Patents

Literature

168 results about "Integral sliding mode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In 1996, V. Utkin and J. Shi proposed an improved sliding control method named integral sliding mode control (ISMC). In contrast with conventional sliding mode control, the system motion under integral sliding mode has a dimension equal to that of the state space. In ISMC, the system trajectory always starts from the sliding surface. Accordingly, the reaching phase is eliminated, and robustness in the whole state space is promised.

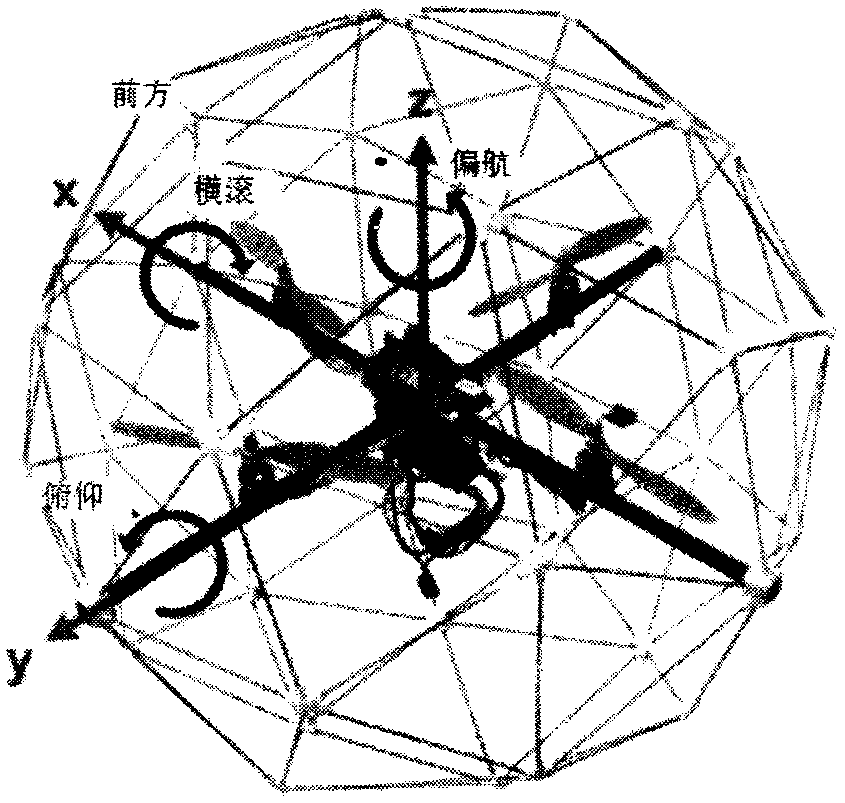

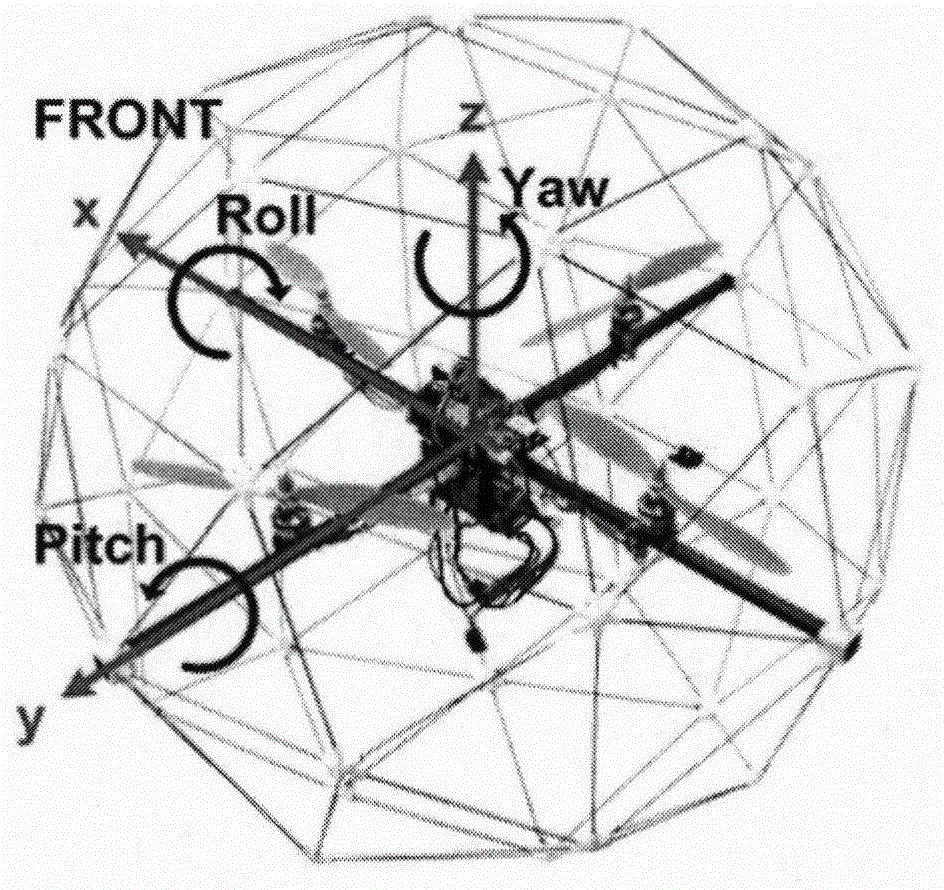

Quadrotor unmanned aerial vehicle finite time attitude tracking control method

ActiveCN106774373ASimple structureEasy to implementAttitude controlPosition/course control in three dimensionsIntegral sliding modeAdaptive method

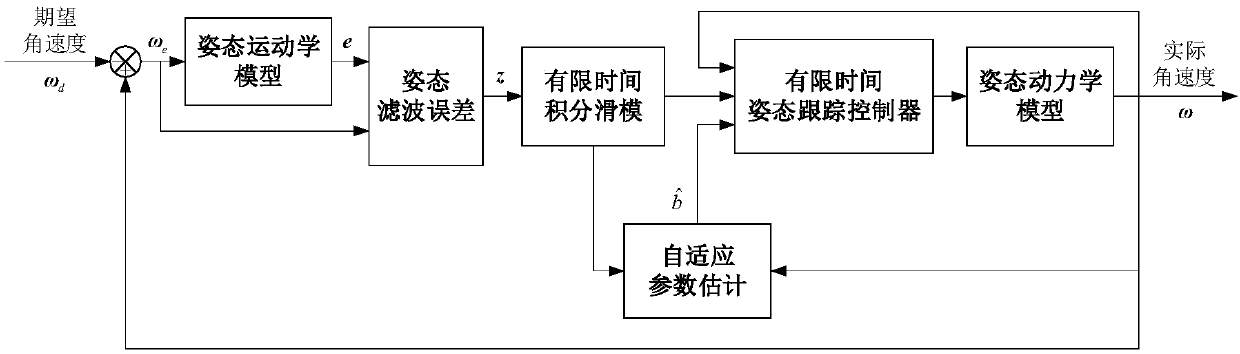

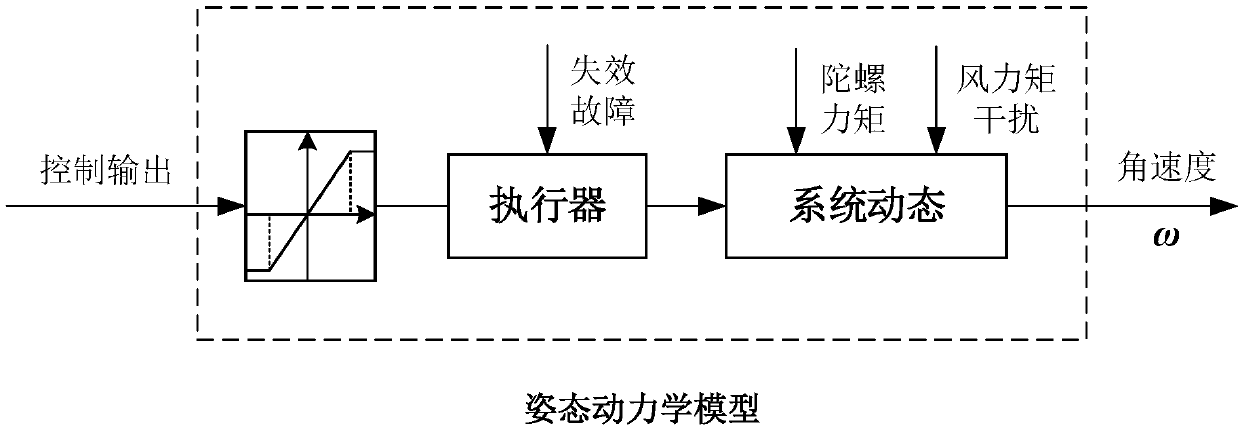

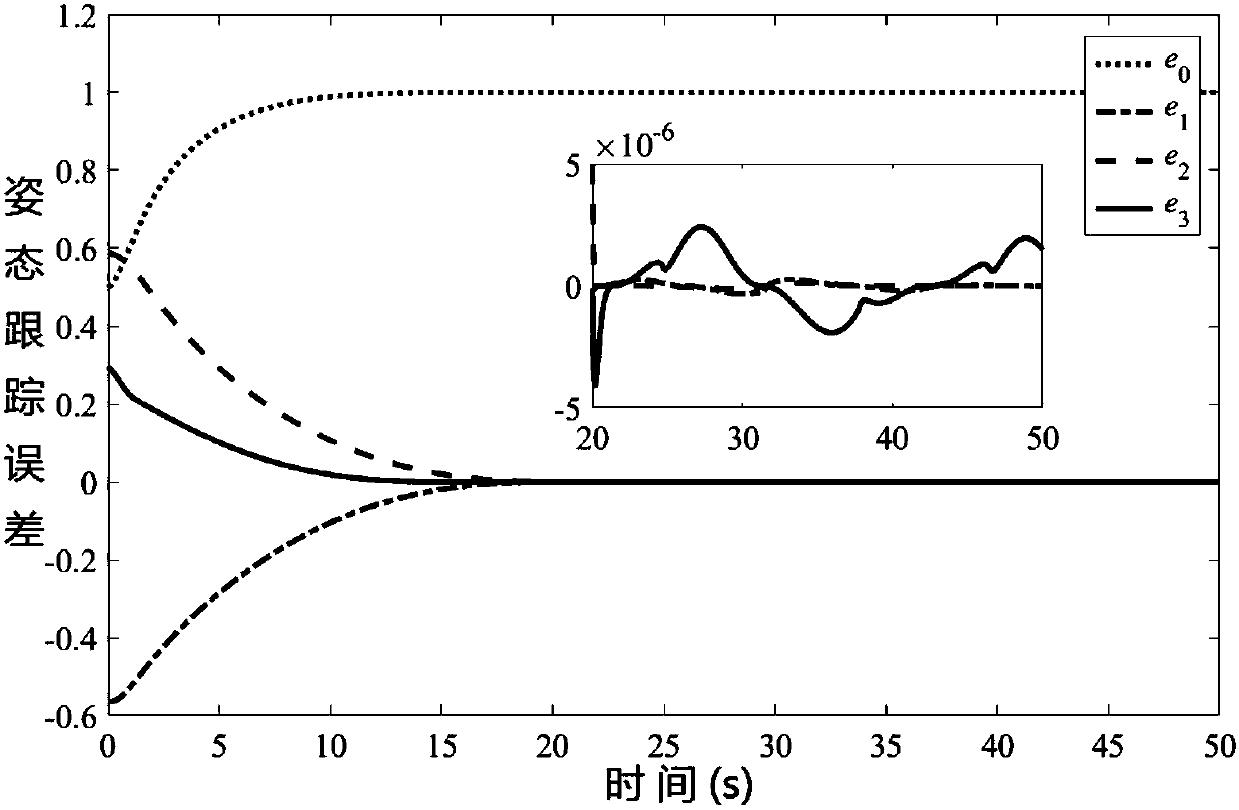

The invention relates to a quadrotor unmanned aerial vehicle attitude control system modeling and finite time attitude tracking control method, in particular to a quadrotor unmanned aerial vehicle finite time attitude tracking control method. Disturbance torque with which a quadrotor unmanned aerial vehicle is confronted is comprehensively analyzed, rotating inertia is unknown, output saturation and actuator failure and other factors are controlled, a passive fault-tolerant controller is designed on the basis of a parameter adaptive method, and the finite time stabilizing function is achieved. The method comprises the steps of 1 building a quadrotor unmanned aerial vehicle attitude tracking kinematic model, 2 building a quadrotor unmanned aerial vehicle attitude tracking kinetic model, 3 defining quadrotor unmanned aerial vehicle attitude smoothing errors, 4 designing a finite time integral sliding mode surface, and 5 designing a quadrotor unmanned aerial vehicle finite time attitude tracking controller. The method is used for the field of unmanned aerial vehicle flight control.

Owner:哈尔滨工业大学人工智能研究院有限公司

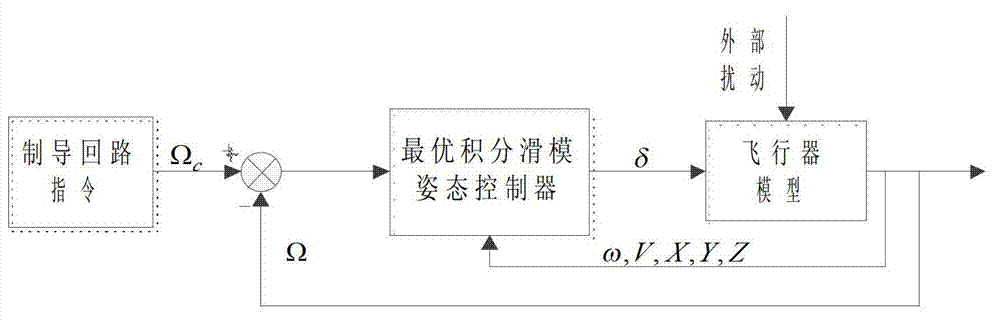

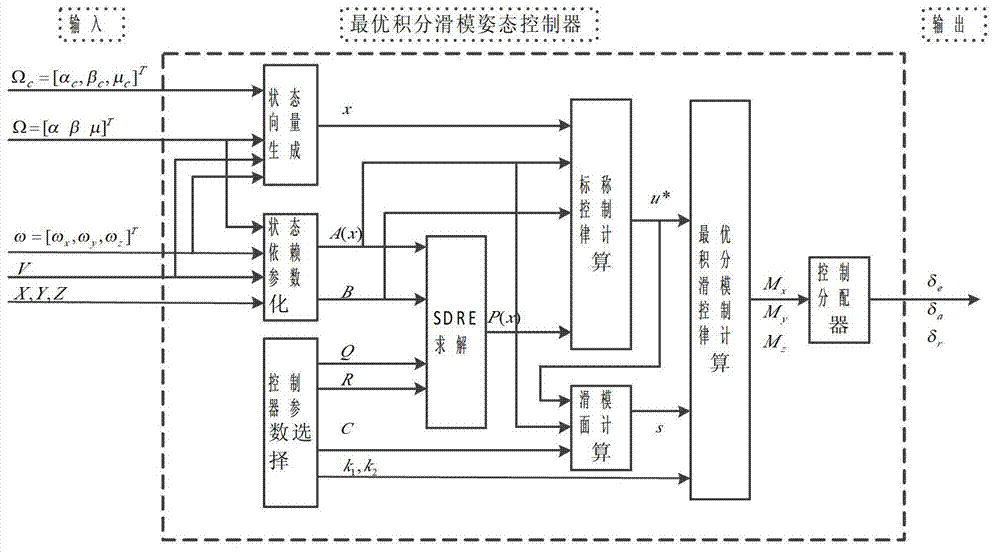

Optical-integral sliding-mode attitude control method of reentry vehicle and controller

InactiveCN102862686APreserve nonlinearityCompromise dynamic performanceGround installationsRiccati equationState dependent

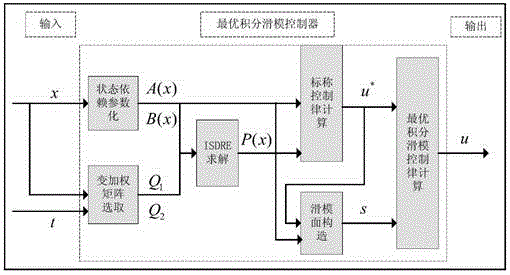

The invention relates to an optical integral sliding-mode attitude control method of a reentry vehicle and a controller, and belongs to the technical field of vehicle control. The optical-integral sliding-mode attitude control method comprises the following steps of: firstly designing an SDRE (State-dependent Riccati Equation) nominal attitude control law according to a nominal model of the vehicle, and enabling the performance of a nominal system to meet the proposed optimal indexes; then considering the uncertainty of the system, designing an integral sliding-mode control law on the basis of the SDRE nominal attitude control law, enabling the system to have robustness while meeting the performance index requirement; and in order to weaken the buffeting, introducing a design idea of a second-order sliding mode and enabling the output of the controller to be smoother. The attitude controller designed by the invention not only can guarantee the expected indexes, but also has better robustness.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

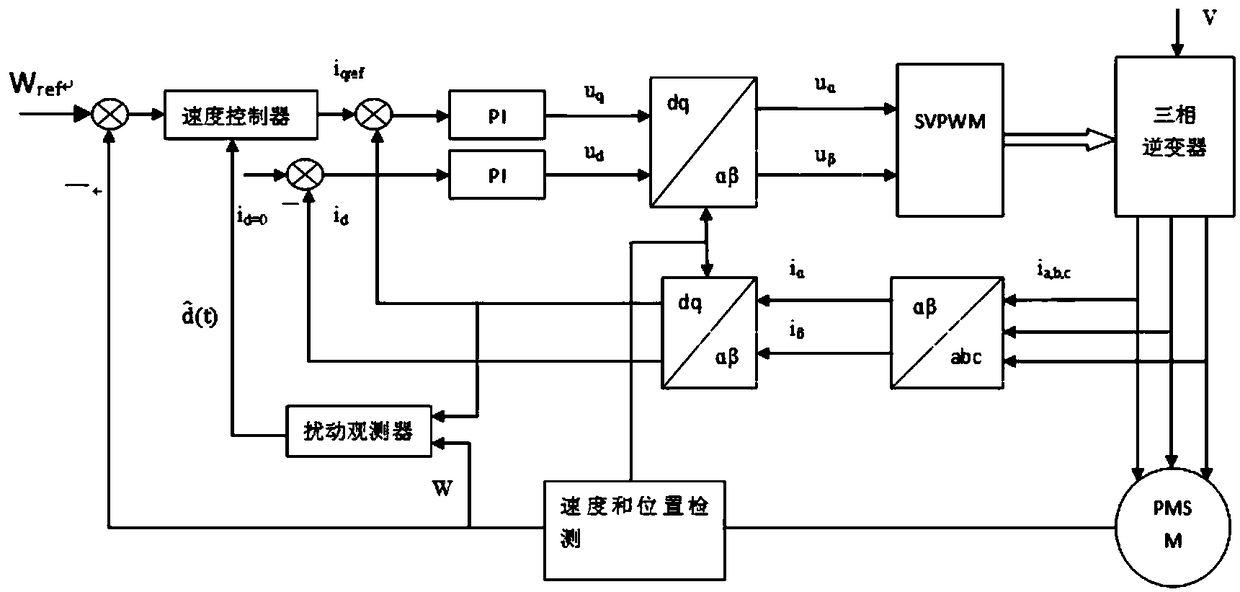

Sliding-mode control method of permanent magnet synchronous motor based on reaching law and disturbance observation compensation

ActiveCN109450320AEliminate chatterImprove anti-interference abilityElectronic commutation motor controlVector control systemsControl systemPermanent magnet synchronous motor

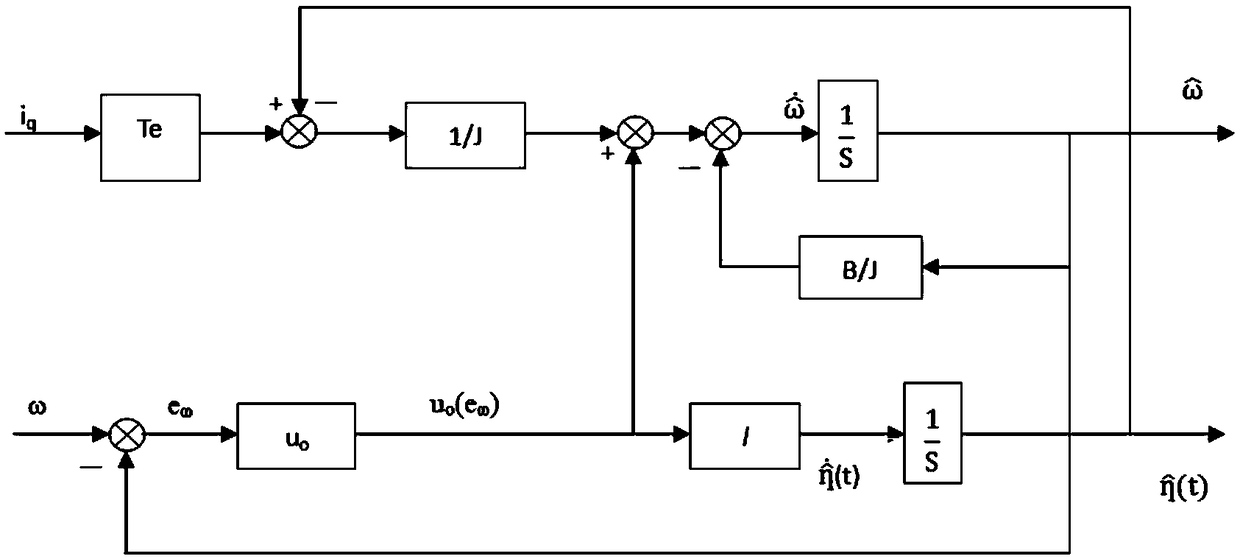

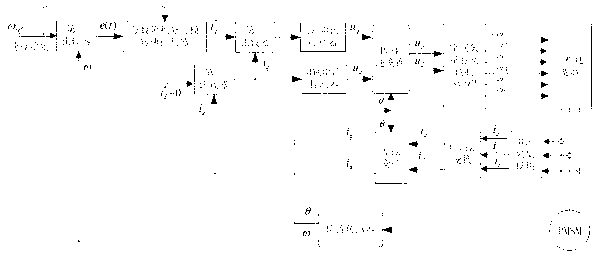

The invention provides a sliding-mode control method of a permanent magnet synchronous motor based on reaching law and disturbance observation compensation. A new reaching law algorithm is designed, and applicable in design of a speed controller in a sliding-mode variable structure; simultaneously, a saturation function is used in a disturbance observer control law, and used for improving a disturbance observer; a value observed by the disturbance observer is compensated in the speed controller; and therefore, a new control strategy is formed. The new control method is applicable in a vector control system of the permanent magnet synchronous motor; a current-speed double-closed-ring control structure is adopted; for buffeting and anti-interference problems in the sliding-mode control, an integral sliding-mode surface and a new reaching law are added based on the conventional sliding-mode speed controller; simultaneously, the disturbance observer is added; disturbance due to load changeis effectively inhibited; the responsiveness of the system is improved; buffeting of the system is reduced; and the anti-interference performance and the robustness of the system in a complex environment are obviously improved.

Owner:ZHEJIANG SCI-TECH UNIV

Neural network inversion control method for flexible manipulator system

ActiveCN104950678AAvoid Control Chattering ProblemsRealize position tracking controlAdaptive controlDynamic modelsModel parameters

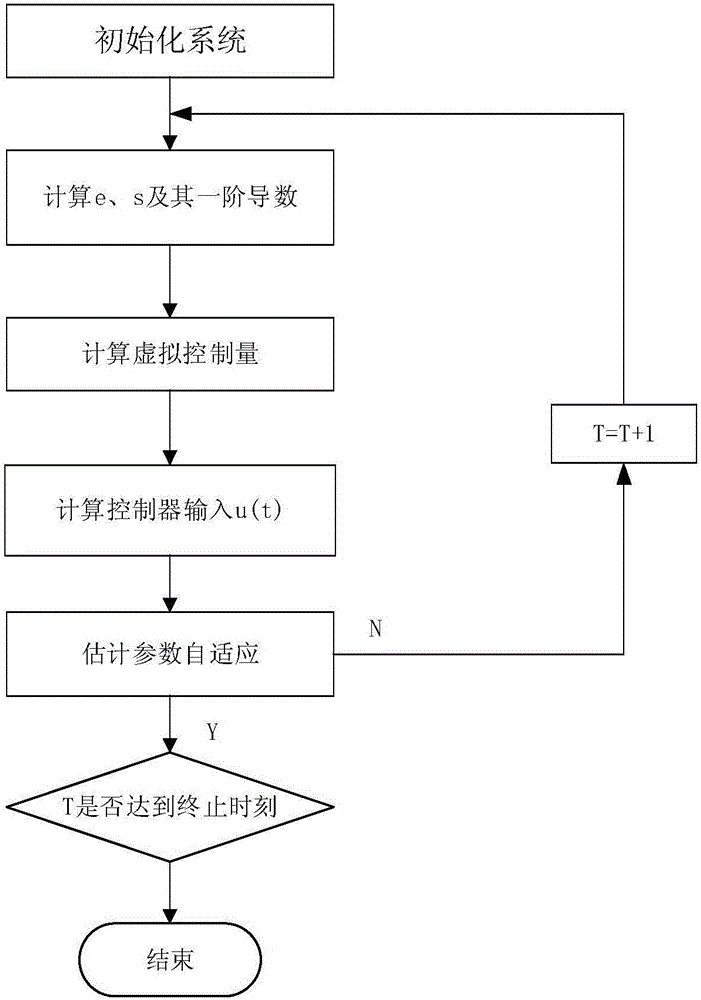

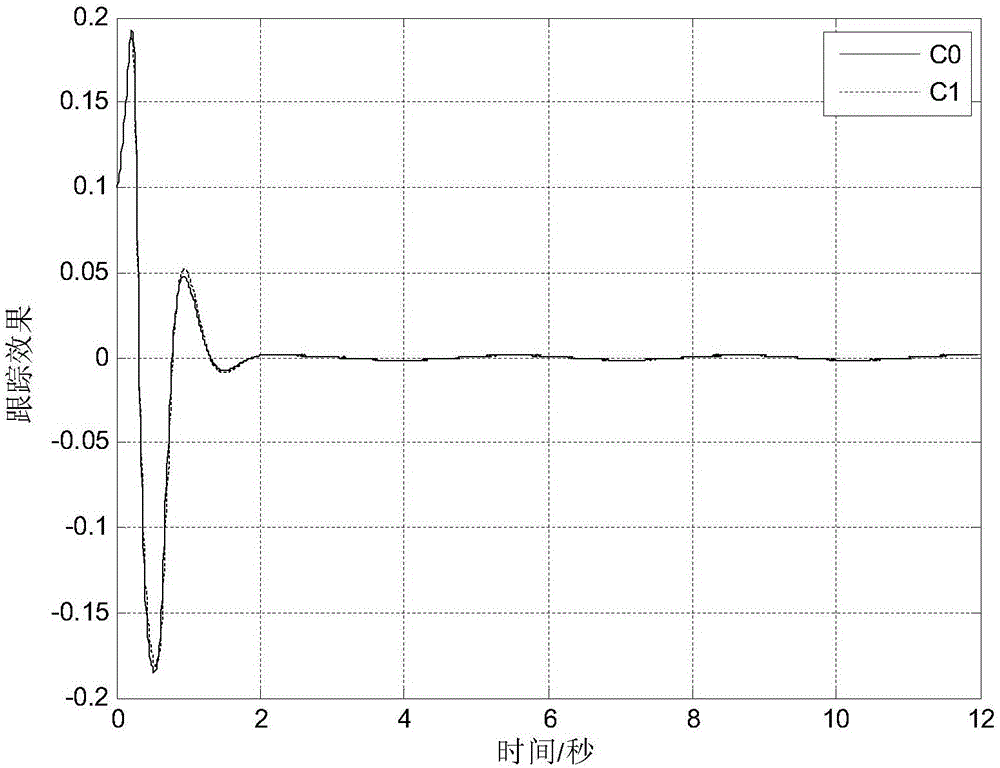

The invention discloses a neural network inversion control method for a flexible manipulator system. The neural network inversion control method comprises the following steps of establishing a dynamic model of a flexible manipulator servo system and performing equivalent transformation on the dynamic model, and initializing a system state, sampling time and a control parameter; introducing a virtual control variable into the design of each step by combining sliding-mode control and an inversion method, and finally deducing self-adapting controller input; calculating the tracking error, the integral sliding mode surface, the error variable and the differential of a control system. Meanwhile, by utilizing the approximation characteristic of a neural network, the complexity explosion problem brought by the inversion method and the approximation of model parameter uncertainty are avoided; the invention provides the neural network inversion control method capable of effectively improving the location tracking control performance of the flexible manipulator servo system, therefore the stable and rapid tracking of the system is realized.

Owner:GUANGZHOU ETON ELECTROMECHANICAL

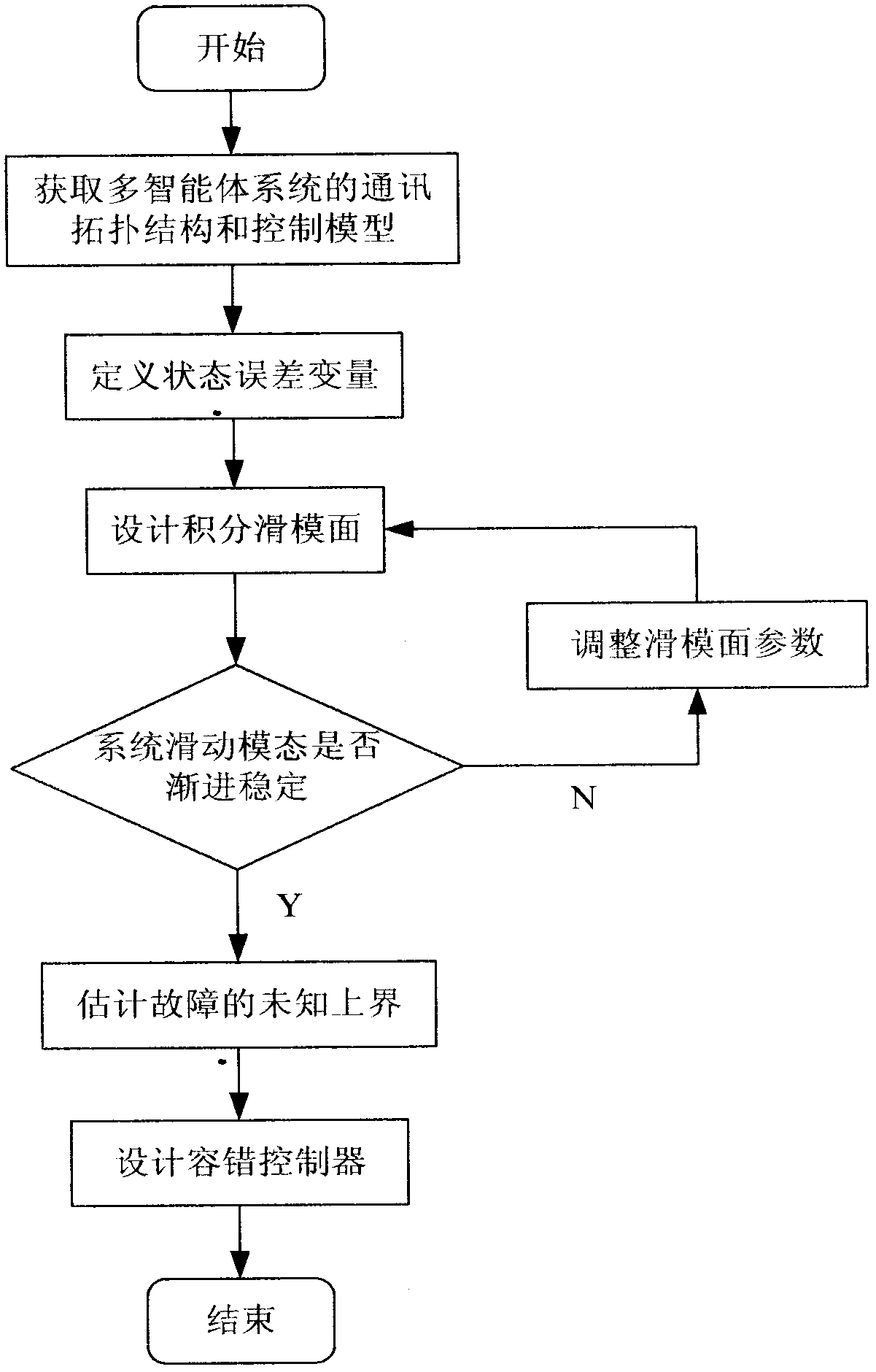

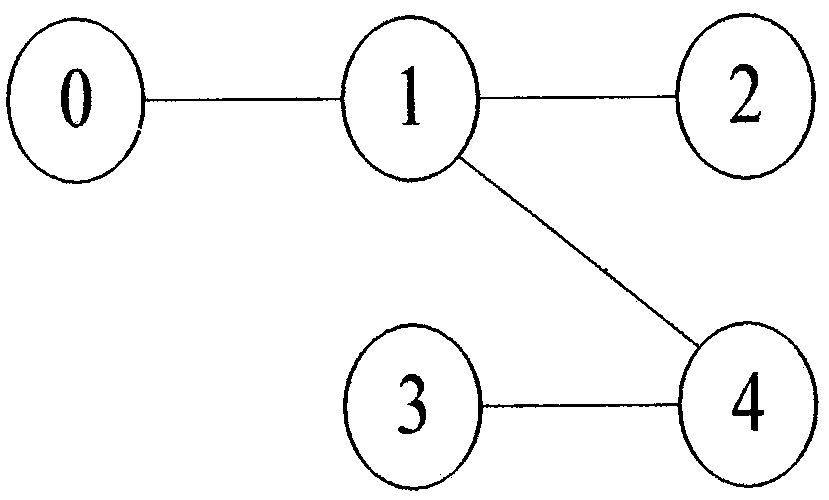

Fault-tolerant control method for linear multi-agent system actuator fault based on sliding mode

ActiveCN109116736AGuaranteed asymptotic stabilityImprove robustnessAdaptive controlMulti-agent systemIntegral sliding mode

The invention discloses a tracking fault-tolerant control method for a linear multi-agent system based on sliding mode control. A fault-tolerant control method based on the sliding mode control methodand adaptive control is proposed for the actuator fault of the linear multi-agent tracking system with external disturbance. Aiming at the actuator partial failure fault that may occur in the agent,the state error variable is defined according to the communication topology between multi-agents, the integral sliding mode surface is designed based on the error variable and sufficient conditions for sliding mode asymptotic stability are given. Then the unknown upper bound of the actuator fault is estimated by the adaptive method, and a sliding mode fault-tolerant controller is proposed to guarantee the tracking stability of the multi-agent system. The integral sliding mode surface is designed according to the state error variable between the multi-agents and the robustness of the system isenhanced, and the fault-tolerant control law having good fault-tolerant ability when the system has partial actuator failure fault and external disturbance is put forward and the tracking stability ofthe multi-agent system is improved. The fault-tolerant control method is used for fault tolerant control of the linear multi-agent system with the actuator failure fault and the external disturbance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

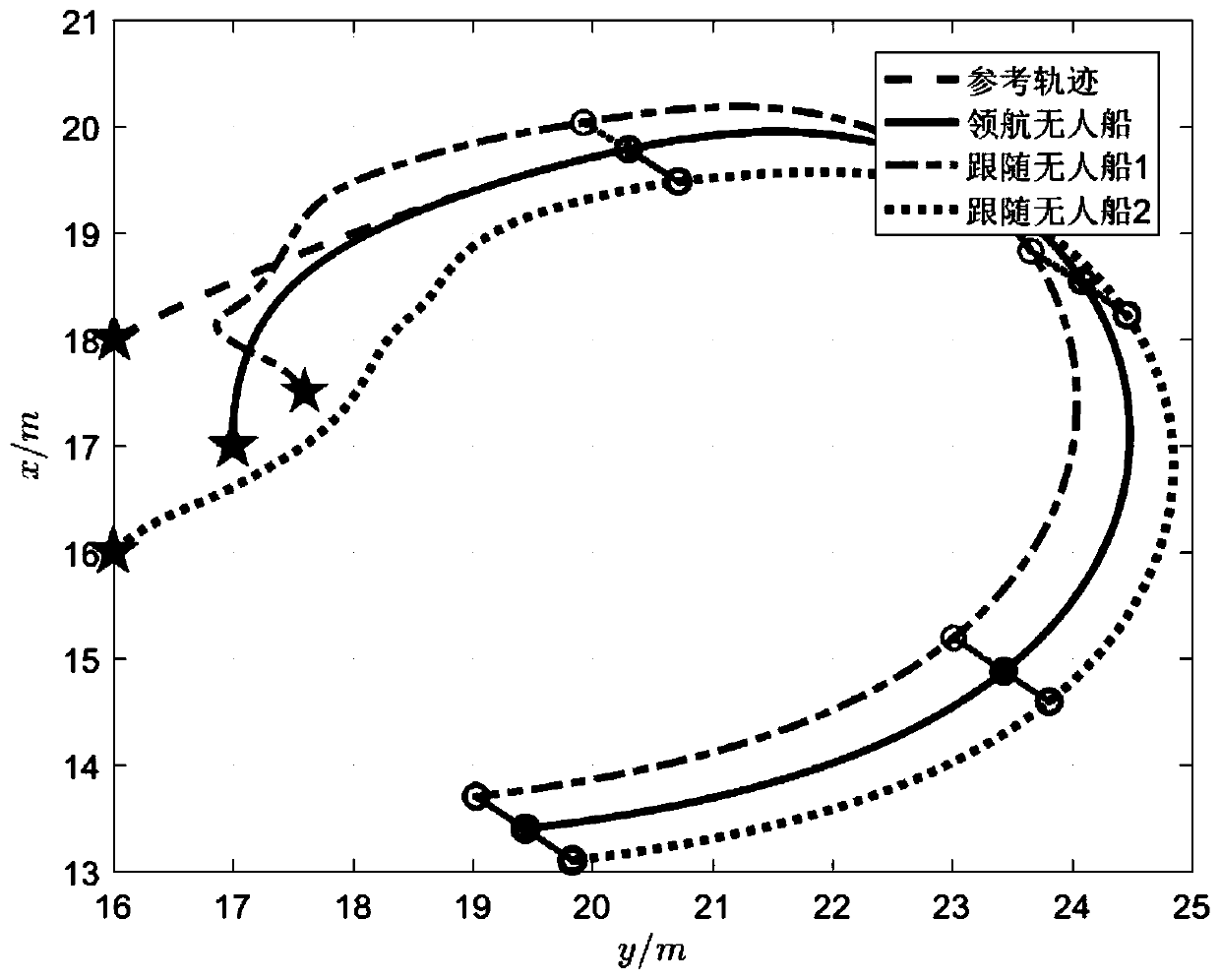

Fixed time formation control method based on finite time disturbance observer

ActiveCN110879599AFast convergenceRapid identificationSustainable transportationPosition/course control in two dimensionsBacksteppingMarine engineering

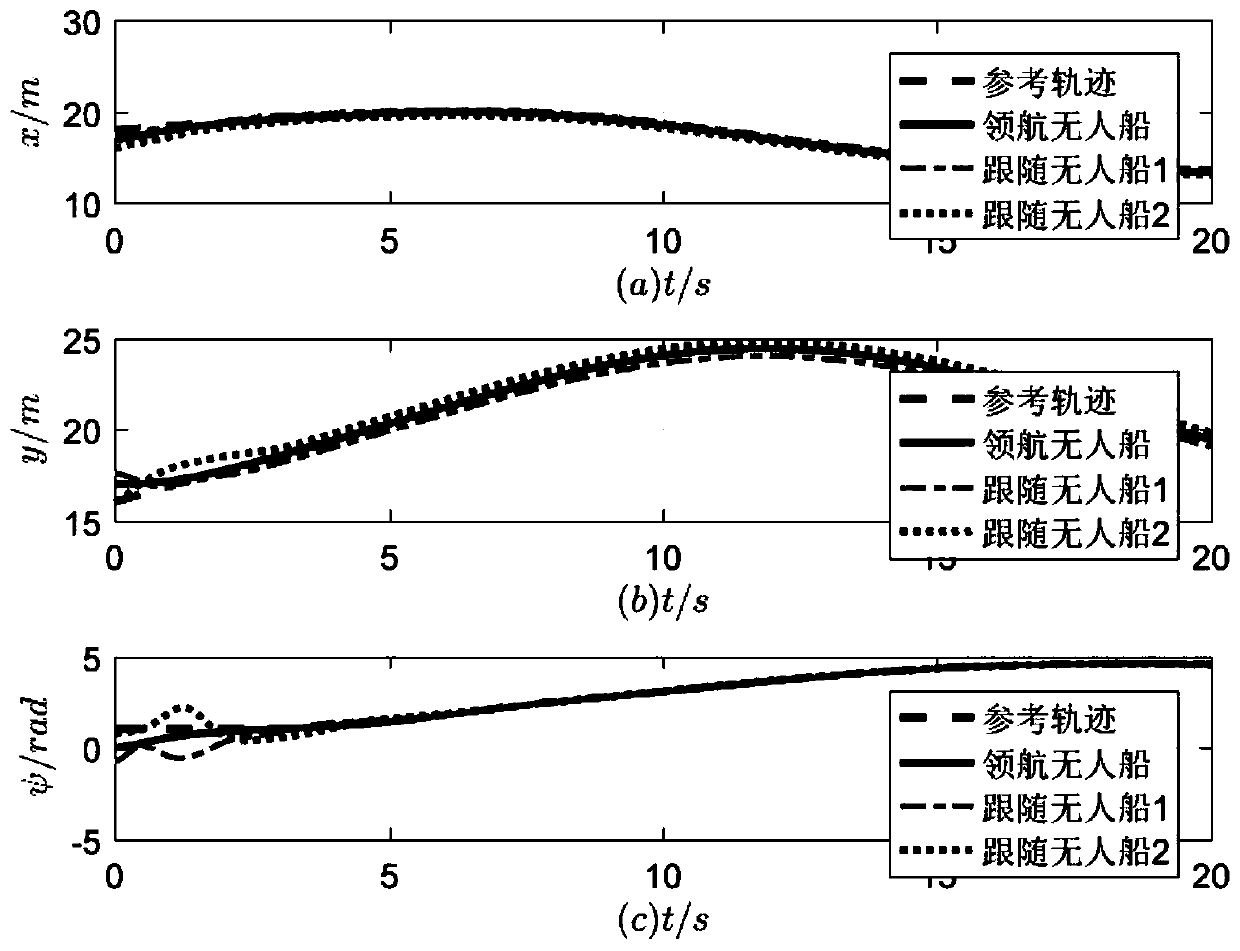

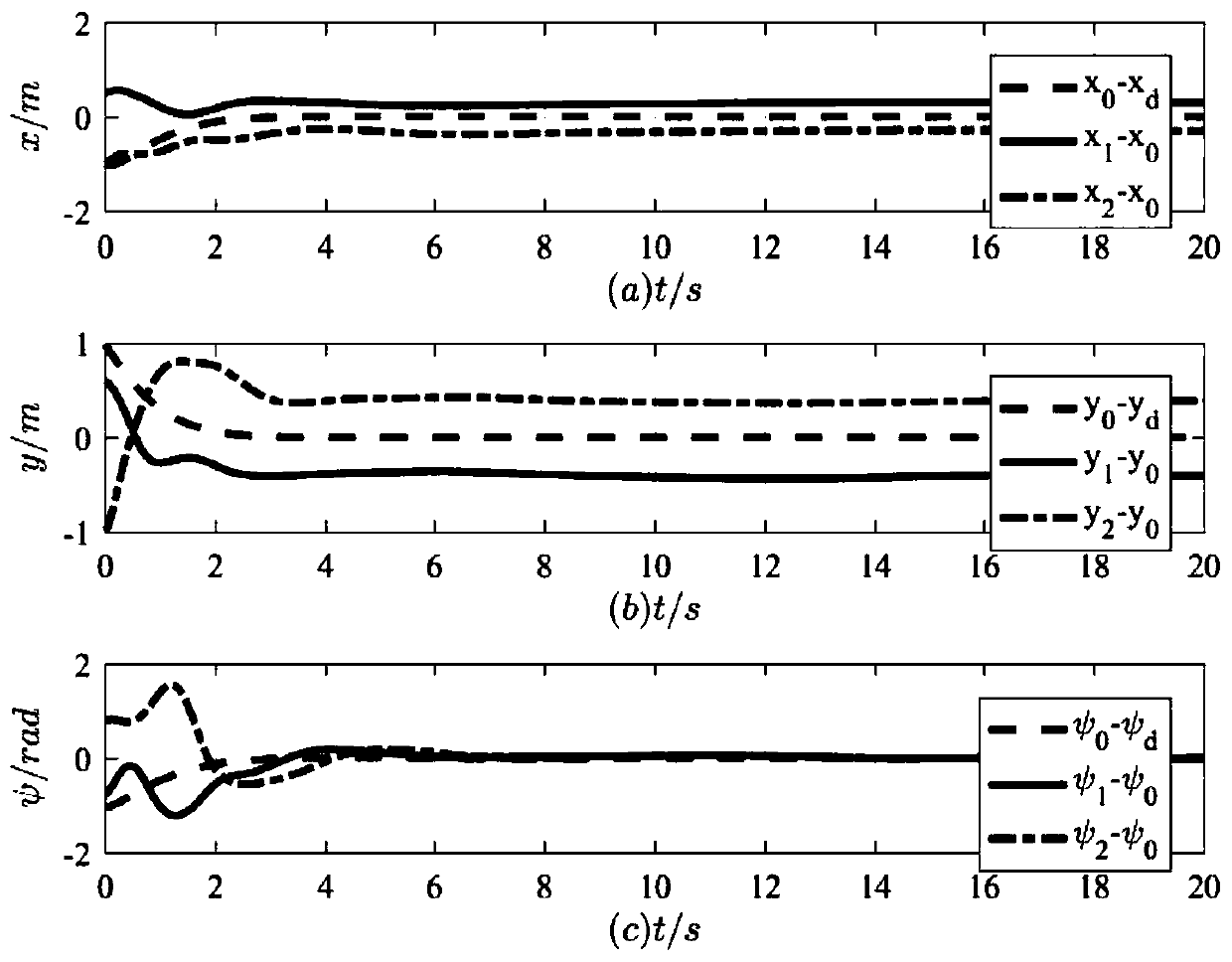

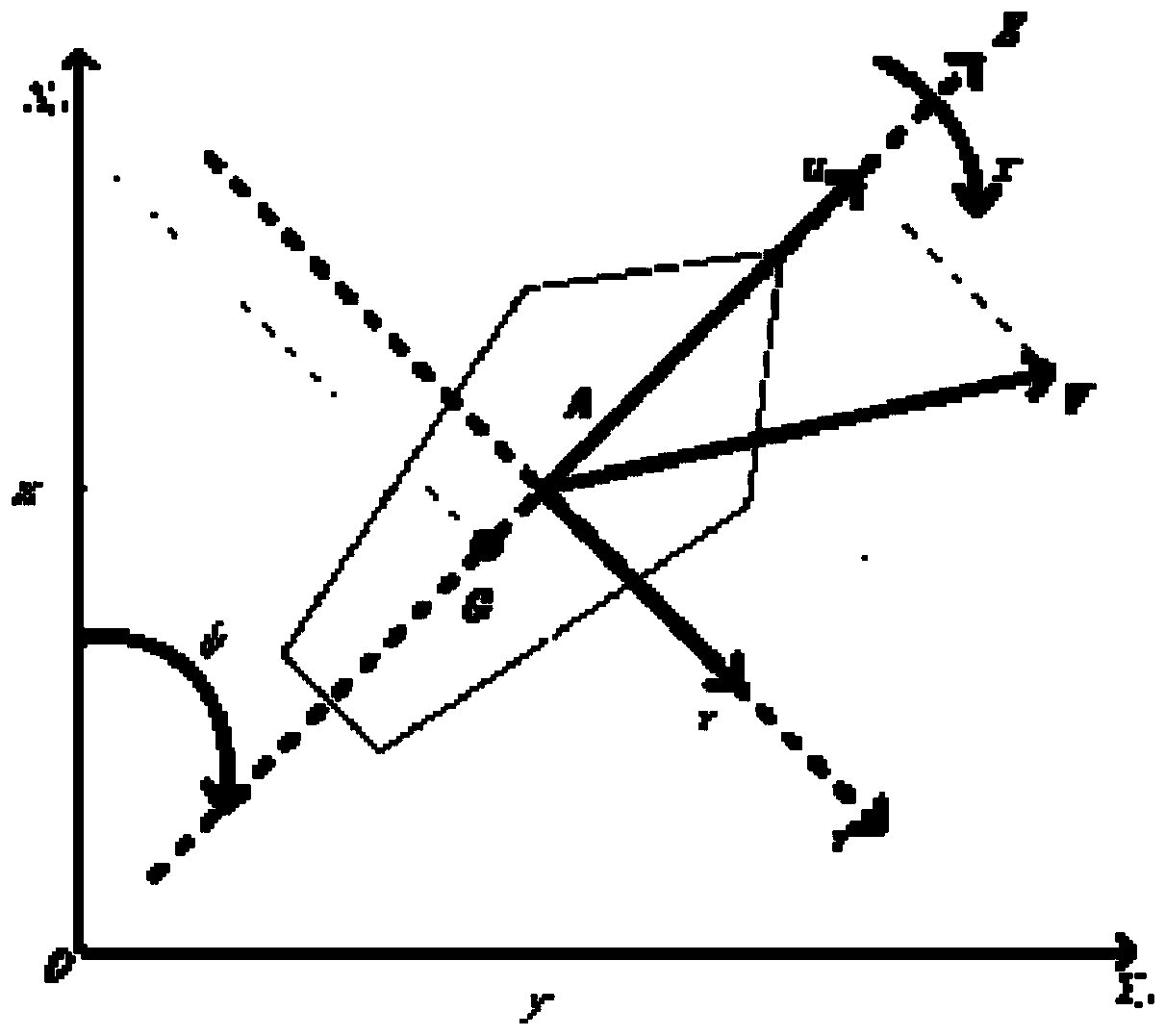

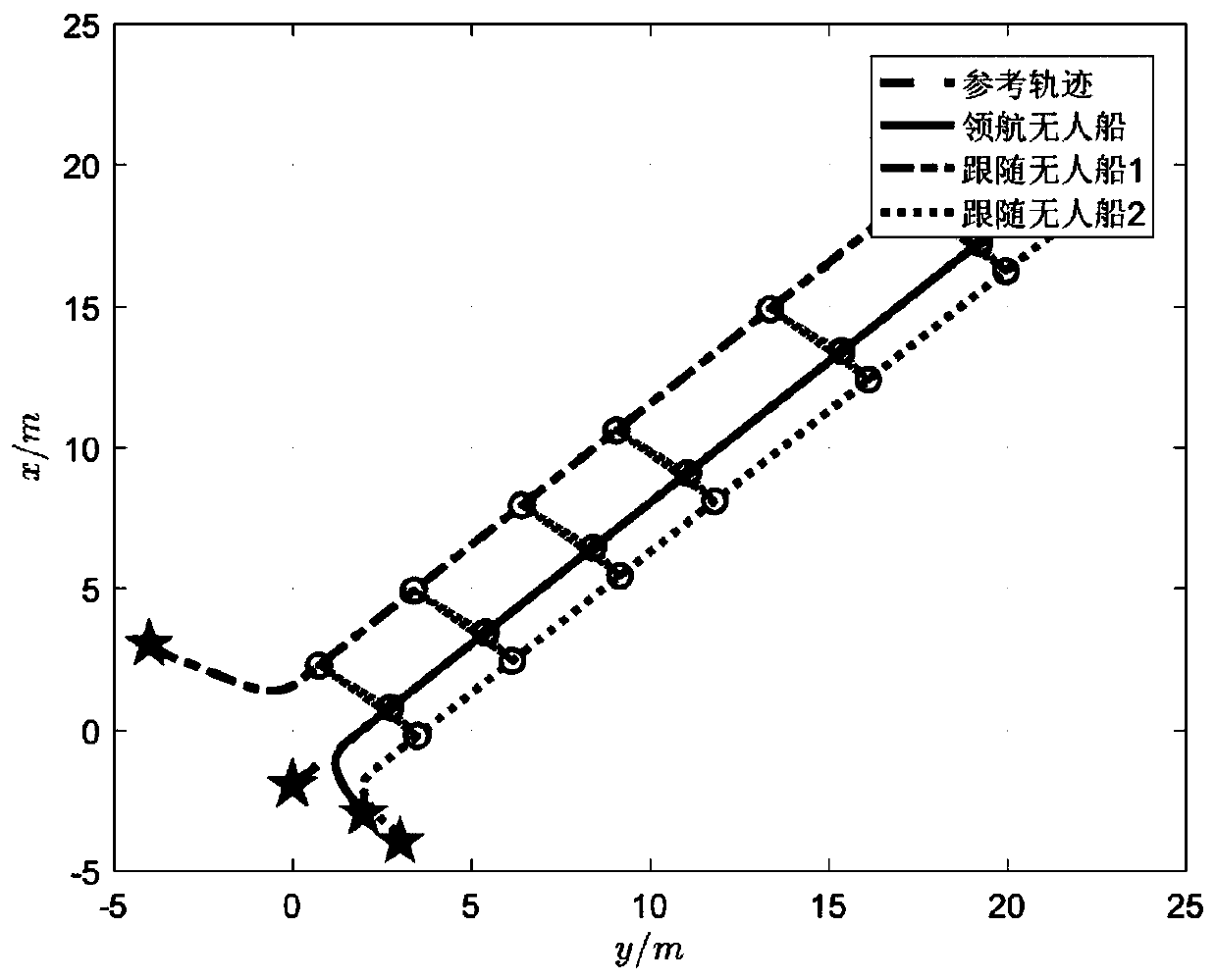

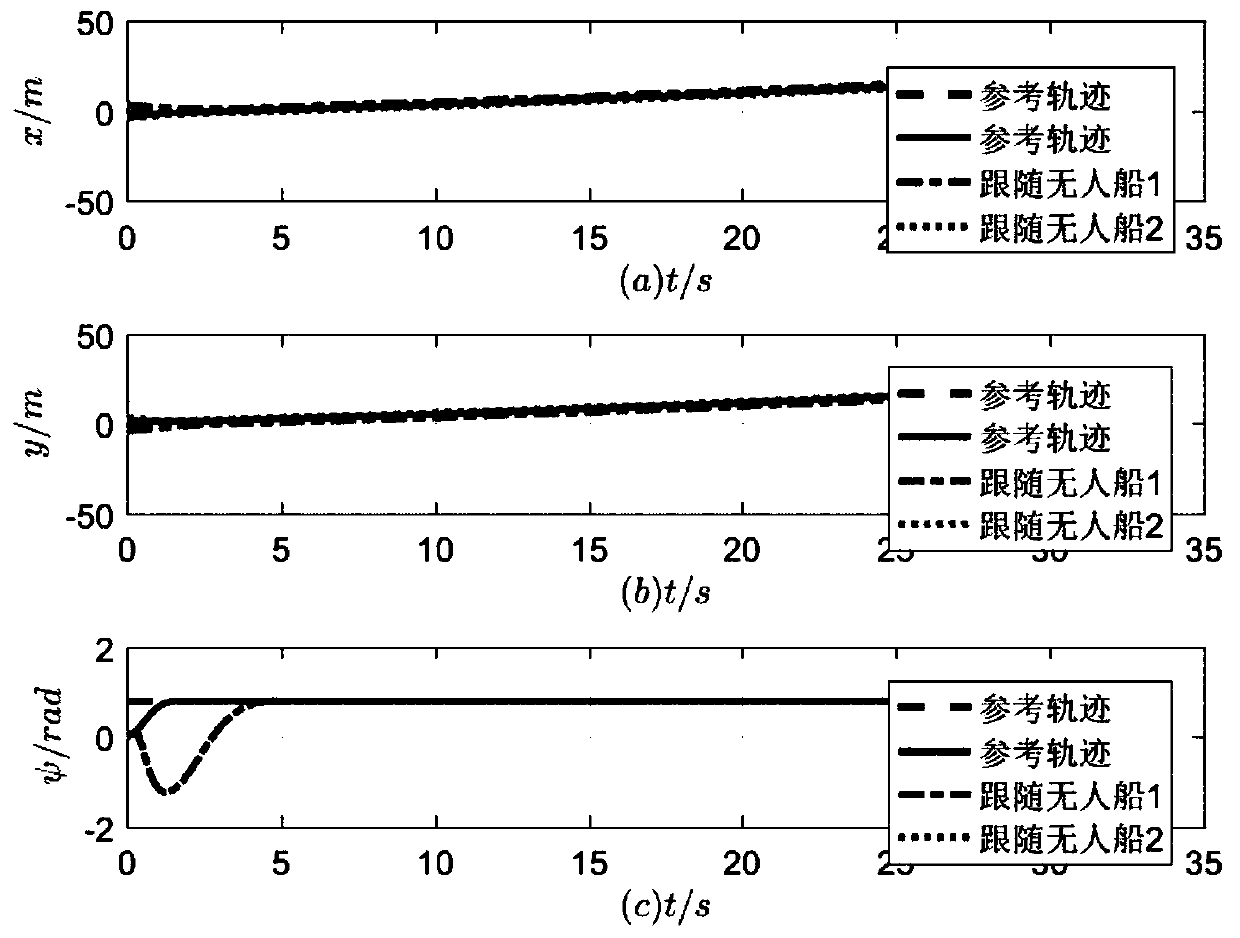

The invention discloses a fixed time formation control method based on a finite time disturbance observer and belongs to the field of multi-unmanned-ship cooperative control. The method comprises thefollowing steps: establishing dynamics and kinematics models of a piloted unmanned ship and a following unmanned ship, establishing an expected trajectory model of a piloted unmanned ship subsystem, and designing a fixed time tracking controller of the piloted unmanned ship subsystem in combination with an integral sliding mode surface so as to realize piloted unmanned ship trajectory control; designing a virtual speed of the following unmanned ship subsystem by adopting a backstepping method to determine a position error between the piloted unmanned ship and the following unmanned ship, and adjusting a tracking error between the piloted unmanned ship and the following unmanned ship by designing a tracking controller of the following unmanned ship; adopting a finite time disturbance observer and providing a fixed time formation control strategy based on a finite time observer in a complex environment in combination with a fixed time control law. Therefore, accurate formation control between the piloted unmanned ship and the following unmanned ship is realized, the maximum convergence time is calculated, the thought of a finite time disturbance observer is provided, and rapid and effective identification of external disturbance can be realized, so that the robustness of an unmanned ship formation system is improved.

Owner:DALIAN MARITIME UNIVERSITY

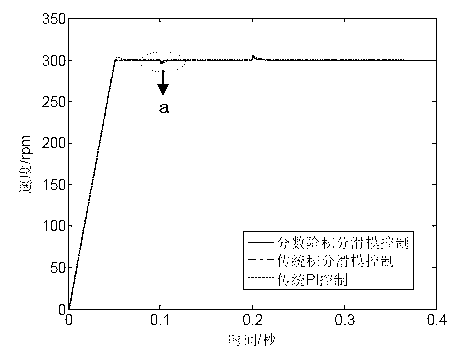

Fractional integral sliding mode-based speed control method and device for permanent magnet synchronous motor

InactiveCN103236814AEasy to controlEliminate the effects ofElectronic commutation motor controlAC motor controlTransient stateElectric machine

The invention discloses a fractional integral sliding mode-based speed control method for a permanent magnet synchronous motor. The fractional integral sliding mode-based speed control method for the permanent magnet synchronous motor comprises the following steps of constructing a fractional integral sliding mode surface S, and designing a fractional integral sliding mode rotary speed controller for performing rotary speed regulation. The invention also discloses a fractional integral sliding mode-based speed control device for the permanent magnet synchronous motor. According to the fractional integral sliding mode-based speed control method for the permanent magnet synchronous motor disclosed by the invention, high-performance speed following control of the motor can be realized under the condition that parameter perturbation and load disturbance exist in a control system for the permanent magnet synchronous motor, and the defect that an integral saturation effect and the transient performance are reduced due to a big initial error or actuator saturation in traditional integral sliding mode control is overcome.

Owner:NANJING INST OF TECH

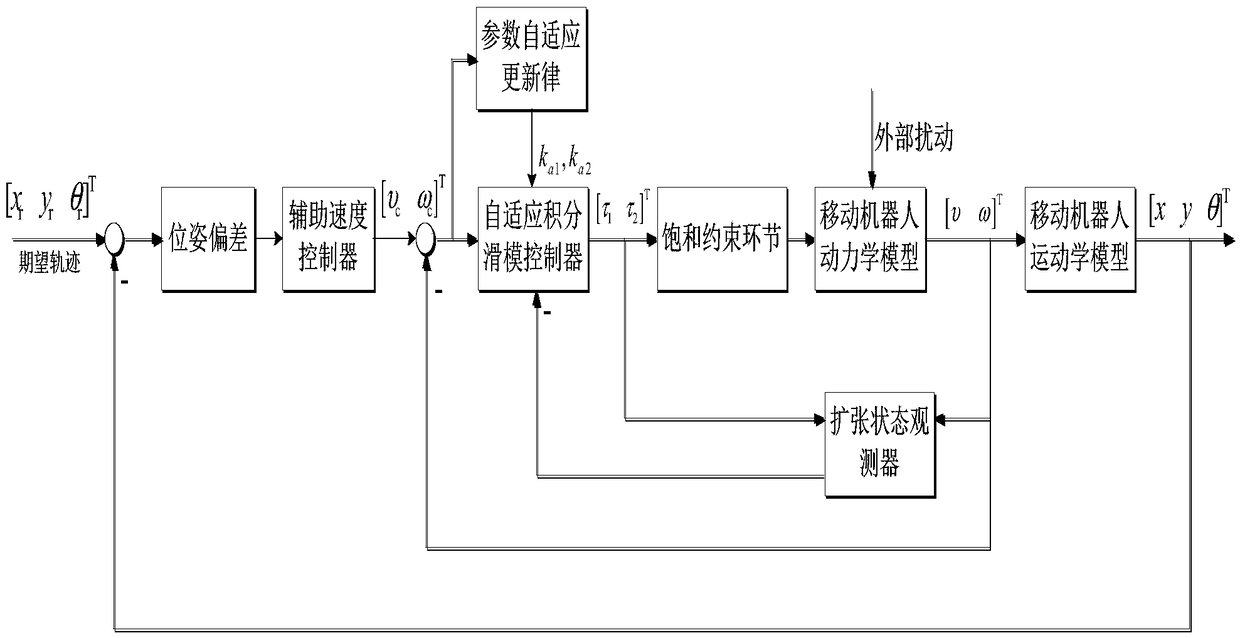

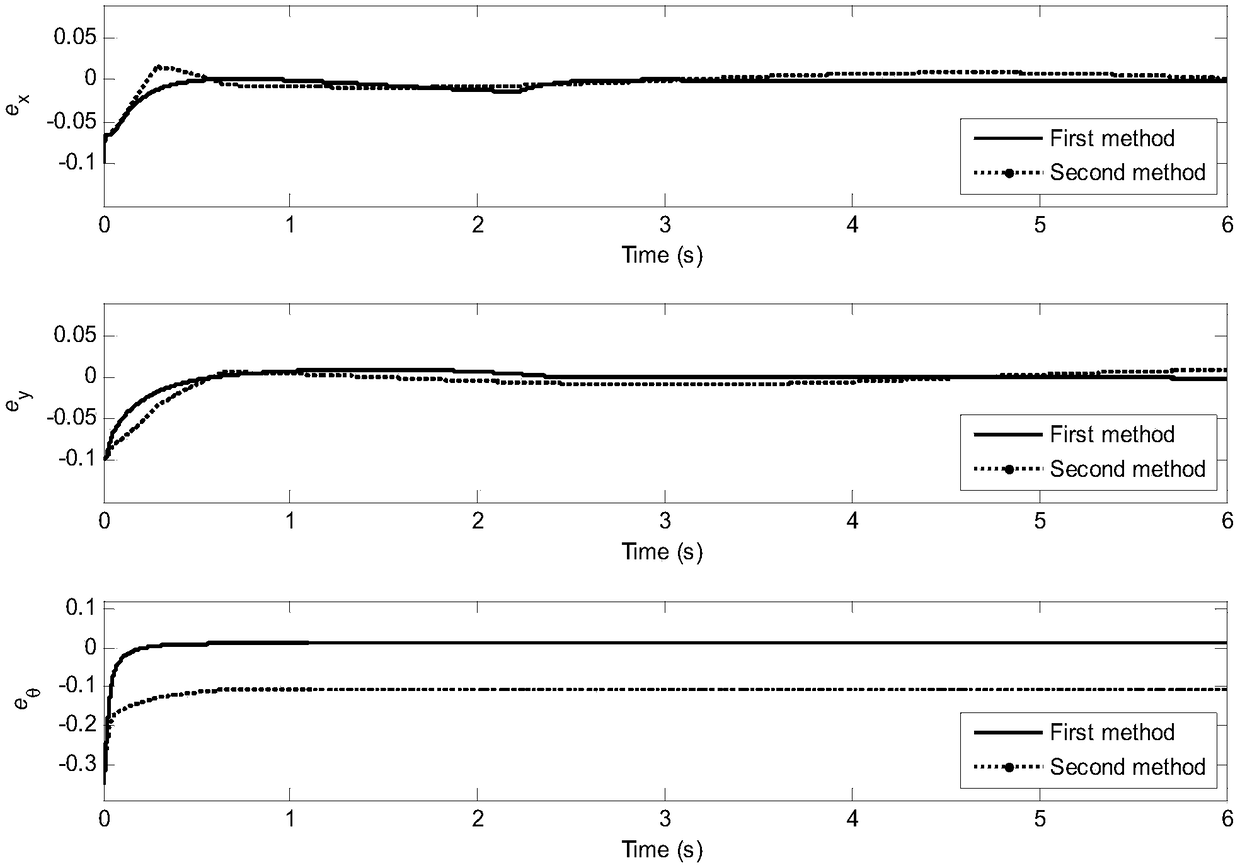

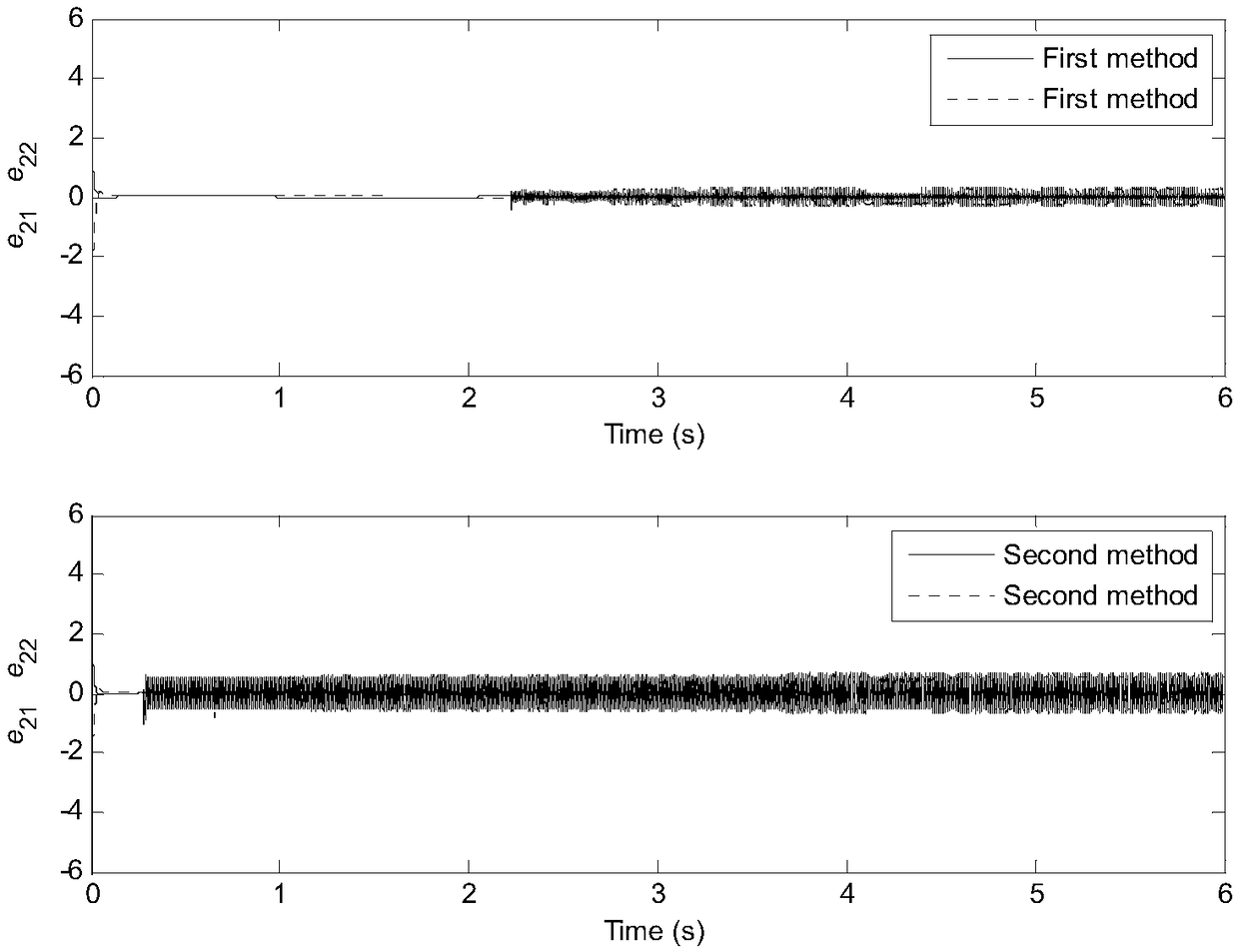

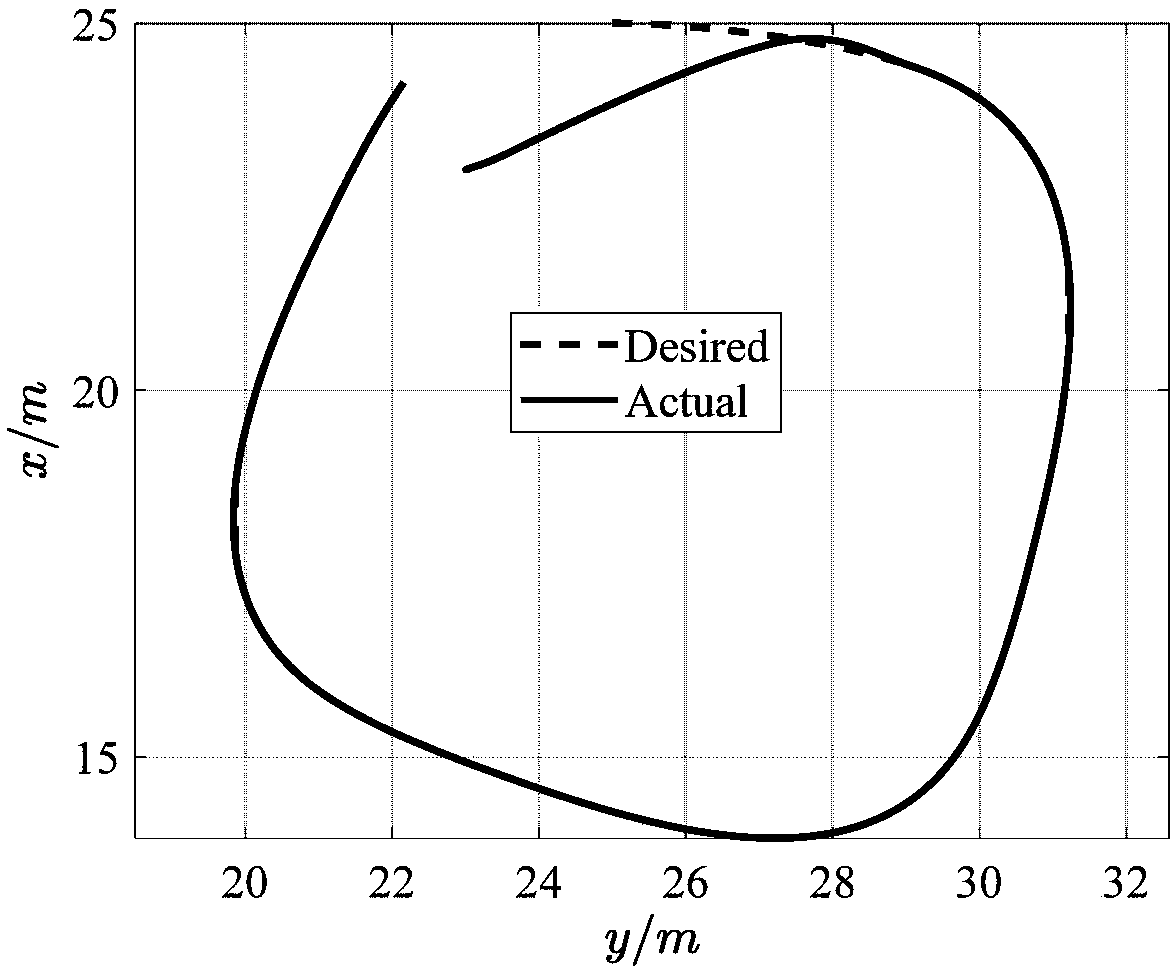

Adaptive integral sliding mode control method of mobile robot

ActiveCN108614425ASatisfy the requirements of saturation constraintsImprove stabilityAdaptive controlControl systemActuator saturation

The invention discloses an adaptive integral sliding mode control method of a mobile robot with consideration of actuator saturation compensation. The method comprises: establishing a mobile robot tracking control system model considering actuator saturation compensation; designing an auxiliary speed controller; designing an extended state observation; and designing mobile robot adaptive integralsliding mode controller with consideration of actuator saturation compensation. Therefore, the system jitter amplitude is weakened and the system stability and robustness are improved while the quickand stable convergence of the system tracking error is ensured.

Owner:HUANGSHAN UNIV

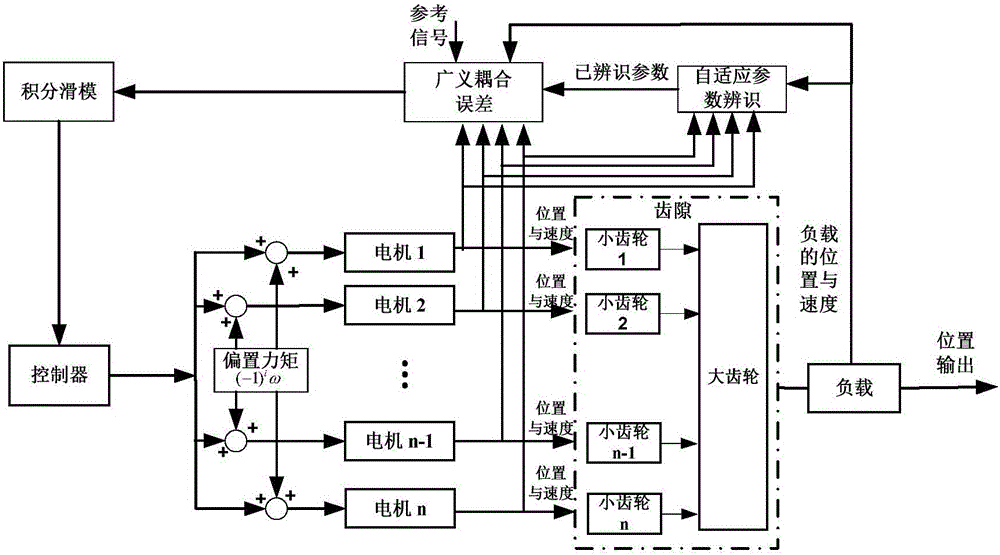

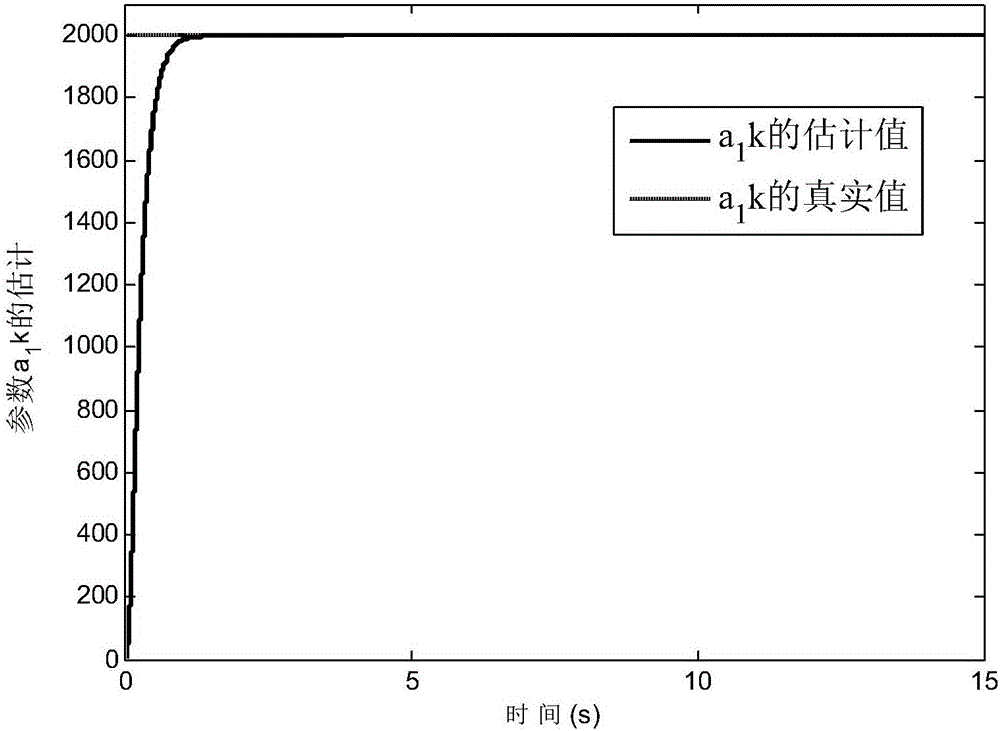

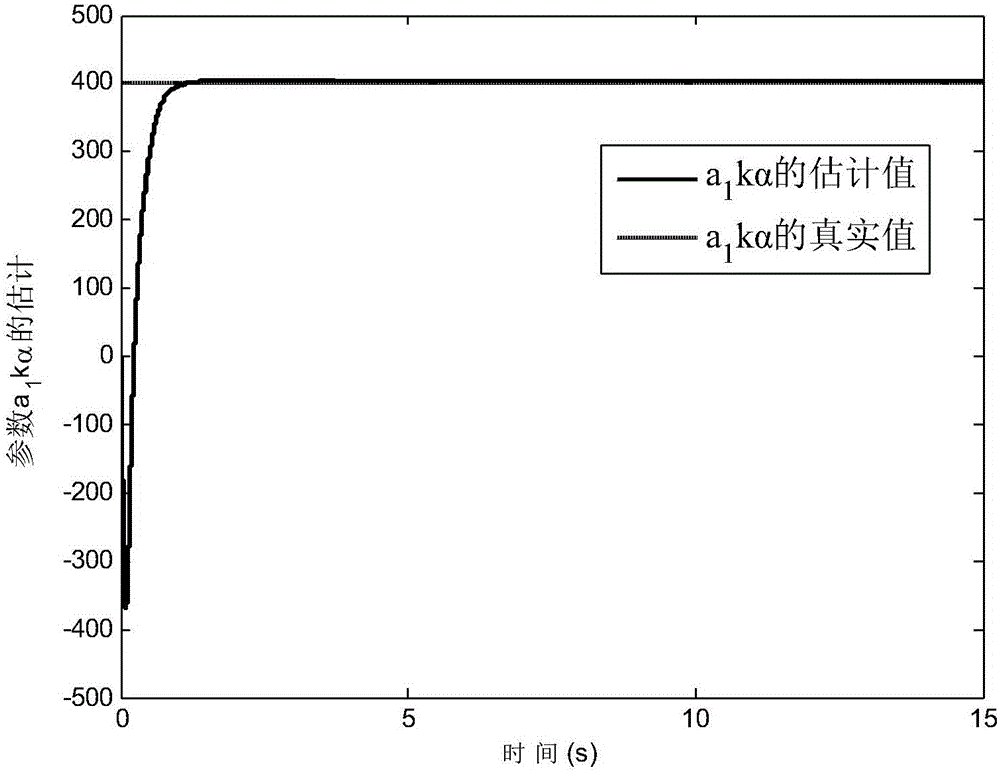

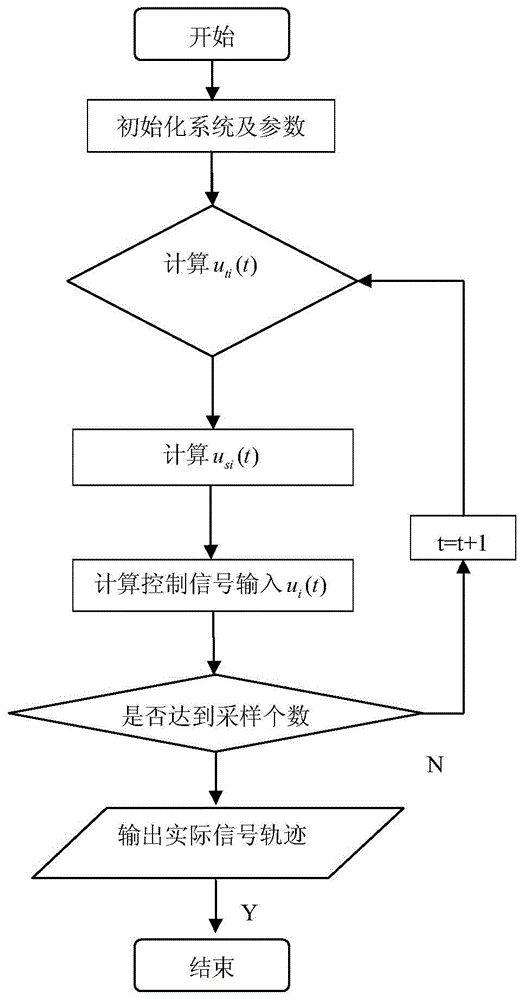

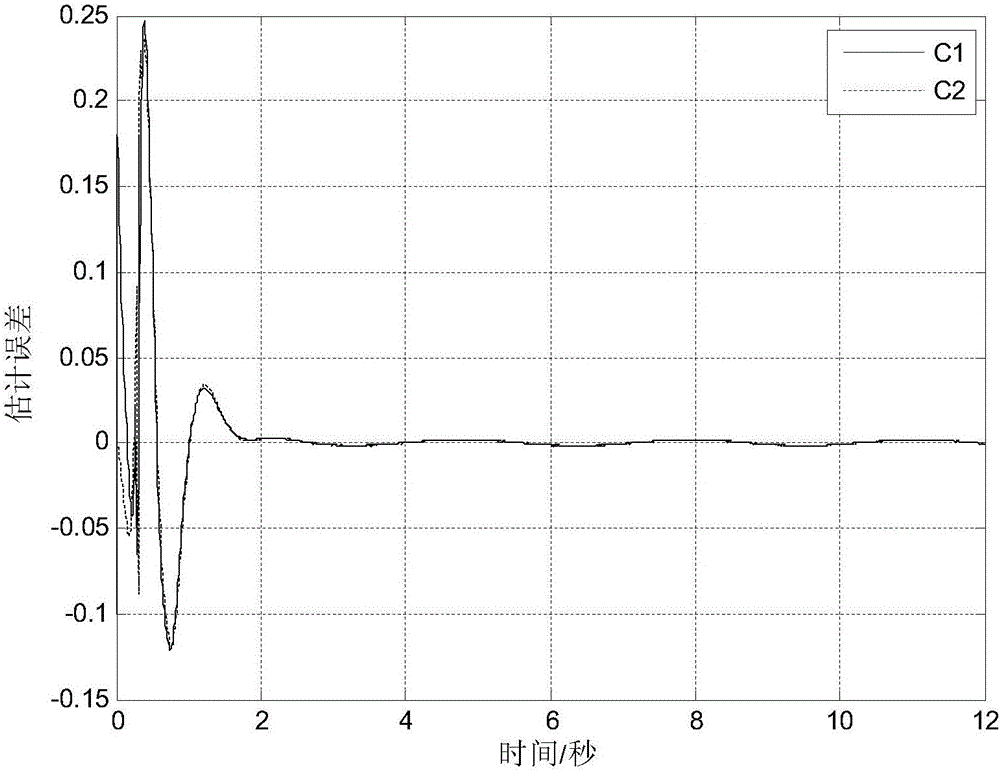

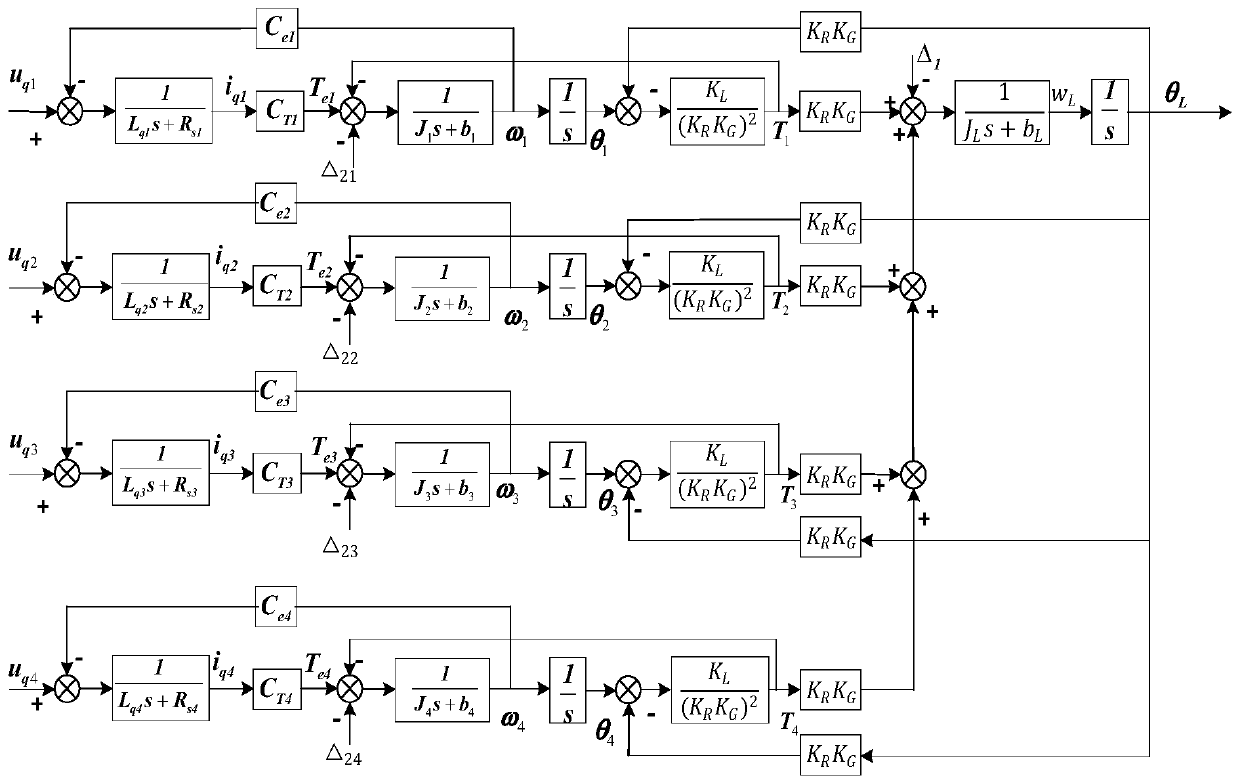

Parameter identification based multi-motor servo system synchronization and tracking control method

InactiveCN105867136AImprove approximationGuaranteed Steady State PerformanceAdaptive controlTransient stateMotor drive

The invention relates to a parameter identification based multi-motor servo system synchronization and tracking control method. The parameter identification based multi-motor servo system synchronization and tracking control method comprises the steps that 1, a multi-motor driven servo system containing unknown parameters is analyzed, and a mathematic model of the multi-motor driven servo system containing unknown parameters is established according to a motor structure and a physical law; 2, a load model established in the step 1 is analyzed, and unknown parameters in the load are estimated by utilizing a variable-gain self-adaptive parameter identification method; 3, synchronization and tracking control is conducted on the multi-motor driven servo system by utilizing neural network integral sliding-mode control algorithm according to a parameter identification result obtained in the step 2. The control method can ensure the steady-state accuracy of synchronization and tracking, effectively ensure transient-state and steady-state performance of parameter estimation, decrease the complexity and calculated quantity of algorithm design and effectively improves the response speed and robustness of the multi-motor driven servo system.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

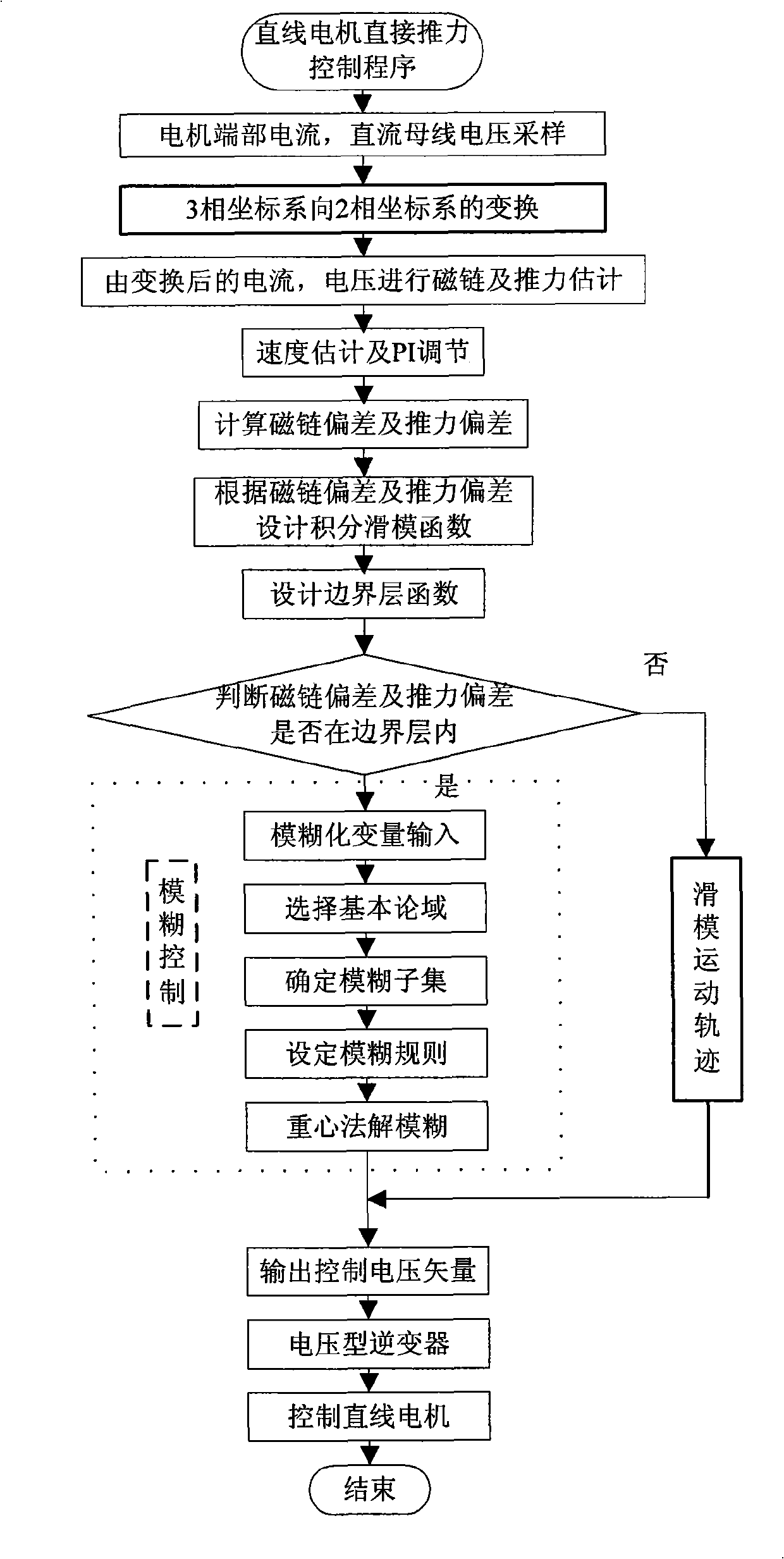

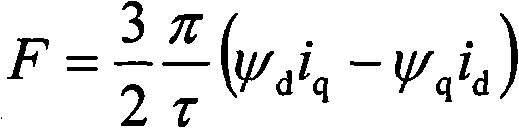

Method for suppressing pulse of linear motor pushing force system

InactiveCN101340173ANon-linearWith multivariateElectronic commutation motor controlAC motor controlData informationControl system

The invention relates to the field of linear motor control, in particular to a method for restraining the pulsation of a thrust system of a linear motor; the method adopts a sliding mode thrust controller and a magnetic flux controller, the thrust deviation and the magnetic flux deviation are selected as controlled variables, an integral sliding mode surface which is composed of the thrust deviation and the magnetic flux deviation design the sliding mode motion trajectory, thereby a system can move according to the sliding mode trajectory and the output thrust and the magnetic flux can better track specified value, wherein, a fuzzy controller utilizes the fuzzy control method which uses language information and data information to approach any specified continuous function to solve the jitter problem of a sliding mode control system. The method has the advantages that: a direct drive control system of the linear motor has strong coupling property, nonlinear property, multiple variables and unique end effect, the use of the direct thrust control method of the fuzzy sliding mode linear motor with high robust performance can solve the impacts of various factors on the control performance, thereby achieving the purposes of restraining the thrust pulsation of the linear motor and obtaining great dynamic response performance.

Owner:SHENYANG POLYTECHNIC UNIV

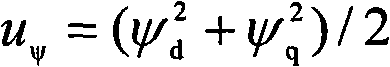

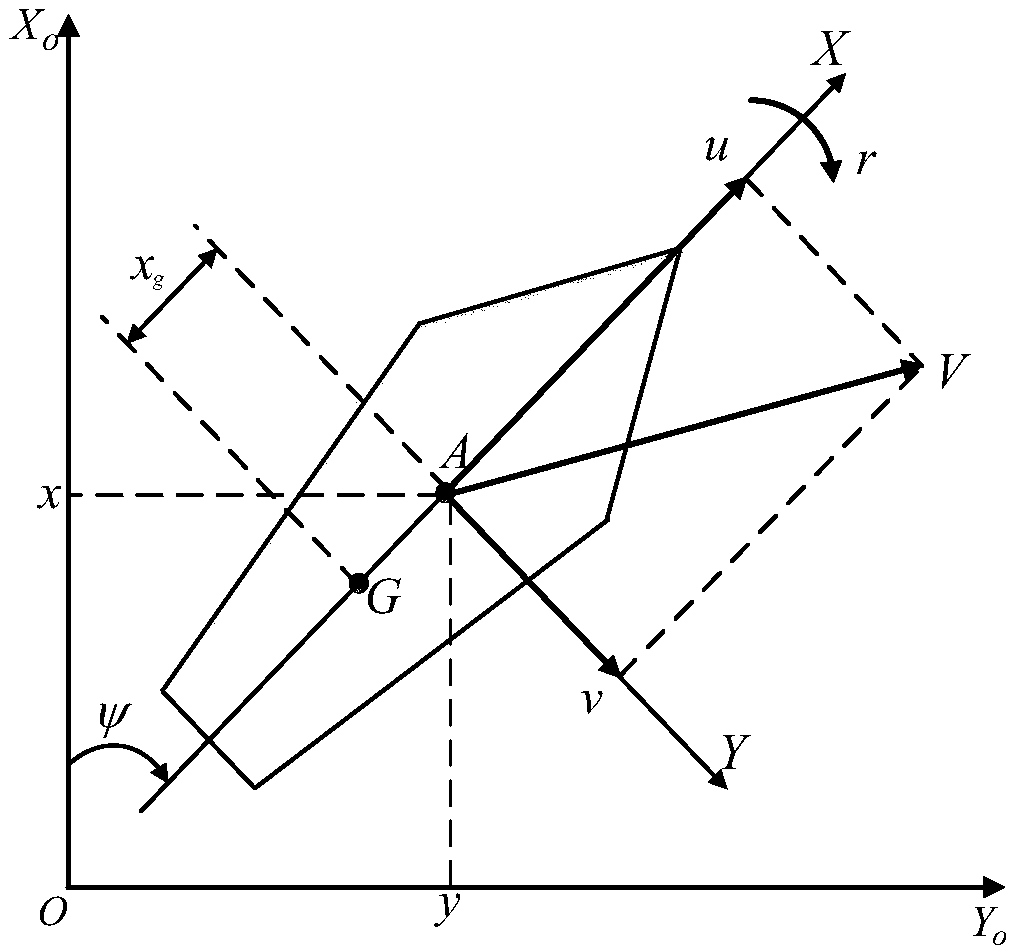

Unmanned surface ship track tracking method based on actuator faults

The invention discloses an unmanned surface ship track tracking method based on actuator faults, comprising the following steps: S1: analyzing various types of information of actuator faults, and modeling the actuator faults of an unmanned ship; S2: performing coordinate conversion of the velocity [Nu] in a mathematical model M1 of the unmanned surface ship in S1 to obtain a new velocity [Omega] and a new model M1'; S3: establishing an actuator fault observation device based on a track and speed tracking error model M in S2, and reconfiguring the actuator faults and external disturbance; S4: according to the track and speed tracking error model M in S2, establishing an integral sliding mode surface and a precise track tracking control law [Tau] of the unmanned surface ship with actuator faults; and S5: measuring the actual unmanned ship position to determine whether the unmanned surface ship reaches the end point of the actual track [Eta]d in S1.

Owner:DALIAN MARITIME UNIVERSITY

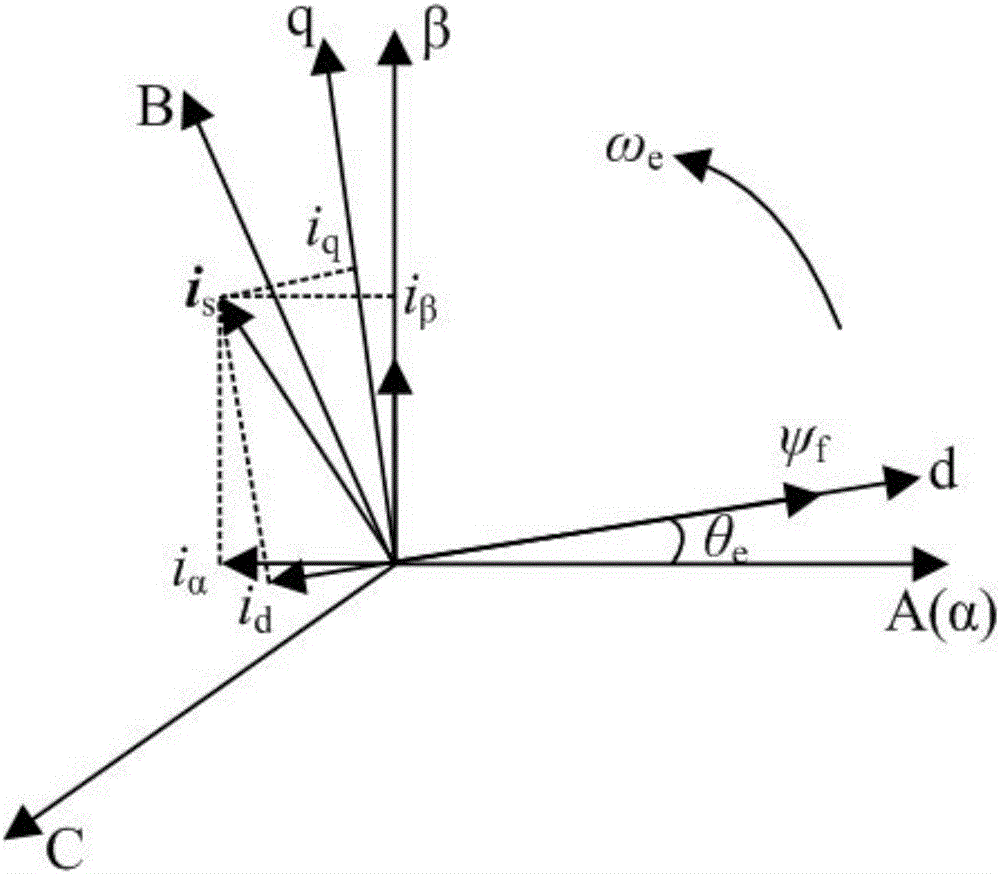

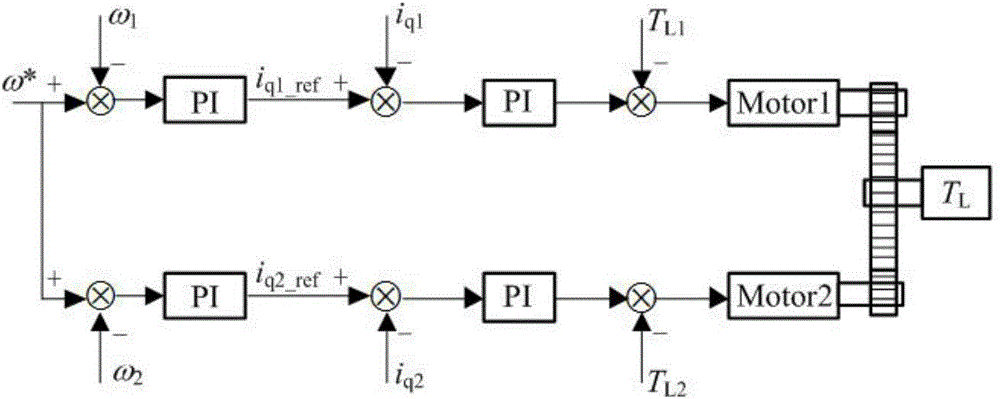

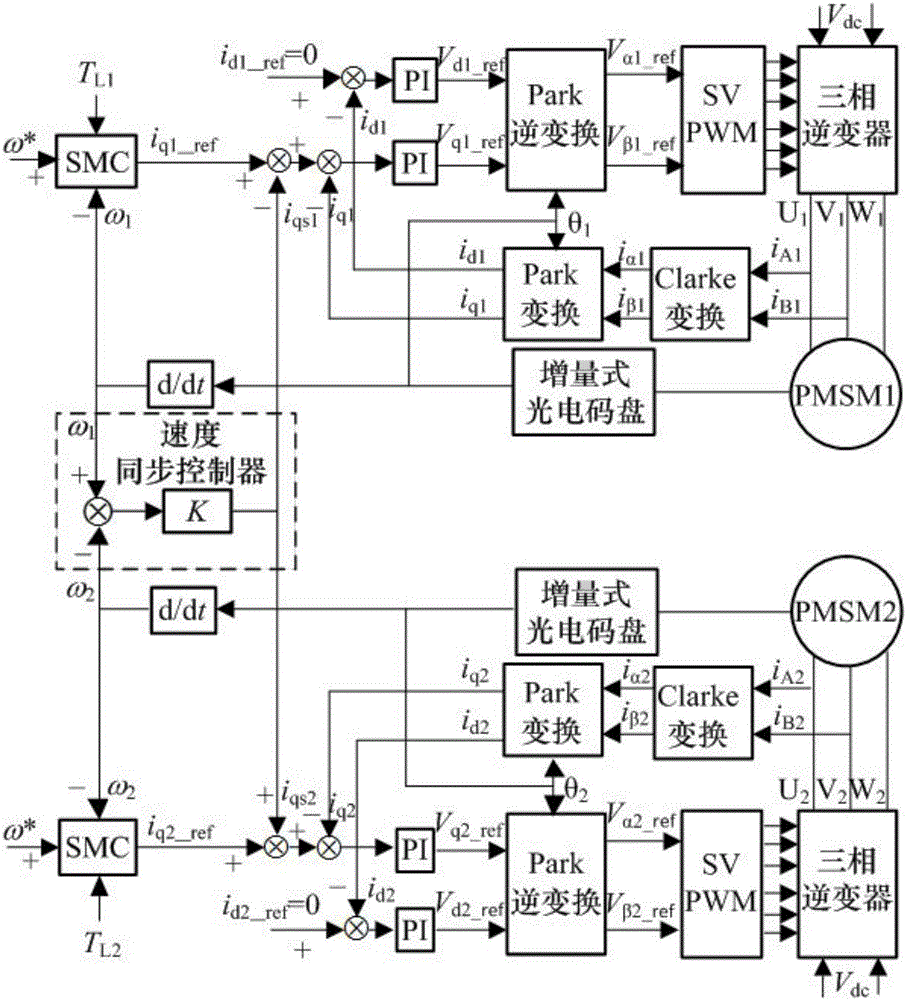

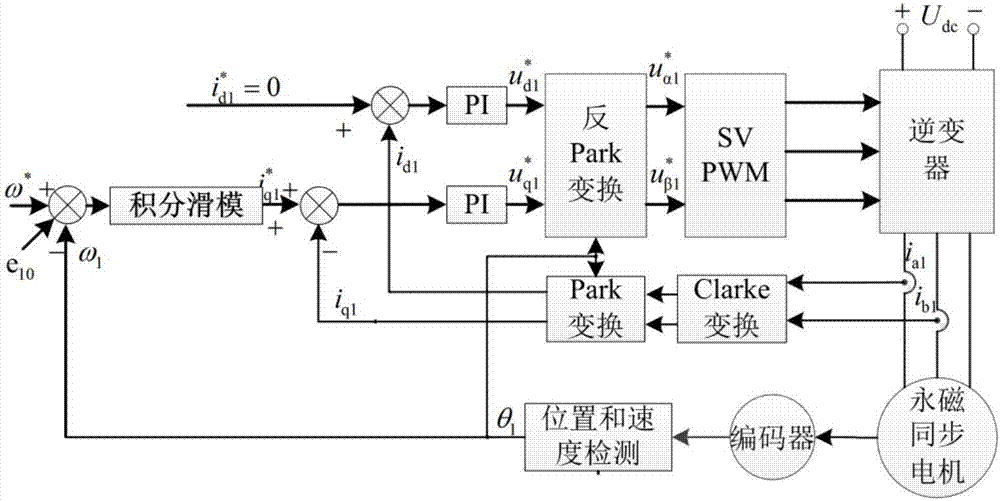

Method for controlling rotating speed synchronization of dual-permanent magnet synchronous motor drive system

InactiveCN106533298AEnhanced speed couplingWith multivariateAC motor controlVector control systemsMotor driveMathematical model

The present invention discloses a method for controlling rotating speed synchronization of a dual-permanent magnet synchronous motor drive system. The method comprises the steps of establishing a discrete mathematical model of a permanent magnet synchronous motor, wherein the discrete mathematical model comprises a voltage equation and an electromagnetic torque equation of the permanent magnet synchronous motor in a d-q axis coordinate system, and a motion equation of the permanent magnet synchronous motor; according to a slide mode control principle, designing rotating speed ring controllers of two permanent magnet synchronous motors into integral slide mode speed controllers; and according to a cross coupling principle, designing a speed synchronous controller, and compensating current rings of the two permanent magnet synchronous motors. The system has good robustness and is rapid when load disturbance occurs, and the rotating speed tracking and synchronization performance of the dual-motor drive system are effectively improved.

Owner:TIANJIN POLYTECHNIC UNIV

Unmanned ship navigation following fixed time formation control method

ActiveCN110928310AImprove robustnessImprove tracking accuracyPosition/course control in two dimensionsMarine engineeringControl theory

The invention discloses an unmanned ship navigation-following fixed time formation control method. The method belongs to the field of unmanned ship control, and comprises the following steps: establishing dynamics and kinematics models of a navigation unmanned ship and a following unmanned ship, designing a fixed time control law of a navigation unmanned ship subsystem so as to realize navigationunmanned ship trajectory control, and providing a control input signal for the following unmanned ship subsystem; designing a finite time disturbance observer to realize effective observation of environmental disturbance of the following unmanned ship; establishing integral sliding mode surface, determining a following error between the following unmanned ship and the navigation unmanned ship; designing a fixed time formation control scheme based on a finite time disturbance observer under complex disturbance. A fixed time tracking control strategy based on a sliding mode technology is appliedto the navigation unmanned ship subsystem, the navigation unmanned ship is driven to accurately track an expected trajectory, the tracking precision of the system is effectively improved, a stable navigation-following unmanned ship formation pattern can still be realized in the presence of external disturbance, and the robustness of the formation system is remarkably improved.

Owner:DALIAN MARITIME UNIVERSITY

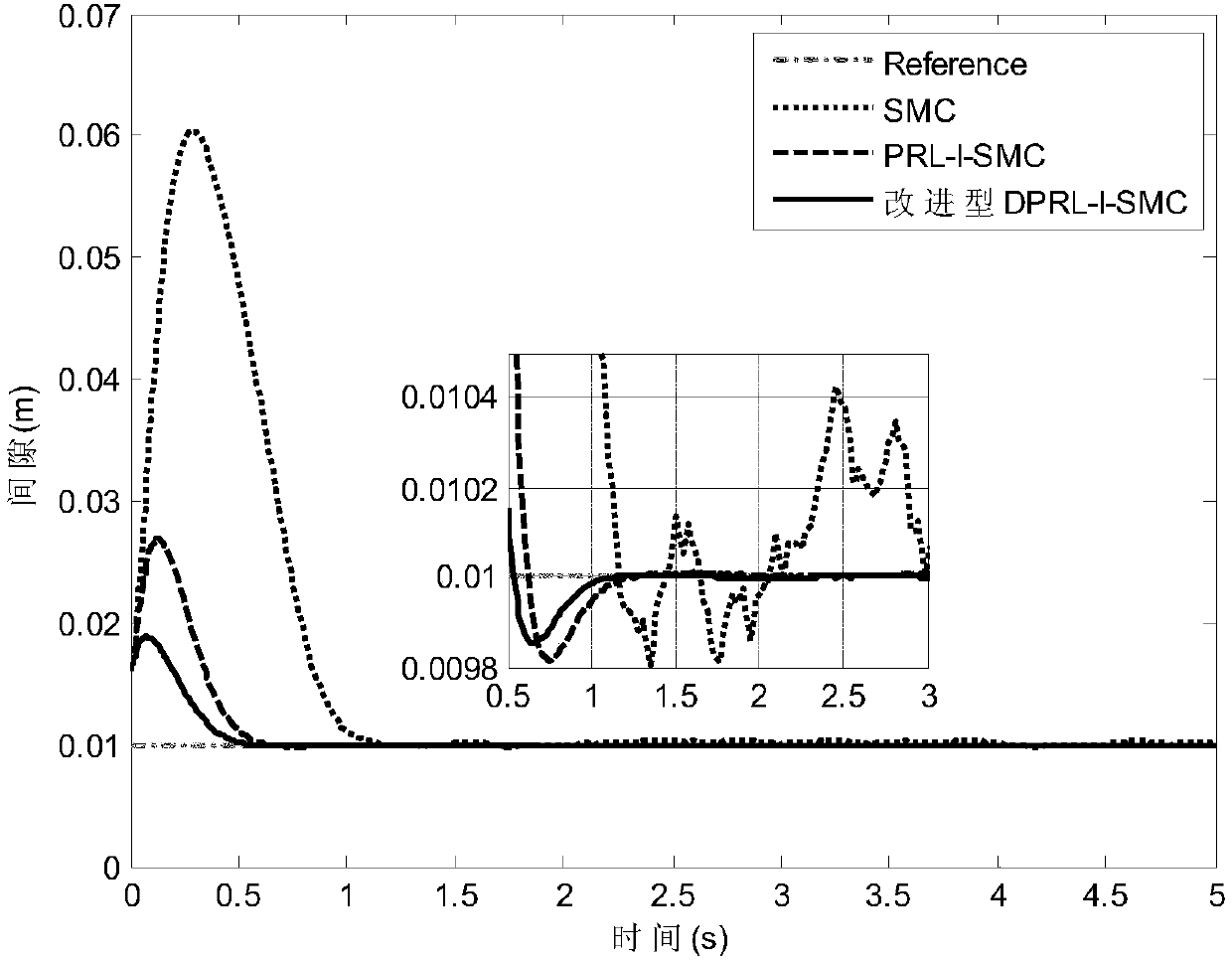

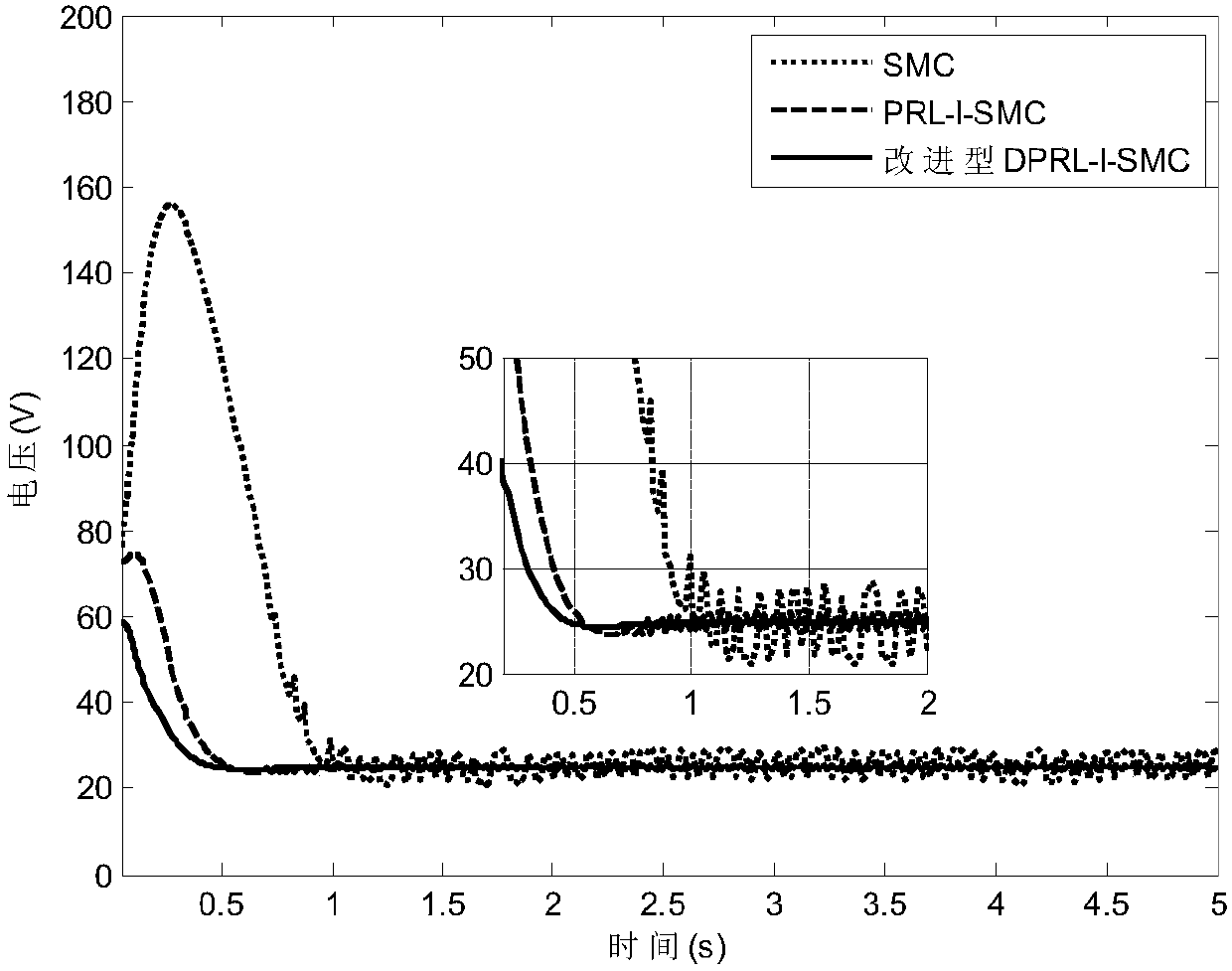

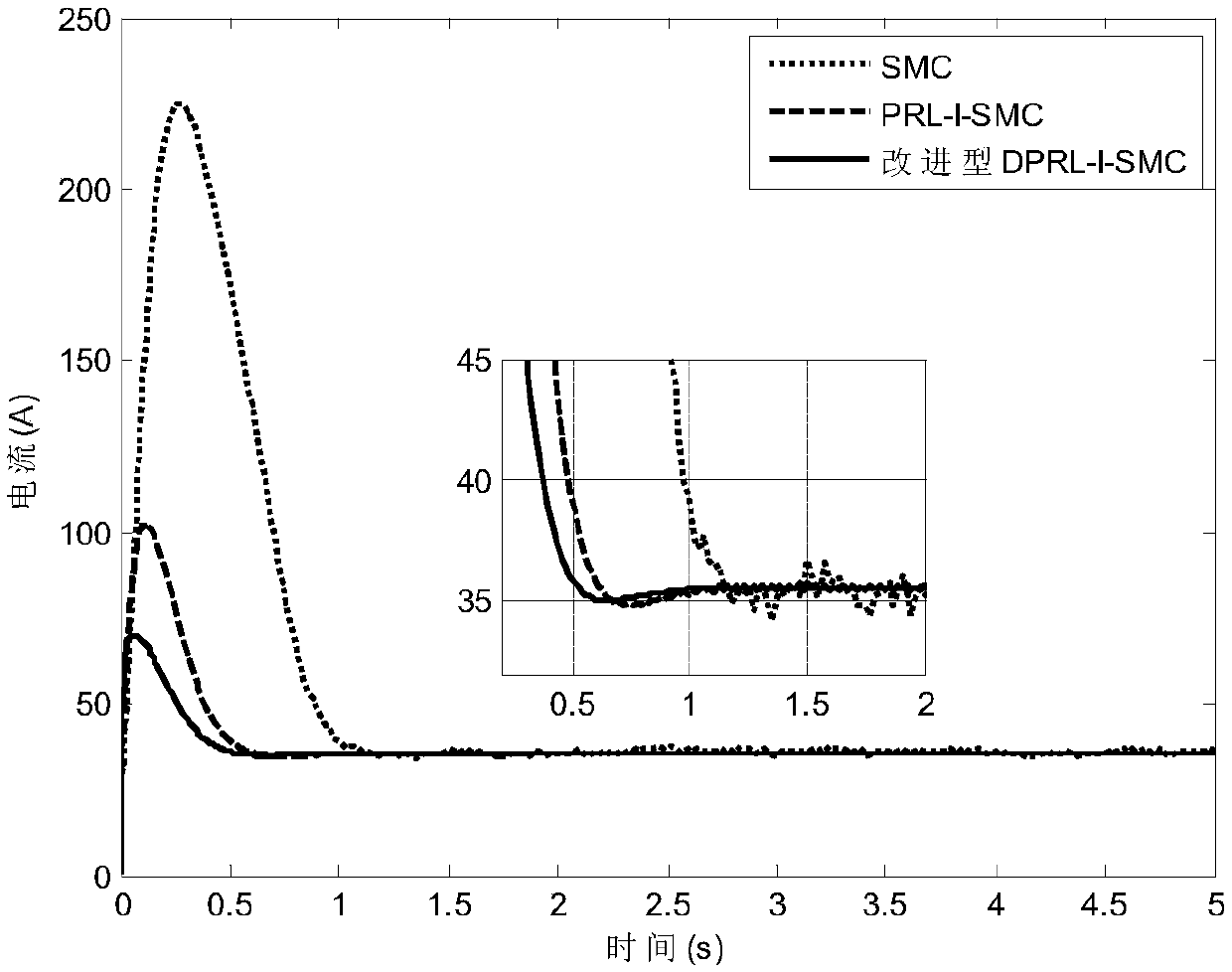

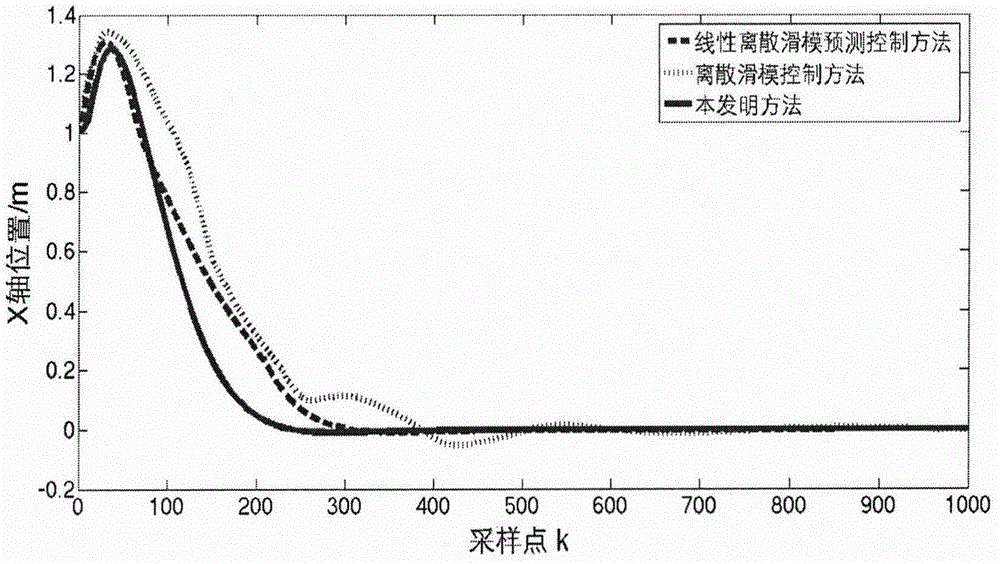

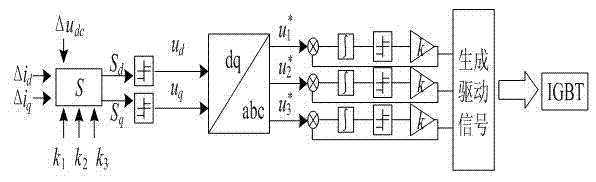

Maglev train system control method based on integral sliding mode control of improved double power reaching law

ActiveCN107608212AImprove anti-interference abilityQuick responseAdaptive controlAnti jammingIntegral sliding mode

The invention relates to a maglev train system control method based on integral sliding mode control of a double power reaching law (DPRL-I-SMC), and especially relates to a maglev train system control method based on integral sliding mode control of an improved double power reaching law. A sliding mode controller is designed by combining the double power reaching law and the exponential reachinglaw and using a saturation function and an integral function. The improved DPRL-I-SMC method is superior to the traditional sliding mode control (SMC) and power reaching law-integral sliding mode control (PRL-I-SMC) methods in all aspects, can effectively eliminate the chattering of the system, reduce overshoot, accelerate convergence and overcome nonlinear factors to make a nonlinear system stably suspended, and shows excellent dynamic performance and anti-jamming performance.

Owner:HUBEI UNIV OF TECH

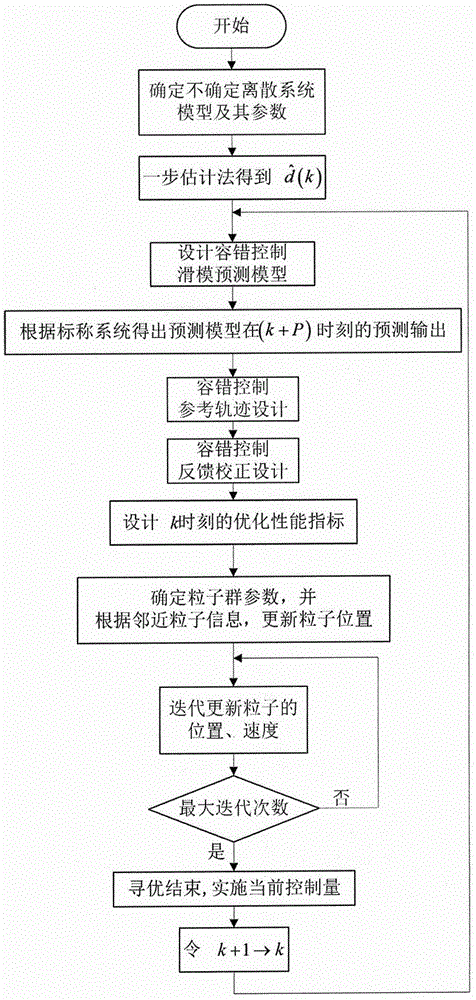

Robust fault-tolerant control method for small unmanned aerial vehicle flight control system

ActiveCN106597851ASuppress chatterAvoid easy to fall into local extreme pointsAdaptive controlControl systemUncrewed vehicle

The invention discloses a robust fault-tolerant control method for small unmanned aerial vehicle flight control system. According to the discrete system with parametric uncertainties and time-varying delays in the case of actuator failure, a simulated-integral sliding mode prediction model is constructed. The model can ensure the global robustness of an entire dynamic process and deal with the influence of the fault incurred from the parametric uncertainties and time-varying delays on the progressive stability of the sliding mode. Through the use of the improved chaotic particle swarm optimization (PSO) algorithm to improve the rolling optimization process, the method can effectively avoid the problems that the traditional particle swarm algorithm is easy to fall into the local extreme point in the excellence seeking process and that the convergence rate is slow. In the invention, a new reference trajectory is proposed, which can reduce the influence of system uncertainty and time-varying delay to an acceptable range through compensation, and can also suppress the buffeting phenomenon of the sliding mode obviously. The invention is used for the robust fault-tolerant control for a discrete system with parametric uncertainties and time-varying delays in the case of actuator failure.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

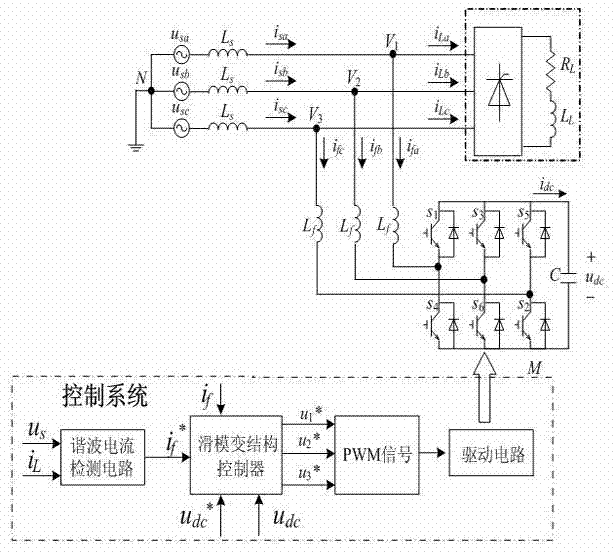

Control method for sliding mode converter control structure of active power filter containing parameter perturbation

ActiveCN102655327AChange control strategyAchieve unified controlActive power filteringAc network to reduce harmonics/ripplesCapacitor voltageMathematical model

The invention discloses a control method for a sliding mode converter control structure of an active power filter containing a parameter perturbation, which comprises the following steps: firstly, building a state space mathematical model under an abc coordinate system; converting the state space mathematical model to be under a dq coordinate system to obtain a uniform mathematical model by taking dq components of harmonic current and capacitor voltage on a direct-current side as state variables; constructing a sliding mode surface; decoupling the sliding mode surface for control; defining a control rate; carrying out inverse transformation on the control rate to obtain an effective control rate; constructing an integral sliding mode surface; and redefining a new control rate, so as to finally obtain a PWM (Pulse-Width Modulation) signal for driving a switch tube. The control method adopts the sliding mode converter structure, so that current tracking and the capacitor voltage on the direct-current side are uniformly controlled. The sliding mode converter control structure is simple in design and is easy to realized, has good robustness on the internal parameter perturbation and internal interference of a system and has good dynamic performance, and the current variation can be quickly tracked when a load is suddenly changed.

Owner:UONONE GRP JIANGSU ELECTRICAL CO LTD

Four-rotor aircraft output-limited backstepping control method based on integral sliding mode obstacle Lyapunov function

ActiveCN108037662AImprove dynamic response performancePrevent overshootAdaptive controlResponse processFlight vehicle

Provided is a four-rotor aircraft output-limited backstepping control method based on an integral sliding mode obstacle Lyapunov function. For the dynamic system of a four-rotor aircraft, an integralsliding mode obstacle Lyapunov function is selected, and a four-rotor aircraft output-limited backstepping control method based on the integral sliding mode obstacle Lyapunov function is designed. Theintegral sliding mode obstacle Lyapunov function is designed in order to ensure that the output of the system is limited within a certain range, avoid too large overshoot and reduce the time of arrival. Therefore, the dynamic response performance of the four-rotor aircraft system is improved. The invention provides a four-rotor aircraft output-limited backstepping control method based on an integral sliding mode obstacle Lyapunov function, which enables the system to have a good dynamic response process.

Owner:ZHEJIANG UNIV OF TECH

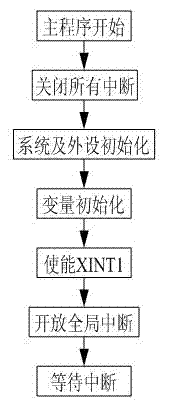

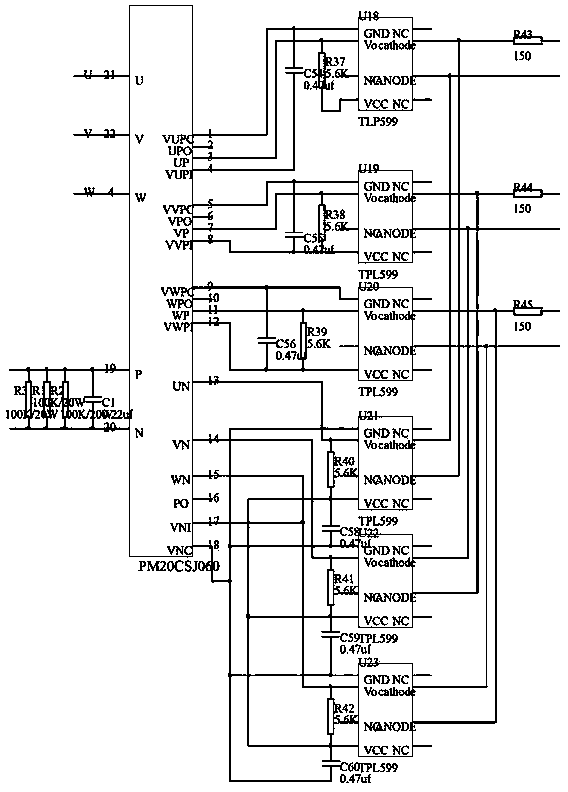

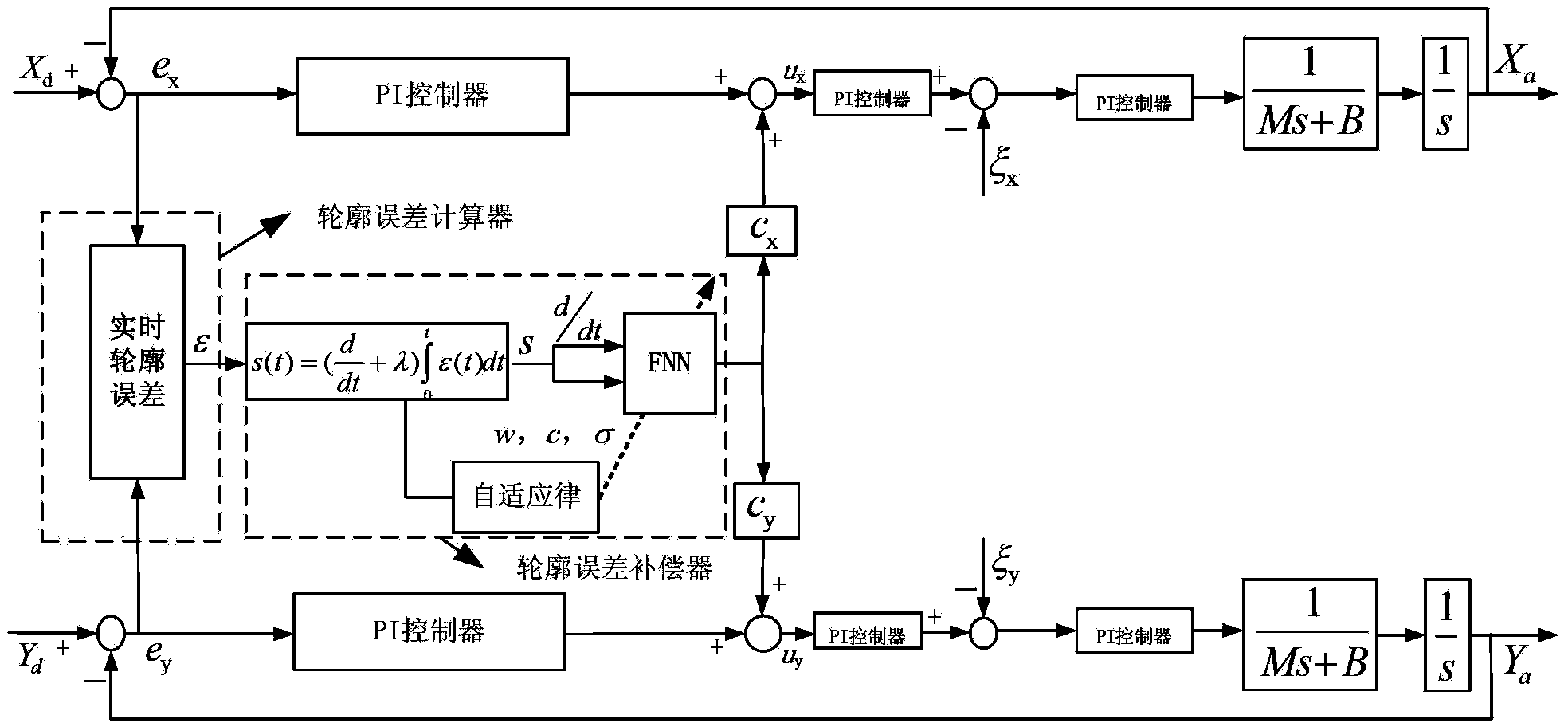

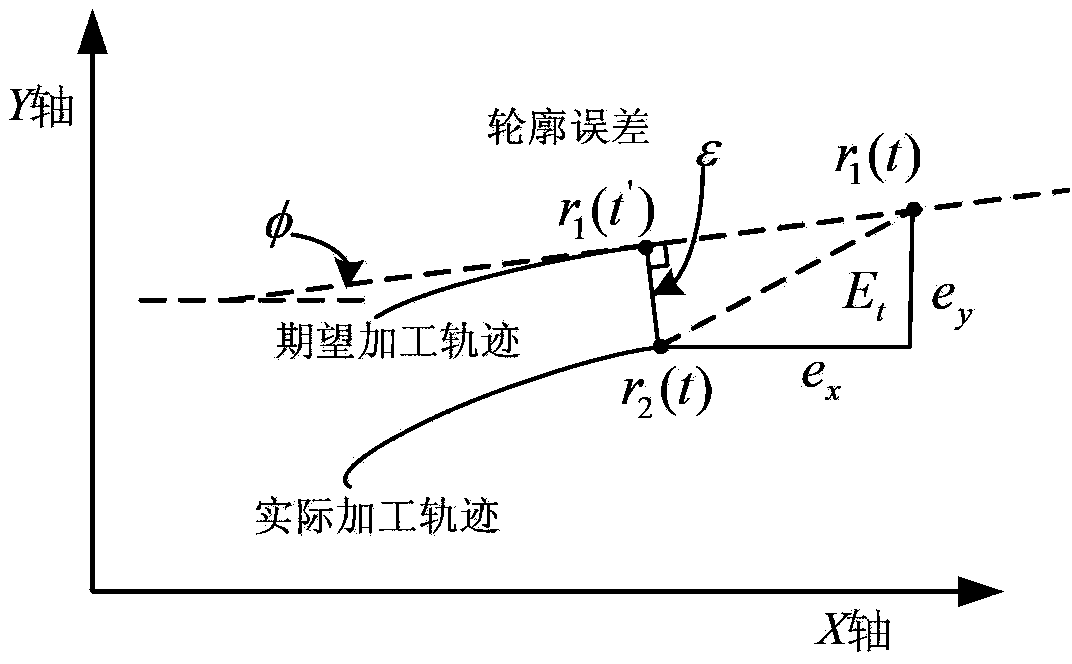

Double-linear-motor contour compensation device and method based on fuzzy RBF network sliding mode

InactiveCN103414419AEliminate chatterImprove profile accuracyElectronic commutation motor controlVector control systemsDigital signal processingGrating

The invention provides a double-linear-motor contour compensation device and method based on a fuzzy RBF network integral sliding mode with respect to a double-linear-motor numerical control feeding system with the axial direction being in mutual vertical movement. A real-time contour error is used as the input of a controller, the powerful self-learning ability of the controller enables the contour error to tend to zero within limited time, and thus contour machining precision is improved. The double-linear-motor contour compensation device comprises a commutating and voltage-stabilizing unit, an IPM inverter, a DSP, a Hall sensor, a grating ruler, a current detection unit, a position and speed detection unit, an optical coupling isolation circuit, a driving protection circuit and a fault detection and protection circuit. The DSP comprises a QEP circuit of an event manager EVA, an ADC module, a PWM unit, a Flash storage module, a program storage, a timer and a PDPINT pin. A PI controller of a position signal setter, a linear motor position loop, a speed loop and an electric current loop, a contour error calculator, a fuzzy RBF network integral sliding mode contour compensator and a driver device are further arranged inside the DSP. The double-linear-motor contour compensation device is good in robustness, suitable for contour machining tasks of any track and capable of achieving high-precision contour control.

Owner:SHENYANG POLYTECHNIC UNIV

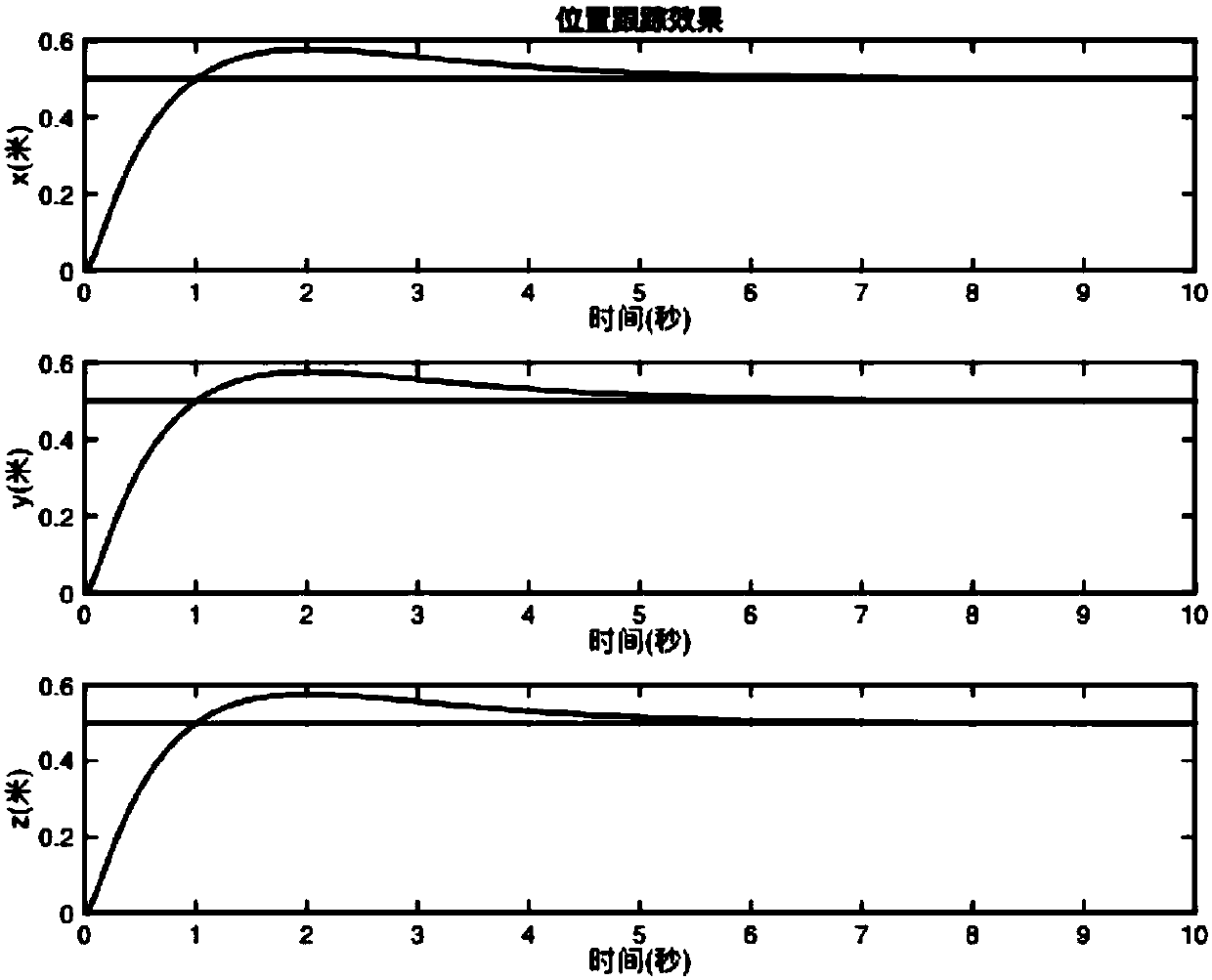

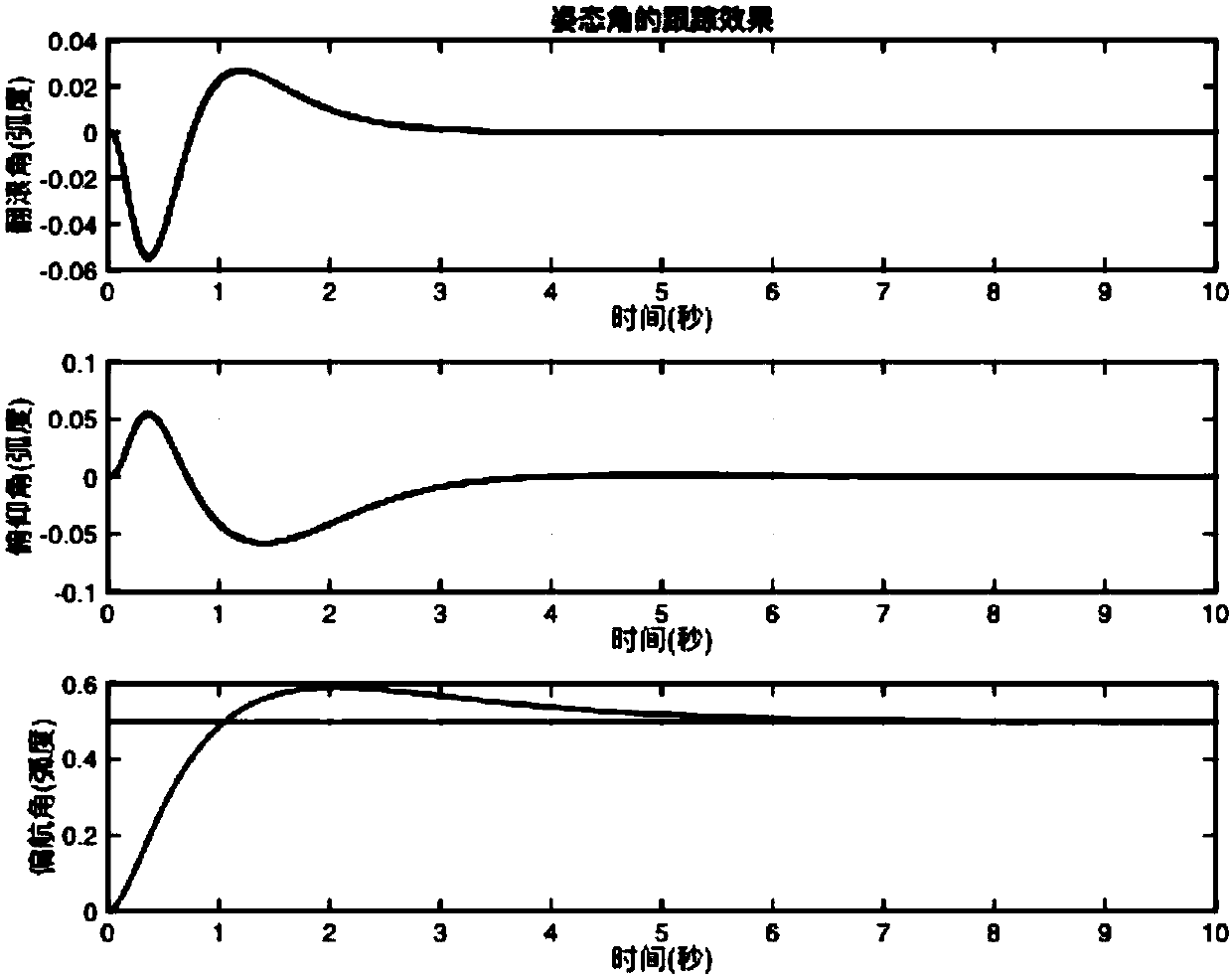

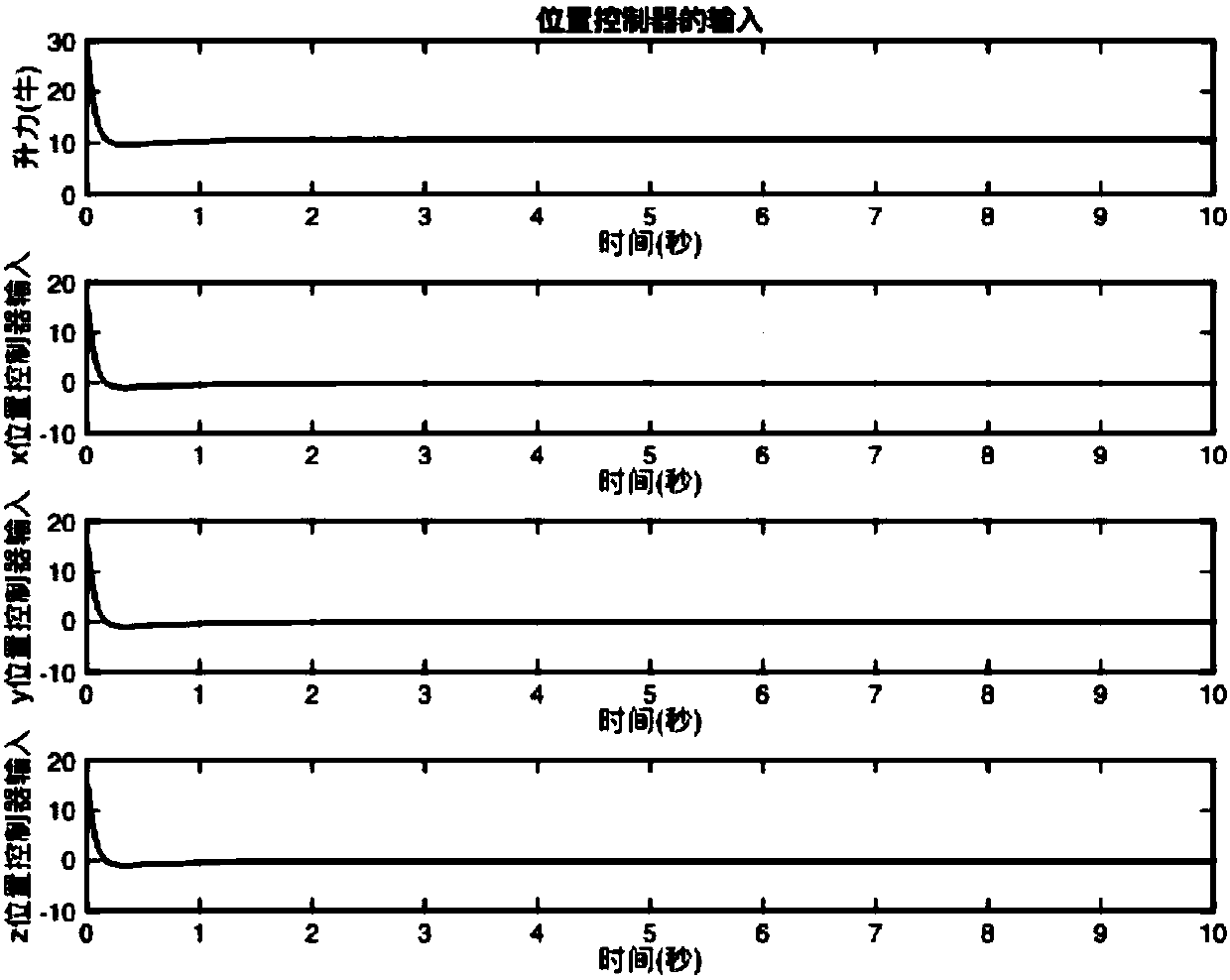

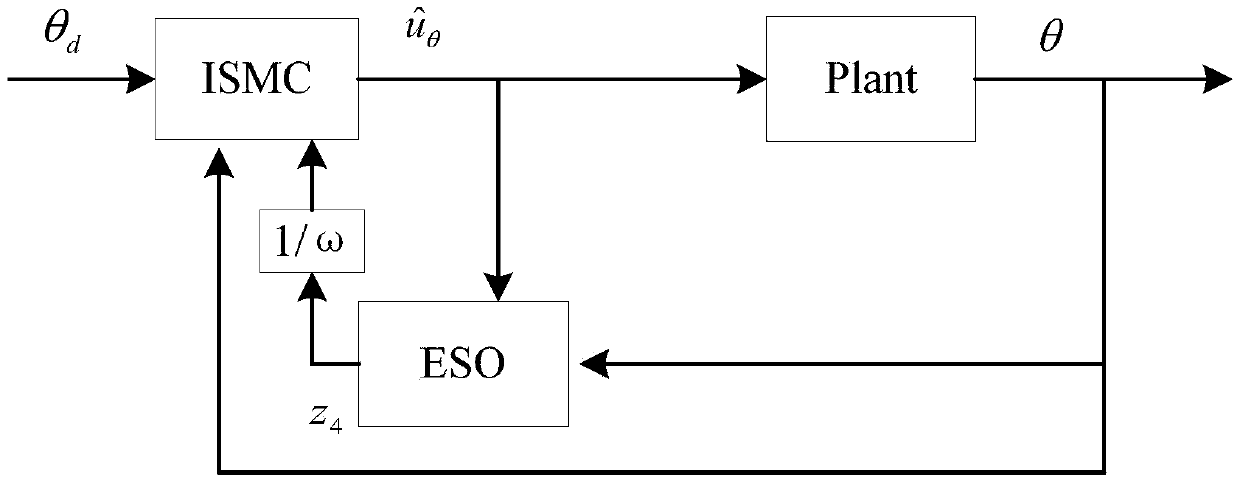

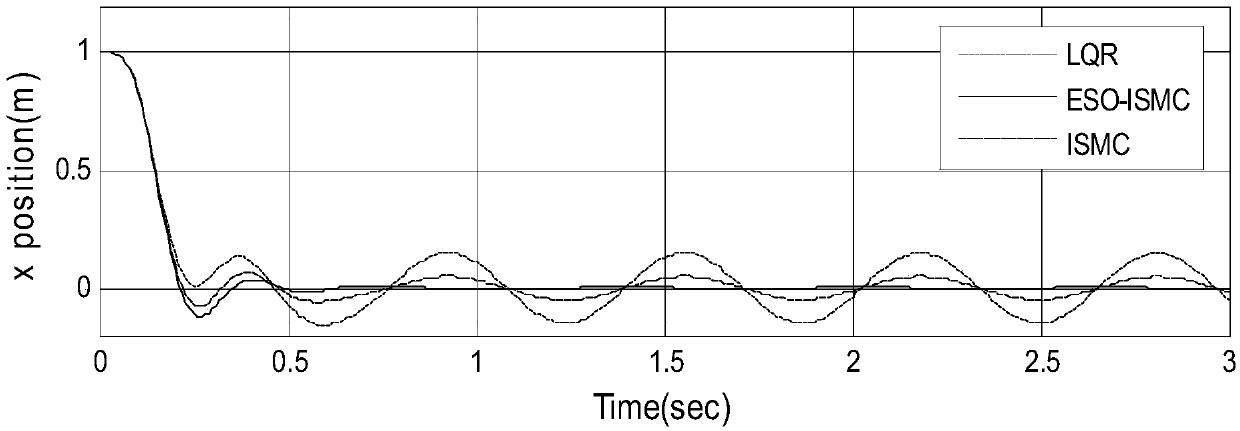

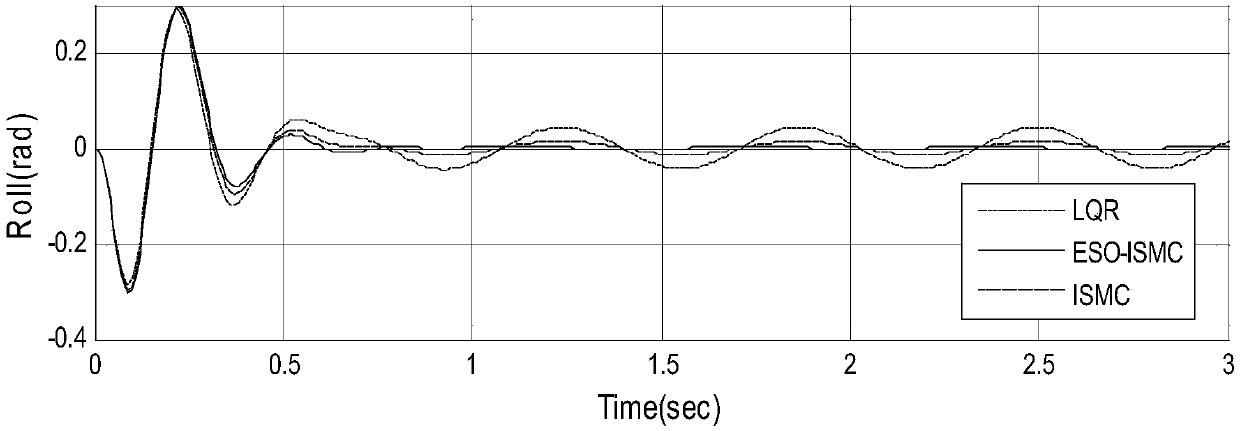

Quad-rotor unmanned aerial vehicle integral sliding mode control method based on expansion state observer

ActiveCN109062052AGuaranteed accuracyChattering does not occurAdaptive controlDynamic modelsState observer

The invention relates to a quad-rotor unmanned aerial vehicle integral sliding mode control method based on an expansion state observer. On the basis of a dynamics model and a propeller model of a quad-rotor unmanned aerial vehicle, the integral sliding mode control rate is obtained through integral sliding mode control; and by adopting the expansion state observer, external interference on a system is estimated according to an input and an output of the quad-rotor unmanned aerial vehicle system to obtain an estimated value of the interference on the system, and then the integral sliding modecontrol rate is compensated. The method ensures the precision of tracking expected input of the quad-rotor unmanned aerial vehicle, and has a strong anti-interference capability.

Owner:HUBEI UNIV OF TECH

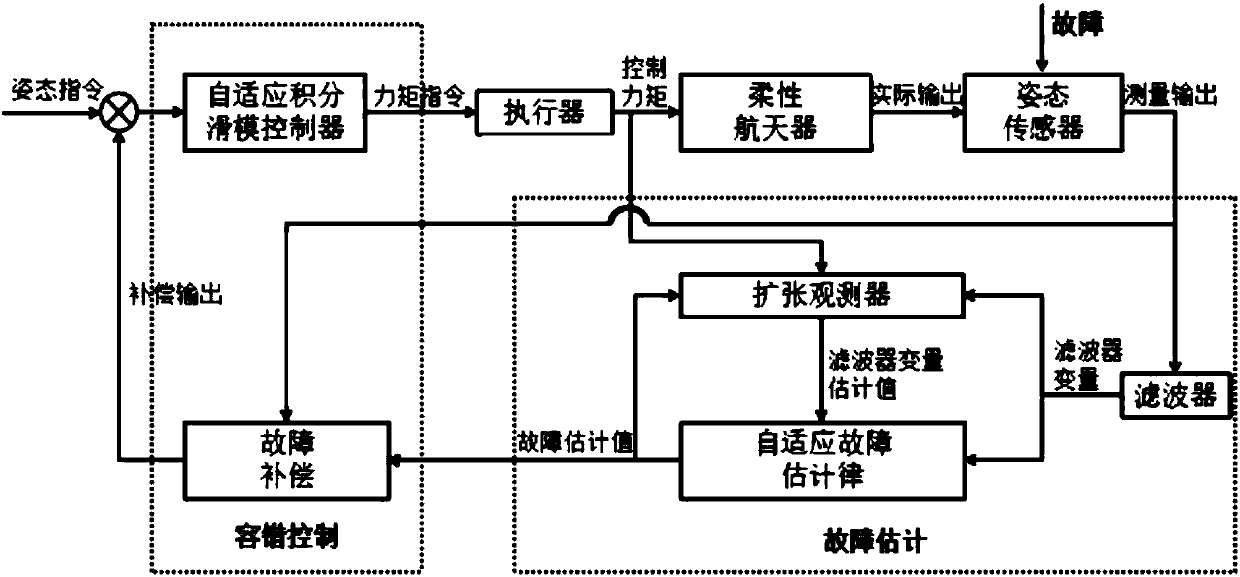

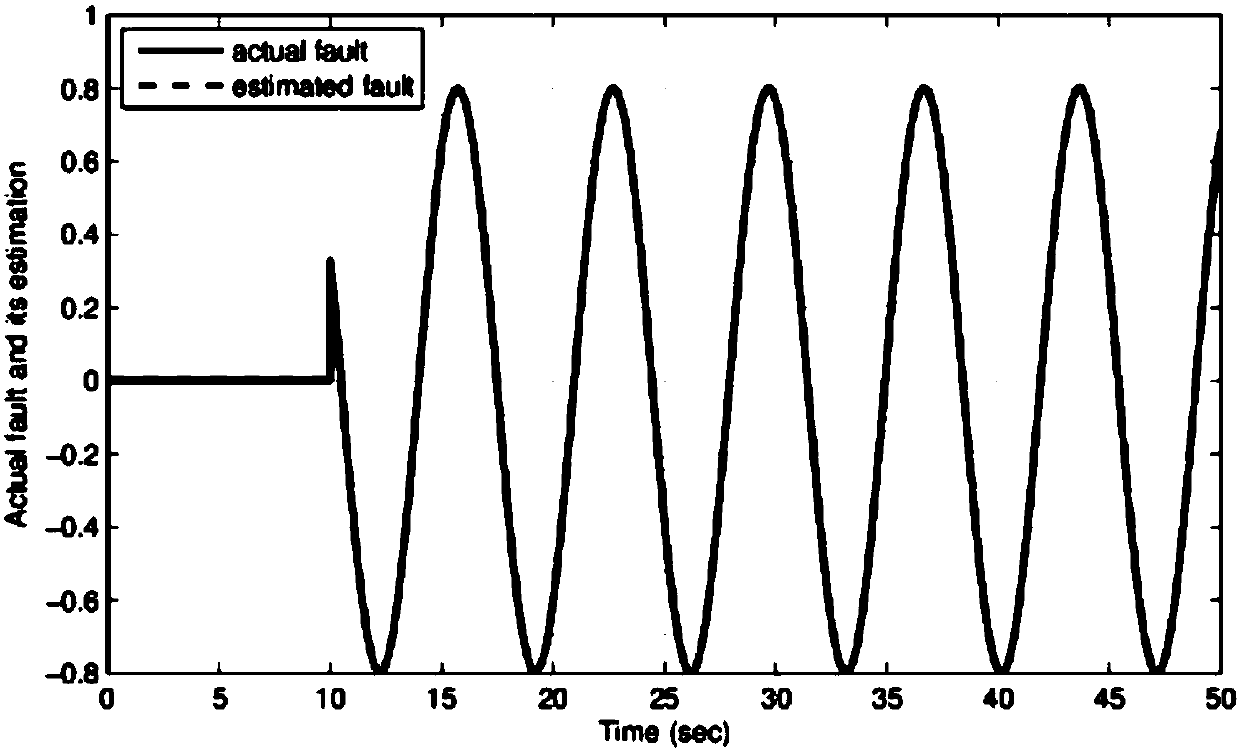

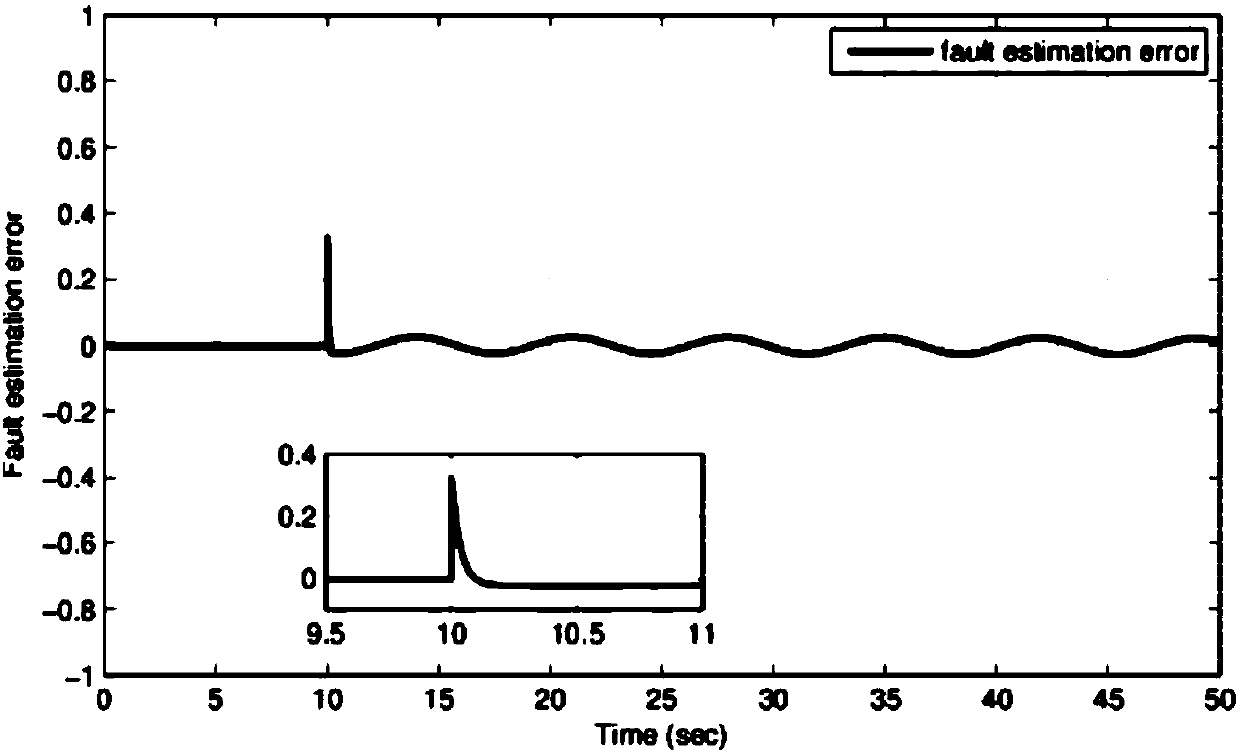

Flexible spacecraft sensor fault adjustment method

ActiveCN107703742AImprove robustnessStrong application valueAdaptive controlAviationLyapunov stability

The present invention discloses a flexible spacecraft sensor fault adjustment method, belonging to the field of aerospace flight control technology. A fault estimation module and a fault tolerance controller are mainly employed by the flexible spacecraft sensor fault adjustment method, and the method comprises the steps that: a filter and an adaptive observer are employed to form a fault estimation module; fault estimation information and sensor output signals are employed to establish the fault tolerance controller through combination of adaptive integral sliding mode control technology; through adoption of the Lyapunov stability theory, the asymptotic stability of a system is proved in a condition of generation of sensor faults; and finally, a simulation experiment result proves the validity of the method provided by the invention. The fault tolerance control problem when sensor measurement offset faults are generated in an operation process of a flexible spacecraft is solved so thataccurate control of an attitude angle in the sensor fault condition is achieved and the system has a high tolerance capability for the faults; and moreover, the method fully takes the consideration of disturbances generated by spacecraft parameter uncertainty and flexible accessories in the design process and is suitable for engineering application.

Owner:NANJING UNIV OF POSTS & TELECOMM

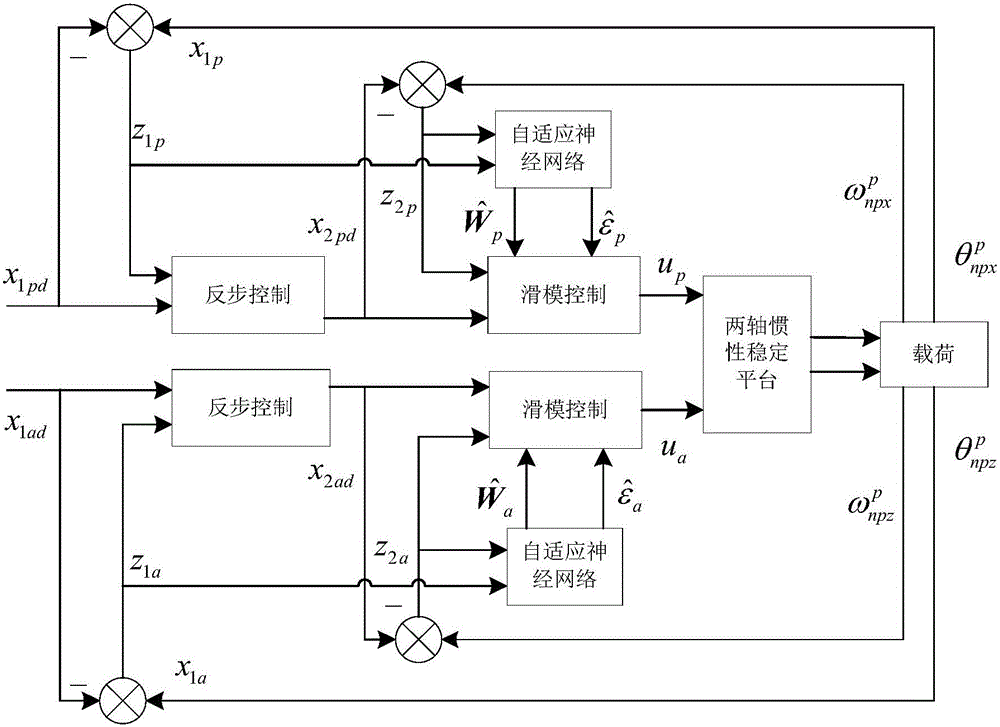

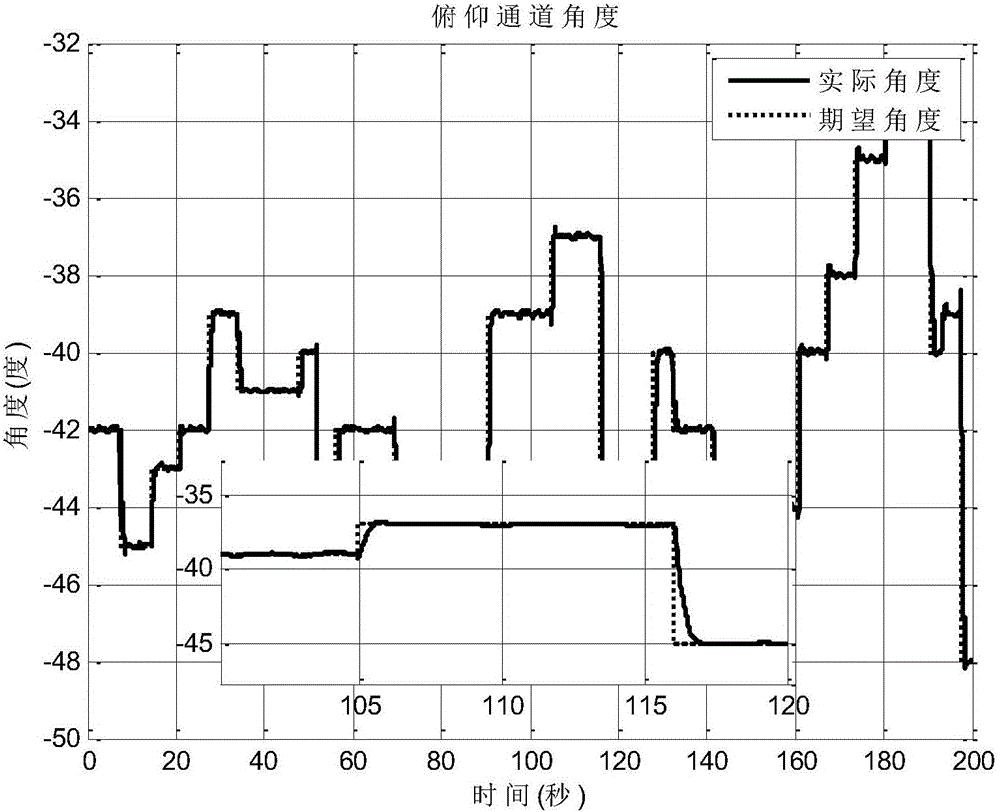

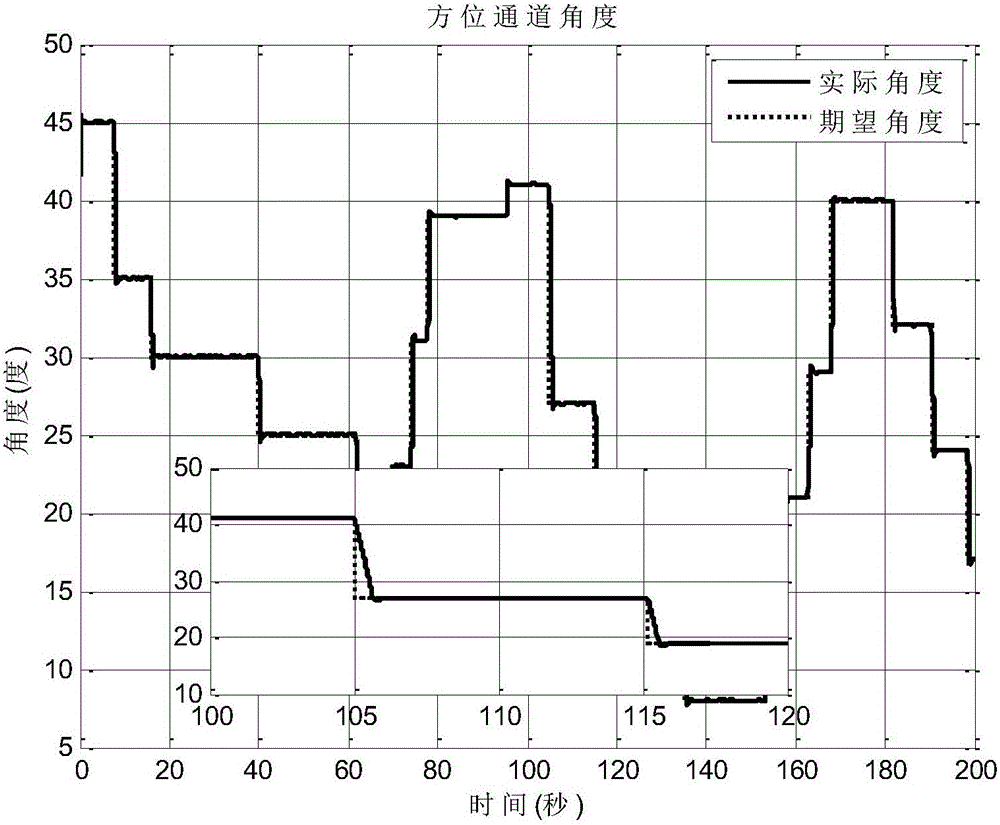

Bi-axis inertially-stabilized platform high-precision control method based on self-adaptive backstepping sliding mode

ActiveCN105785762ASuppress uncertaintySuppress interferenceAdaptive controlBacksteppingModel parameters

The invention provides a bi-axis inertially-stabilized platform high-precision control method based on a self-adaptive backstepping sliding mode, and relates to design of a composite controller for backstepping sliding mode control based on an auxiliary integral sliding mode surface and adaptive neural network construction and optimization. The method is characterized by, to begin with, designing a backstepping sliding mode control method based on the auxiliary integral sliding mode surface according to a bi-axis inertially-stabilized platform dynamical model, and generating a control command according to state error information to realize suppression of indeterminacy and interference of dynamical model parameters; and then, constructing an adaptive neural network, constructing an adaptive neural network weight updating matrix based on the error information to update a weight matrix of the neural network online, estimating upper bound of interference error in real time, and realizing bi-axis inertially-stabilized platform high-precision control under complex environment. The method has the advantages of good real-time performance, fast dynamic parameter response and high multisource interference adaptability and the like, and can used for high-precision control and the like under the complex multisource interference environment.

Owner:BEIHANG UNIV

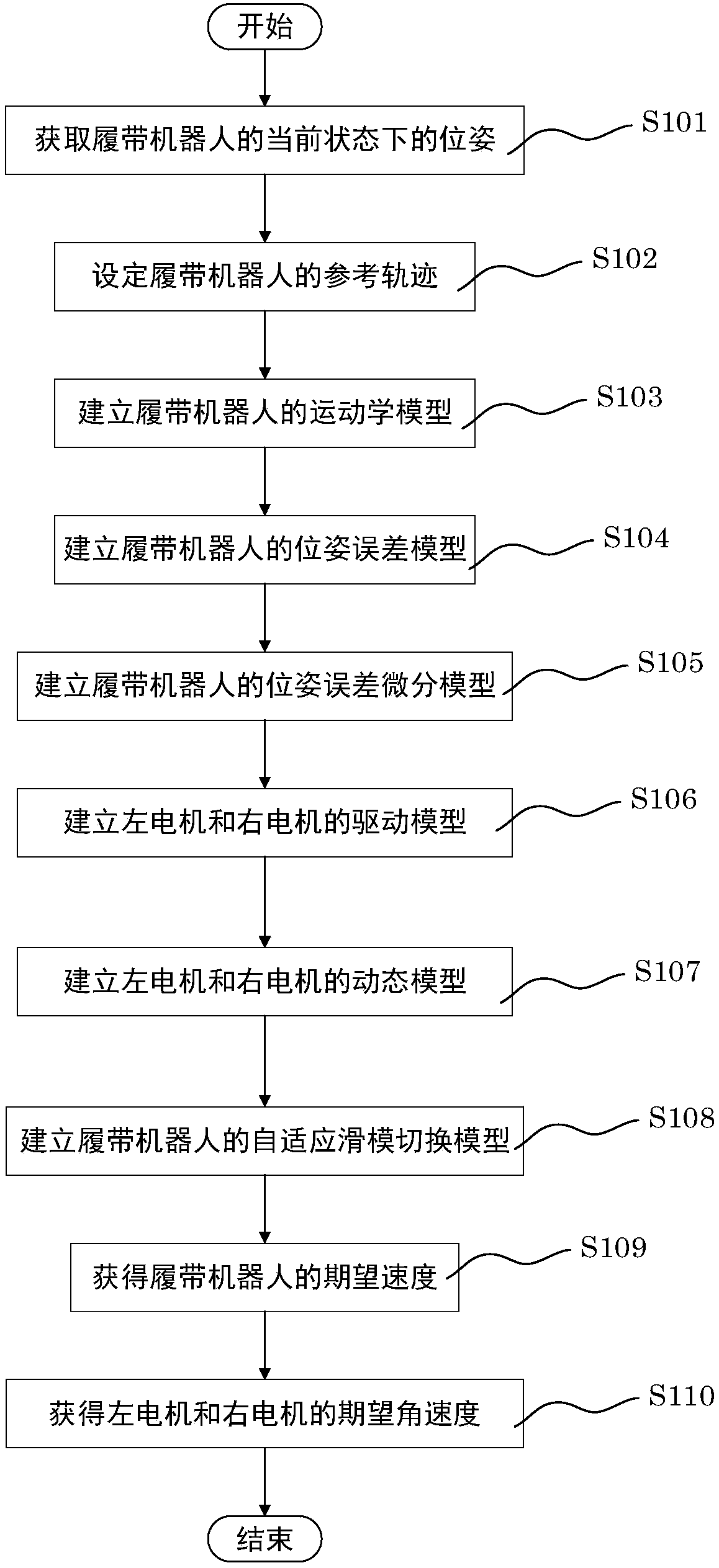

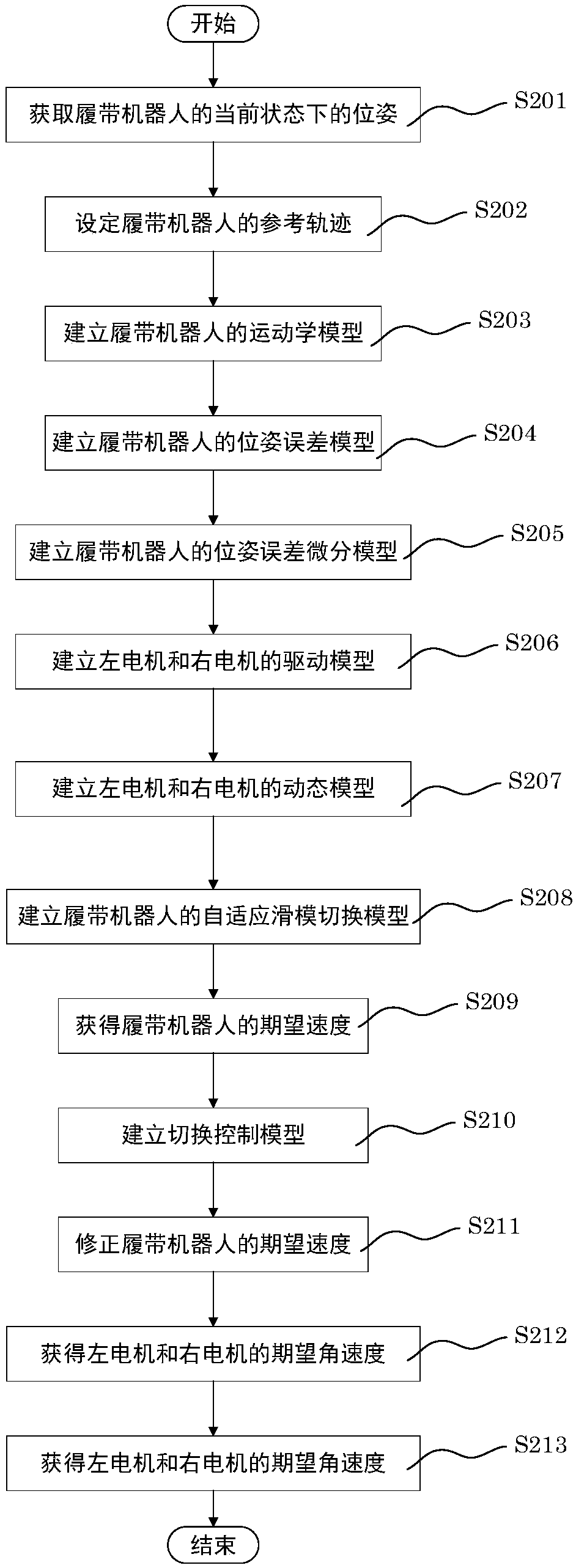

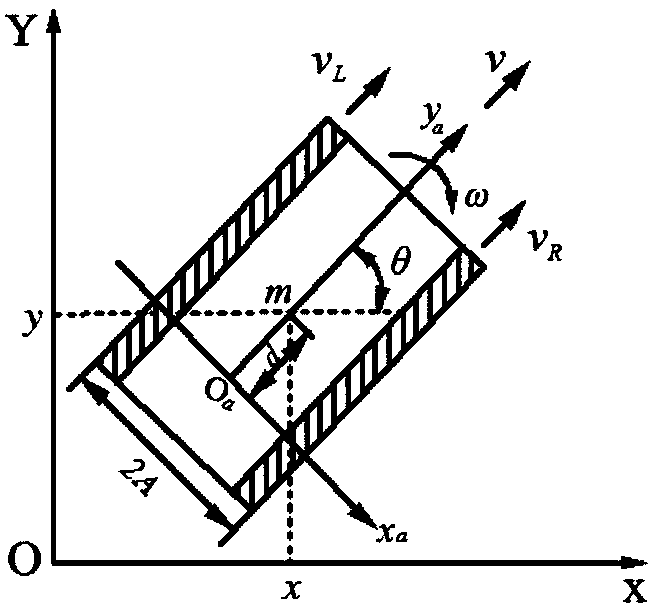

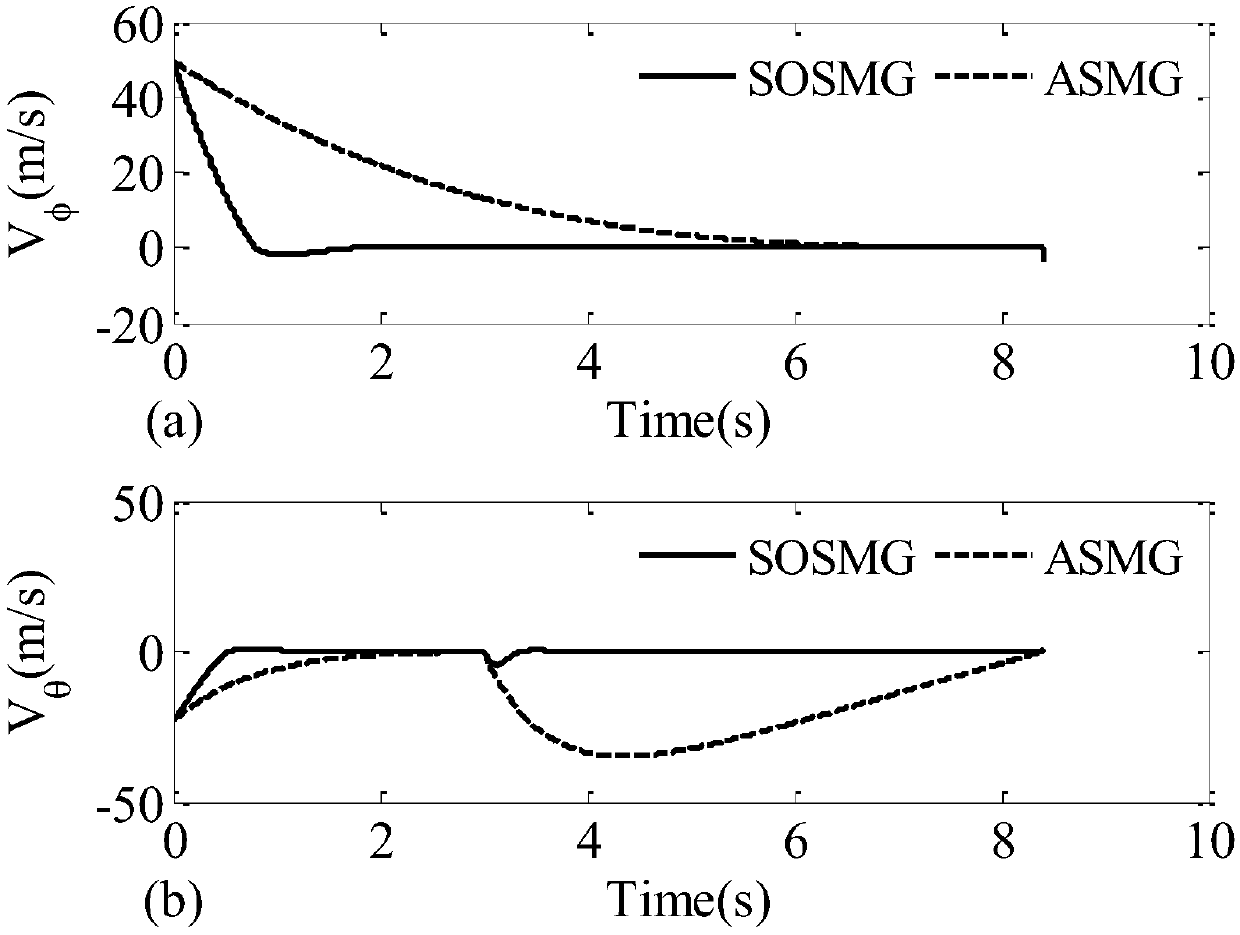

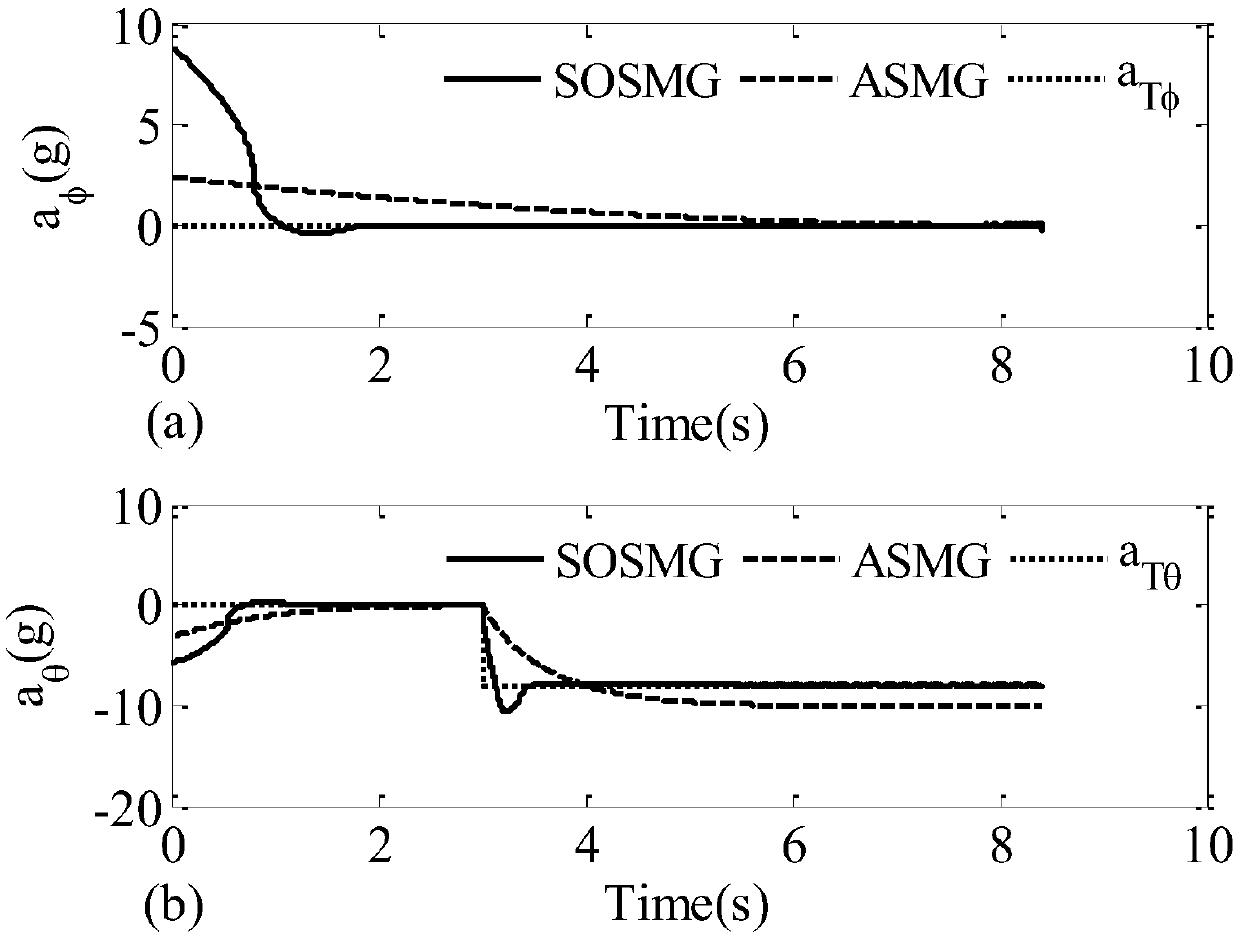

Control method for tracked robot, and tracked robot

ActiveCN108153309AStable motion controlPosition/course control in two dimensionsVehiclesMotor driveEquivalent control

The invention relates to the field of mobile robot motion control, and discloses a control method for a tracked robot, and the tracked robot. According to the invention, the method comprises the steps: taking the tracked robot as a cascading system which consists of a motor drive system and a vehicle body motion system; constructing an adaptive integral sliding-mode switching function of a variable inclination parameter, and proposing adaptive sliding-mode tracking control based on the equivalent control and switching control according to the adaptive integral sliding-mode switching function;feeding back a drive motor time-varying uncertainty parameter, obtained through the online recognition and the speed of the robot, and a target posture error which is solved in a kinematic model to acontroller of a drive system; decomposing the expected speed of each motor according to the kinematic relation, and achieving the stable motion control of the robot.

Owner:ANHUI AGRICULTURAL UNIVERSITY

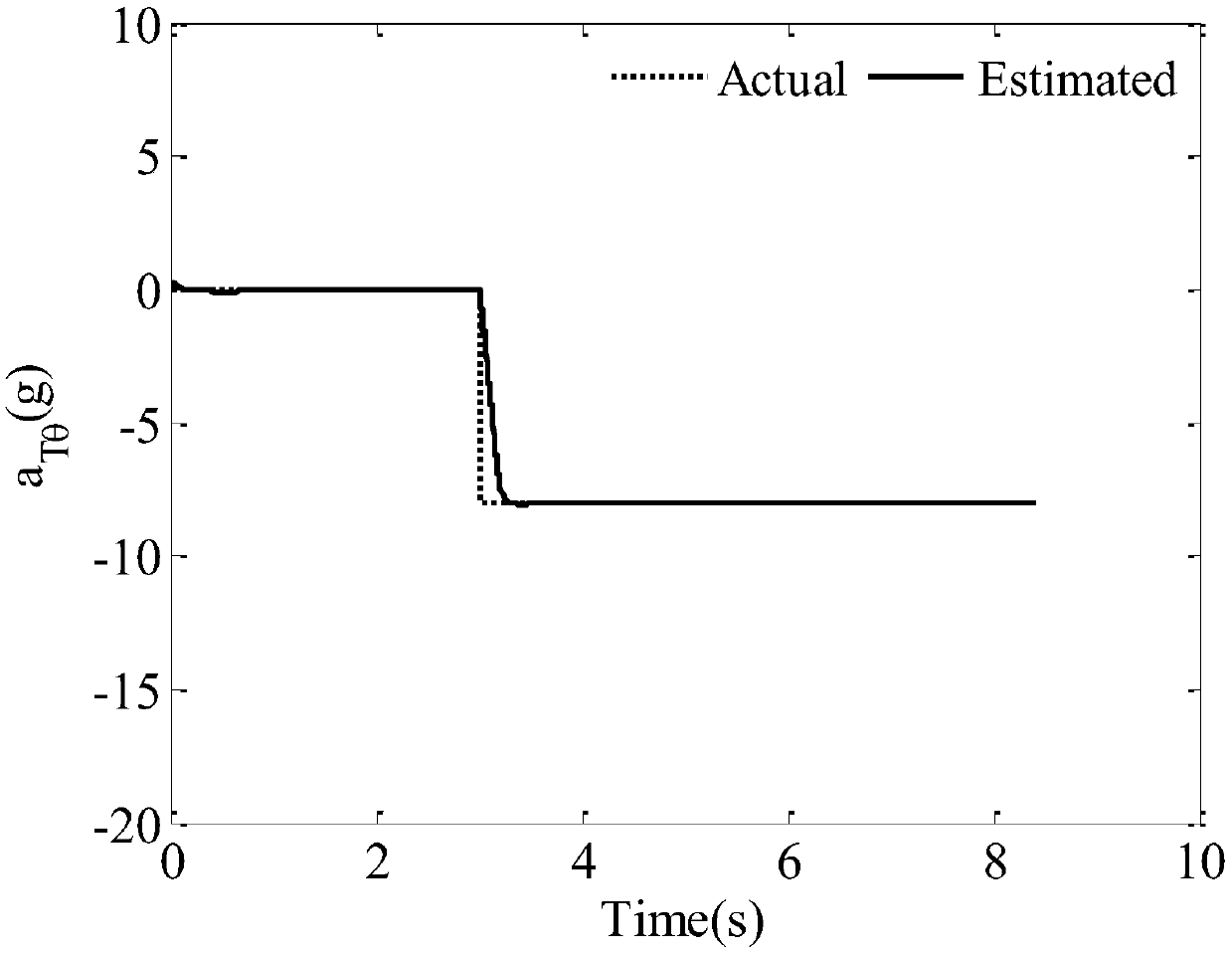

Finite time integral sliding mode terminal guidance law

The invention discloses a finite time integral sliding mode terminal guidance law based on a super-twisting algorithm. The guidance law comprises the following steps: step 1, establishing a three-dimensional target-missile relative motion equation; step 2, designing a guidance law. A stability analysis is conducted on the guidance law. The invention provide the finite time integral sliding mode terminal guidance law based on the super-twisting algorithm by combining an integral sliding mode, a super-twisting algorithm and a finite time disturbance observer. According to the finite time integral sliding mode terminal guidance law based on the super-twisting algorithm, the finite time can be converged, the buffeting phenomenon can be eliminated, so that the maneuvering acceleration of a target can be better estimated, and the guidance accuracy is high; and the guidance law can be used for intercepting high-speed large-maneuvering targets such as unmanned aerial vehicles, ballistic missiles and the like, and has a wide application prospect.

Owner:SICHUAN AEROSPACE SYST ENG INST

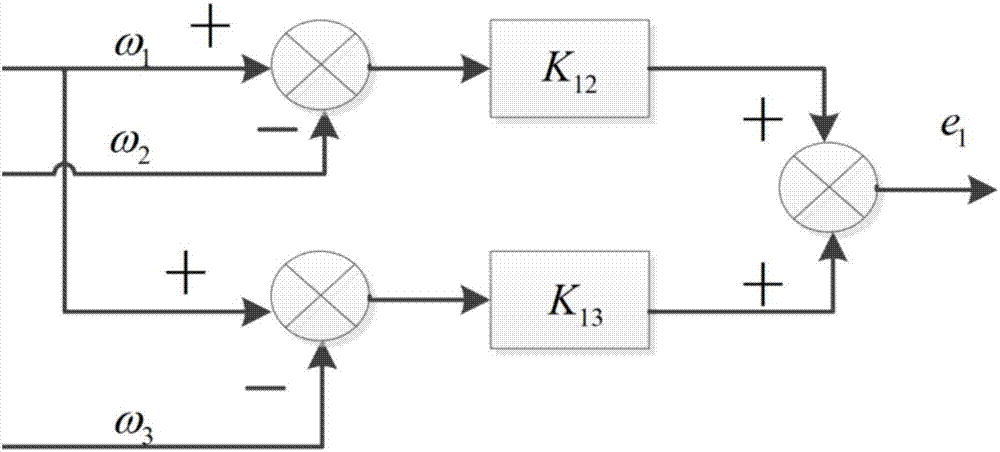

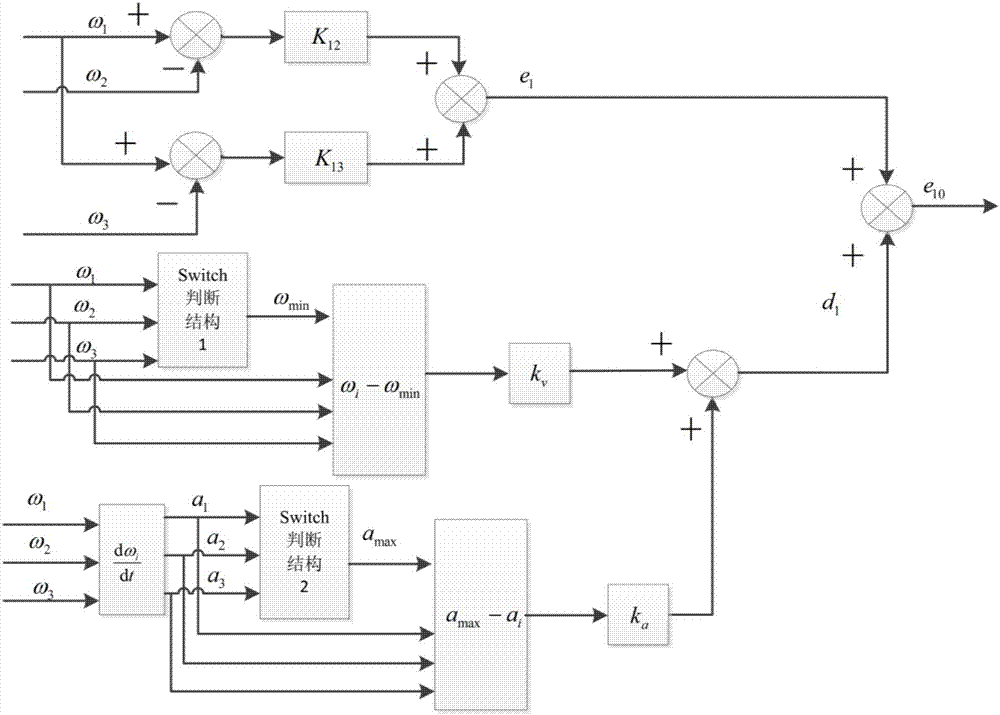

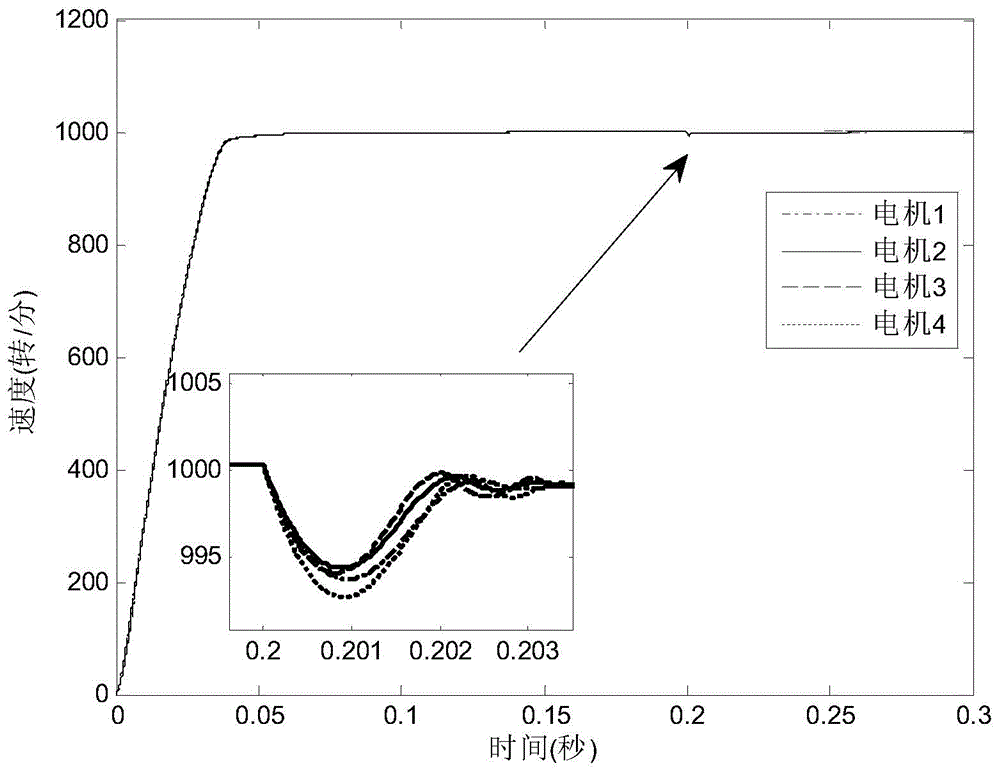

Accelerated speed considered multi-permanent magnet synchronous motor relative coupling control method

ActiveCN106887976AGood synchronizationGood followabilityElectric motor controlMultiple motor speed/torque controlCouplingElectric machinery

The invention relates to a multi-motor relative coupling control. In order to present an improved relative coupling strategy, the minimum rotation speed of each motor is obtained by comparison and other motors follows the lowest rotation speed so that the synchronization performance of each motor can be preferably improved. Moreover, an accelerated speed of each motor is taken into consideration and each motor is accelerated at a maximum accelerated speed. The invention adopts the technical scheme that an accelerated speed considered multi-permanent magnet synchronous motor relative coupling control method comprises the steps of considering i motors as the whole system, comparing the rotation speeds of the i motors to obtain the minimum rotation speed and enabling other motors to follow the lowest rotation speed; comparing the accelerated speeds of all motors to obtain a maximum accelerated speed and enabling the i motors to be accelerated at the maximum accelerated speed; on the basis of using accelerated speed considered relative coupling control on a multi-motor control structure, and enabling the single motor to use an integral sliding mode control algorithm to finally realize the motor relative coupling control. The multi-motor relative coupling control provided by the invention is mainly applied to design and manufacture fields.

Owner:TIANJIN POLYTECHNIC UNIV

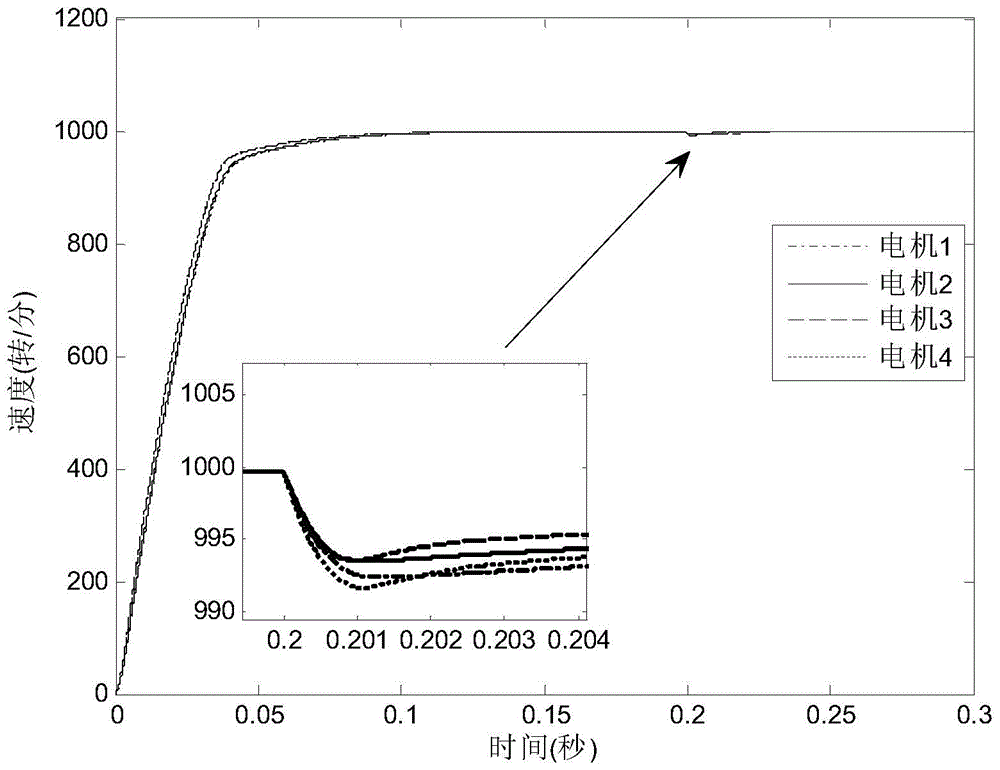

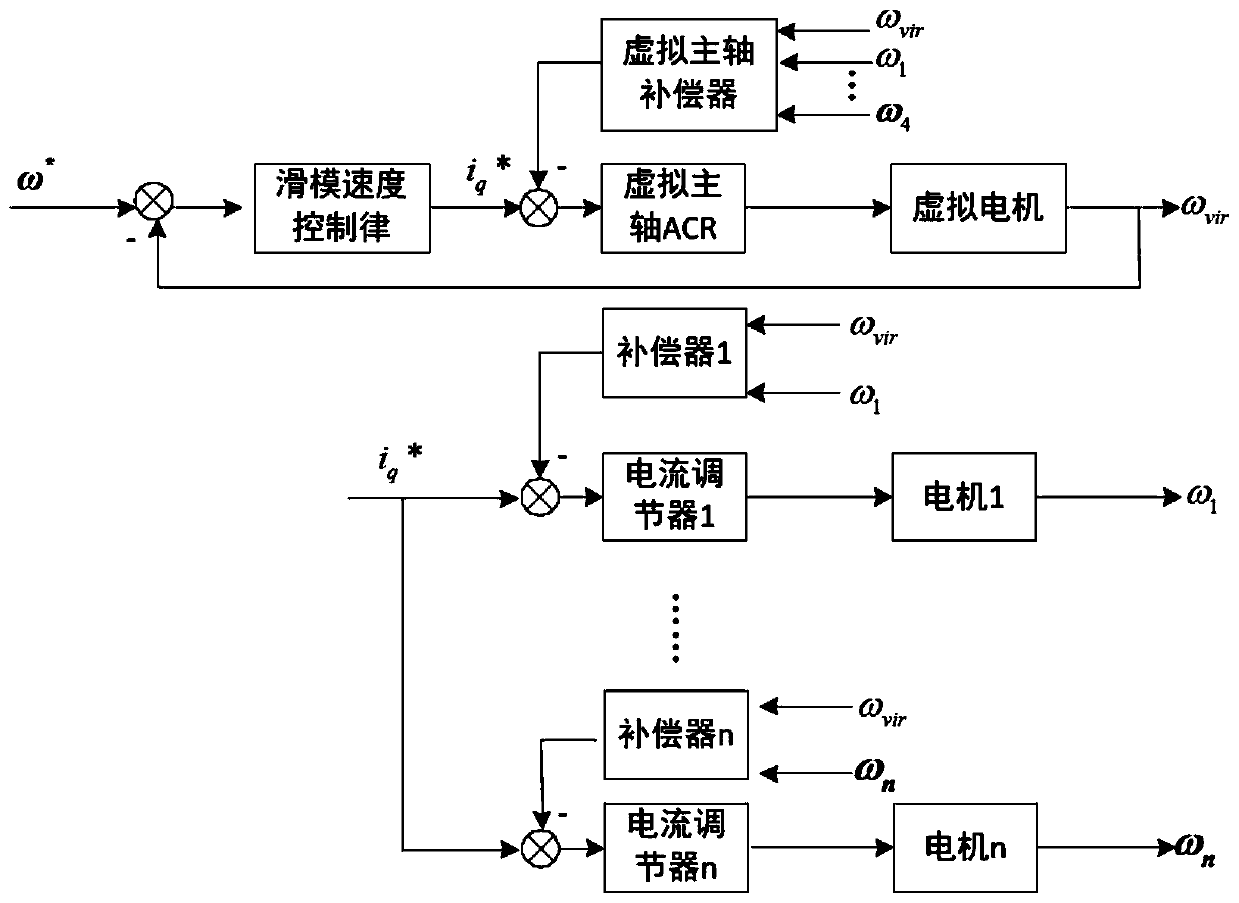

Multi-motor motion synchronization improved adjacent coupling control method based on active disturbance rejection

ActiveCN105743395ASynchronization speed is fastAchieve precise speed controlElectric motor controlMultiple motor speed/torque controlMotor speedDesign improvement

A multi-motor motion synchronization improved adjacent coupling control method based on active disturbance rejection comprises the steps of establishing a model of a permanent magnet synchronous motor system and initializing the system state and control parameters, designing an improved adjacent coupling control strategy, designing a multi-motor speed controller based on an active disturbance rejection technology, and designing a multi-motor synchronization controller by combining the improved adjacent coupling control strategy and an integral sliding mode technology. The speed consistency problem of a multi-motor synchronization system is solved effectively, the tracking performance and robustness of the system are improved, and stable operation of the multi-motor synchronization system is realized.

Owner:ZHEJIANG UNIV OF TECH

Guided missile pitching channel simple sliding-mode control method based on overload and angular velocity measurement

InactiveCN103994698ASimple Adjustment SelectionSimple compositionSelf-propelled projectilesAngular velocityEngineering

The invention discloses a guided missile pitching channel simple sliding-mode control method based on overload and angular velocity measurement. The method comprises the steps of processing overload signal and angular velocity signal measurement and amplitude limiting; establishing an integral sliding-mode face and selecting simplified sliding-mode control law parameters; performing continuous simulation verification on a simplified missile body model; performing robustness checkout and parameter adjustment under aerodynamic parameter perturbation. The guided missile pitching channel simple sliding-mode control method is a simple sliding-mode control method based on a gyroscope measurement attitude angle and rate gyroscope measurement guided missile attitude angular velocity technology, enables control parameter adjustment and selection to be simple and concise compared with similar control methods. The guided missile pitching channel simple sliding-mode control method is simple in control law composition and good in control low robustness, does not rely on accurate model information and has not high requirements for the overload measurement accuracy, angular velocity measurement accuracy and an on-missile computer sampling period.

Owner:NAVAL AERONAUTICAL & ASTRONAUTICAL UNIV PLA

Inverted pendulum system integral sliding mode control method for dollies with unknown hysteresis loops

The invention discloses an inverted pendulum system integral sliding mode control method for dollies with unknown hysteresis loops. The method comprises the following steps: building a dynamic model for an inverted pendulum system; conducting equivalent transformation together with hysteresis loops; initializing the system, sampling time and controlling parameters; together with sliding mode control and an inverted method, introducing a virtual control variable into the design of every step, and finally inferring the input for a self-adaptive controller; at the same time, utilizing the characteristics of a Nussbaum function, which solves the problem with unknown control directions; and calculating the tracking errors of the control system, the integral sliding mode surface, errors in variables and differentiations. The control method provided by the invention can effectively improve the position of an inverted pendulum system, which ensures that the inverted pendulum system to quickly and stably converge to the zero point, thus effectively eliminating the buffeting problems in sliding mode control.

Owner:ZHEJIANG UNIV OF TECH

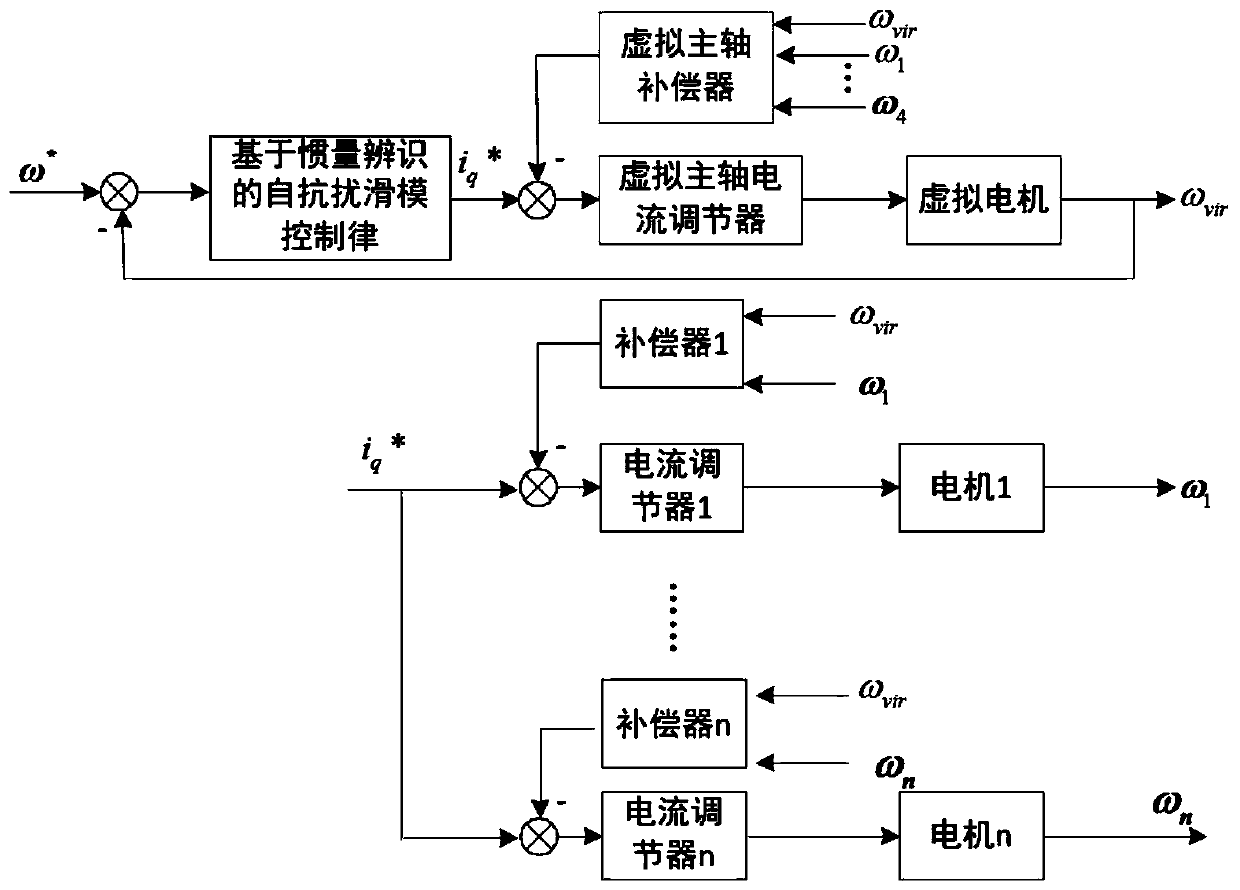

Multi-motor servo system active disturbance rejection sliding mode speed control method based on inertia identification

ActiveCN110518846AReduce chatteringSmall steady state errorElectronic commutation motor controlVector control systemsDifferentiatorControl system

The invention discloses a multi-motor servo system active disturbance rejection sliding mode speed control method based on inertia identification. The method comprises the steps that: a kinetic equation of a multi-motor servo system is constructed; the load inertia input by the multi-motor servo system is identified by using a model reference adaptive method; a first-order active disturbance rejection model is constructed according to disturbance in a first-order tracking differentiator, a second-order extended state observer and a multi-motor servo system speed loop to obtain a nonlinear state error feedback control law; and a reaching law is improved based on a hyperbolic tangent softening switching function, sliding mode control with integration is constructed to compensate and optimizethe nonlinear state error feedback control law, a final control law is obtained, and then active disturbance rejection sliding mode speed control of the multi-motor servo system is achieved. Comparedwith partition PID control and integral sliding mode control, under the condition of variable inertia, the composite control strategy has better adaptability to the inertia change condition, a bettercontrol effect can be obtained, and the robustness of the control system is high.

Owner:NANJING UNIV OF SCI & TECH

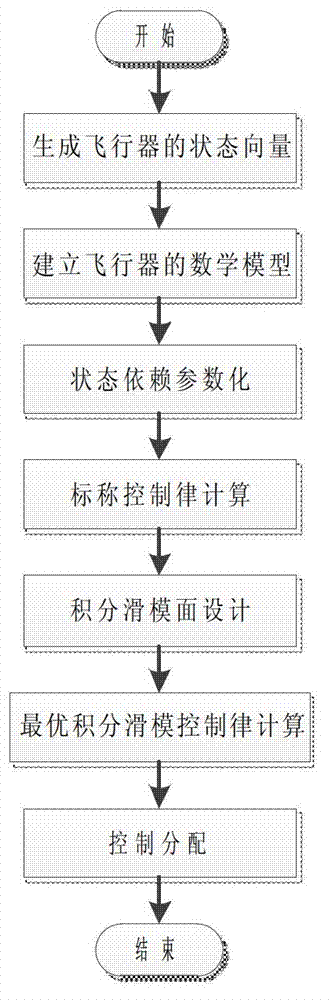

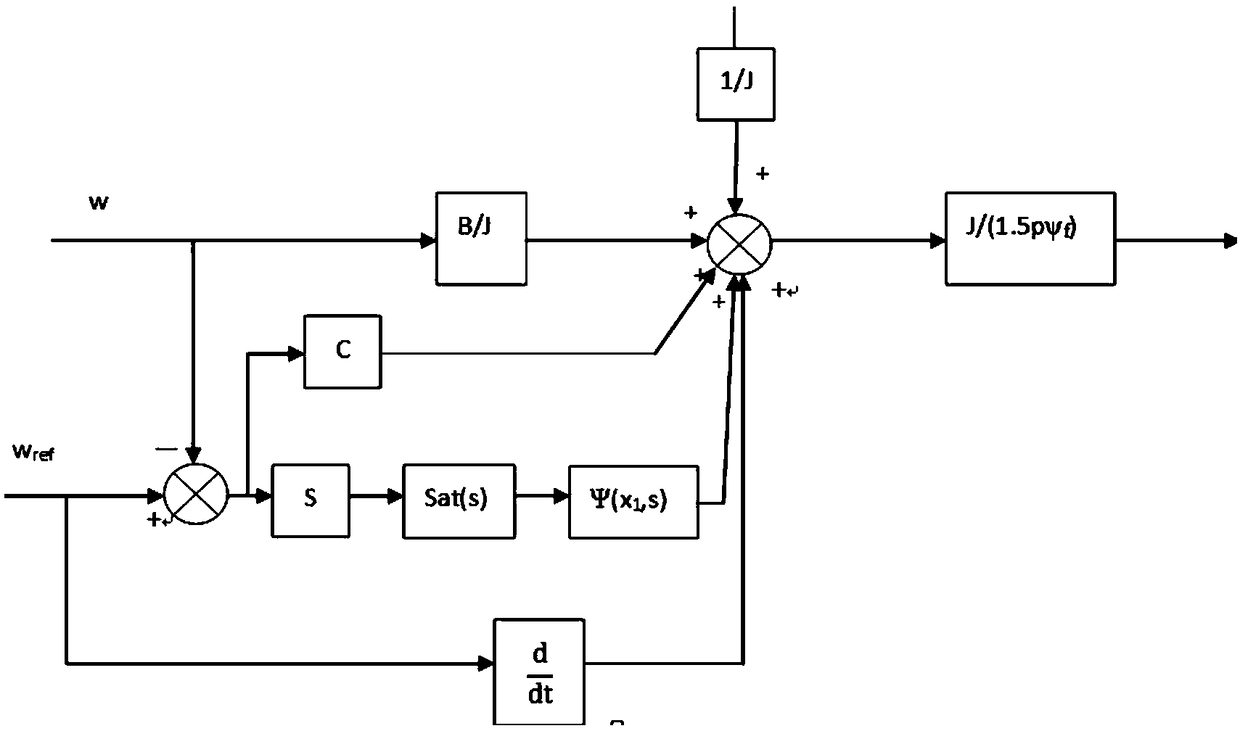

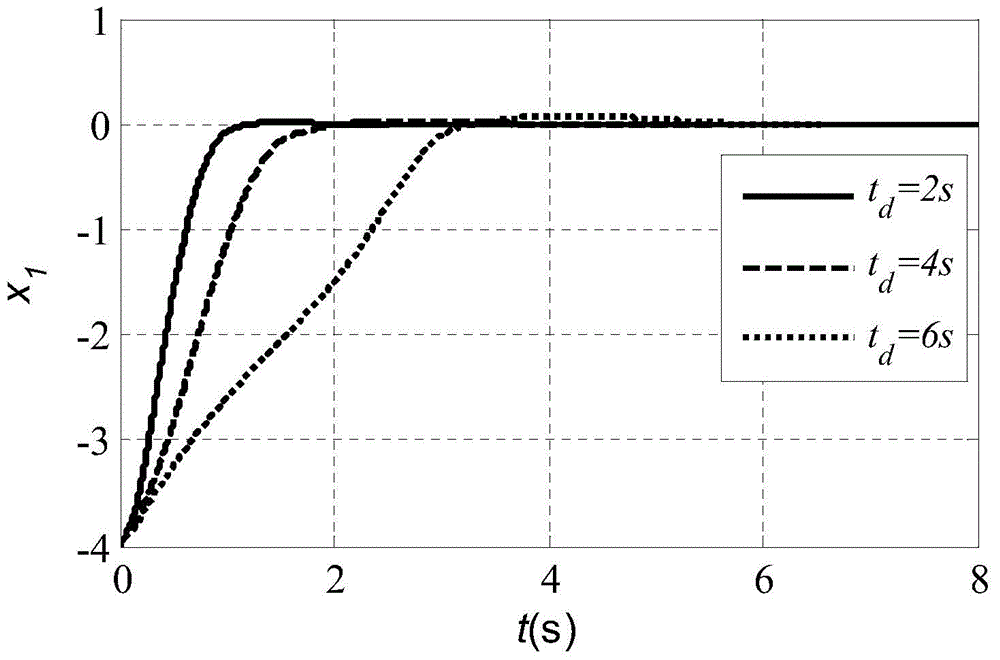

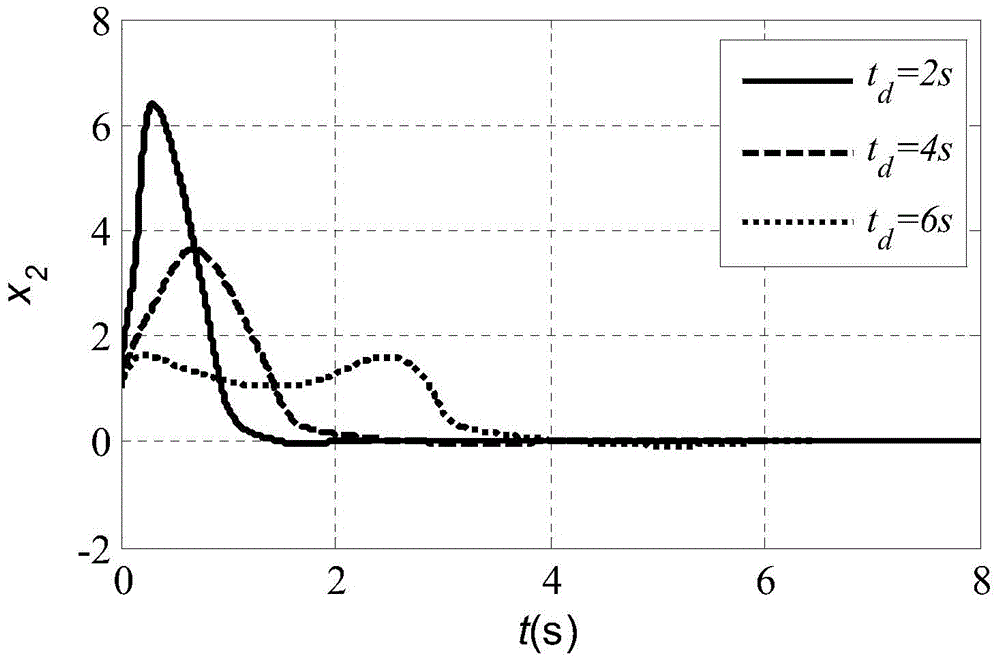

Optimal integral sliding mode control method

InactiveCN104950672APreserve nonlinearityGlobal robustnessAdaptive controlRiccati equationDynamic models

The invention discloses an optimal integral sliding mode control method, relates to an integral sliding mode control method, and belongs to the technical field of control. The optimal integral sliding mode control method includes the steps: firstly, building a dynamic model of a second-order nonlinear system; secondly, realizing system state finite-time convergence through an ISDRE (improved state-dependent Riccati equation), and effectively compromising the contradiction between system response time and overshoot; thirdly, combining the ISDRE with an integral sliding mode to further improve robustness of the system under disturbance. The optimal integral sliding mode control method has universality, and can be applied to control systems such as an aircraft and an inverted pendulum.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Novel reaching law based bearingless asynchronous motor sliding-mode control method

InactiveCN106208888AImprove control effectShorter approach timeElectronic commutation motor controlAC motor controlMotor speedState variable

The invention discloses a novel reaching law based bearingless asynchronous motor sliding-mode control method. A motor rotational speed ring adopts a novel reaching law based sliding-mode speed controller, the controller adopts a novel reaching law having an automatic speed change function, an integral sliding-mode surface is built by means of a rotational speed error in a bearingless asynchronous motor speed regulation system, and a current signal i<*><Iq> of the speed ring is extracted by combining an electromagnetic torque and motion equation. On the basis of a traditional index reaching law, a first-order norm / / x / / 1 of a system state variable is introduced, and the problems of buffeting existing in traditional index reaching rate and poor convergence performance are solved; the bearingless asynchronous motor sliding-mode speed controller applying the reaching law design has relatively high robustness on uncertainty disturbance of the system, the running quality of the bearingless asynchronous motor speed regulation system is effectively improved, moreover, the control strategy is simple, and engineering implement is facilitated.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com