Multi-stage loading testing device for simulating excavation of rock mass in different dip angles

A loading test device and loading device technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of affecting the accuracy of test results, excessive deviation of test results, cumbersome component pouring, etc., and achieve easy operation and The effect of loading, convenient test and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

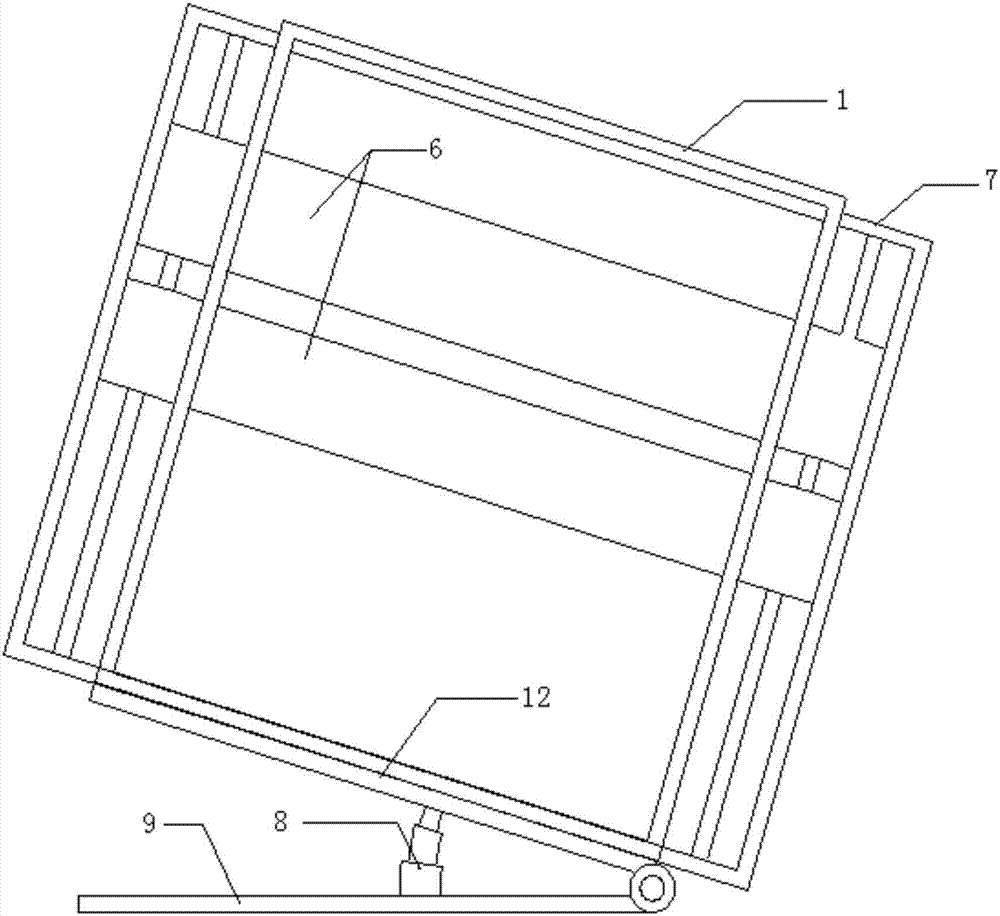

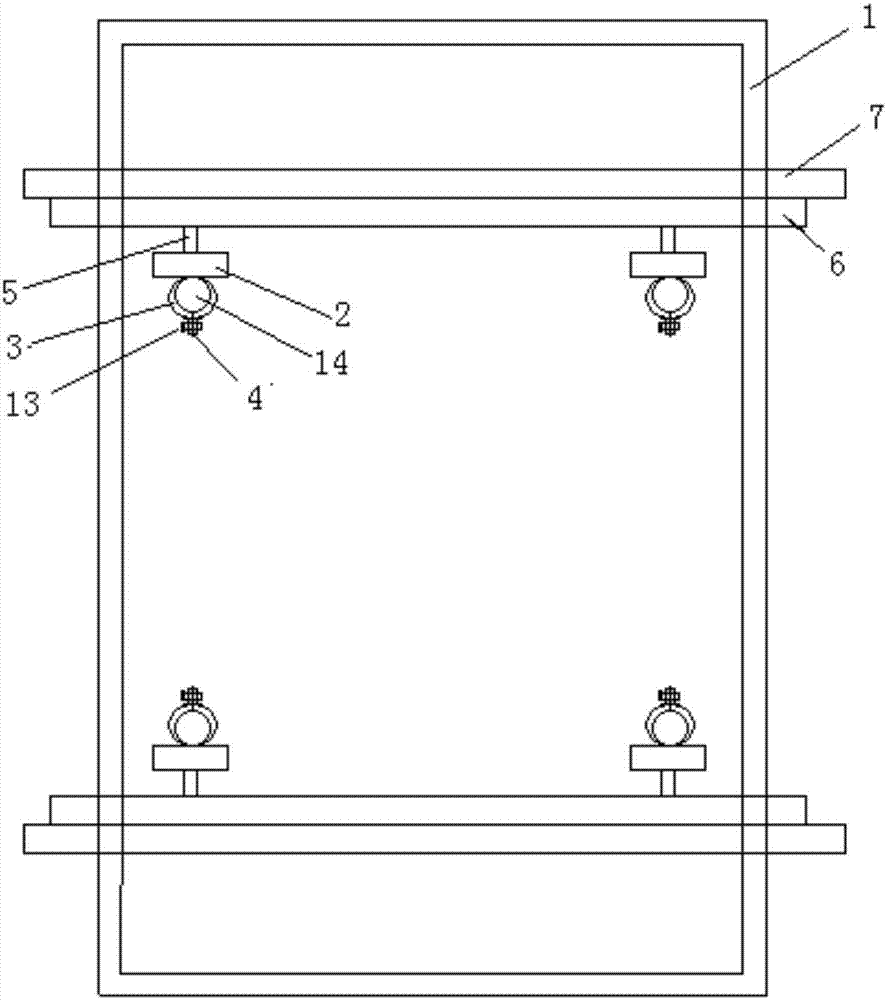

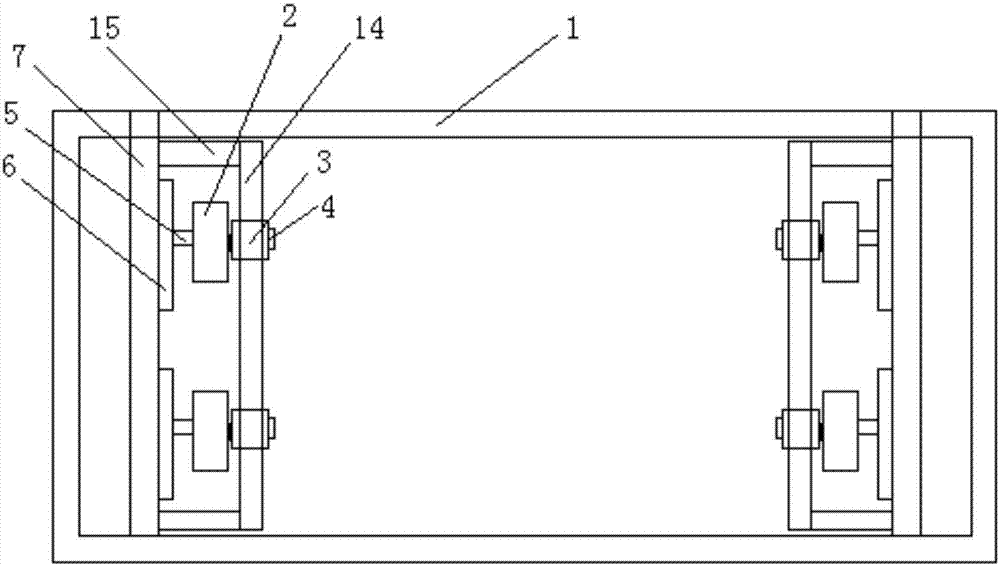

[0024] Such as Figure 1-5 As shown, a multi-stage loading test device for simulating the excavation of rock masses with different inclinations includes an outer frame and a multi-stage loading device. The outer frame includes a fixed frame, a tiltable steel plate, a hydraulic lifting column and a fixed bottom plate. It is located at the bottom of the fixed frame, the top of the hydraulic lifting column is connected to the bottom surface of the tiltable steel plate, and the fixed end of the hydraulic lifting column is connected to the fixed bottom plate; the multi-stage loading device is installed on the fixed frame, and the multi-stage loading device includes the inner frame, steel plate, reset device, electromagnetic loading device and connecting fasteners. The inner frame includes an inner frame body, a connecting pipe and two vertical steel pipes. The two vertical steel pipes are respectively arranged outside the two ends of the inner frame body. The upper and lower ends o...

Embodiment 2

[0028] It is basically the same as Embodiment 1, except that there are more than two multi-stage loading devices arranged in parallel on the fixed frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com