Self-weight-adjustable immersed tube of reinforced concrete embedded tube and design and construction method

A technology of reinforced concrete and construction method, applied in caisson, artificial island, water conservancy project and other directions, can solve the problems of difficult construction of navigation and installation, difficult optimization of structural design, difficulty in self-weight adjustment, etc. The effect of time, reducing construction difficulty and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

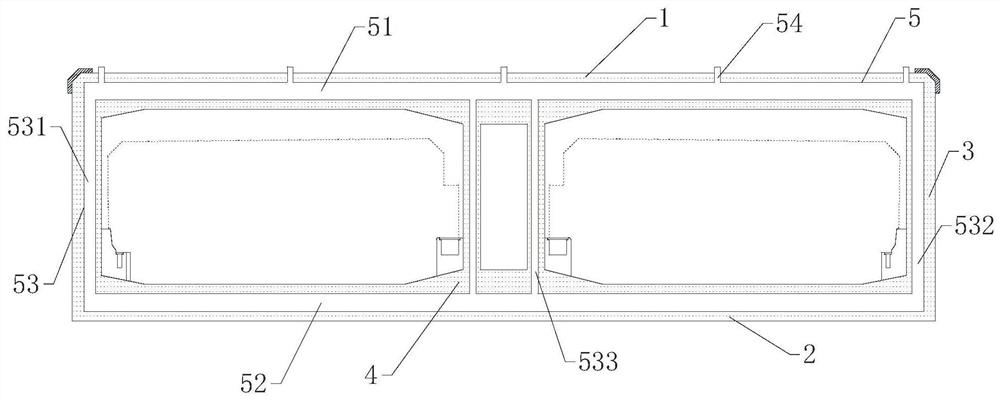

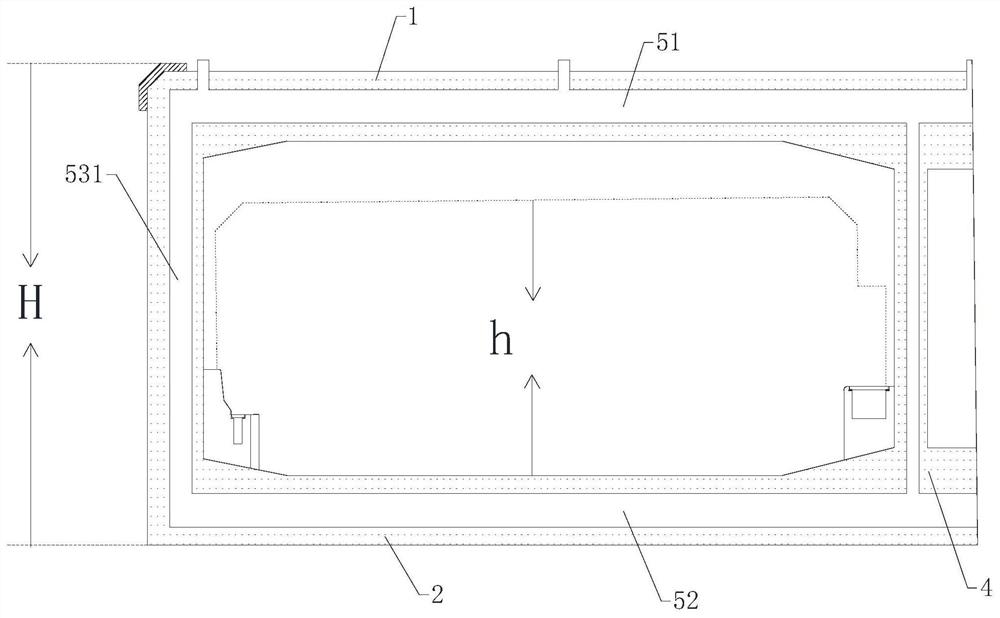

[0062] Please refer to figure 1 , this embodiment provides a reinforced concrete buried pipe with adjustable self-weight immersed tube, including an immersed tube structure body, and a pipeline 5 arranged inside the concrete of the immersed tube structure body, and the immersed tube structure body refers to an entity formed by pouring reinforced concrete part, the immersed tube structure body includes a concrete structure top plate 1, a concrete structure bottom plate 2, a concrete structure side wall 3, and a concrete structure middle wall 4, wherein, the above-mentioned concrete structure components are all formed by binding steel bars and pouring concrete, and the built-in The pipe is provided with an inlet and outlet pipe 54 connecting the inside of the pipe 5 to the outside of the immersed tube structure body. The inlet and outlet pipe 54 is used to pour ballast fluid into the pipe 5. The pipe 5 includes a first built-in pipe 51, a second built-in pipe 52, and a connecting...

Embodiment 2

[0068] This embodiment is roughly the same as Embodiment 1, the differences are: the size of the immersed tube structure body, the third connecting pipe 533 is eliminated in the pipe 5, the transverse through pipe 55 is provided in the pipe 5, the material and size of the pipe 5, etc.

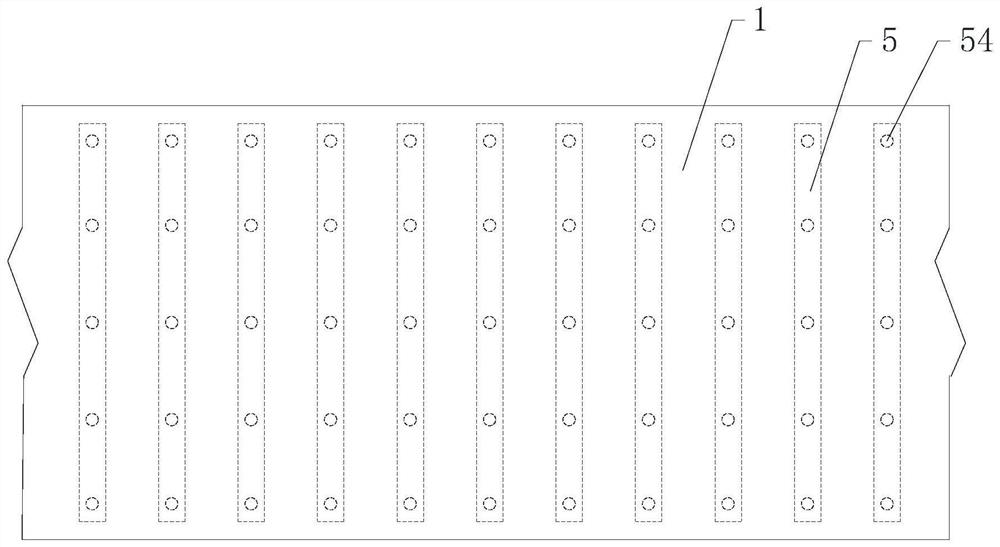

[0069] Please refer to Figure 4 and Figure 5 , this embodiment uses multiple groups of pipes 5, which are the same as in Embodiment 1, and also set up transverse through pipes 55 between the multiple groups of pipes 5, the spacing between adjacent groups of pipes 5 is 800mm, and the width of the transverse through pipes 55 Both ends are used to connect adjacent groups of pipes 5, and a plurality of transverse through pipes 55 can be connected between adjacent groups of pipes 5, and the connection position is not limited to a specific part of the pipes 5, such as the first built-in pipe 51 can be connected , the second built-in pipe 52, the first connecting pipe 531 and the second connecting ...

Embodiment 3

[0072] This embodiment is substantially the same as Embodiment 1, except for the arrangement of the transverse through-pipe 55 , the structure, material and size of the pipe 5 , and the arrangement of the inlet and outlet pipes 54 .

[0073] Please refer to Image 6 and Figure 7 , in this embodiment, the transverse through pipes 55 are connected between each adjacent two groups of pipes 5, and similarly, the two ends of the transverse through pipes 55 are respectively connected to the first built-in pipe 51 of the adjacent group or the second built-in pipe of the adjacent group. Pipe 52, a total of three transverse through pipes 55 are arranged to connect the first built-in pipe 51, and three transverse through pipes 55 are connected to the second built-in pipe 52, so that every two groups of pipes 5 and six through pipes together constitute a perfusion unit. The structure is the same as that of the first embodiment, and the circuit composed of the first built-in pipe 51 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com