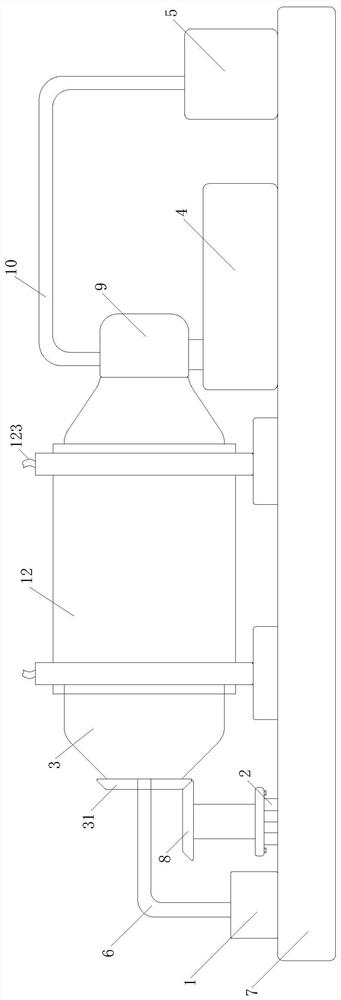

Alcohol distillation system

A distillation system and alcohol technology, applied in the field of alcohol distillation system, can solve the problems of poor distillation effect, influence production efficiency, limited contact time, etc., and achieve the effect of improving distillation effect, reducing cleaning steps, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

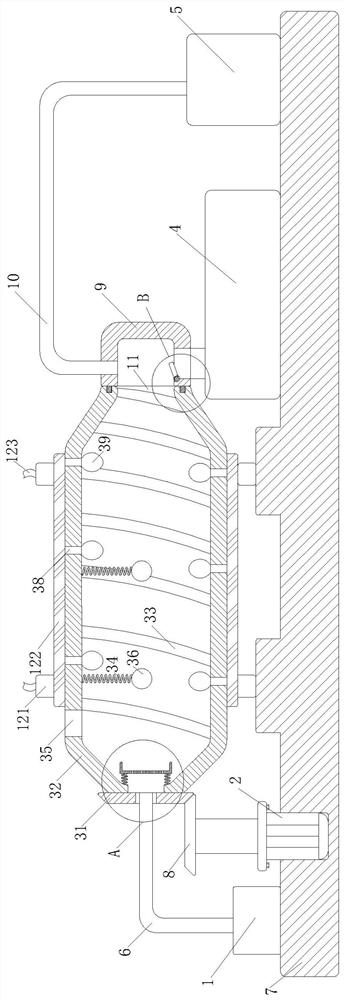

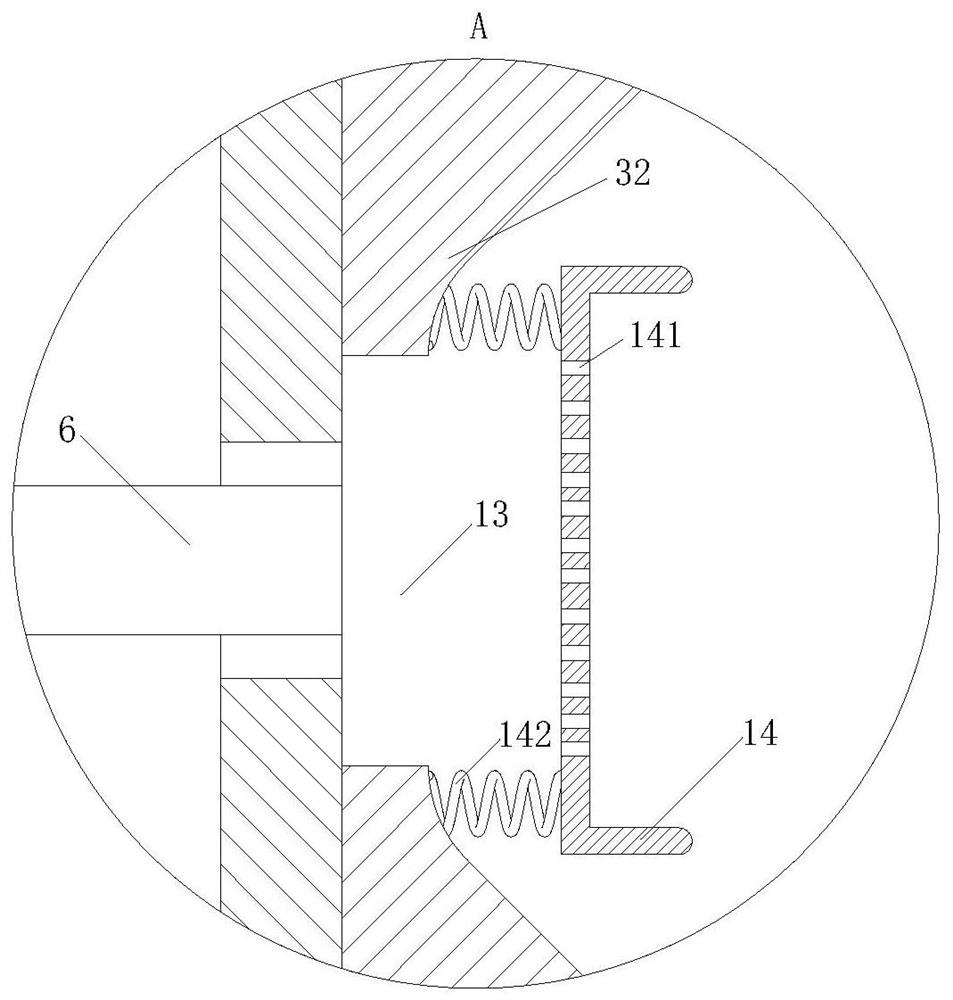

[0036]As a specific embodiment of the present invention, an air slip ring 12 is installed on the outer wall of the tank body 32. The air slip ring 12 includes an air slip ring rotor end 121 and an air slip ring stator end 122. The air slip ring rotor The end 121 is fixedly connected with the outer wall of the tank body 32, the air slip ring stator end 122 is rotationally connected with the air slip ring rotor end 121, and the air slip ring stator end 122 communicates with the air pump through the air pipe 123; More than one air bag 39 is connected, and an air channel 38 is opened at the joint between the tank body 32 and the air bag 39 , and the air channel 38 communicates with the air pipe inside the rotor end 122 of the air slip ring.

[0037] During the rotation of the tank body 32, the stator end 121 of the air slip ring is fixed, and the rotor end 122 of the air slip ring rotates together with the tank body 32. Air is supplied in the air passage 38, and the air pipe 123 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com