A method of constructing a semi-submersible vessel using dry dock mating

A semi-submersible, dry-dock technology, used in dry-dock, ship construction, hull, etc., to solve problems such as high-risk connection operations, harsh sea conditions, and uncontrollable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

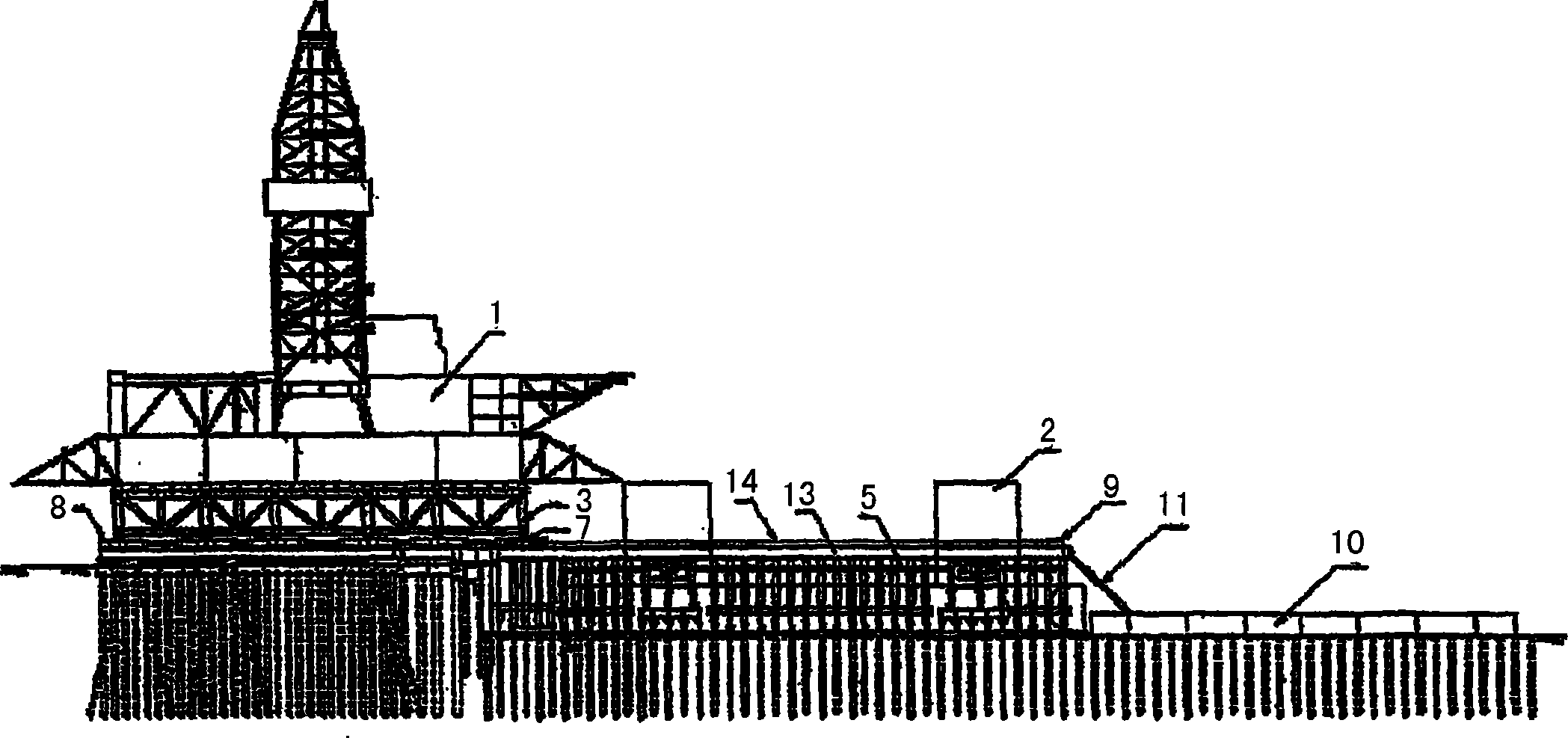

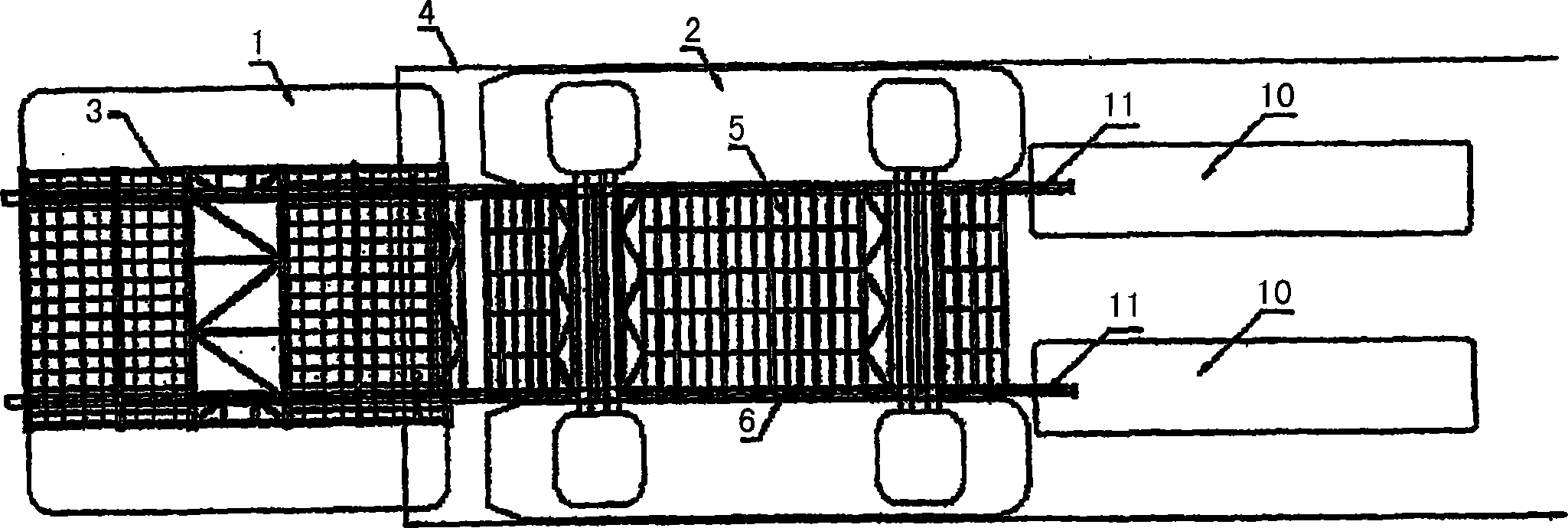

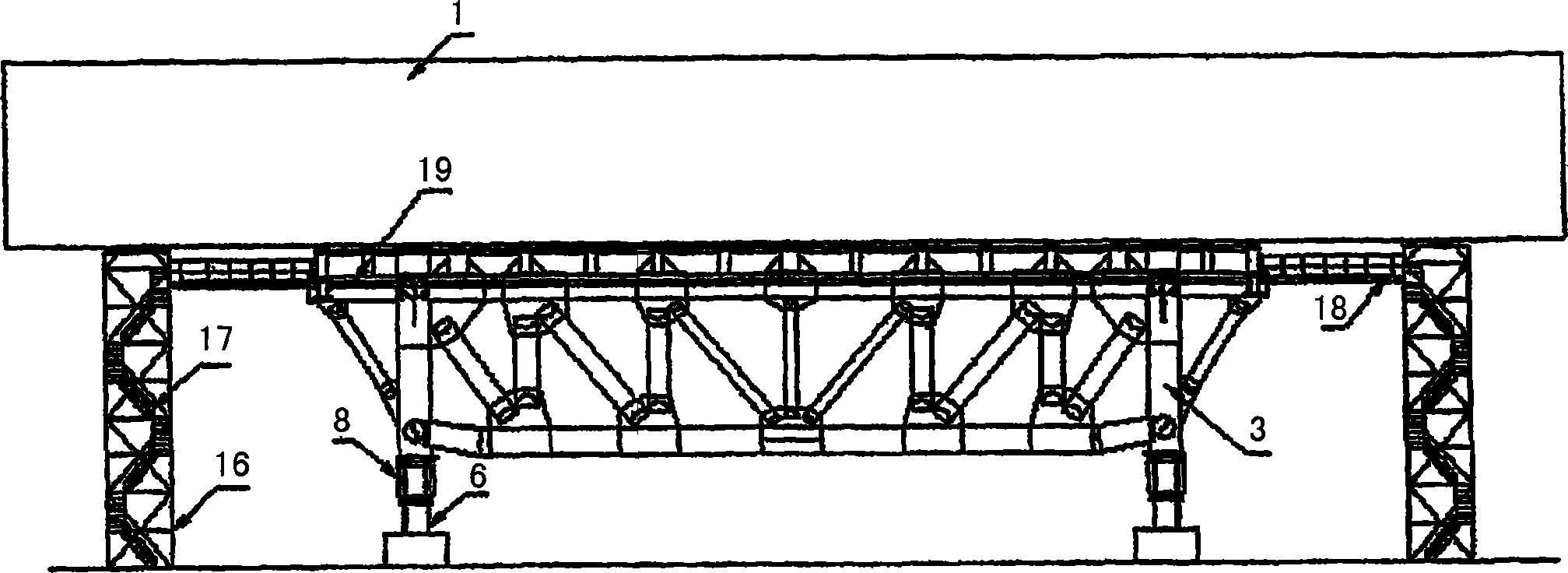

[0024] Now describe in more detail in conjunction with accompanying drawings, figure 1 and figure 2 A general setup of a dock is shown, including a dry dock, in which a semi-submersible drilling rig according to the invention has been built and engaged. Such as figure 1 and figure 2 As shown, the semi-submersible drilling equipment includes an upper shell 1 and a lower shell 2 . During construction, the upper hull 1 is supported by sliding trusses 3 located on the shore adjacent to the dry dock 4 . The truss 3 is also designed to be able to slide the entire upper shell on the sliding beam 6 using the sliding shoes 8 during unloading operations. The auxiliary support structure 5 or support truss 5 is erected in the dry dock 4 .

[0025] Sliding beams or connecting members 6 extend between the support truss 5 and the bottom of the sliding truss 3 . The connecting members 6 are removed from the support trusses after the joining operation is complete, as will be described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com