Novel three-roller grinding mill

A three-roll mill and mill technology, which is applied in grain processing and other directions, can solve problems such as inconvenient movement, and achieve the effects of low production cost, convenient movement and adjustment, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A preferred embodiment of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0015] Such as figure 1 Shown:

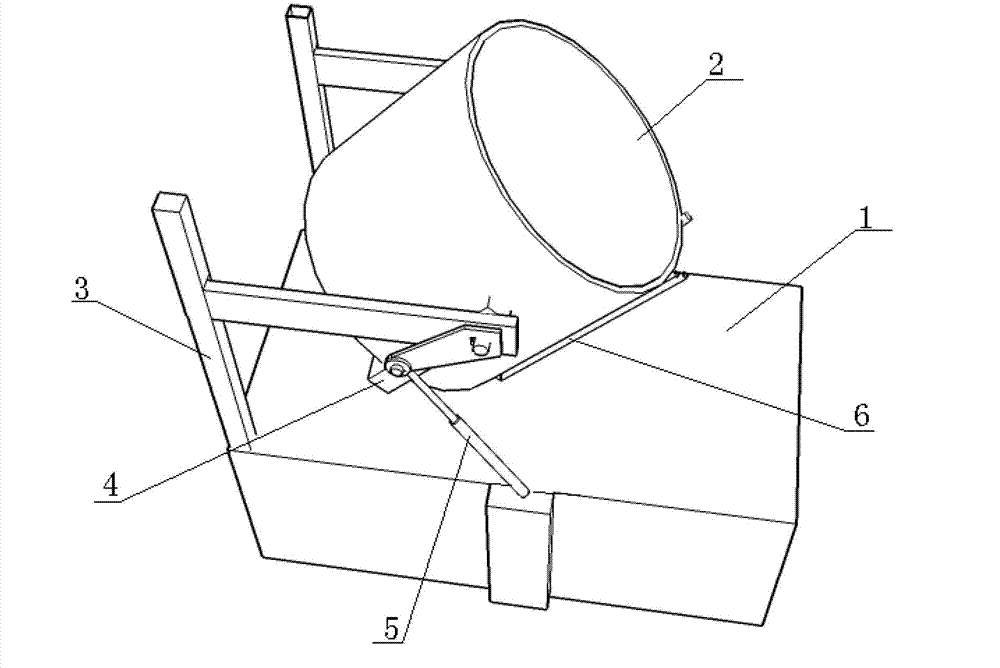

[0016] The new three-roller grinder includes a grinder body 1, a bracket 3 is provided on the grinder body 1, and an ink injection device is installed on the bracket 3, and the ink injection device includes a barrel 2, a base 4 and a hydraulic system 5 , the base 4 is U-shaped, the bottom of the base 4 is welded with a plurality of L-shaped support rods 6, the base 4 is fixedly supported on the outside of the barrel 2, the two ends of the base 4 are connected with the bracket 3 through bearings, and the two ends of the base 4 The part extending from the bracket 3 is connected with the hydraulic steel piston of the hydraulic system 5 through a connecting piece.

[0017] The ink injection device is installed on the grinder body 1, and the hydraulic system 5 automatically adjusts the inclination angle of the bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com