Slipway and ship transfer method

A technology for berths and ships, which is applied in the direction of berths, ships, transportation and packaging, etc., and can solve problems such as high cost and ecological damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

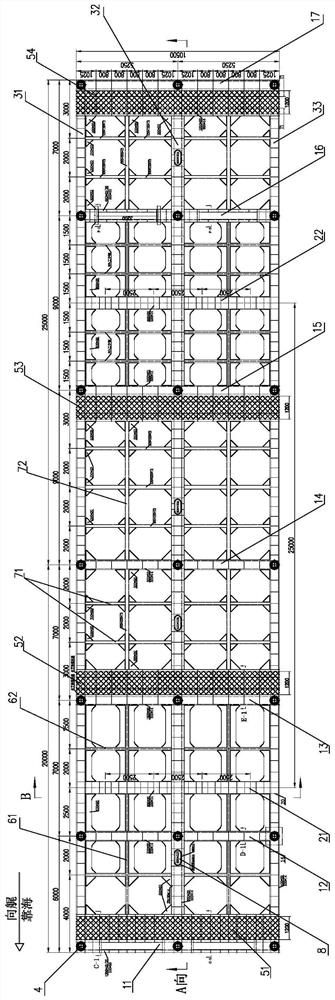

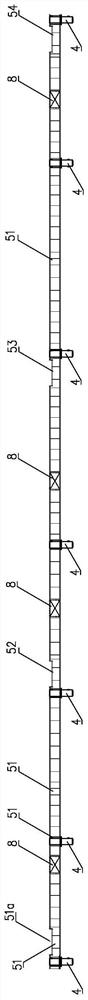

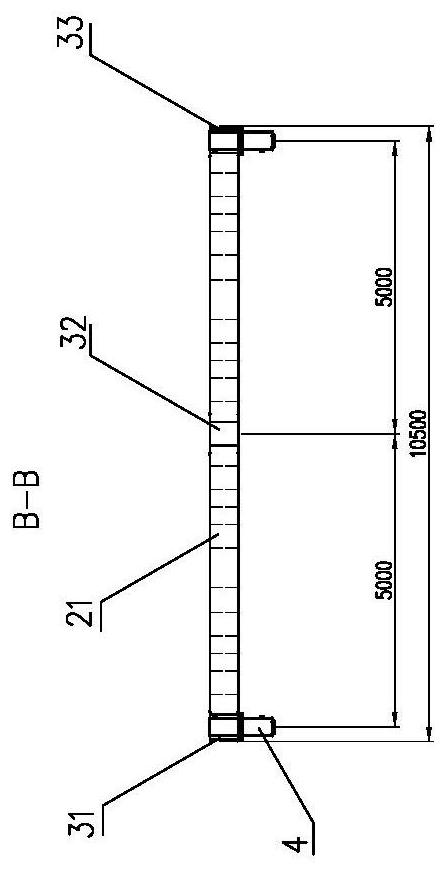

[0061] Embodiment 1 This embodiment provides a slipway, including a frame body, a connecting structure and a lifting mechanism arranged at the bottom of the frame body. Such as figure 1 As shown, the frame body is a rectangular single-layer truss structure, with the length direction of the frame body as the longitudinal direction. At least one longitudinal middle rod and horizontal middle rod are respectively distributed between the beams, and the longitudinal beams, cross beams, longitudinal middle rods, and horizontal middle rods are made of steel materials. In order to ensure the structural strength of the frame, the length of the frame can be adjusted according to the hull length of the corresponding ship. For example, when it is applied to a ship with a hull length of less than 25m, the frame can be composed of at least 3 longitudinal beams and at least 5 beams; When applied to ships with a hull length of 50~65m, such as figure 1 As shown, it is equipped with 3 longitud...

Embodiment 2

[0074] Embodiment 2 The difference between this embodiment and Embodiment 1 is that the combination figure 1 right side and Figure 9 , Figure 10 As shown, in this embodiment, the frame body corresponds to the front end of the ship and has at least one side support mechanism on both lateral sides (see Figure 11 shown): as Figure 10 As shown, part of the upper surface of the sub-beam six between the first and second longitudinal beams, and between the second and third longitudinal beams is provided with an upper slot structure—that is, an open design, in which the second hydraulic rod is installed 1. Support rod, one end of the support rod is hinged to the side of the auxiliary beam six close to the second longitudinal beam, and the other end of the support rod is close to a certain point in the middle ( figure 1 The example in the example is 400mm away from the other end) and the movable end of the hydraulic rod is hinged, and the other end of the hydraulic rod is hinged...

Embodiment 3

[0075] Embodiment 3 The difference between this embodiment and Embodiment 1 is that a support adjustment mechanism is provided (see Figure 17 shown): Combined figure 1 left and Figure 4 As shown, the upper part of the sub-beam is also provided with an upward slot—that is, an open design, which allows the sub-beam to be connected to the outside world and can be installed inside it. Raised third hydraulic lever. The third hydraulic rod can extend upwards and touch the bottom of the rear side of the ship to assist in fixing the ship.

[0076] In this embodiment, a two-way universal joint vertical output structure is used in combination with a translation screw and a translation handwheel, such as Figure 17 The translation structure shown in , enables the third hydraulic rod to move appropriately in the slot in the length direction of the auxiliary beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com