Test loading device for passenger seat embedded part

A technology of loading device and embedded parts, applied in the field of tooling and fixtures, can solve the problems of inability to load multiple embedded parts, failure to simulate force conditions, unsatisfactory design effect, etc., achieving convenient installation, solving site restrictions, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical problem solved by the present invention: through the design of guide rail mounting platform, mobile actuator mounting seat, mobile Z-direction mounting seat, mobile insert mounting seat, beam, loading assembly, and mobile insert mounting seat. The insert can bear loads in all directions to avoid loading interference, and according to changing the combination of insert loading components, the test piece can be loaded through the mobile actuator mounting seat and the mobile insert mounting seat, which is convenient for installation and stable loading .

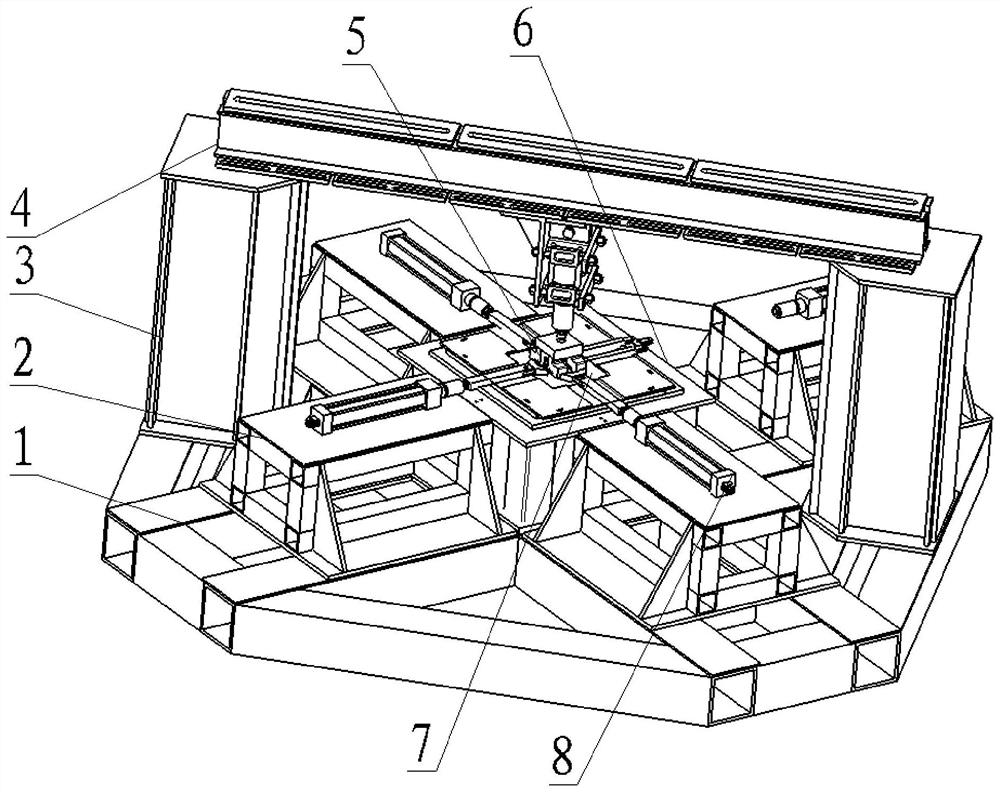

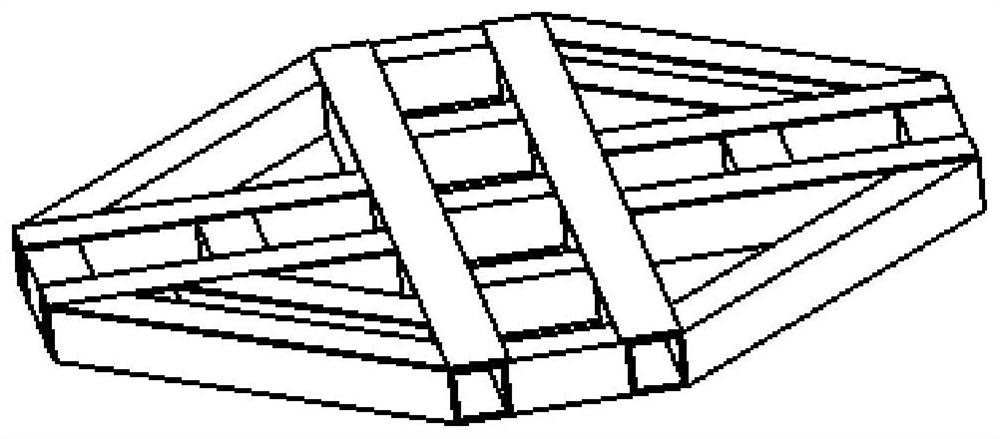

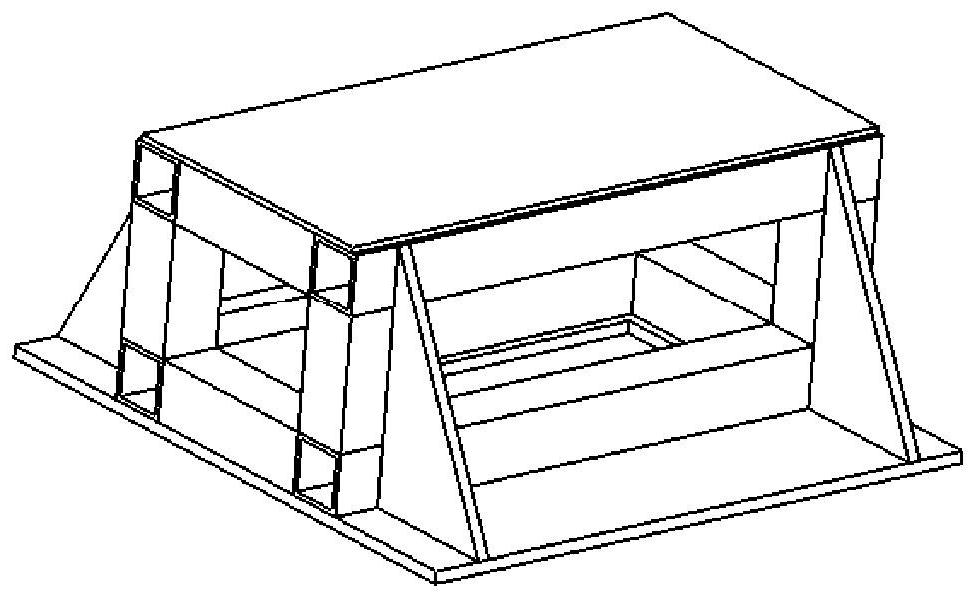

[0031] see Figure 1-4 , The device provided by the present invention consists of a rail-type mounting platform 1, a mobile actuator mounting base 2, a movable Z-direction mounting base 3, a beam 4, a loading assembly 5, and a mobile insert mounting base 6.

[0032] In the embodiment of the present application, the rail-mounted installation platform 1 is used to install the movable actuator mount 2, the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com