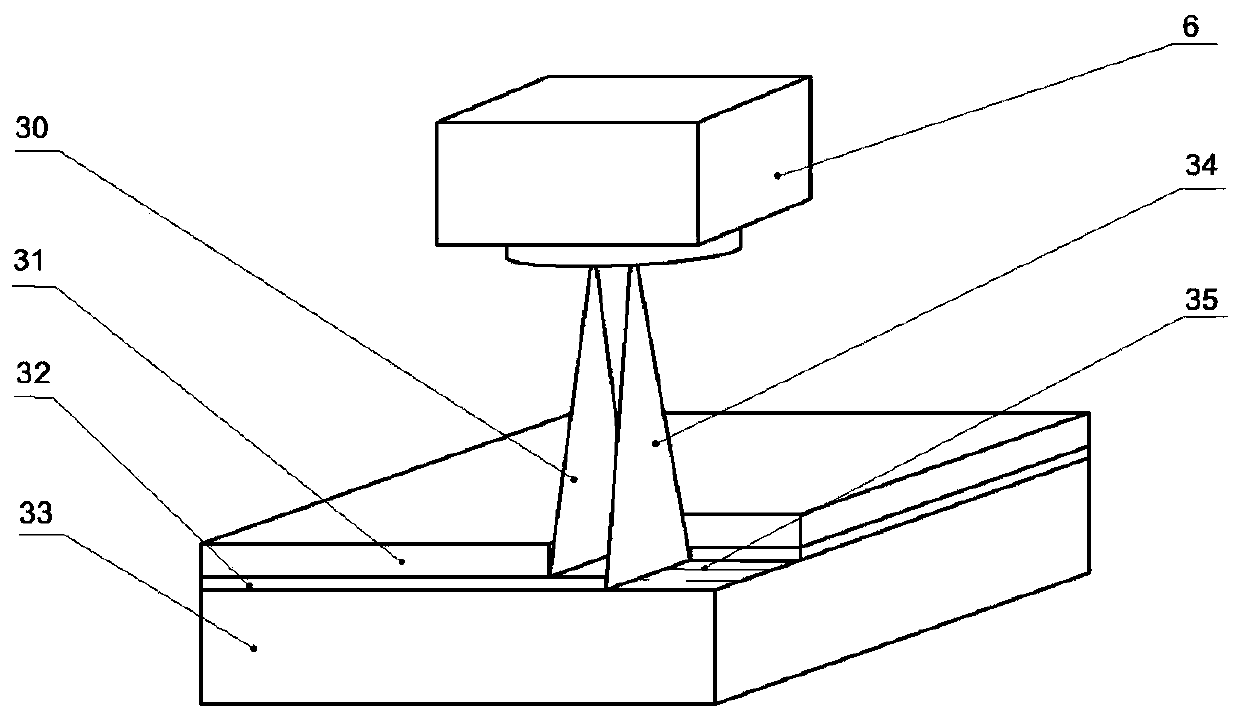

[0033] Example 1, the aircraft skin surface paint layer is removed by using a dual-laser combined high-efficiency laser cleaning method. The coating system of aircraft skin surface is complex, mainly including skin substrate pretreatment layer, primer layer and topcoat layer. Such as image 3 As shown, the aircraft skin material to be cleaned is 2024 aluminum alloy, and the topcoat layer of the coating is polyurethane topcoat 31 with a thickness of 45-60 μm; the primer layer is epoxy resin primer 32 with a thickness of 15-30 μm; The thickness of the anodized film 36 is 5-15 μm, and the substrate is the aluminum plate 33 .

[0034] Laser cleaning of the old paint of the multi-coating system on the surface of the substrate and the thicker layer to be removed is carried out by combining laser beams with two pulse widths of long and short, which greatly improves the efficiency and quality of laser cleaning, and effectively protects the surface of the substrate from ablation. Cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com