Method for increasing elvator pit examination and repair safety space and elvator pit maintain check protection system

A technology for elevator pits and safe spaces, applied in the field of elevators, can solve problems such as the depth of large pits and the impact of buildings, and achieve the effect of saving construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

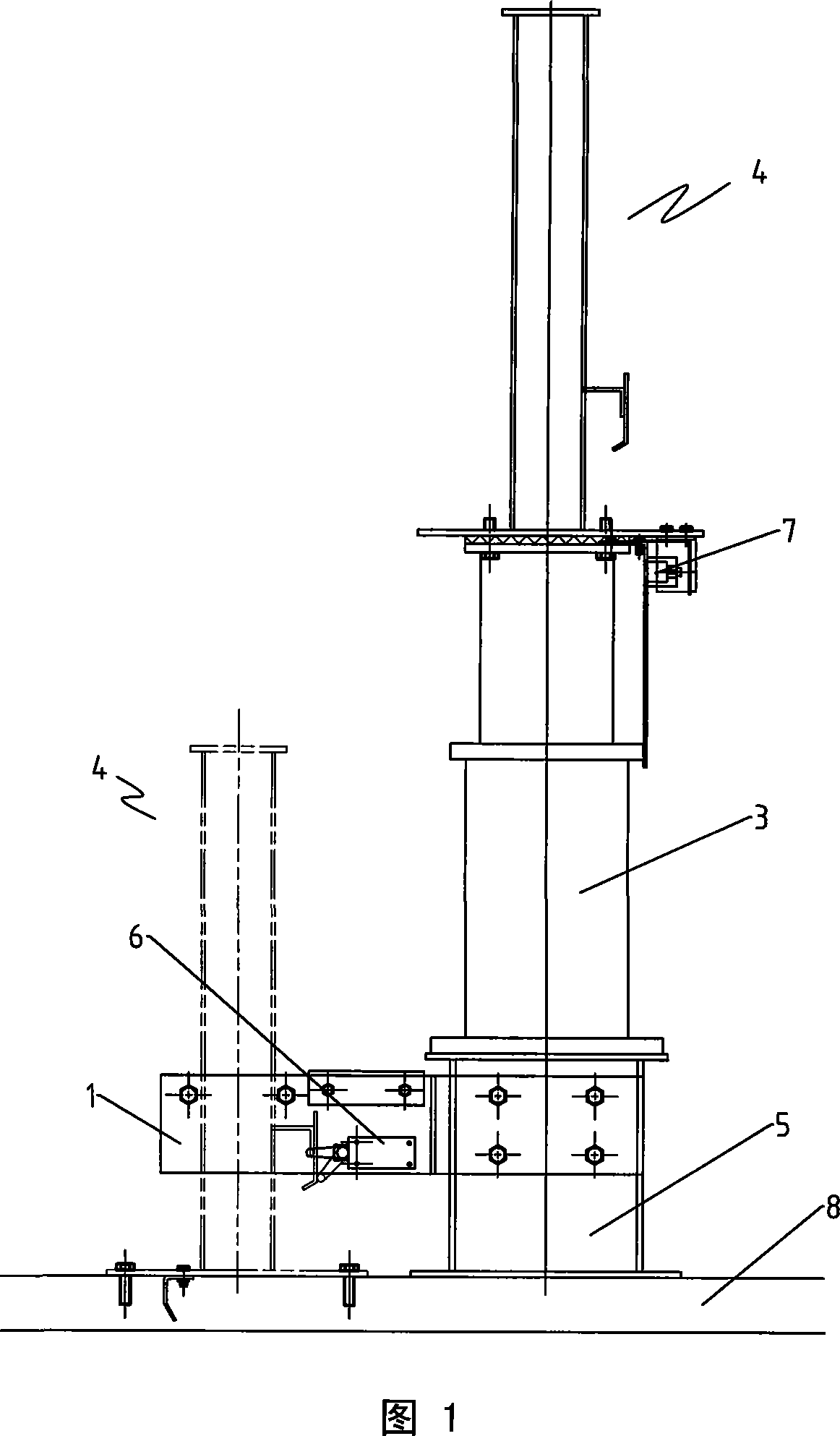

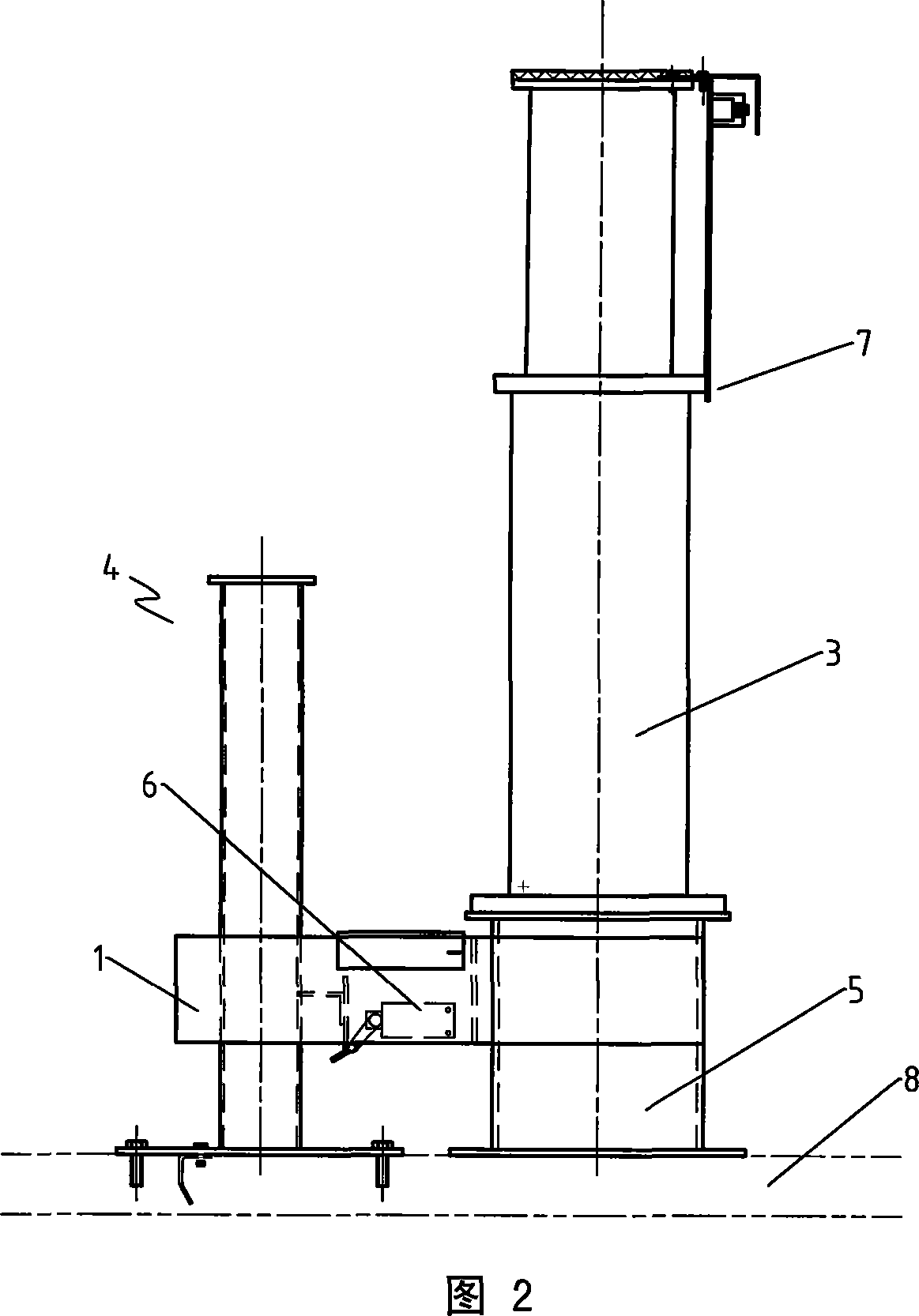

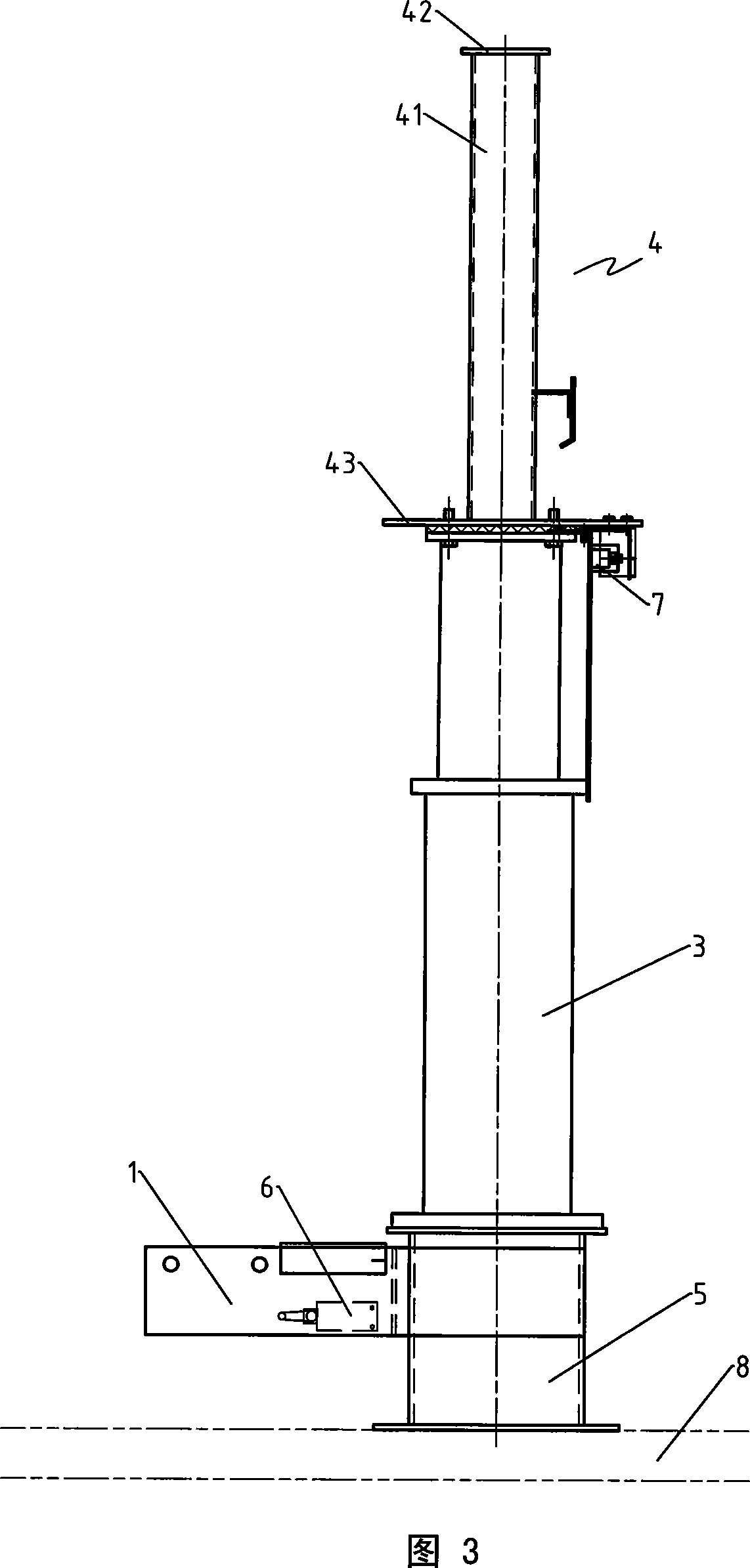

[0035] As shown in Figures 1 to 5, the elevator pit maintenance, inspection and protection system according to the present invention mainly consists of a pit base 8 installed in the pit, a buffer seat 5, a car buffer 3, a detection system, and a secondary detection system. The control device 2 and the maintenance protection device 4 are composed. In this embodiment, the car buffers 3 are oil pressure buffers, the number is 1-2, and they are arranged side by side on the base 8 of the pit. The main body of maintenance protection device 4 is a column body 41, and one end of column body 41 has a support surface 42, and the installation part 43 of column body other end is an installation end surface, and each maintenance protection device can be installed on the car by installation part 43 movably. Car buffer 3 supporting surface. The limit support 1 is installed on the buffer seat 5 by bolts. The detection system includes a limit switch 6 and another limit switch 7, the limit sw...

Embodiment 2

[0039] As shown in Figures 6 to 9, in this embodiment, the difference between the elevator pit maintenance, inspection and protection system of the present invention and Embodiment 1 is that the car buffer 3 is a spring buffer, and the spring buffer There is a cylindrical inner hole 31 in the device; the installation part 43 of the maintenance protection device 4 is a post; the other limit switch 7 is installed in the buffer seat. Other structures are the same as in Embodiment 1. When the cylinder of the maintenance protection device 4 is fixed between the limit brackets 1 by bolts, it does not need to be fixed with the pit base. When the maintenance protection device 4 needs to be installed on the buffer, it is only necessary to insert the post into the cylindrical inner hole in the buffer.

[0040] As shown in Figure 7, when the maintenance protection device 4 is fixed between the limit brackets 1, the detection switch 6 will be triggered to act, and the detection switch se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com