Immersed tube segment batch prefabricating method capable of reducing scale of dry dock

A technology of pipe joints and dry docks, applied in construction, artificial islands, infrastructure engineering, etc., can solve the problems of difficult concrete compactness and water tightness requirements, high cost of temporary dredging of waterways, and high requirements for concrete construction, so as to improve the compactness High degree and water tightness, reduced negative impact and temporary construction cost, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

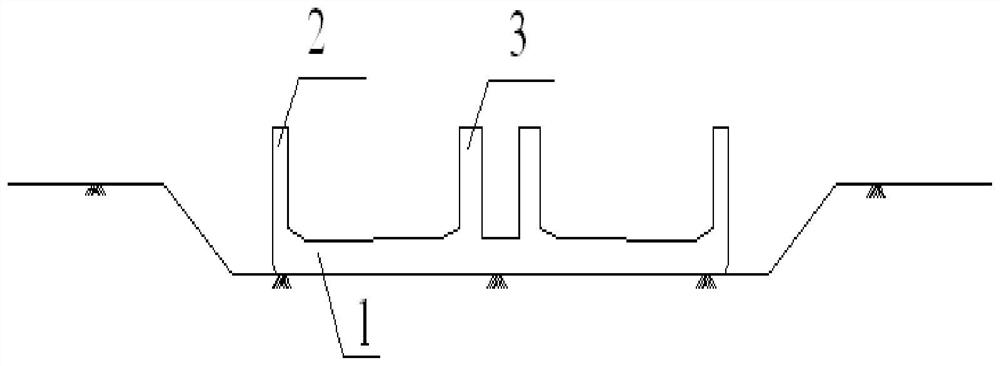

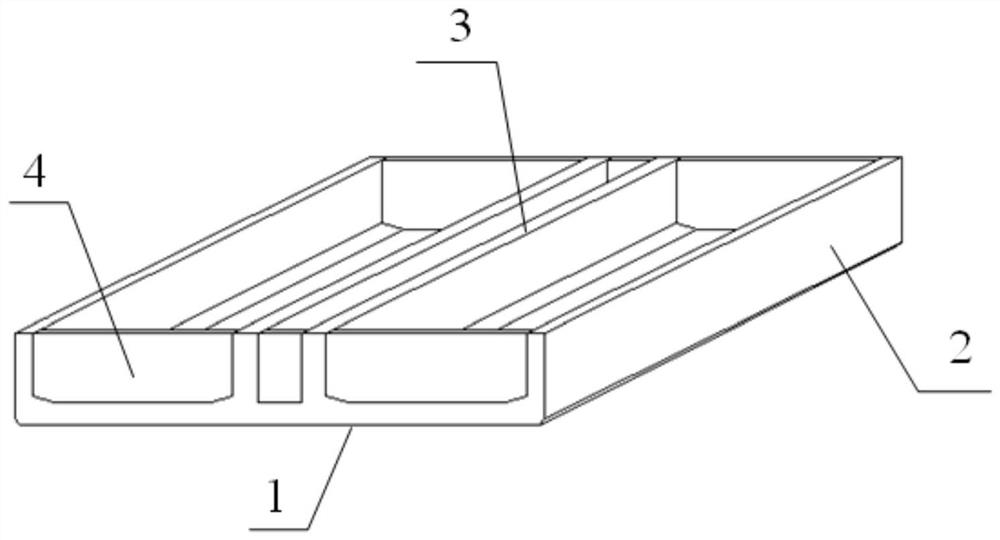

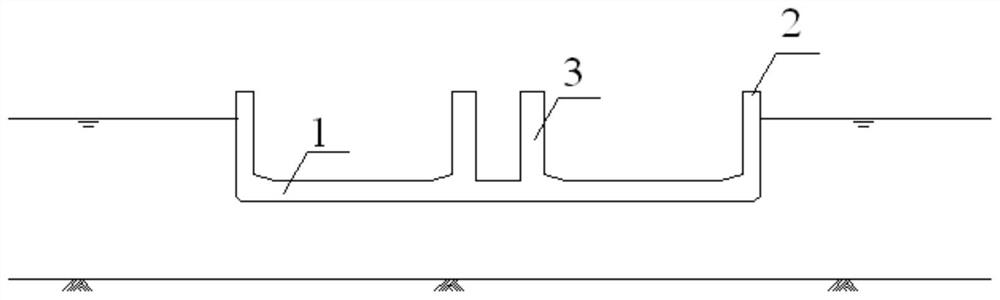

[0037] Embodiment 1: as Figures 1 to 6 As shown, a batch prefabrication method of immersed tube joints that can reduce the scale of dry dock, specifically includes the following steps:

[0038] S1, select a site near the tunnel site and build a small temporary dry dock;

[0039] S2, pouring an open-type pipe joint structure in the small temporary dry dock built in step S1, the open-type pipe joint structure includes a pipe joint bottom plate 1, part of the pipe joint side walls 2, a pipe joint middle partition wall 3, and The sealing door 4 at both ends of the joint, wherein: the schematic diagram of the structure of the open pipe joint is as follows figure 2 shown;

[0040] S3, injecting water into the dry dock to make the open pipe joint structure float in the dry dock;

[0041] S4, select a non-silting prefabricated site in the water area near the tunnel site, and level the foundation of the prefabricated site; place multiple uninflated airbags 5 in the prefabricated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com