Elevator pit maintaining, checking and protection system

An elevator pit, inspection and protection technology, applied in the field of elevators, to achieve the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

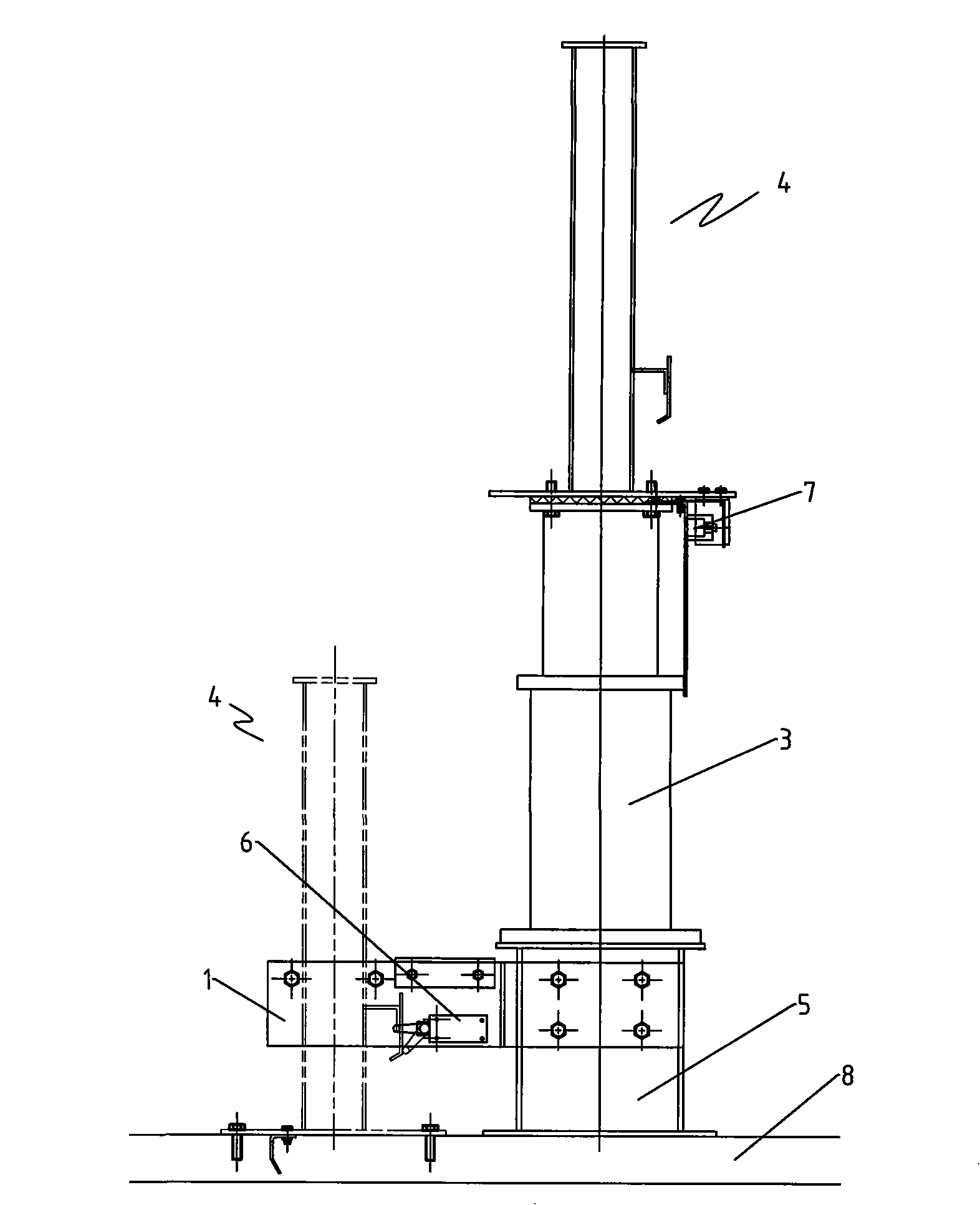

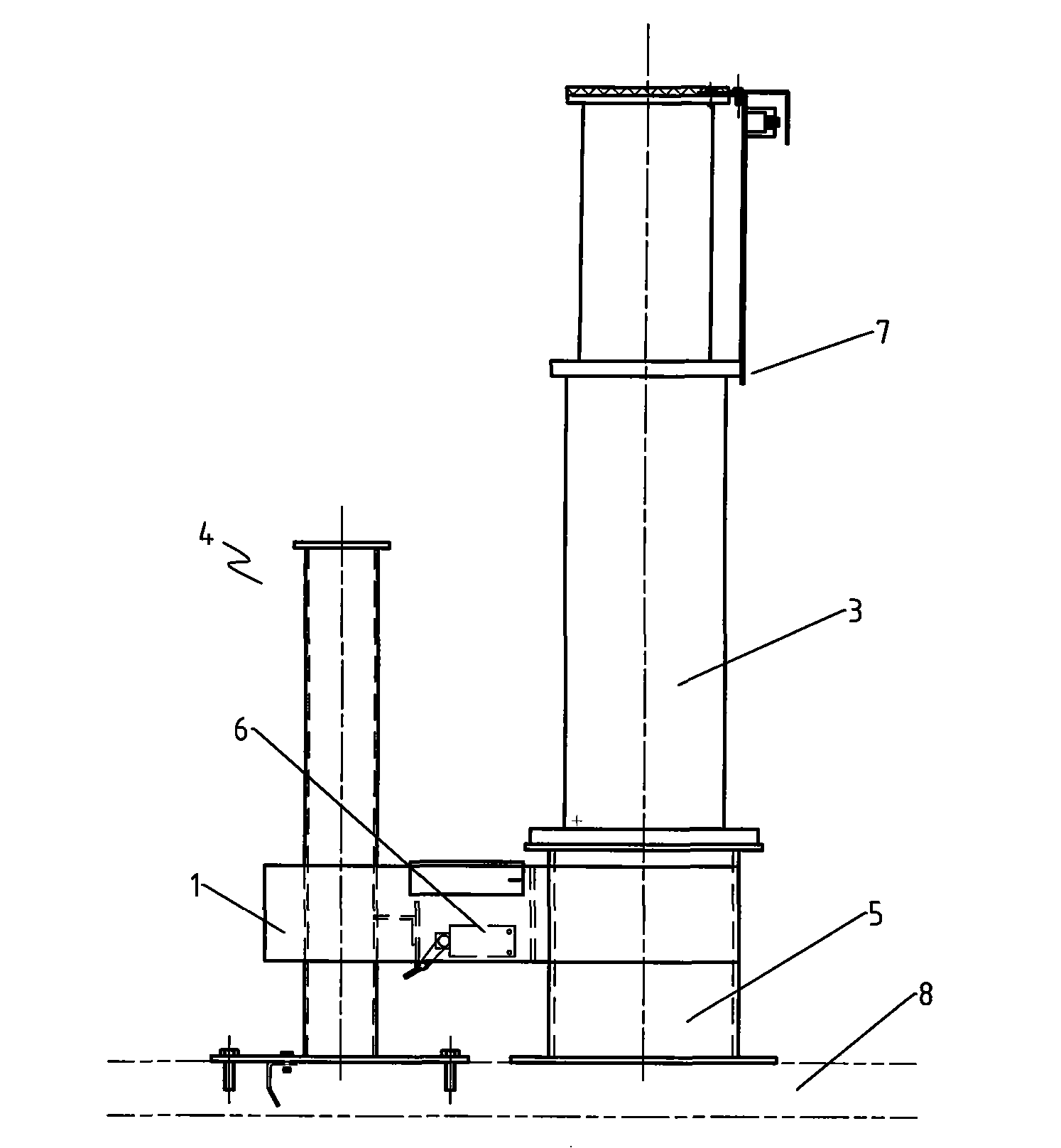

[0037] like image 3 As shown, when the elevator needs to be overhauled, the maintenance personnel enter the pit, and according to the operation instructions of the pit, the maintenance protection device 4 is detached from the bottom pit base and the limit bracket and fixed on the car buffer 3 by bolts. On the support surface, another detection switch 7 detects the existence of the maintenance protection device 4 and sends a signal to the elevator control system to control the elevator to be in the inspection running state. At this time, the pit of the elevator is equivalent to a safe space that meets the requirements for the depth of the pit in 5.7.3.3 of the "GB7588-2003 Safety Code for Elevator Manufacturing and Installation". After the maintenance personnel complete the work, the maintenance protection device must be detached from the car buffer and reset to figure 2 Only in the form shown can the elevator return to the normal operation state, otherwise, the elevator can...

Embodiment 2

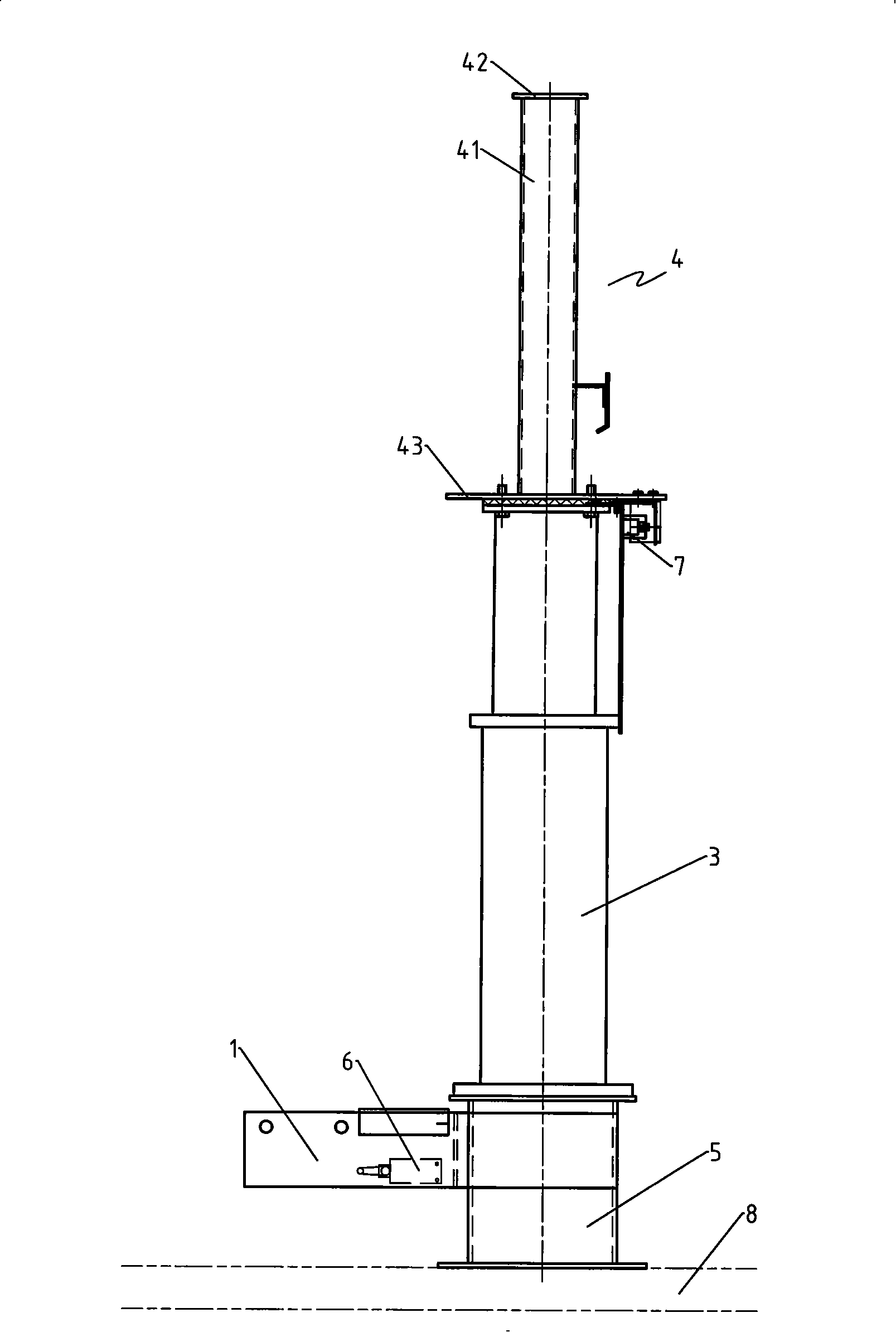

[0041] like Figure 8 , Figure 9 As shown, when the elevator needs to be overhauled, the maintenance personnel enter the pit, and according to the operation instructions of the pit, detach the maintenance protection device 4 from the limit bracket 1 and insert the post of the maintenance protection device 4 into the buffer 3 Cylindrical endoporus 31 gets final product, and this moment, maintenance protection device 4 can trigger another detection switch 7 action in the buffer seat, and another detection switch sends signal to elevator control system control elevator and is in maintenance running state. During the inspection running state, only the auxiliary inspection control device 2 is allowed to control the elevator to perform inspection operation. At this time, the pit of the elevator is equivalent to a safe space that meets the requirements for the depth of the pit in 5.7.3.3 of the "GB7588-2003 Safety Code for Elevator Manufacturing and Installation". After the maintena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com