Decoupling control method of rare earth extraction process

A decoupling control and extraction technology, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of control system performance deterioration, ignoring the influence of control loop coupling, and inability to adjust online in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

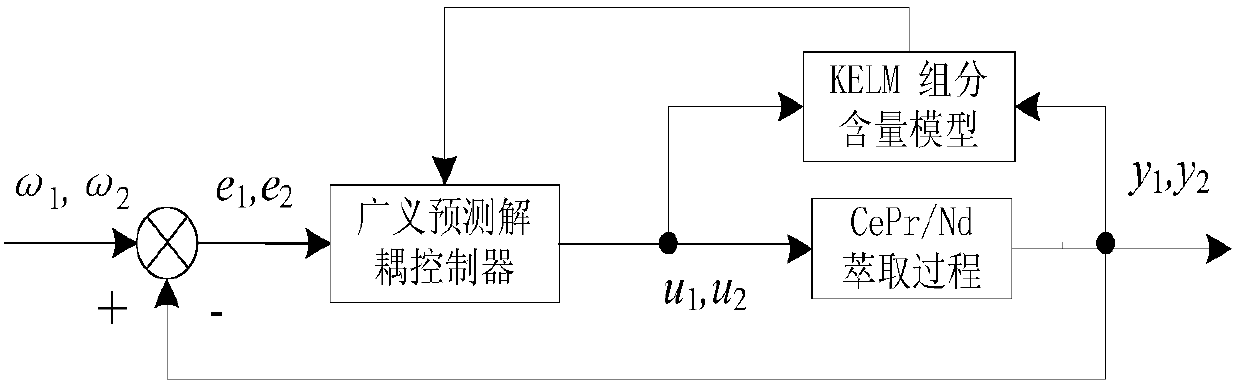

[0093] The present invention will be described in detail below in conjunction with specific embodiments.

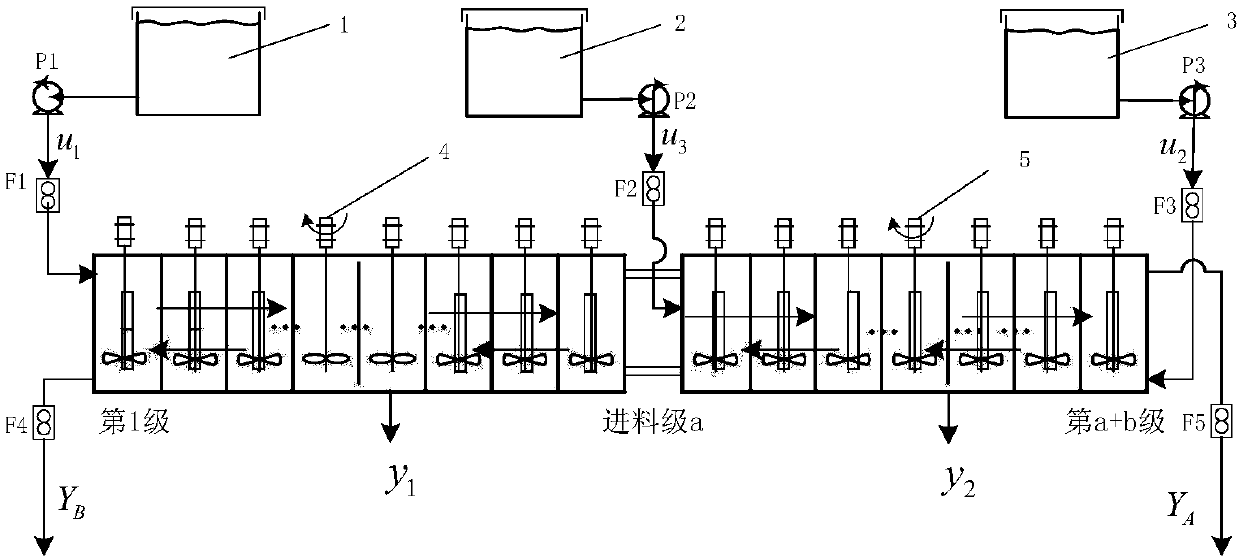

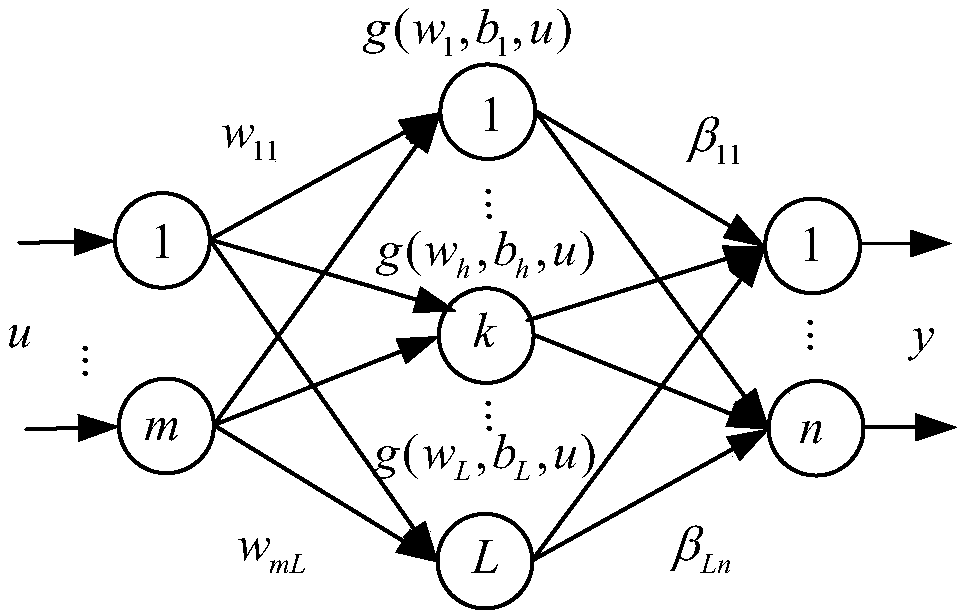

[0094] In view of the characteristics of rare earth extraction process, such as multi-variable, nonlinear, strong coupling, etc., the rare earth extraction process description method of KELM component content model is proposed; combined with the dynamic process data of rare earth elements CePr / Nd in different operation stages of the extraction process, KELM is used to establish a rare earth extraction process. Process identification model; the decoupling control method of rare earth extraction process is proposed to realize the optimal control of rare earth extraction process. The technical solution is specifically described as:

[0095] (1) KELM component content model of rare earth extraction process based on cascade extraction theory:

[0096] Due to the similar chemical properties between rare earth elements and small separation coefficients, the rare earth cascade e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com