Construction method of prestressed immersed tunnel pipe joint

A construction method and technology of immersed tube tunnels, which are applied in construction, water conservancy projects, artificial islands, etc., can solve the problems of inconvenient concrete pouring and vibration, difficulty in adapting to long-span structures, and large burial depth of immersed tube tunnels, etc. Corrosion ability, reduced labor intensity, and low project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

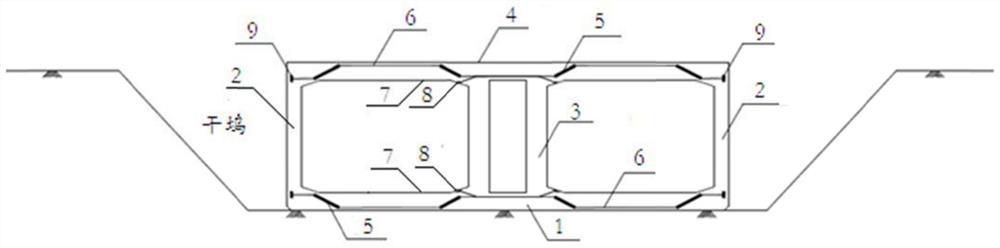

[0028] This embodiment provides a method for constructing pipe joints of prestressed immersed tube tunnels, such as figure 1 As shown, the method includes the following steps:

[0029] Step S1, tying steel bars of the pipe joint bottom plate 1 in the dry dock, laying prestressed tensioned casings and steel strands 7 on the pipe joint bottom plate 1, and pouring concrete for the pipe joint bottom plate 1;

[0030] Step S2, constructing reinforced concrete for pipe section side wall 2 and pipe section middle partition wall 3;

[0031] Step S3, tying the steel bars of the pipe joint top plate 4, laying the prestressed tensioned casing and the steel strand 7 on the pipe joint top plate 4, and pouring the pipe joint top plate 4 concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com