Method and apparatus for printing on rigid panels and other contoured or textured surfaces

A rigid board and outline technology, applied in printing devices, power transmission devices, printing, etc., can solve problems affecting printing quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

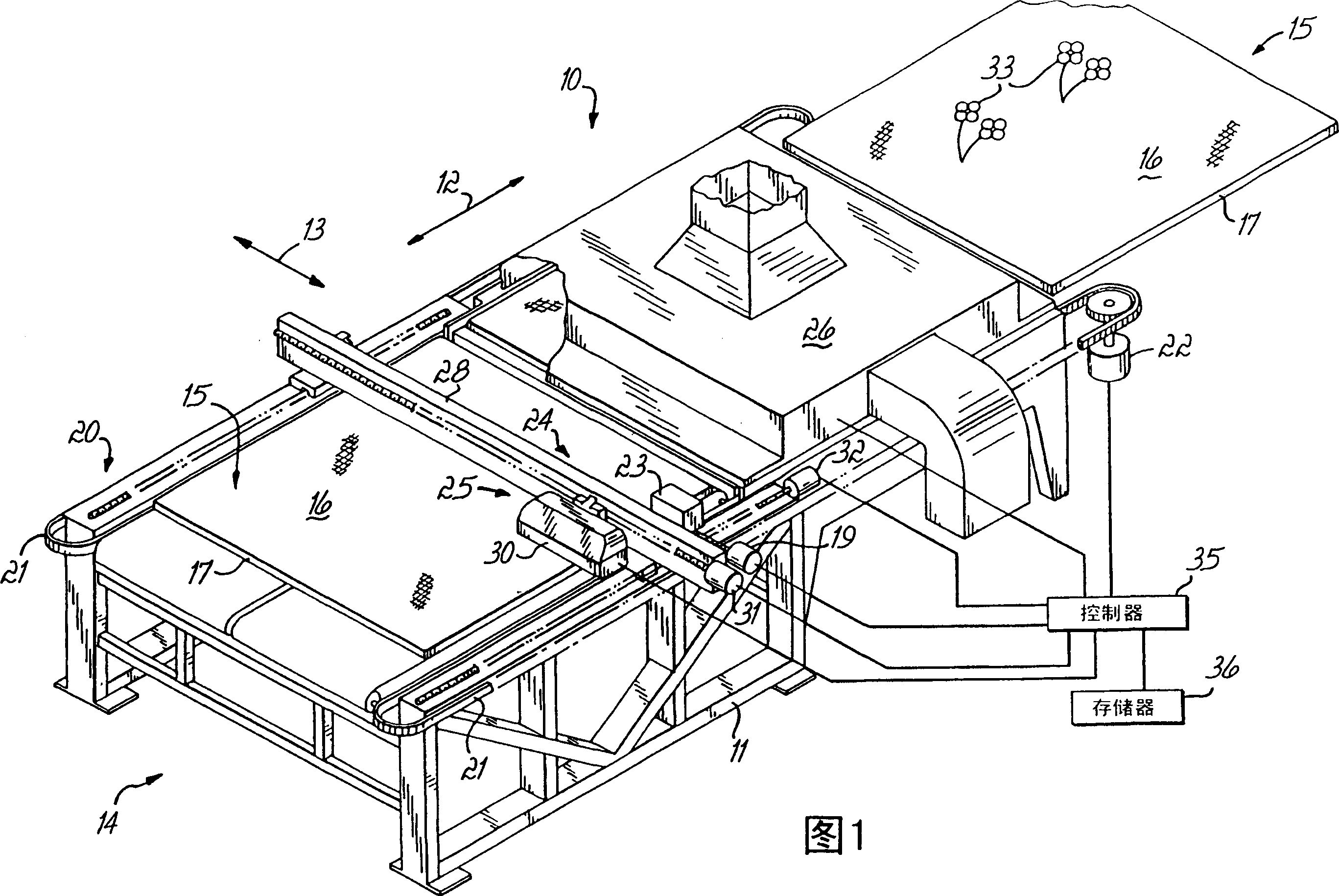

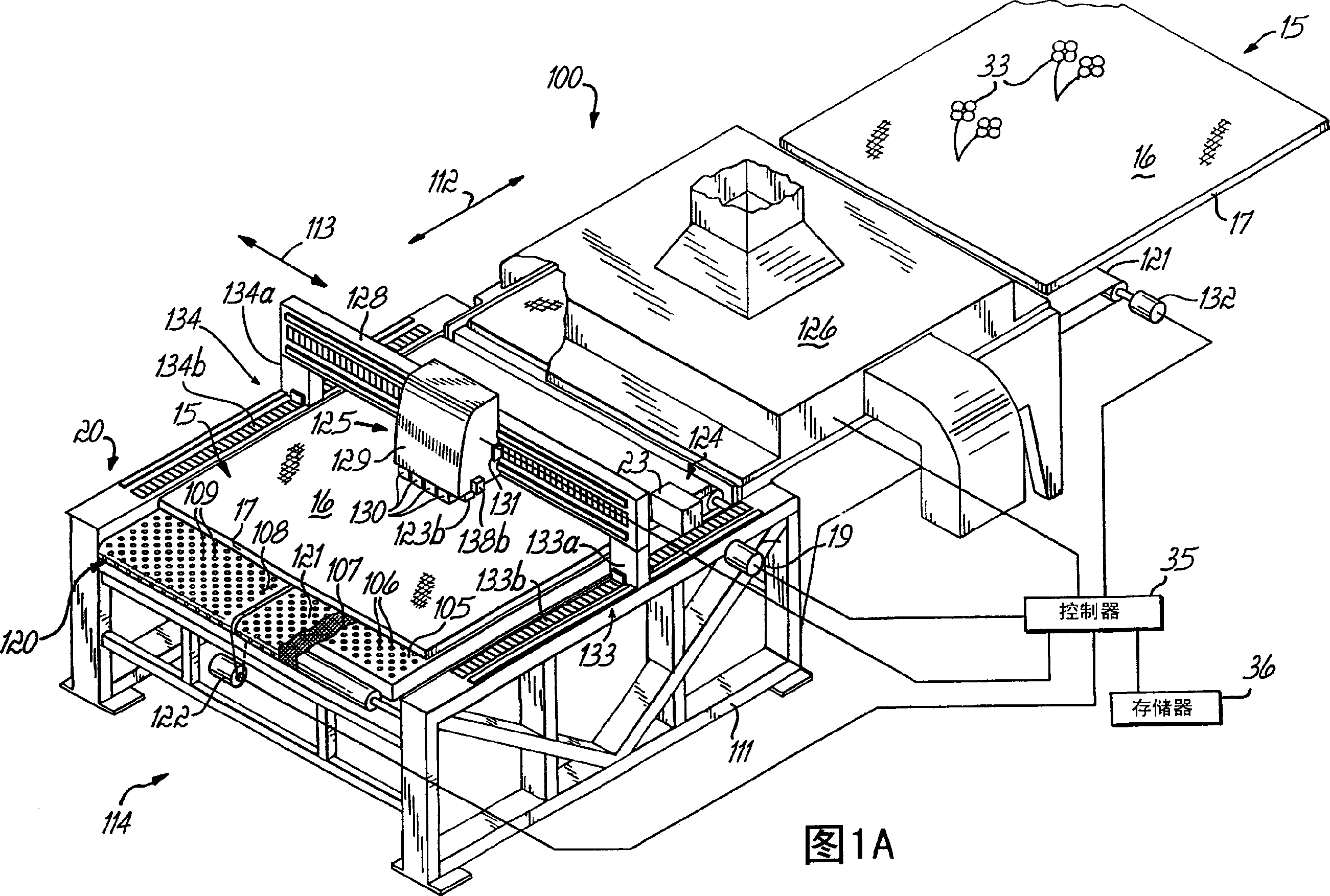

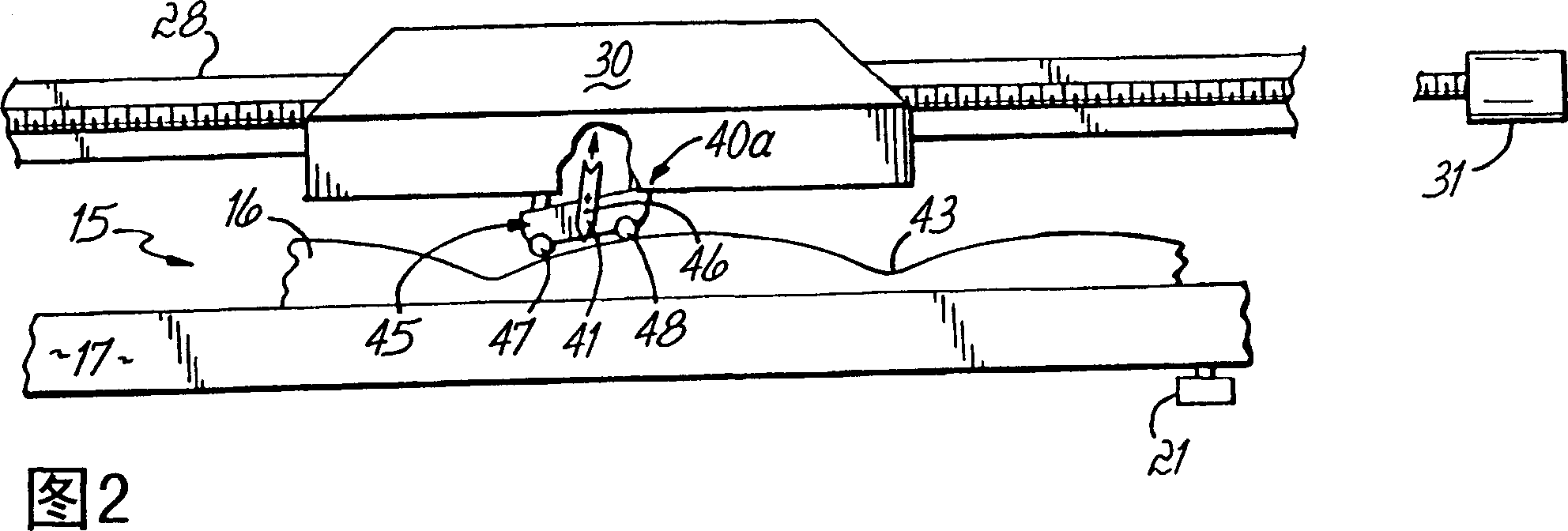

[0023] Figure 1 shows an apparatus 10 for printing on rigid boards. The device 10 comprises a stationary frame 11 whose longitudinal extent is indicated by arrow 12 and whose transverse extent is indicated by arrow 13 . The device 10 has a front end 14 into which a rigid board 15, such as may be used to make office dividers, enters. The rigid board 15 may comprise a metal or wooden frame 17 over which a fabric 16 forming the surface to be printed is stretched. Surface 16 may also be a flat but highly textured fabric, a molded material such as foam, or other contoured or variable surface. The hard board 15 is transported longitudinally on the apparatus 10 by a conveyor or conveyor system 20 formed by a pair of opposed pin tenter belt assemblies 21 which extend through the apparatus 10 and with the hard board 15 on the apparatus 10. The leading end 14 is given to the belt assembly. The belt assembly 21 holds the rigid board 15 in a precisely known longitudinal position on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com