Method for prefabricating pipe joints of immersed tube tunnel

An immersed tube tunnel and tube section technology is applied in the field of immersed tube section prefabrication, which can solve the problems of low practicability of prefabricated tube section scheme, complex tunnel construction engineering conditions, strict navigation requirements in surrounding waters, etc., so as to reduce dry docking. Depth requirements, flexible transportation methods, and the effect of saving rental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the purpose, structure and function of the present invention, a method for prefabricating immersed tunnel pipe joints according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

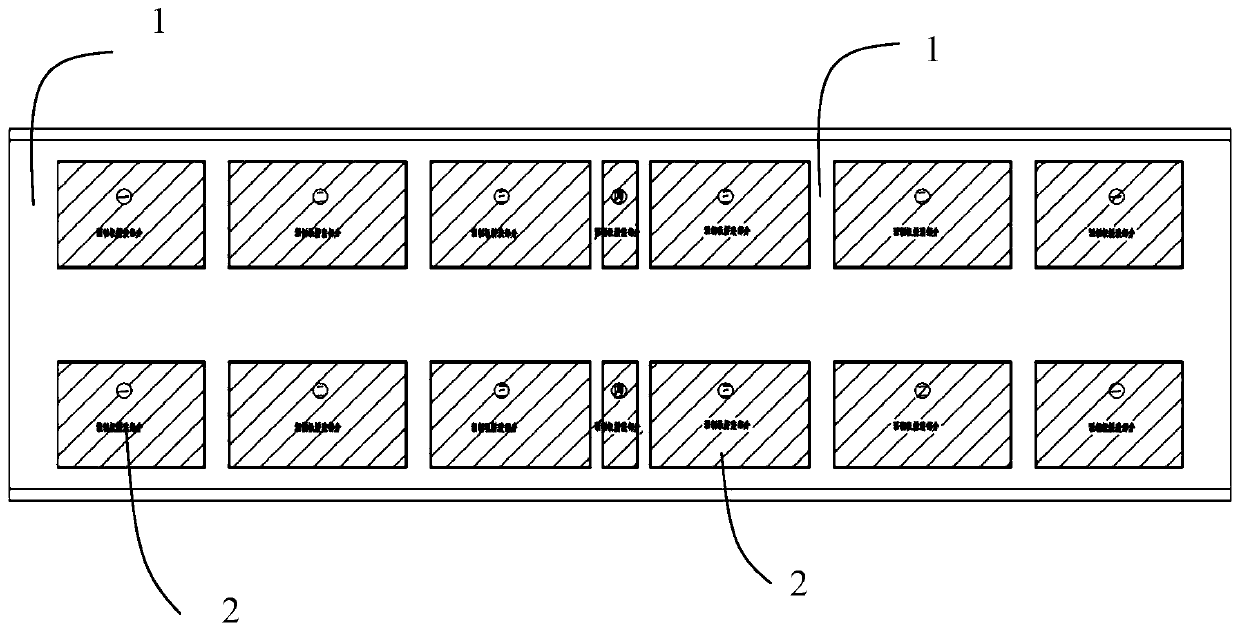

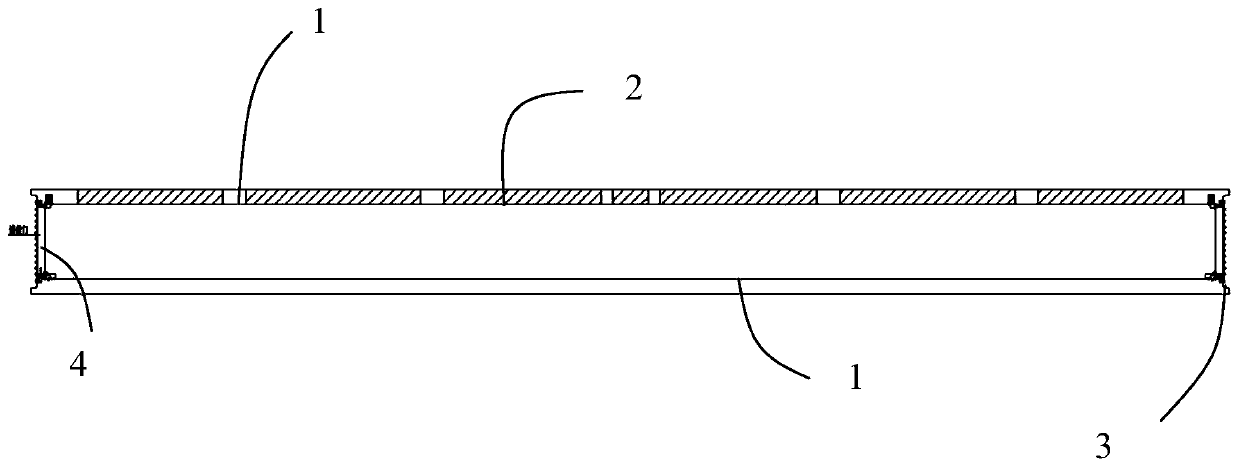

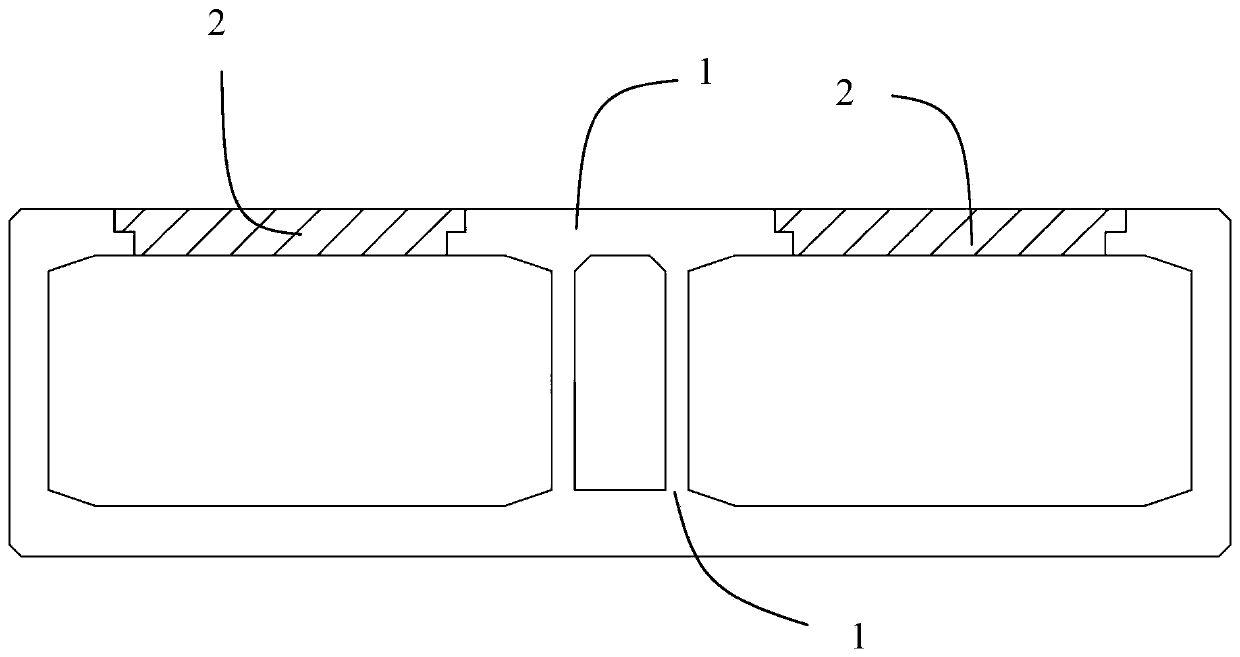

[0036] Such as Figure 1 to Figure 4 As shown, it is shown as a method for prefabricating pipe joints of an immersed tube tunnel of the present invention, and the specific steps are as follows:

[0037] Step 1, tie steel bars and pour pipe joint 1 in shallow dry dock.

[0038] Wherein, when pouring the pipe joint 1, except for the opening area of the prefabricated slab 2 on the pipe joint 1, the rest are all prefabricated in the shallow dry dock.

[0039] Among them, the prefabricated platform of the shallow dry dock can use a newly excavated foundation pit, and the depth is determined according to the requirements of the floating transportation of the pipe joints, so as to reduce the amount of dre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com