A method of contemporaneously constructing more than one semi-submersible rig using transverse skidding

A technology of drilling platform, level height, applied in the field of construction of marine buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

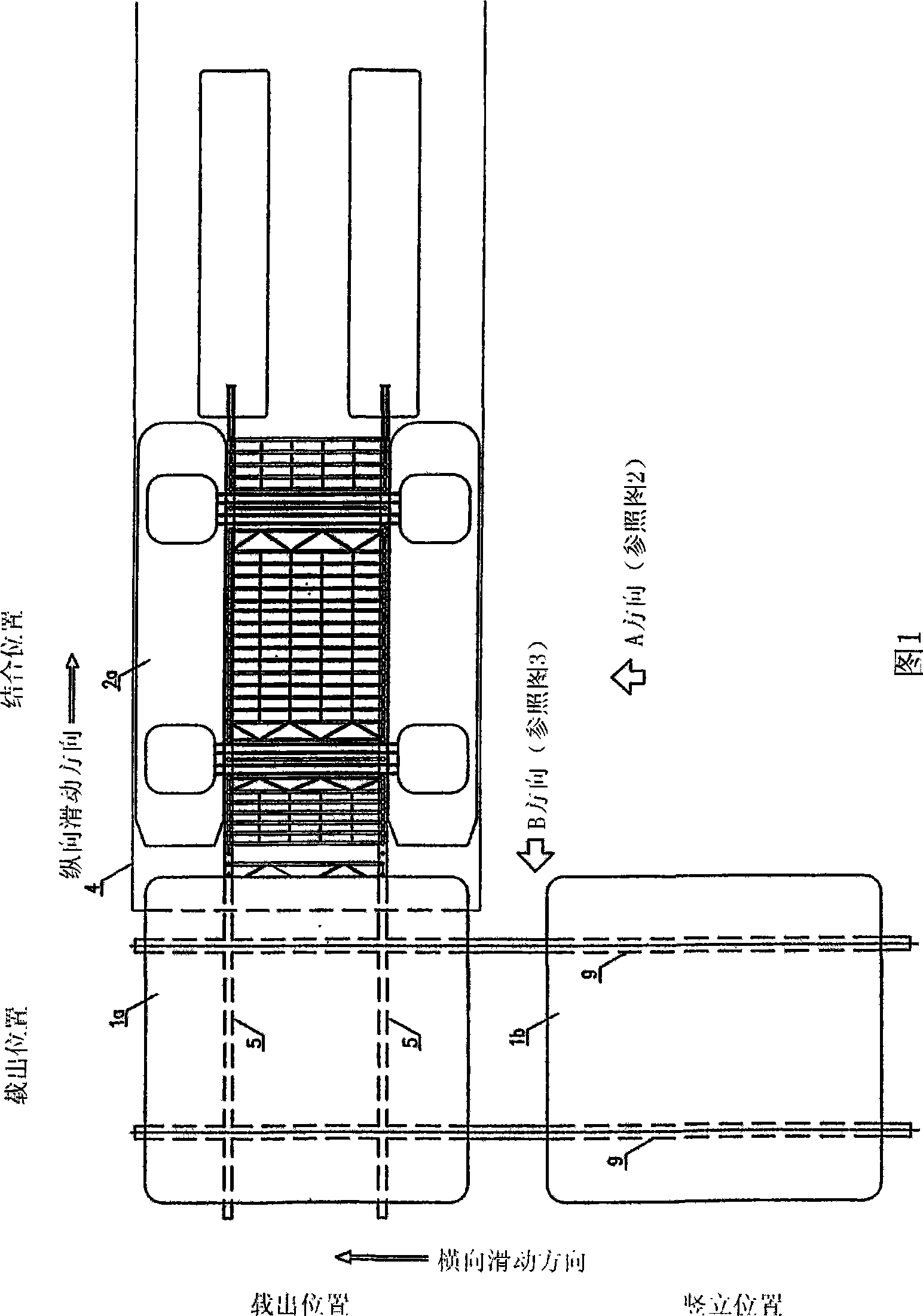

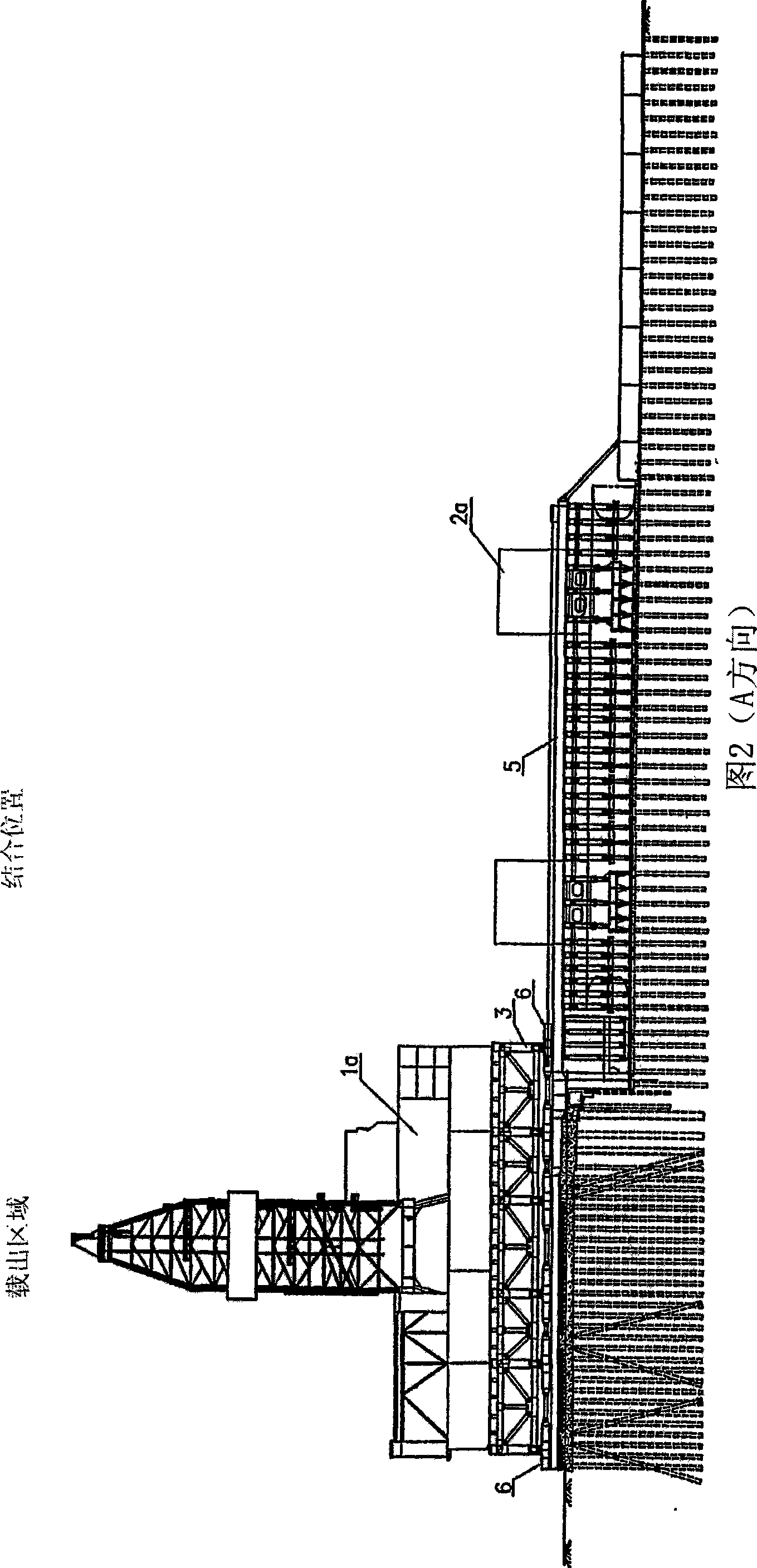

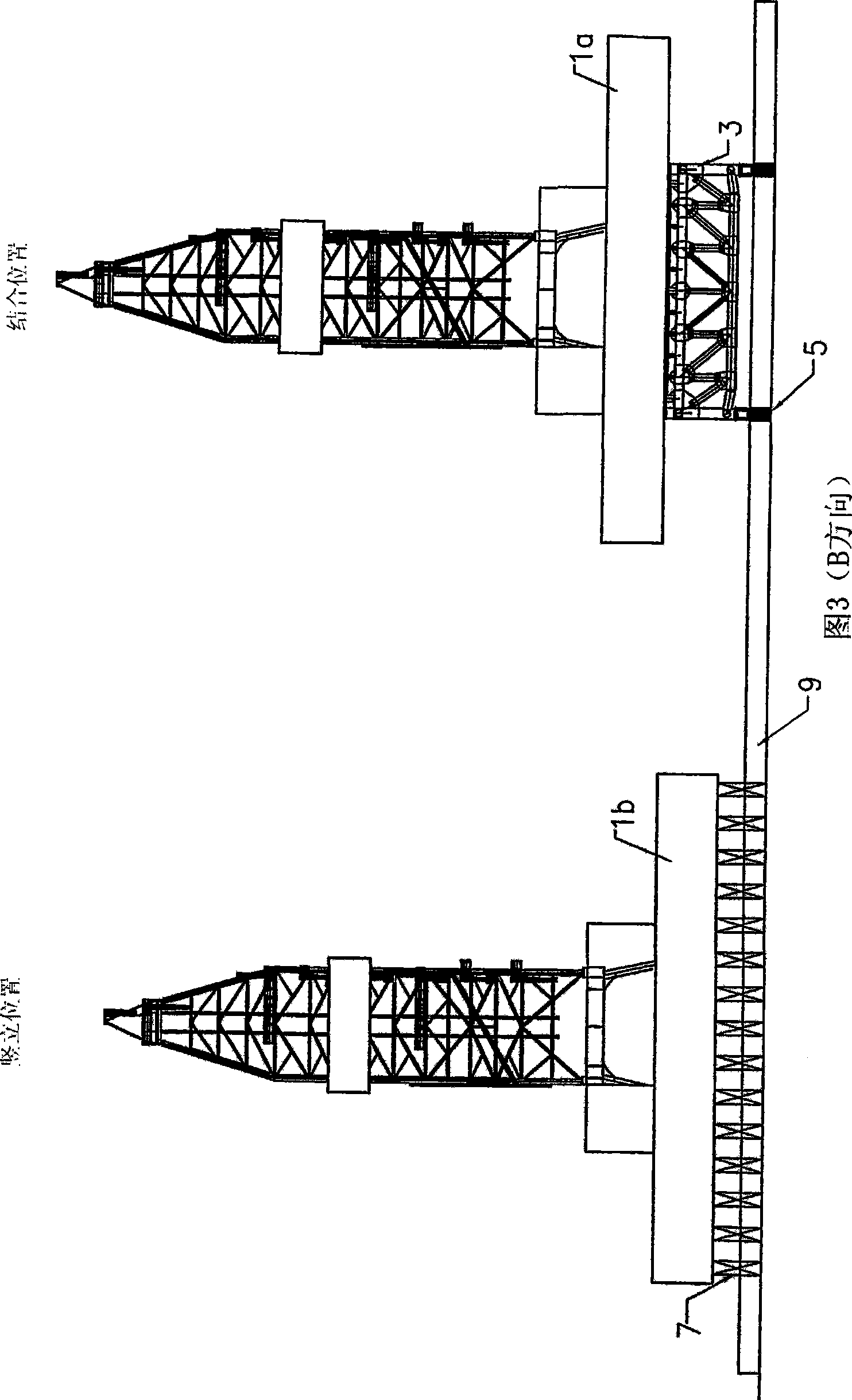

[0026] The present invention will be further described below in conjunction with specific drawings. Figures 1-3 show the general arrangement of the shipyard area including the dry dock 4 where two semi-submersible drilling rigs of the present invention are constructed and combined. As shown in Fig. 2 and Fig. 3, the first semi-submersible drilling platform is composed of a first upper hull 1a and a first lower hull 2a. During construction, the first upper hull 1 a is supported by sliding trusses 3 located on land adjacent to the dry dock 4 . The sliding trusses 3 are designed to slide the completed upper hull 1a on the longitudinal sliding beams 5 using longitudinal sliding shoes 6 during the load-out operation.

[0027] As shown in FIG. 1 , the longitudinal sliding beam 5 extends parallel to the longitudinal axis of the sliding truss 3 . The detailed configuration of the unloading and bonding operations is further disclosed in detail in the previous International Publicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com