Hydraulic oil cylinder buffering piston for elevator

A hydraulic cylinder and buffer plug technology, which is applied in the field of hydraulic cylinder buffer plugs for elevators, can solve the problems of deep pit depth and high height in the elevator shaft, and achieve the effect of reducing the depth of the pit and reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

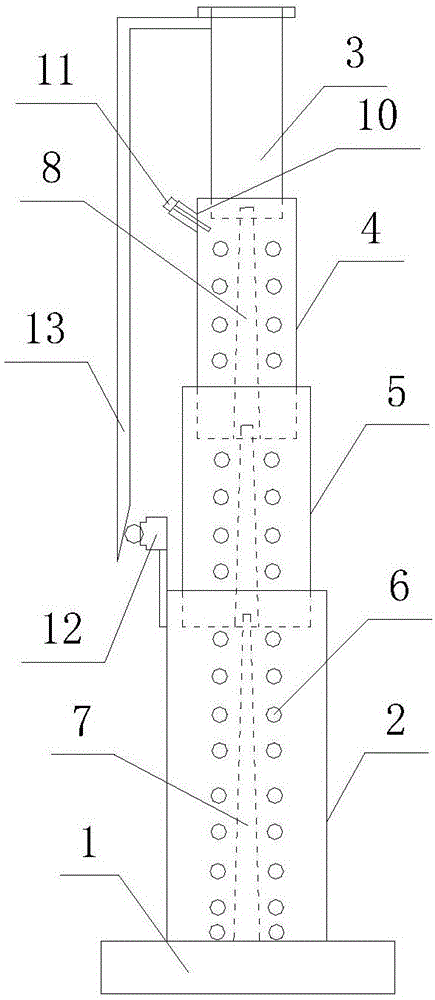

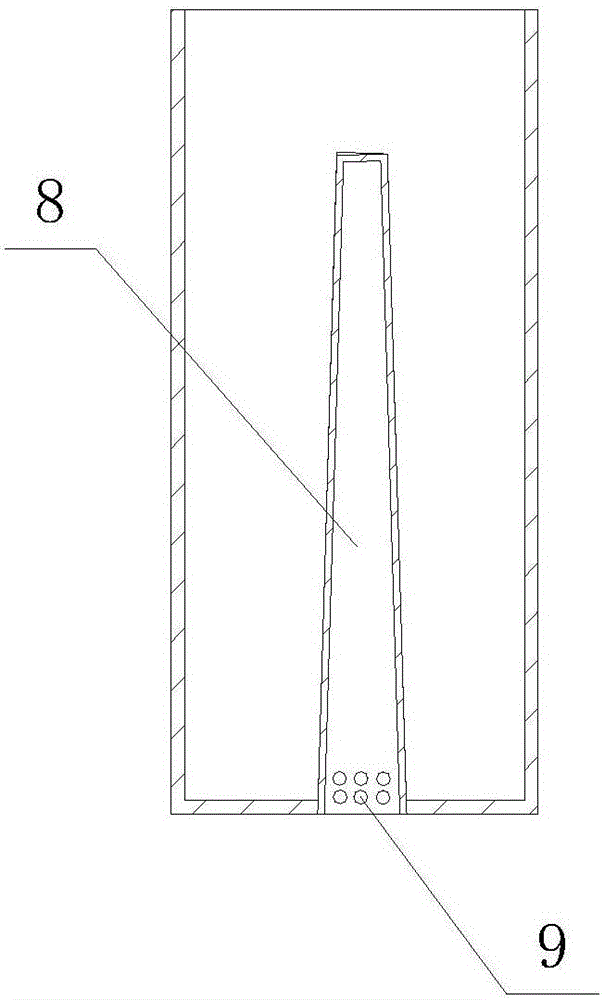

[0019] Such as Figure 1 to Figure 3 As shown, a hydraulic cylinder buffer plug for an elevator includes a base 1 , a hydraulic cylinder 2 disposed on the base 1 and a multi-stage plunger nested in the hydraulic cylinder 2 . The multi-stage plunger is composed of three plungers nested from top to bottom, and from top to bottom are the first-stage plunger 3 , the second-stage plunger 4 and the third-stage plunger 5 . Compression return springs 6 are provided between the plungers of all levels, between the three-stage plunger 5 and the hydraulic cylinder 2, and are used to restore each plunger after compression to the elongated state before compression. The spring 6 is installed inside the plunger and the inside of the hydraulic cylinder 2 . The bottom of the hydraulic oil cylinder 2 is provided with an oil passing rod 7, and the oil passing rod 7 can be hollow or solid. The bottoms of the first-stage plunger 3 , the second-stage plunger 4 and the third-stage plunger 5 are all...

Embodiment 2

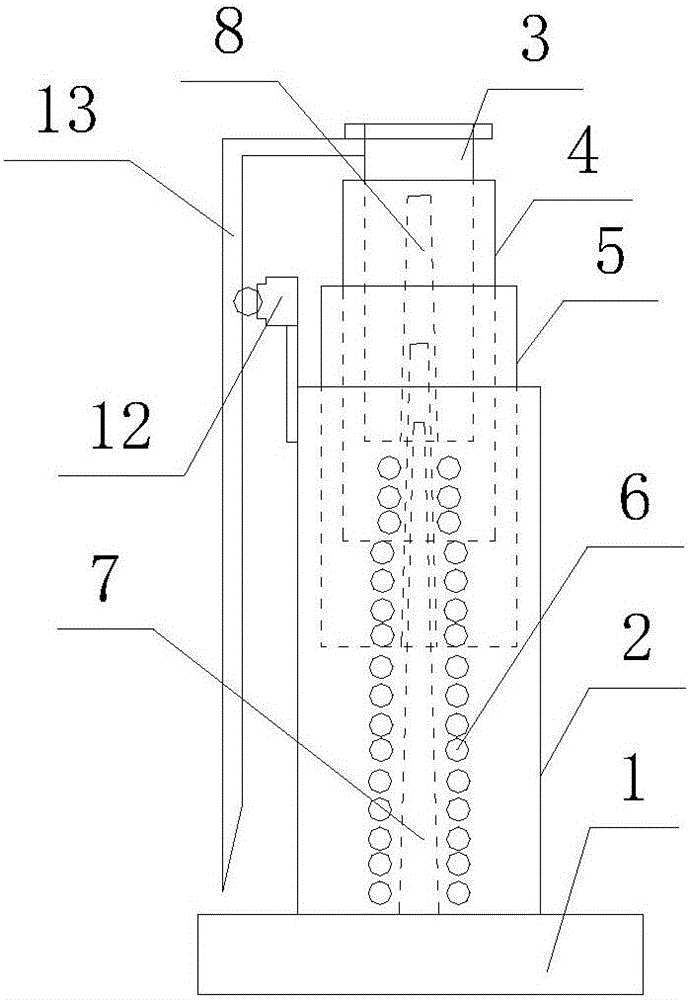

[0023] Such as Figure 4 and Figure 5As shown, a hydraulic cylinder buffer plug for an elevator includes a base 1 , a hydraulic cylinder 2 disposed on the base 1 and a multi-stage plunger nested in the hydraulic cylinder 2 . The multi-stage plunger is composed of three plungers nested from top to bottom, and from top to bottom are the first-stage plunger 3 , the second-stage plunger 4 and the third-stage plunger 5 . Compression return springs 6 are provided between the plungers of all levels, between the three-stage plunger 5 and the hydraulic cylinder 2, and are used to restore each plunger after compression to the elongated state before compression. The spring 6 is installed on the outside of the plunger, and the specific installation method is: one end of the compression return spring 6 is fixed on the outer side of the top circumference of the first-stage plunger 3, the other end is fixed on the outer side of the top circumference of the second-level plunger 4, and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com