Immersed tube floating-state barge-up method

An immersed tube and floating state technology, which is applied to caissons, barges/flat-bottomed boats, buildings, etc., can solve the problems of complicated operations, easy to be restricted by the wharf construction site, and high construction costs, so as to achieve simple construction, improve operational safety and fault tolerance efficiency and control the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

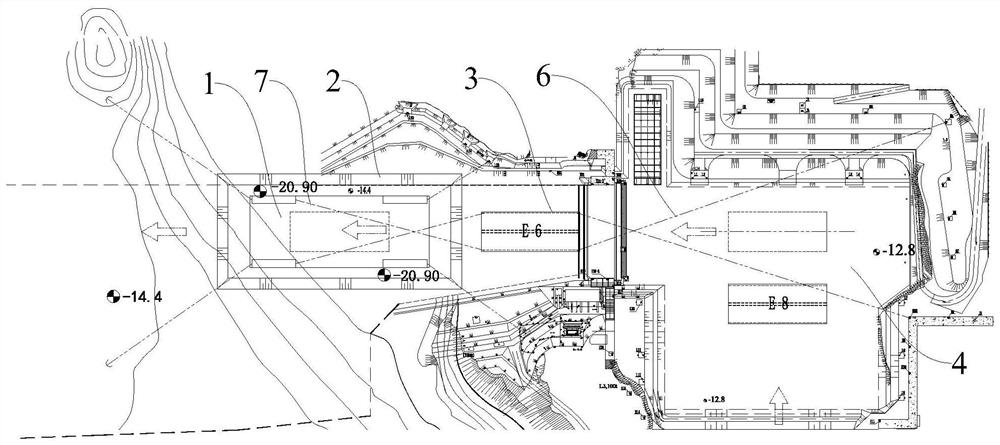

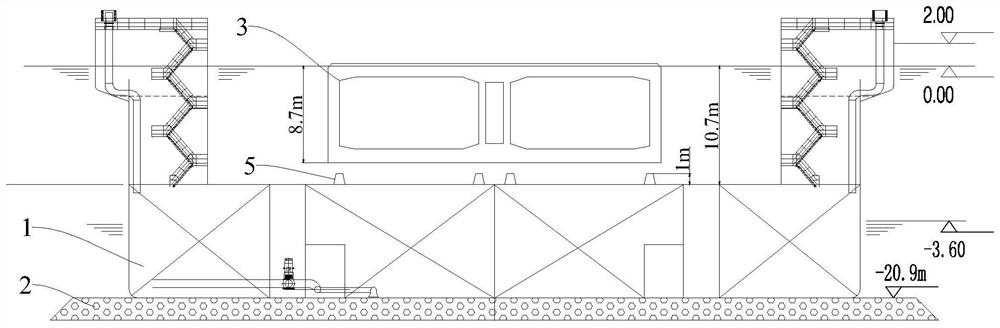

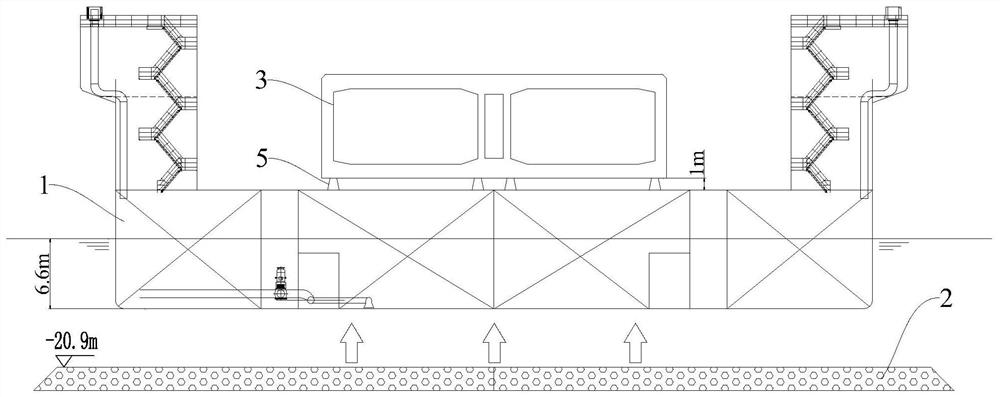

[0048] Such as Figure 1-Figure 3As shown, a method for floating lightering of immersed tubes of the present invention comprises the following steps:

[0049] A. Construct the bottom sitting area 2 for the submerged semi-submerged barge 1, and set up the buttress system 5 on the semi-submerged barge 1;

[0050] B. Operate the semi-submersible barge 1 to dive and sit on the bottom, and float the immersed tube 3 in the dry dock 4;

[0051] C. After the semi-submerged barge 1 sits on the bottom, the immersed tube 3 is floated to the top of the pier system 5;

[0052] D. Position the semi-submerged barge 1 and the immersed tube 3 for mooring, operate the semi-submersible barge 1 to drain and float, the pier system 5 supports the immersed tube 3, lift the immersed tube 3 out of the water surface, and complete the barge work of the immersed tube 3.

[0053] In this embodiment, the draft of the immersed tube 3 floating is 8.7m, and the height difference between the ebb and flow of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com