Method for controlling rotating speed synchronization of dual-permanent magnet synchronous motor drive system

A technology of permanent magnet synchronous motor and synchronous motor, which is applied in multiple motor speed/torque control, motor generator control, AC motor control, etc. It can solve the problem of weak system robustness, difficulty in establishing mathematical models, PMSM Variables and other issues, to achieve the effect of improving tracking performance and robust performance, not requiring high model accuracy, and enhancing the coupling effect of rotational speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

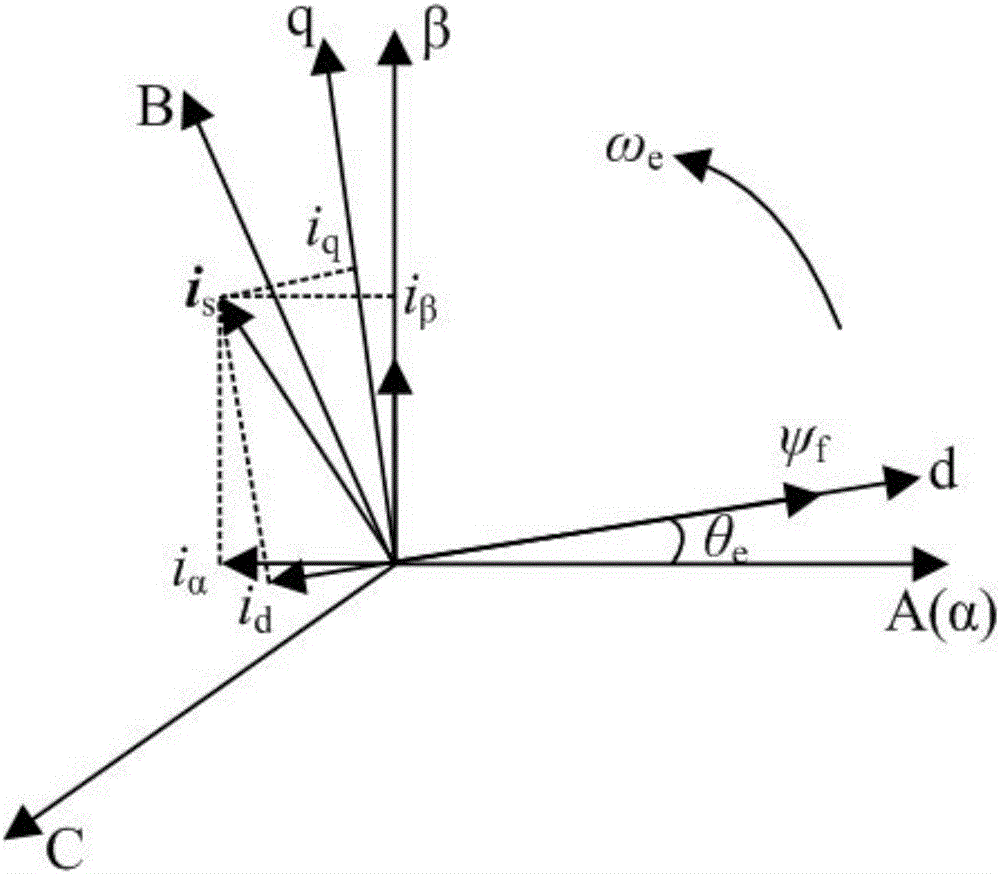

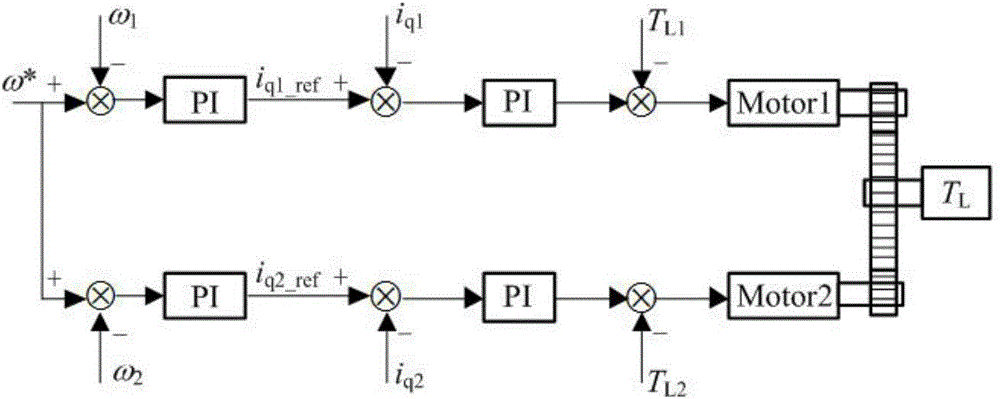

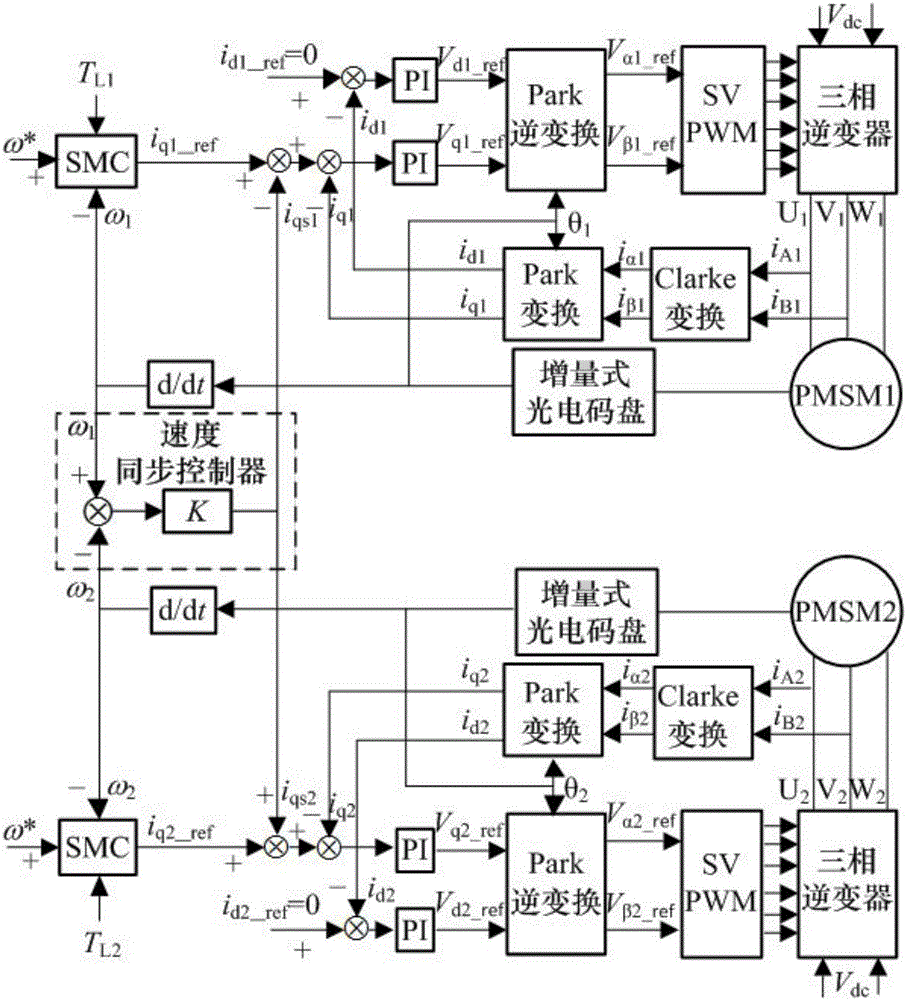

[0042]In order to enhance the robustness of the entire system to load disturbances, the dual permanent magnet synchronous motor drive system speed synchronization control method proposed by the present invention firstly designs an integral sliding mode speed controller based on the principle of sliding mode control to improve the speed of a single motor. For the robustness of load disturbance, based on the principle of cross-coupling, a speed synchronous controller is designed to compensate the current loops of the two motors. By selecting the appropriate feedback synchronization coefficient, the speed of the two motors can be as fast as possible when they are disturbed by the load. Synchronization can be achieved in a timely manner, thereby improving the synchronization of the entire system under load disturbance and the rapidity of speed recovery. The present invention will be further described below from the aspects of the permanent magnet synchronous motor mathematical mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com