Energy-efficient fan filter unit

A fan filter unit and high-efficiency filter technology, which is applied to pump components, mechanical equipment, machines/engines, etc., can solve the problems of time-consuming and labor-intensive, increasing fan energy consumption, and increasing air volume, so as to reduce costs and labor costs. , the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

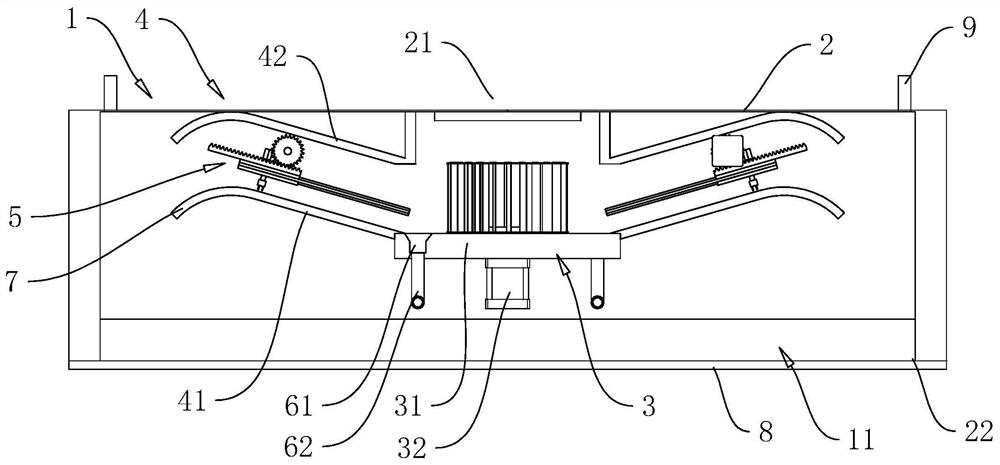

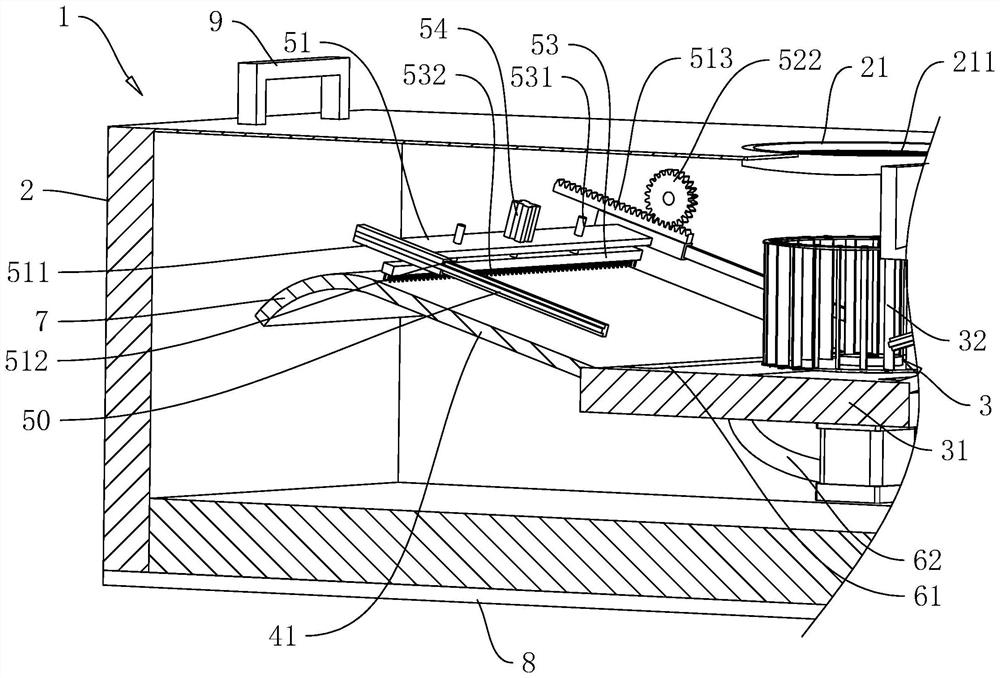

[0034] The following is attached Figure 1-2 The application is described in further detail.

[0035] The embodiment of the present application discloses a high-energy-efficiency fan filter unit. refer to figure 1, including a filter device 1, and a high-efficiency filter 11 is detachably installed at the bottom of the filter device 1. Among them, the filter device 1 includes a shell 2, which is arranged as a hollow square. The structure of the shell 2 can be made of stainless steel, aluminum alloy or cold-rolled steel plate. The material is light in weight and stable in structure, which is beneficial to ensure the shell The service life of body 2.

[0036] The top of the housing 2 is provided with an air inlet 21, the bottom of the housing 2 is provided with an air outlet 22, the high-efficiency filter 11 is located above the air outlet 22, and the inner side of the housing 2 is located at the air outlet of the air inlet 21. A fan unit is installed 3. The air outlet end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com