Liquid coating for protecting surface of aluminum substrate, and preparation method thereof

A technology of liquid coatings and aluminum substrates, applied in the field of coatings, can solve the problems of high temperature resistance, poor adhesion, and acid and alkali resistance of the coating, and achieve the effects of improving production efficiency, reducing production costs, and eliminating cleaning steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

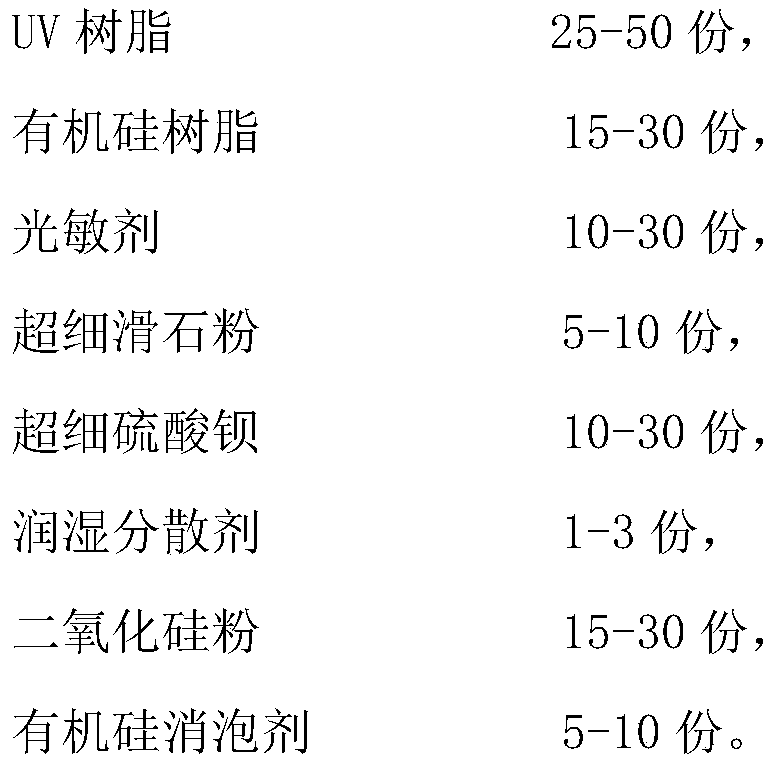

[0028] A liquid coating for protecting the surface of an aluminum substrate, comprising the following components by weight:

[0029]

[0030] The particle size of the superfine talcum powder is 3000 mesh.

[0031] The fineness of ultra-fine barium sulfate is 0.28μm.

[0032] A preparation method for a liquid coating for aluminum substrate surface protection, comprising the following steps:

[0033] (1) Mix the UV curable resin and the UV silicone oligomer, stir and mix to obtain the first mixture; wherein the stirring speed is 500 rpm, and the stirring time is 3 minutes;

[0034] (2) Add photoinitiator 907 to the first mixture, stir and mix to obtain the second mixture; wherein the stirring speed is 500 rpm, and the stirring time is 3 minutes;

[0035] (3) Add ultra-fine talc powder, ultra-fine barium sulfate, silicon dioxide powder and wetting and dispersing agent in the second mixture, stir and mix to obtain the third mixture; wherein the stirring speed is 500 rpm, and ...

Embodiment 2

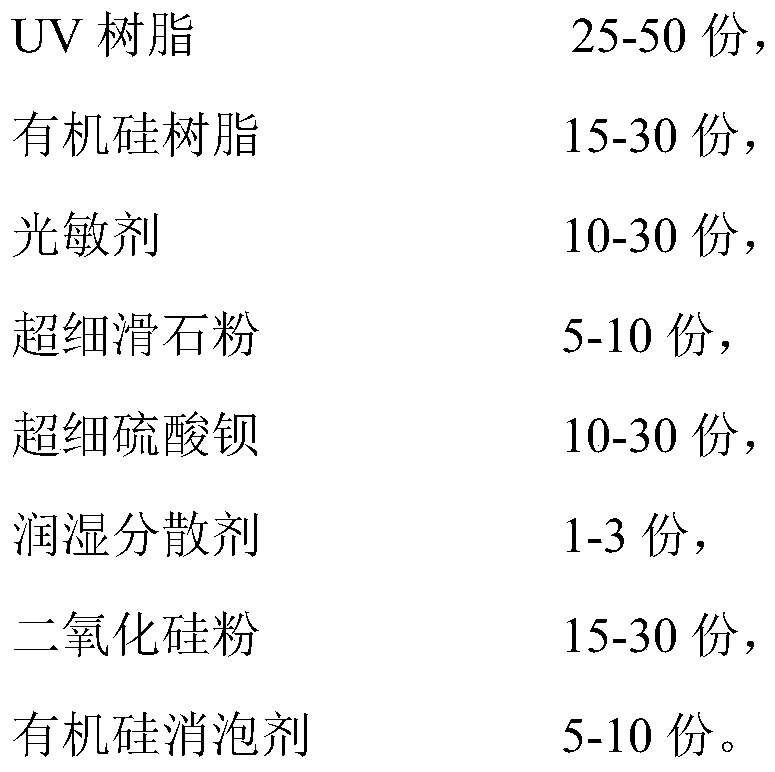

[0040] A liquid coating for protecting the surface of an aluminum substrate, comprising the following components by weight:

[0041]

[0042] Wherein, the particle diameter of the ultrafine talcum powder is 3500 mesh.

[0043] Wherein, the fineness of the ultrafine barium sulfate is 0.25 μm.

[0044] A preparation method for a liquid coating for aluminum substrate surface protection, comprising the following steps:

[0045] (1) Mix UV epoxy acrylic resin and epoxy modified silicone resin, stir and mix to obtain the first mixture; wherein the stirring speed is 600 rpm, and the stirring time is 5 minutes;

[0046] (2) Add photoinitiator ITX in the first mixture, stir and mix to obtain the second mixture; wherein the stirring speed is 600 rpm, and the stirring time is 5 minutes;

[0047] (3) Add ultrafine talc powder, ultrafine barium sulfate, silicon dioxide powder and wetting and dispersing agent in the second mixture, stir and mix to obtain the third mixture; wherein the ...

Embodiment 3

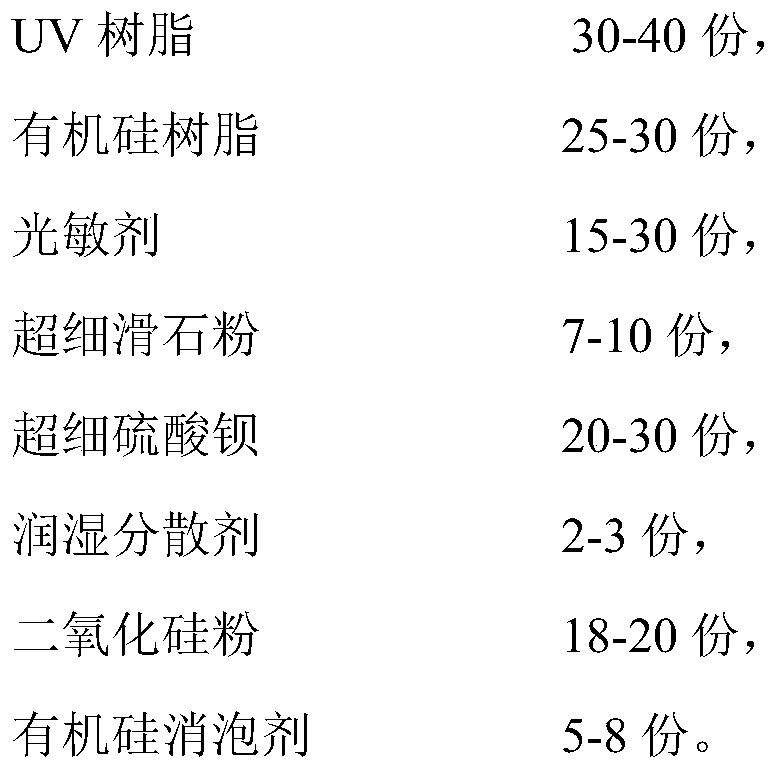

[0052] A liquid coating for protecting the surface of an aluminum substrate, comprising the following components by weight:

[0053]

[0054] Wherein, the particle diameter of the superfine talcum powder is 4000 mesh.

[0055] Wherein, the fineness of the ultrafine barium sulfate is 0.2 μm.

[0056] A preparation method for a liquid coating for aluminum substrate surface protection, comprising the following steps:

[0057] (1) Mix UV urethane acrylate and polymethylphenyl silicone resin, stir and mix to obtain the first mixture; wherein the stirring speed is 650 rpm, and the stirring time is 7 minutes;

[0058] (2) Add photoinitiator 369 to the first mixture, stir and mix to obtain the second mixture; wherein the stirring speed is 650 rpm, and the stirring time is 7 minutes;

[0059] (3) Add ultrafine talcum powder, ultrafine barium sulfate, silicon dioxide powder and wetting and dispersing agent in the second mixture, stir and mix to obtain the third mixture; wherein the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com