Fuzzy control method for revolution speeds of high-pressure diaphragm pumps

A high-pressure diaphragm, fuzzy control technology, used in pump control, liquid variable capacity machinery, machines/engines, etc., can solve problems such as pipeline vibration, and achieve the effect of eliminating synchronization errors, improving synchronization accuracy, and good instant response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

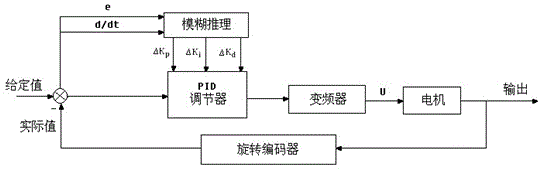

[0015] A high-pressure diaphragm pump speed fuzzy control method of the present invention is that the method adopts the diaphragm pump fixed rotation angle difference control system to strictly maintain all pumps at a constant rotation angle difference synchronous relationship, and can maintain the synchronous speed relationship. In the same pulse period Inside, the initial position of the rotation angle of each pump is strictly coordinated, and the set rotation angle difference is maintained. The fixed rotation angle difference control system of the diaphragm pump adopts a master-slave control structure, and the crankshaft rotation angle and speed of the first diaphragm pump are used as the pump group The rotation angle and rotation speed of each motion axis drive motor are given as reference.

[0016] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com