Patents

Literature

51results about How to "Avoid grinding corners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

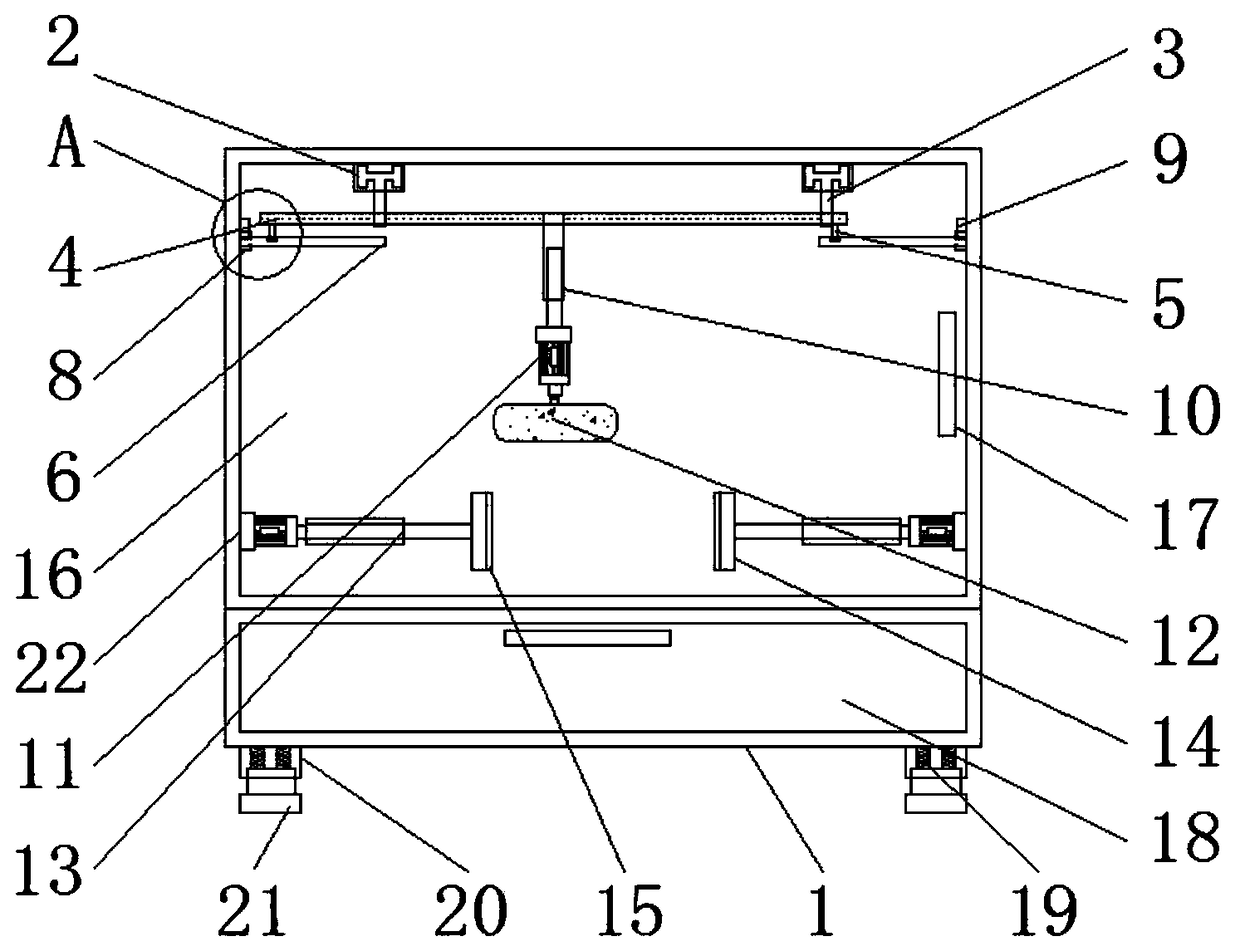

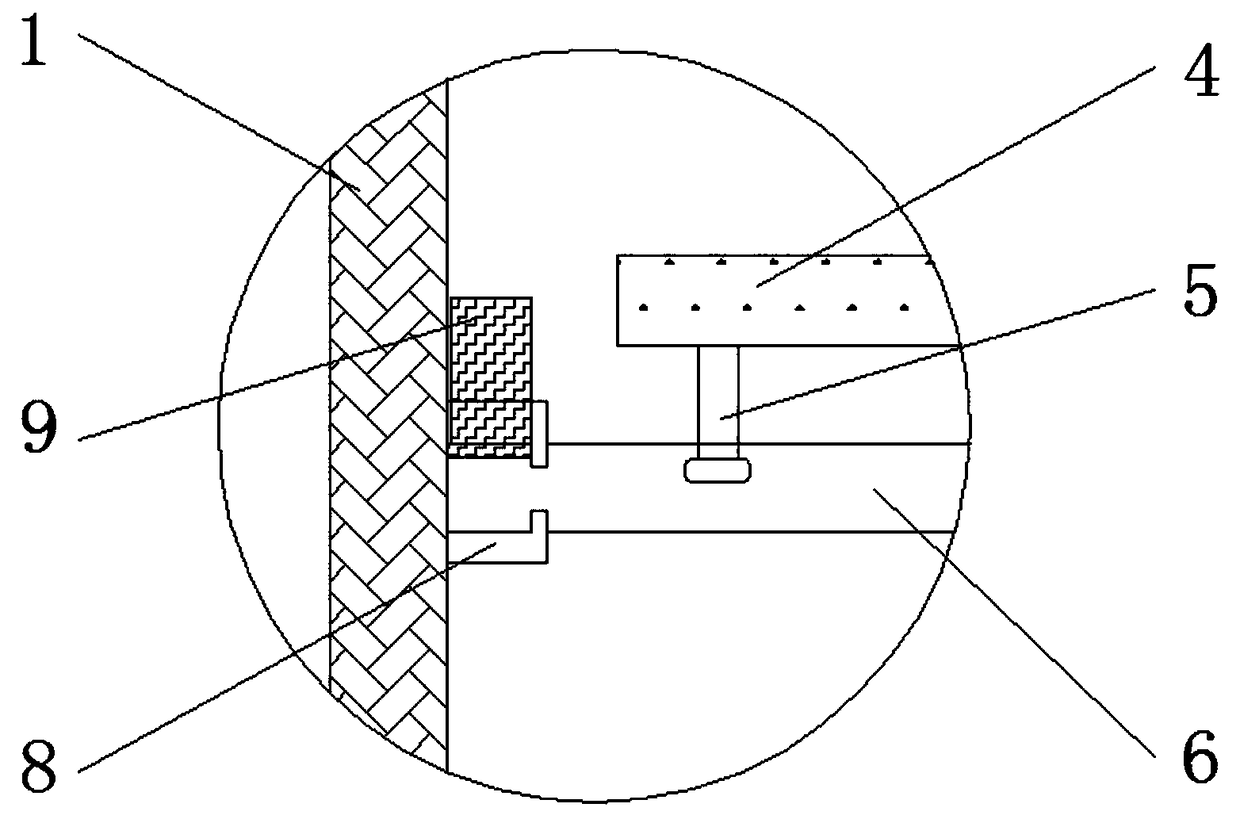

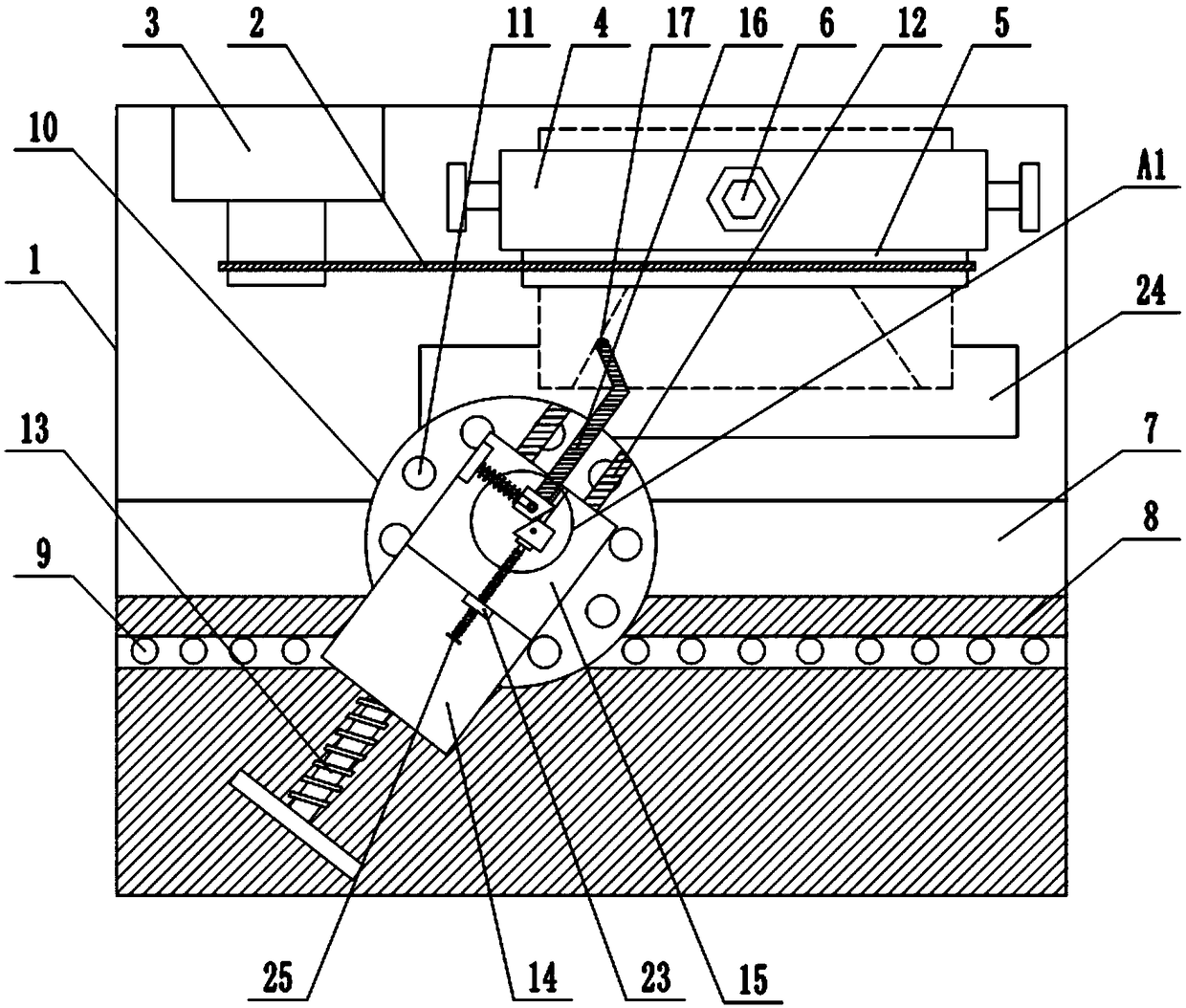

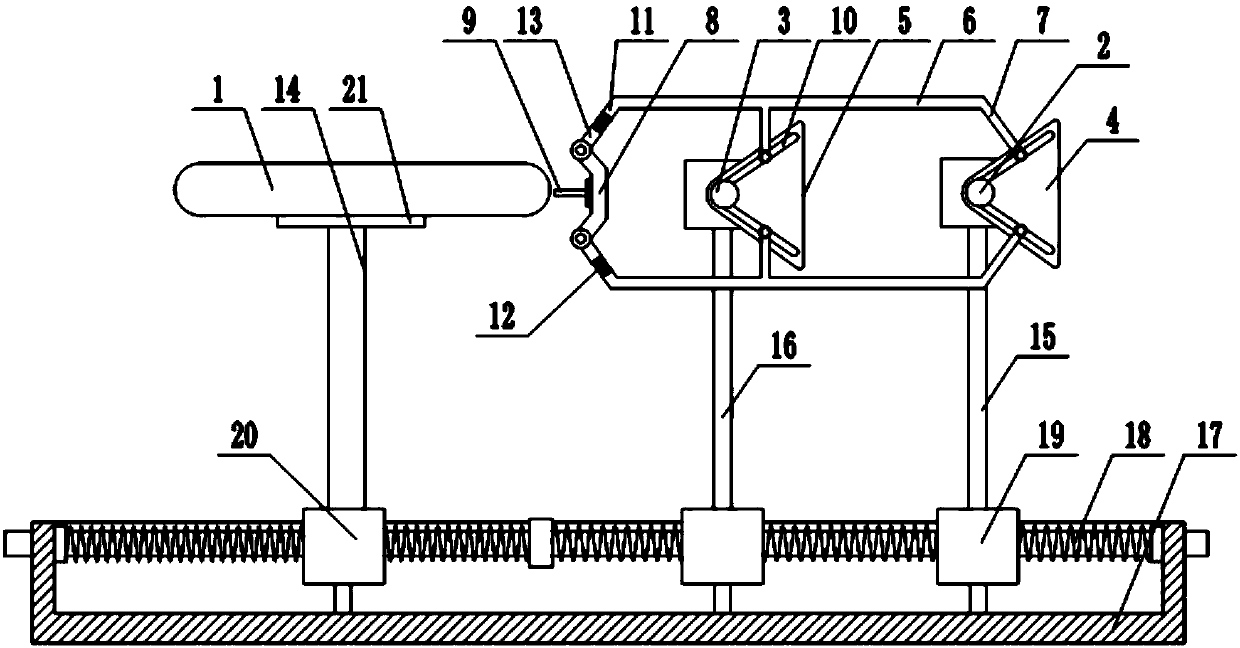

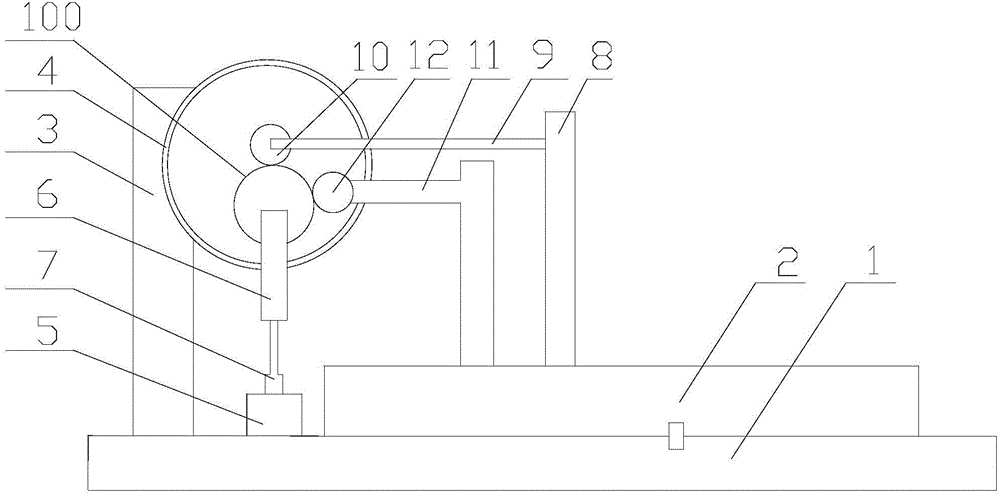

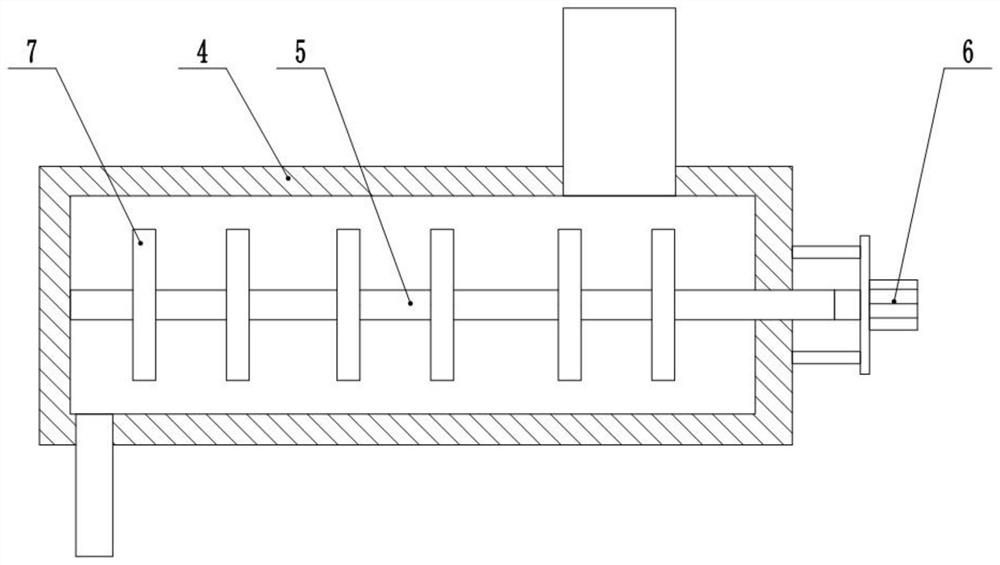

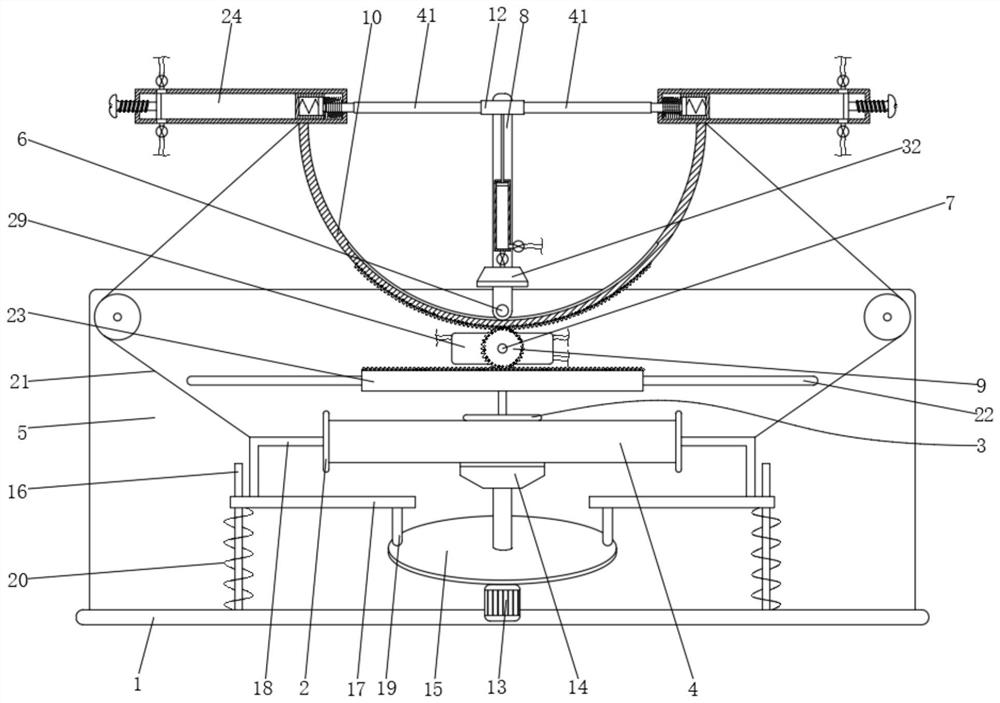

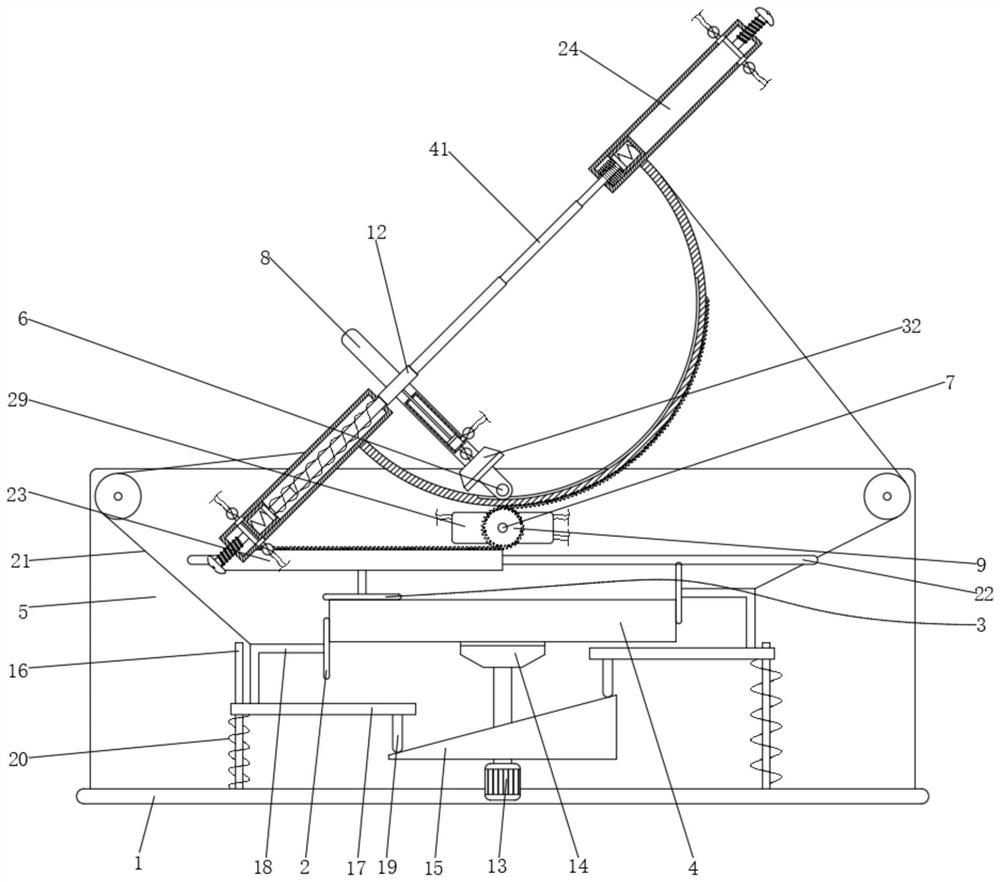

Tabletop processing and polishing device for long metal tables

InactiveCN107443235AAvoid grinding cornersReduce investmentPolishing machinesGrinding drivesDrive shaftFixed frame

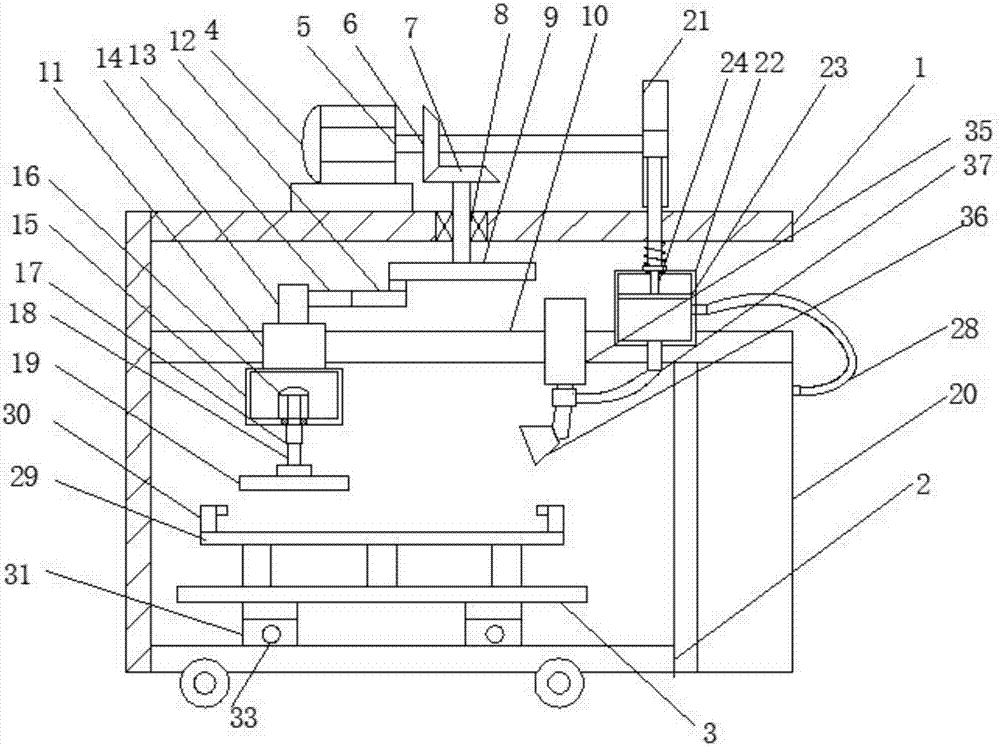

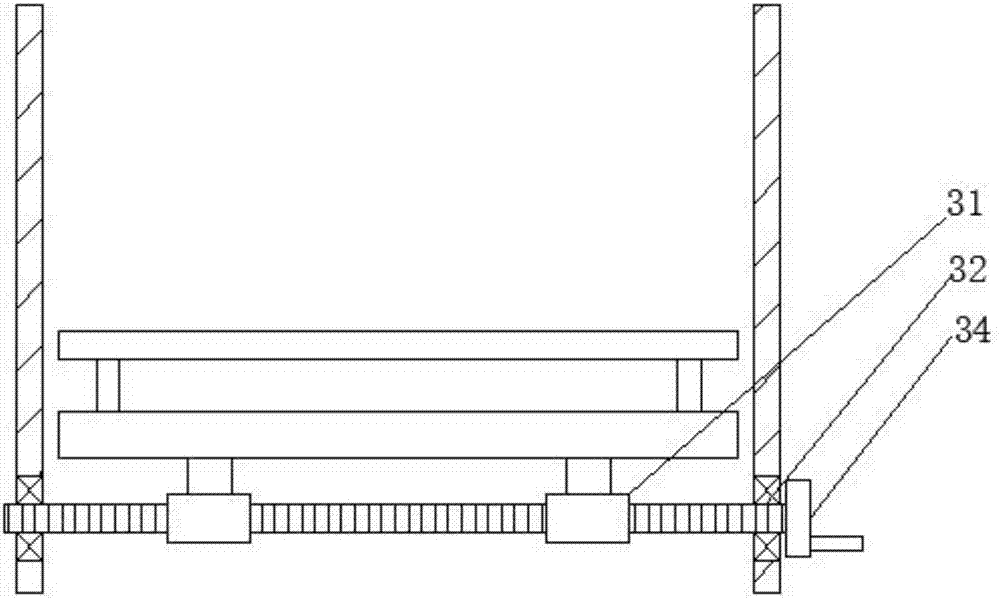

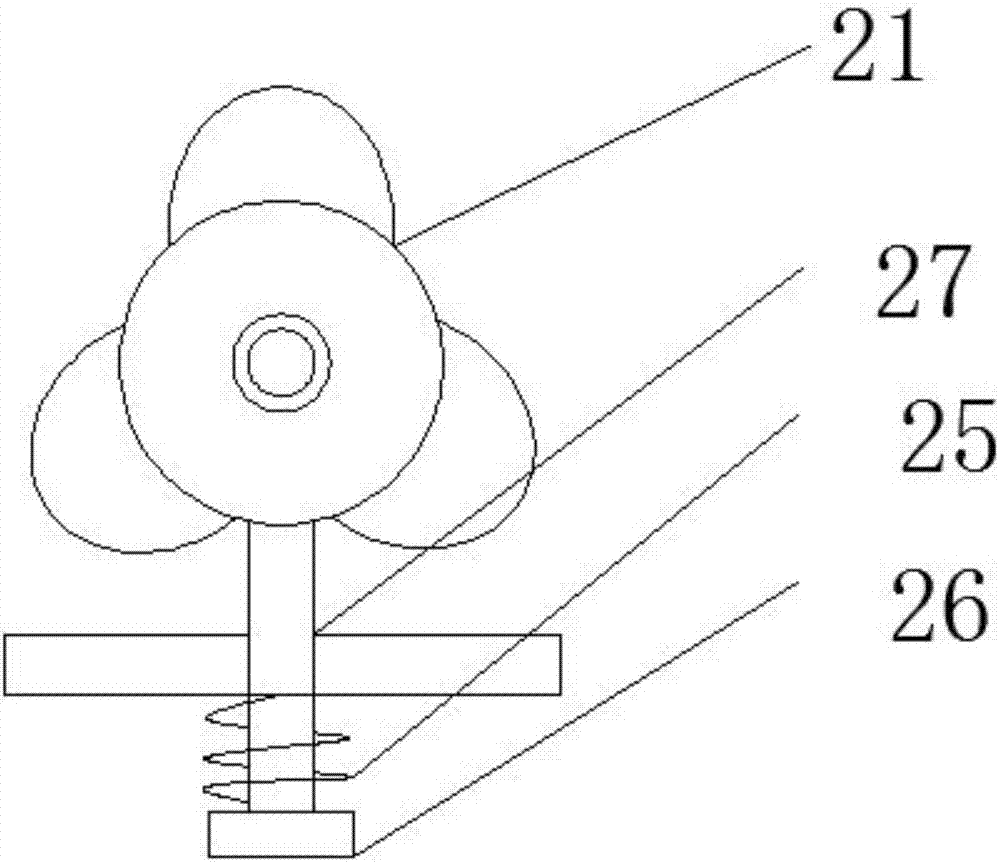

The invention discloses a desktop processing and polishing device for a metal long table, which comprises a frame, a drive motor is installed in the middle of the upper plane of the frame, a rotating shaft is installed at the right end of the driving motor, and the rotating shaft A transmission helical gear is installed on the top, and the middle position of the bottom end of the fixed frame is pierced with a transmission shaft. The top end of the transmission shaft is equipped with a driven helical gear. Engagement, the bottom end of the transmission shaft is equipped with a turntable, the bottom end of the turntable is installed with a first transmission rod, the middle position of the frame is horizontally equipped with a slide bar, and the slide bar is installed with a A slider, the top of the slider is equipped with a connecting block, the top of the connecting block is connected with a second transmission rod, the first transmission rod is connected with the second transmission rod, the present invention makes the feeding cylinder The frequency of liquid discharge is consistent with the frequency of the movement of the grinding disc along the horizontal left and right directions, and the coolant is sprayed out synchronously during grinding.

Owner:朱友富

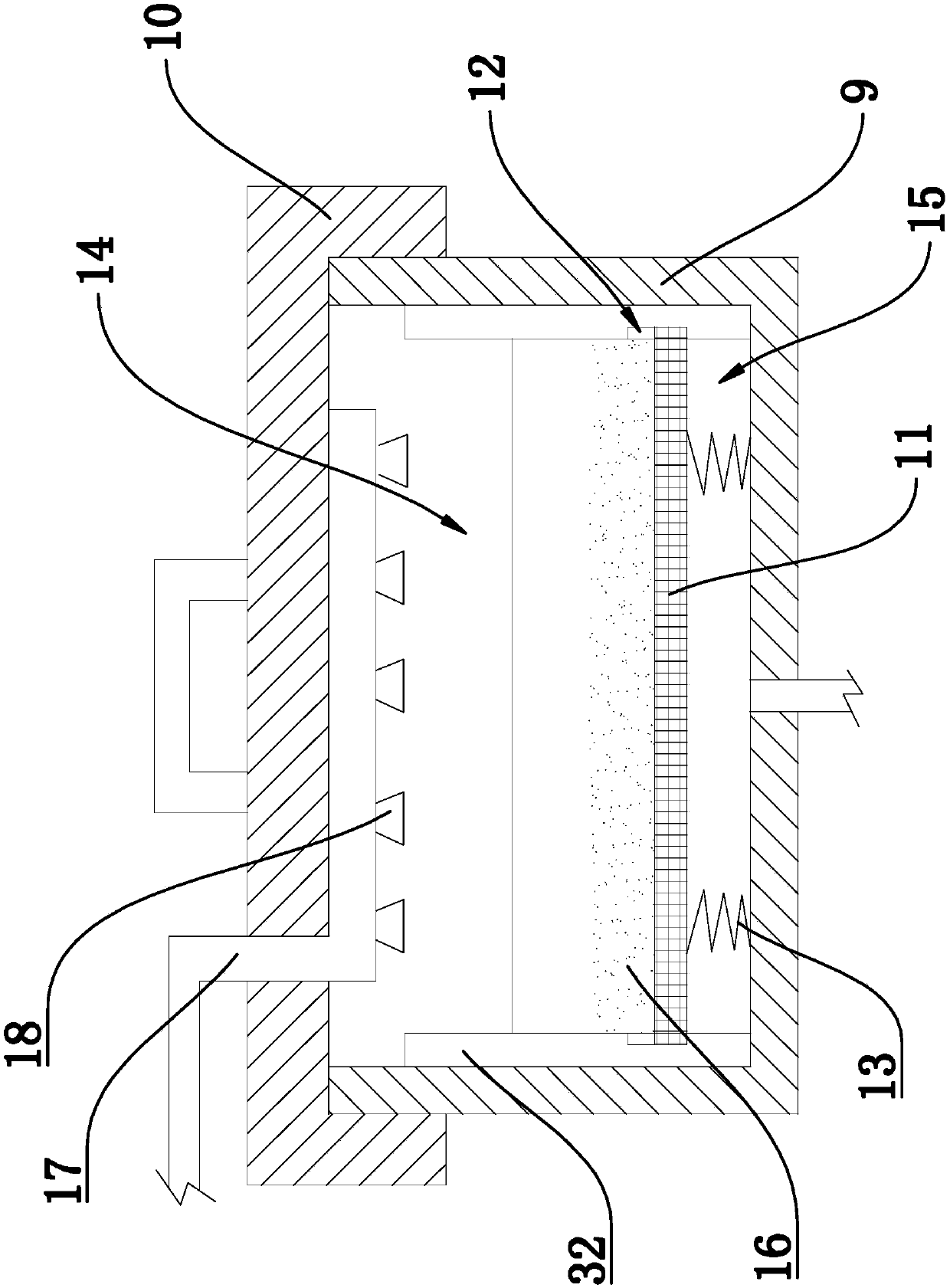

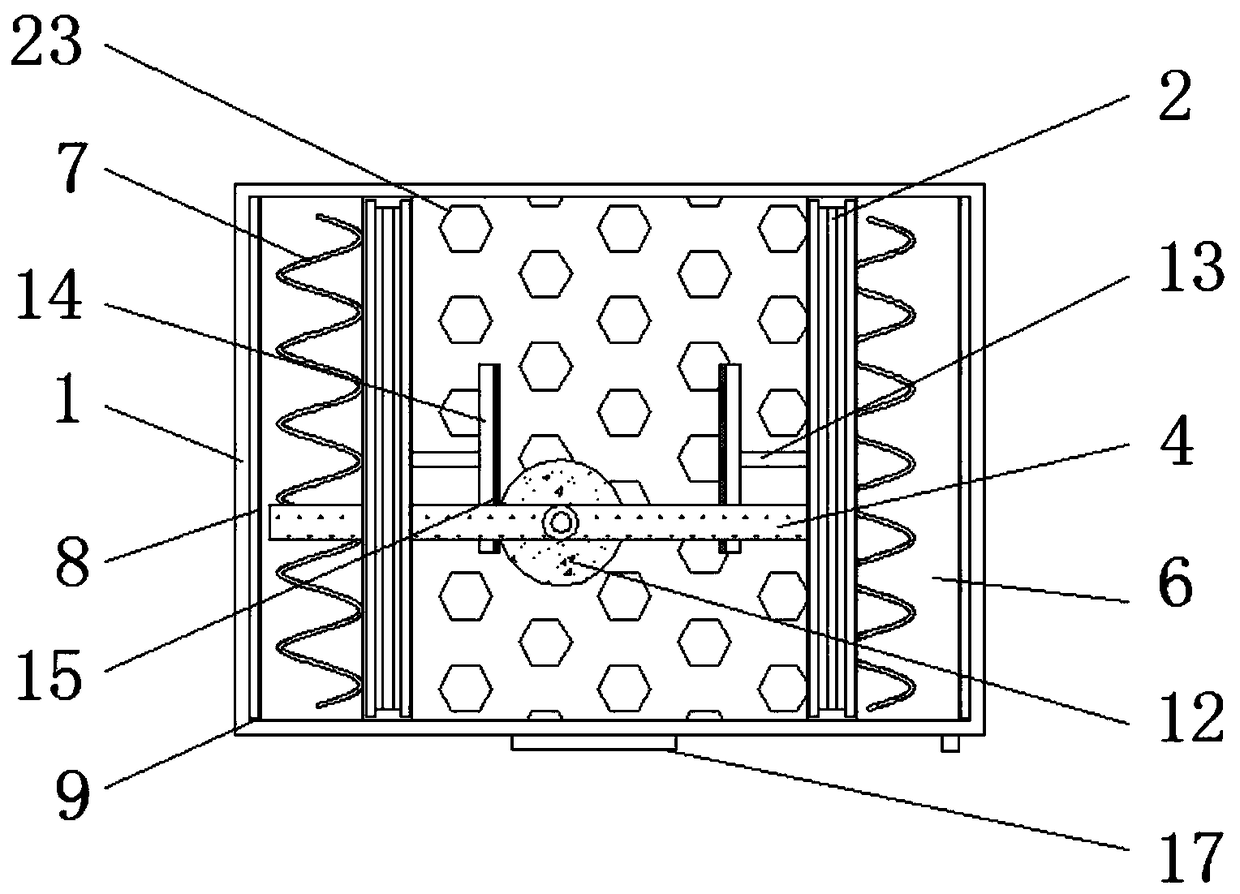

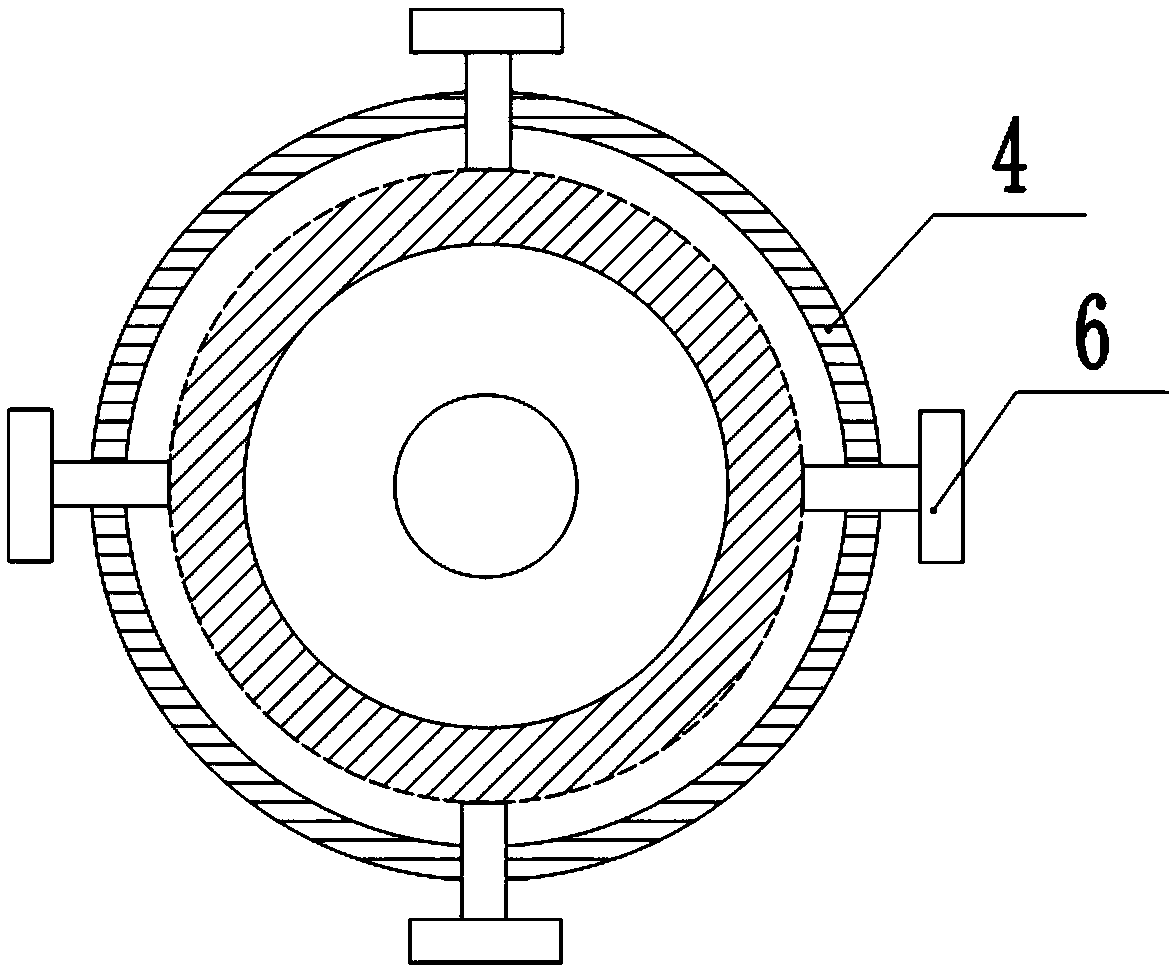

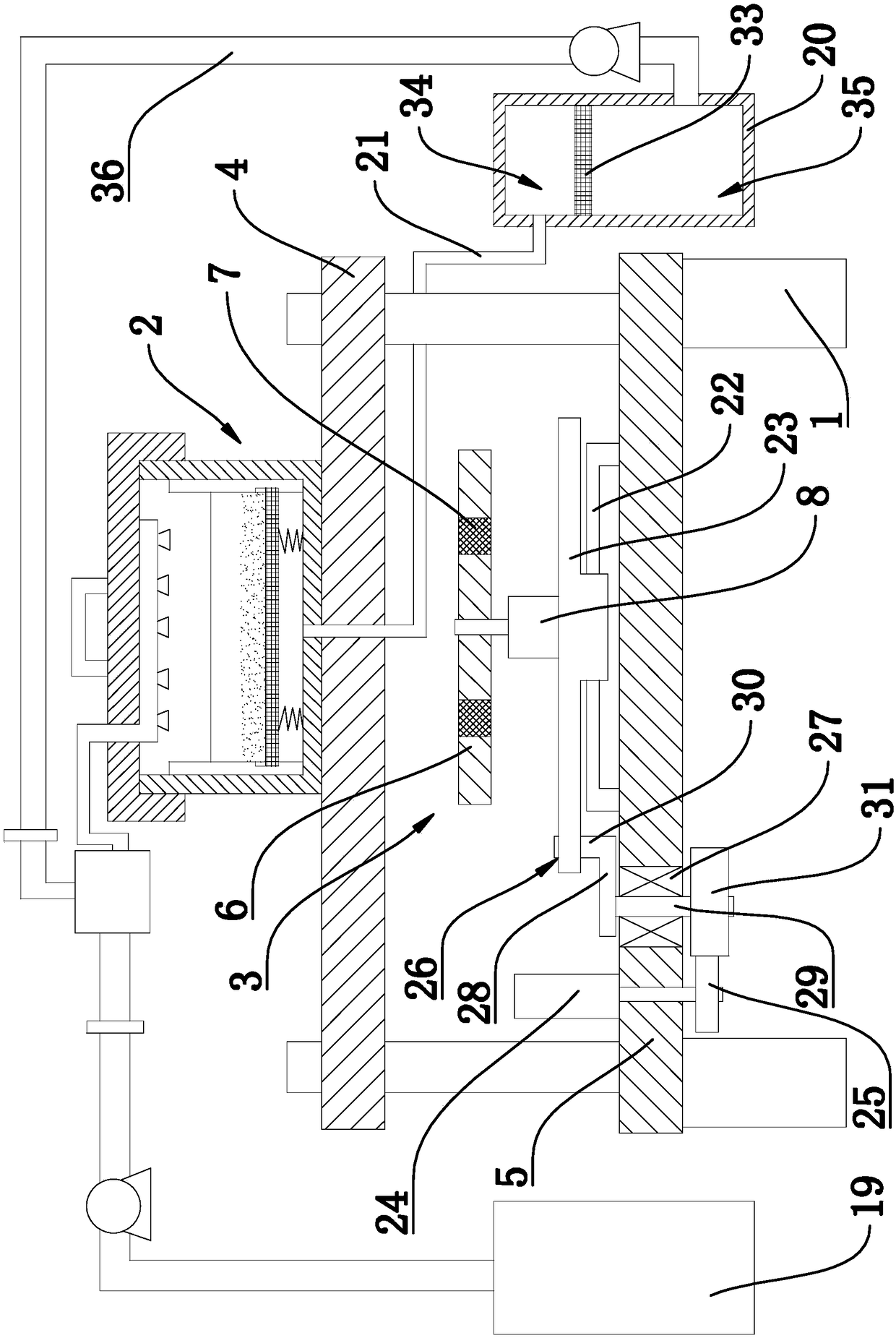

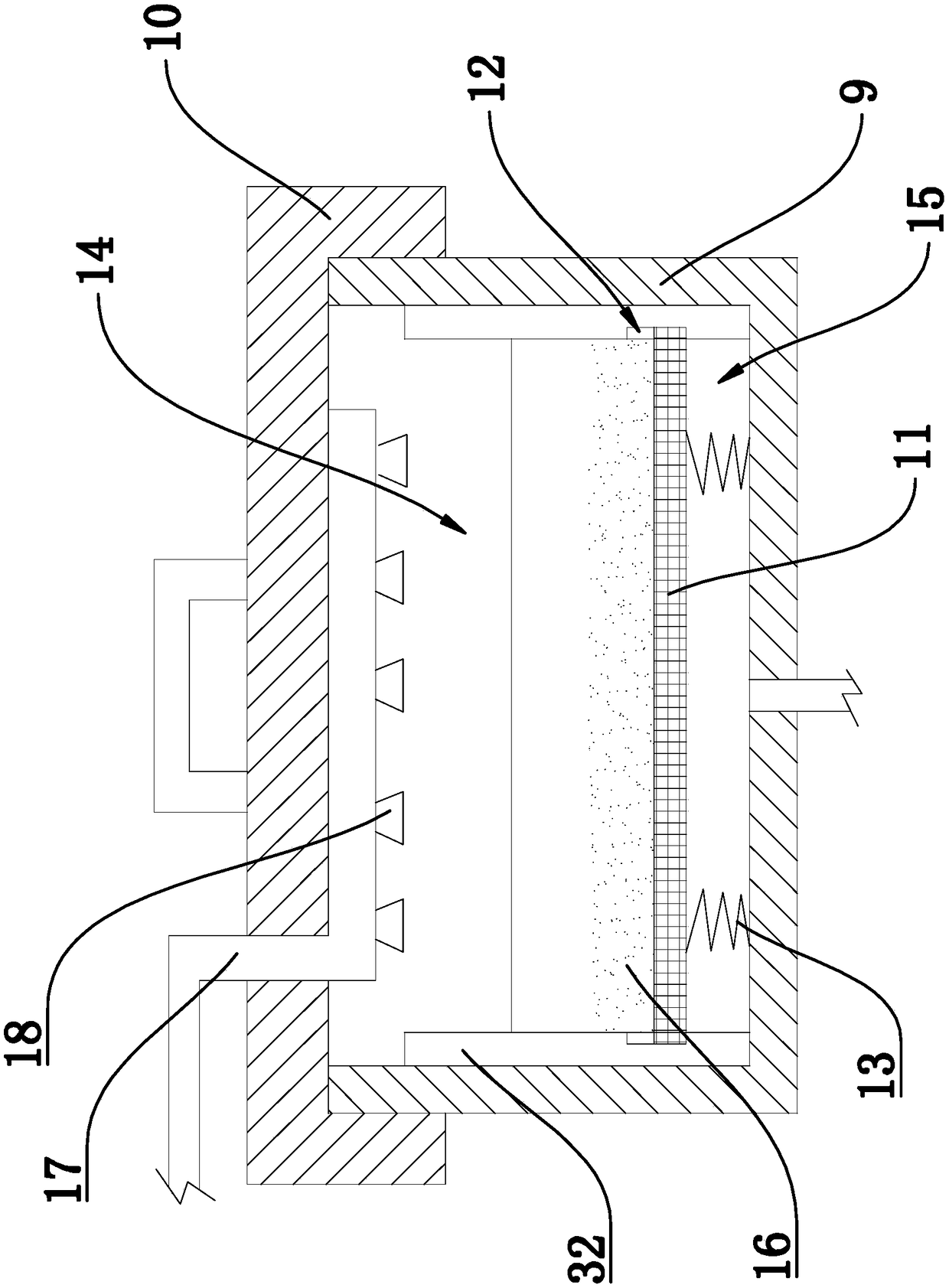

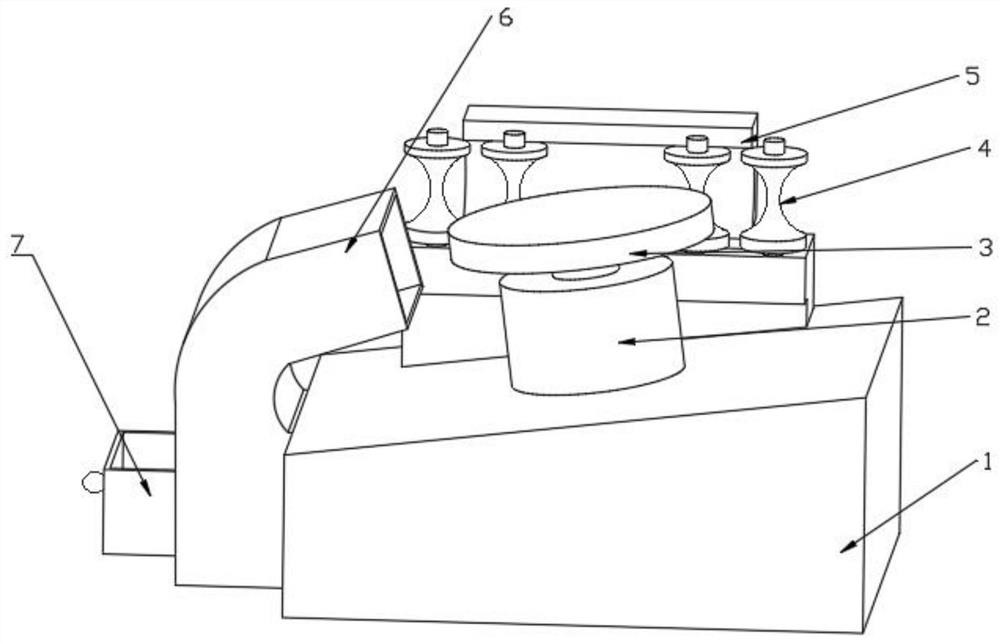

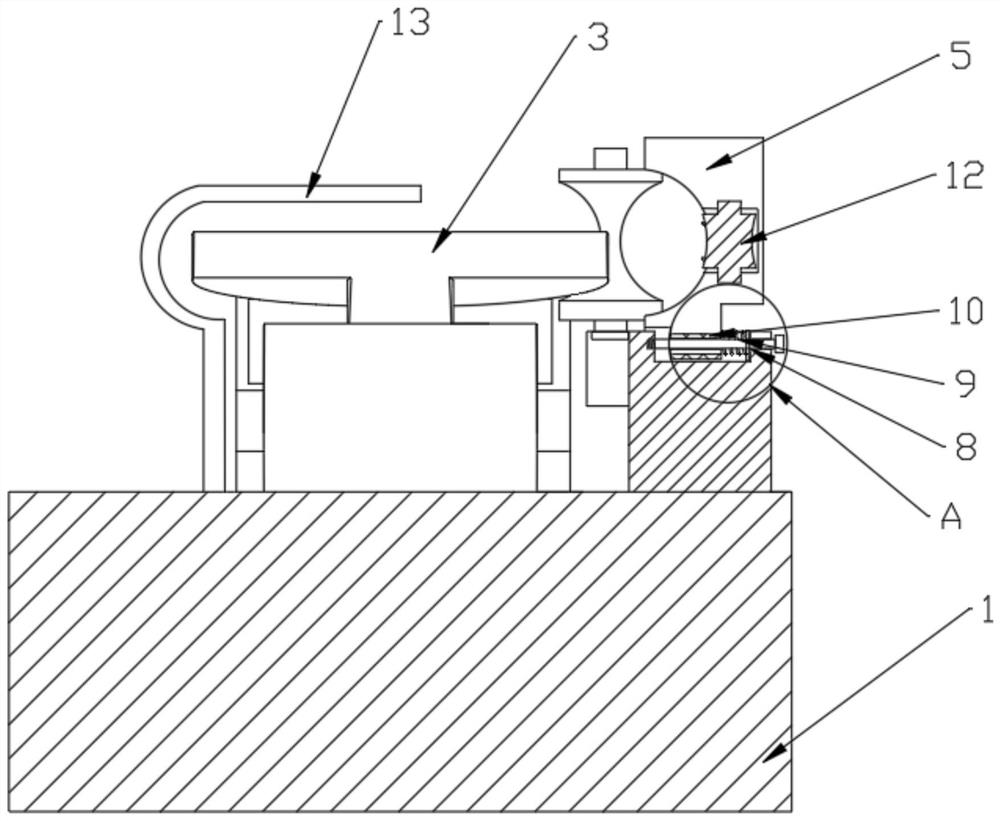

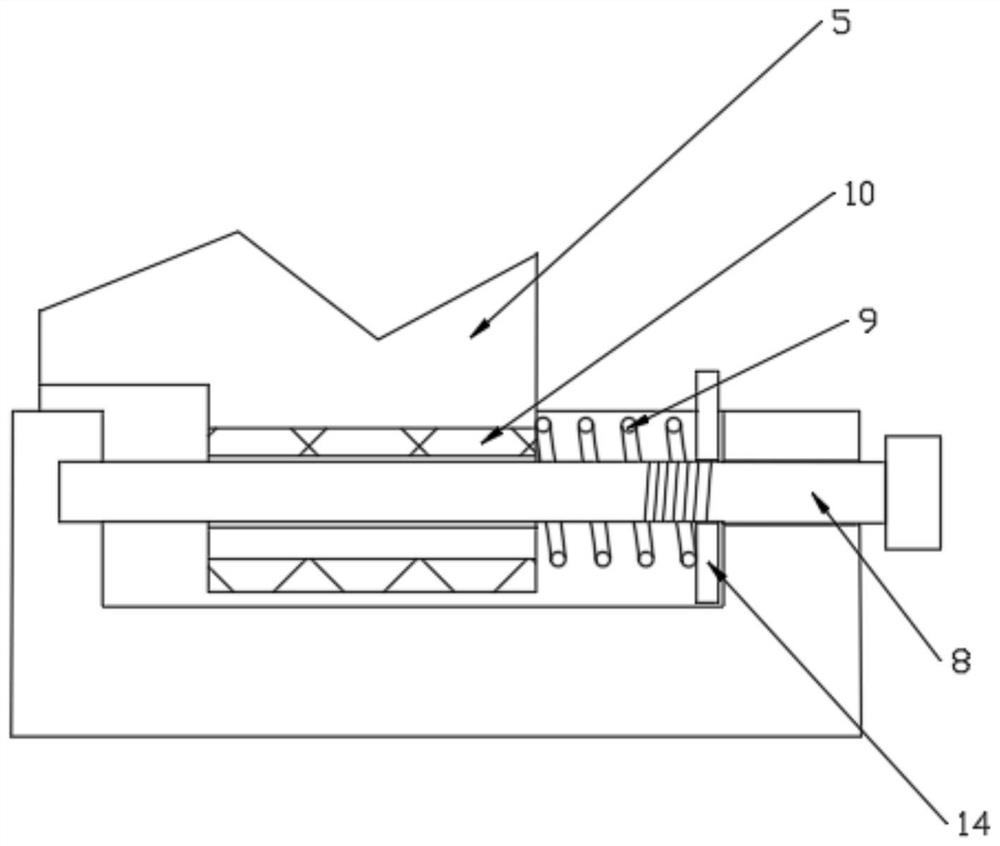

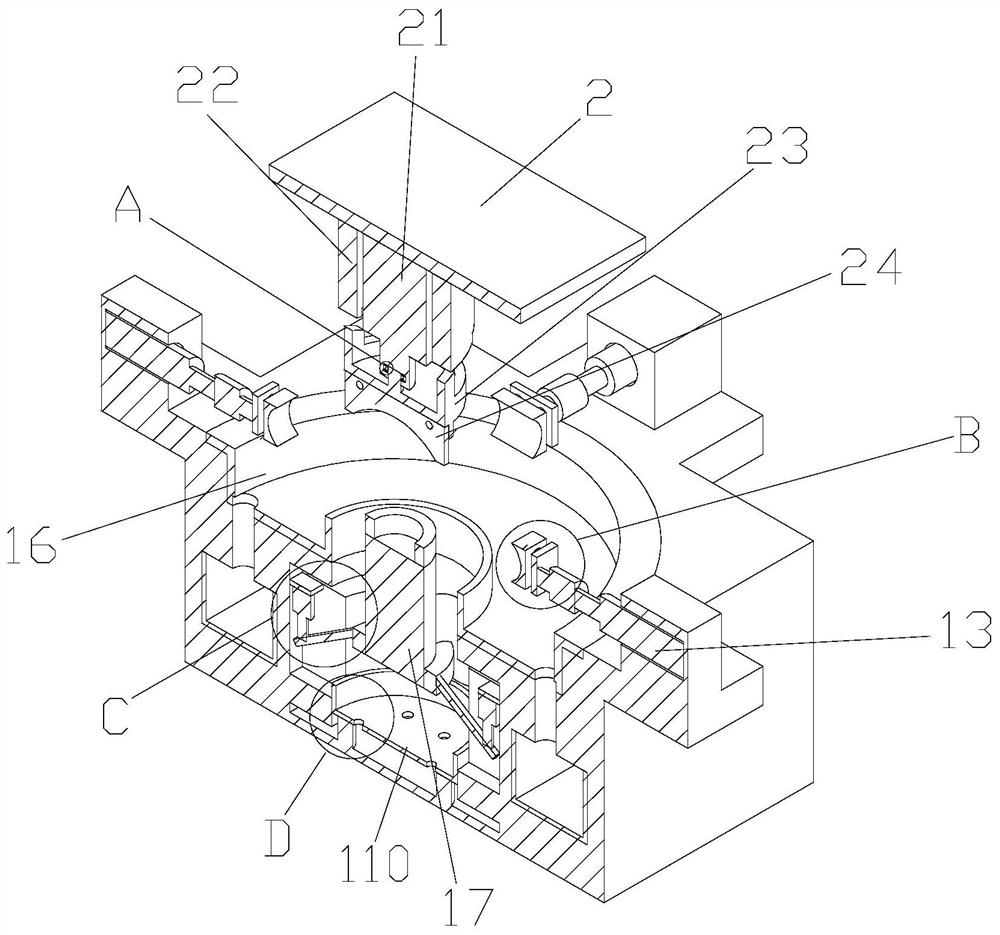

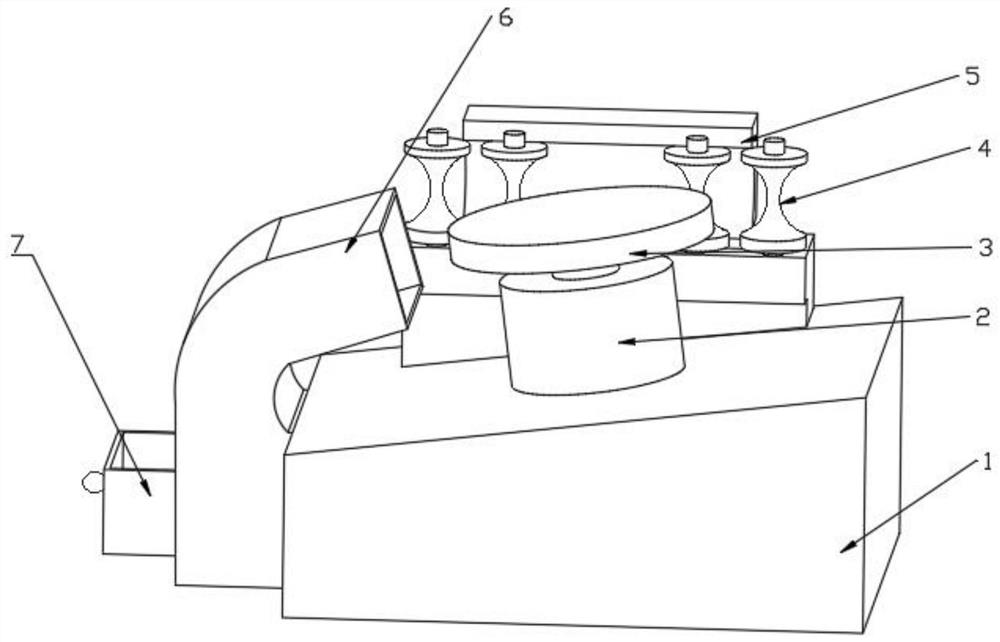

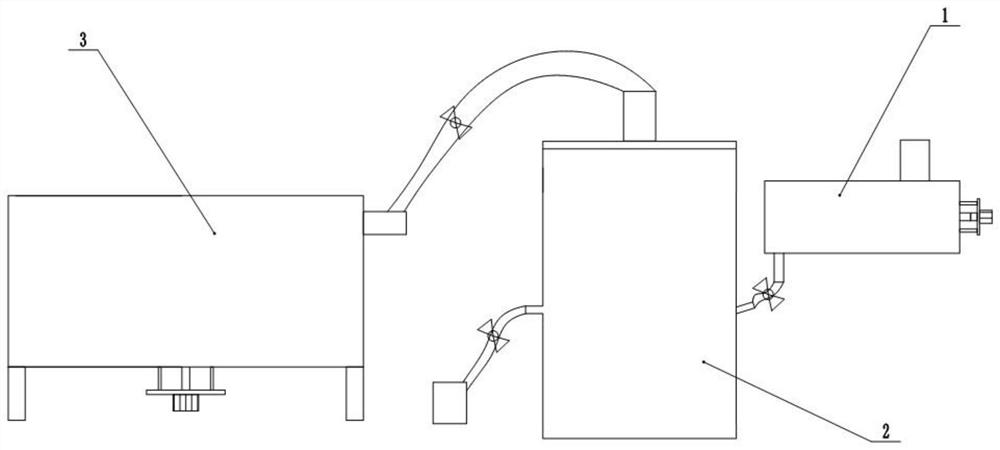

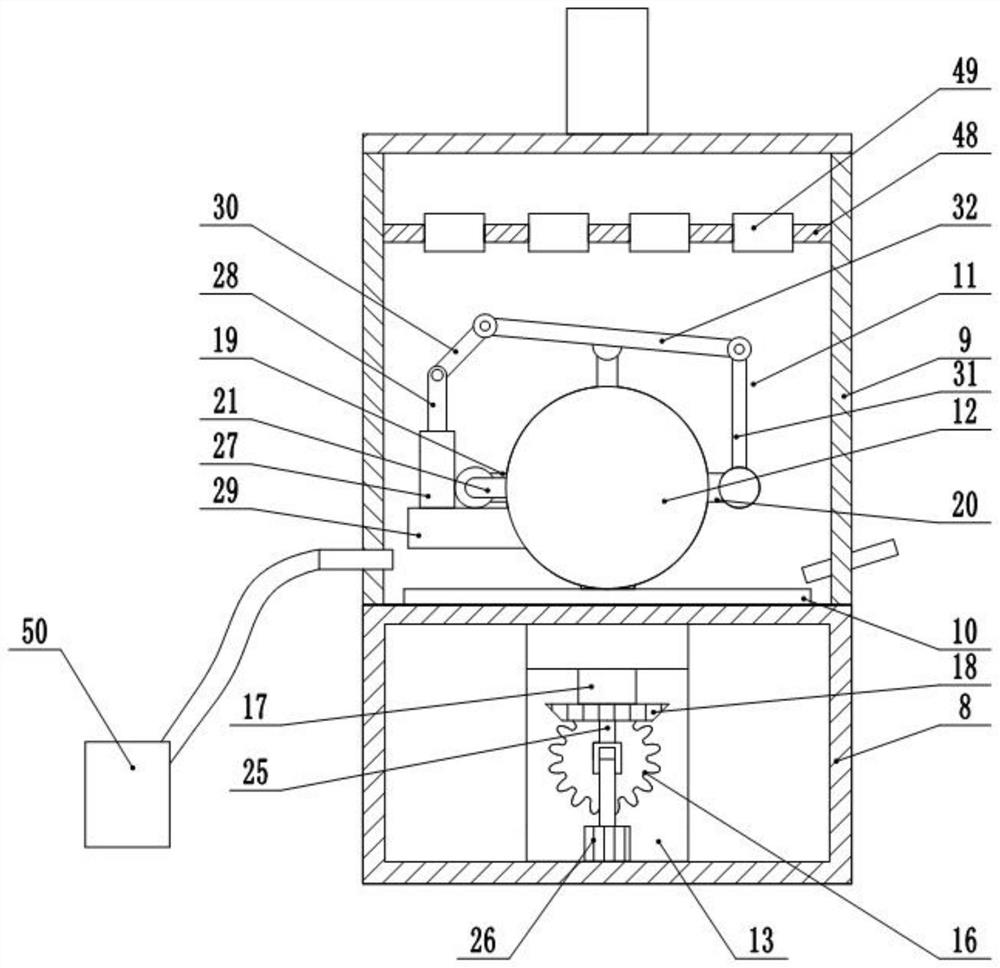

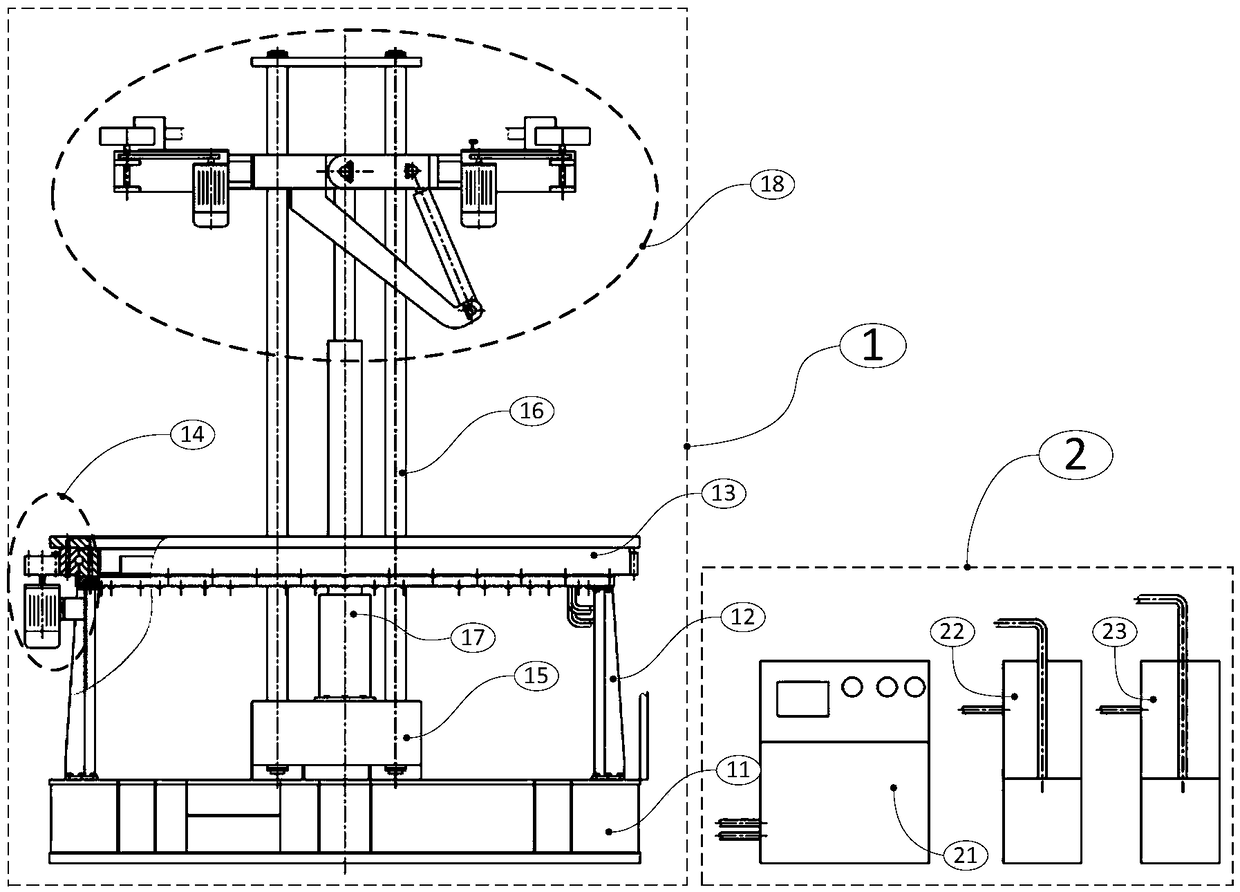

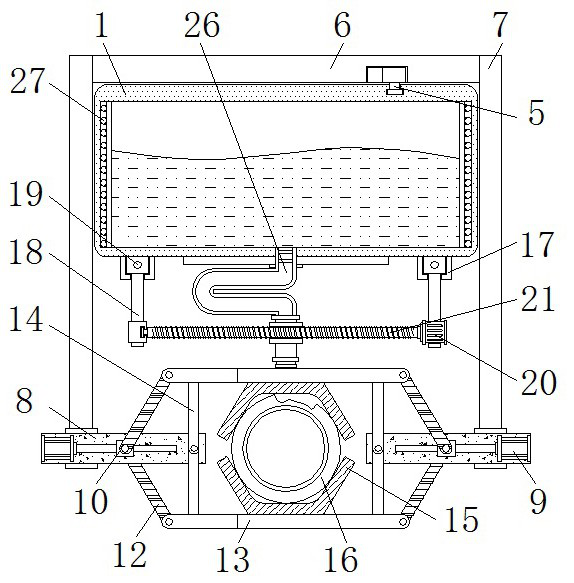

Magnetic abrasive finishing machine

InactiveCN107717637ATimely dischargeInto fastEdge grinding machinesGrinding carriagesEngineeringMachining

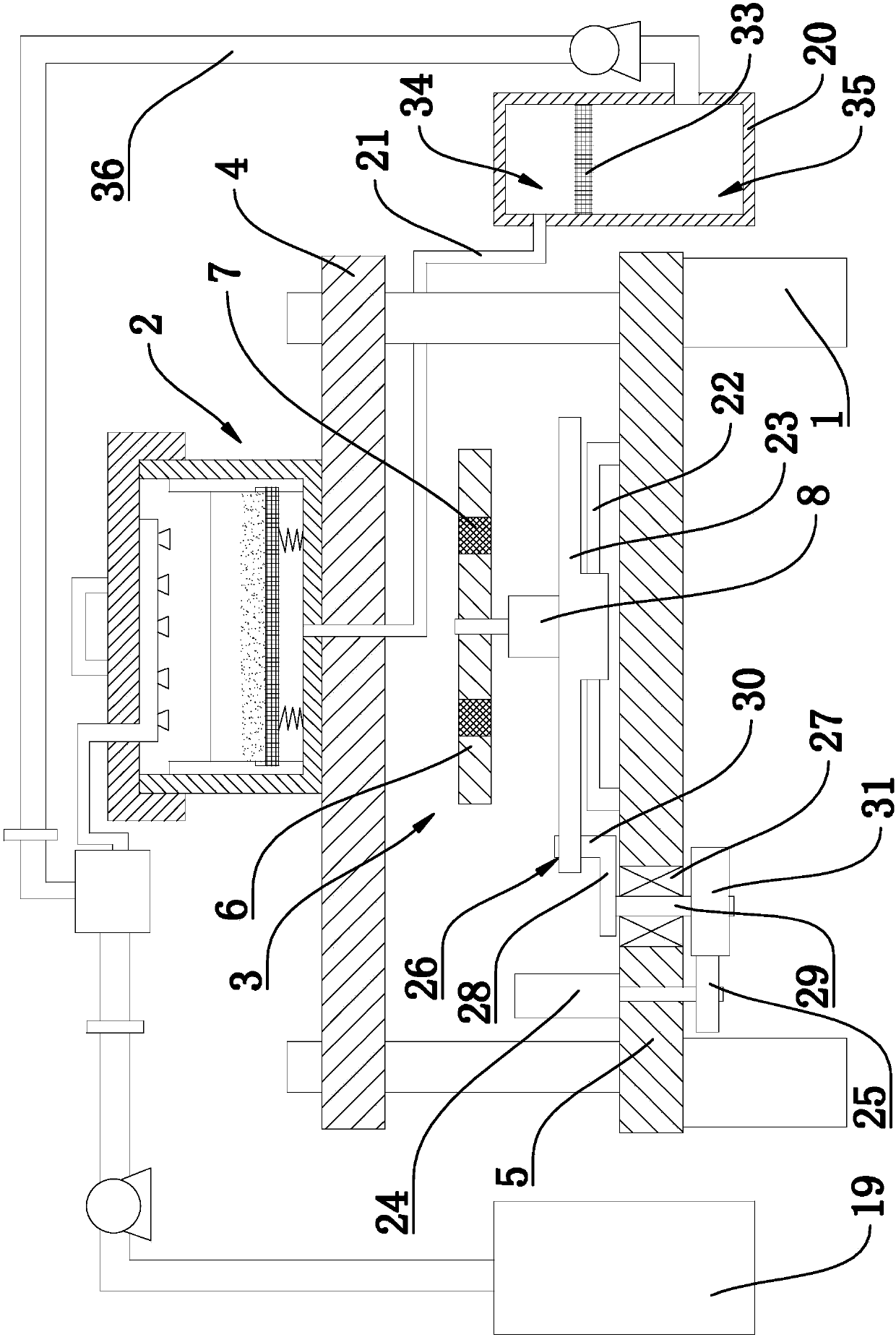

The invention discloses a magnetic abrasive finishing machine which comprises a machine base, a machining box and a rotating magnetic disk. The machine base consists of a first supporting table and asecond supporting table, and the machining box is placed on the first supporting table. The rotating disc consists of a rotating disc body and a magnet, the magnet is embedded and fixed on the rotating disc body, a first motor is installed on the second supporting table, and the rotating disc body is fixed to an output shaft of the first motor. The machining box comprises a box body and a cover body, a filter plate is arranged in the box body, and the filter plate is connected with the box body through a spring. The filter plate divides the box body into a machining cavity and a chip removal cavity, a plurality of magnetic grinding materials are placed in the machining cavity, and the size of the hole diameters of filtering holes is smaller than that of the magnetic grinding materials. Thetop of the inner wall of the cover body is fixedly provided with a liquid inlet pipe, a plurality of nozzles are installed on the liquid inlet pipe, a first liquid storage barrel and a second liquidstorage barrel are arranged beside the machine base, the first liquid storage barrel is connected with the liquid inlet pipe, and the first liquid storage barrel is used for supplying cooling liquid to the liquid inlet pipe. The second liquid storage barrel and the chip removal cavity are connected through a liquid discharge pipe, and the second liquid storage barrel is used for collecting coolingliquid and waste chips discharged by the machining box.

Owner:HAINING SHENGXIANG WIRE

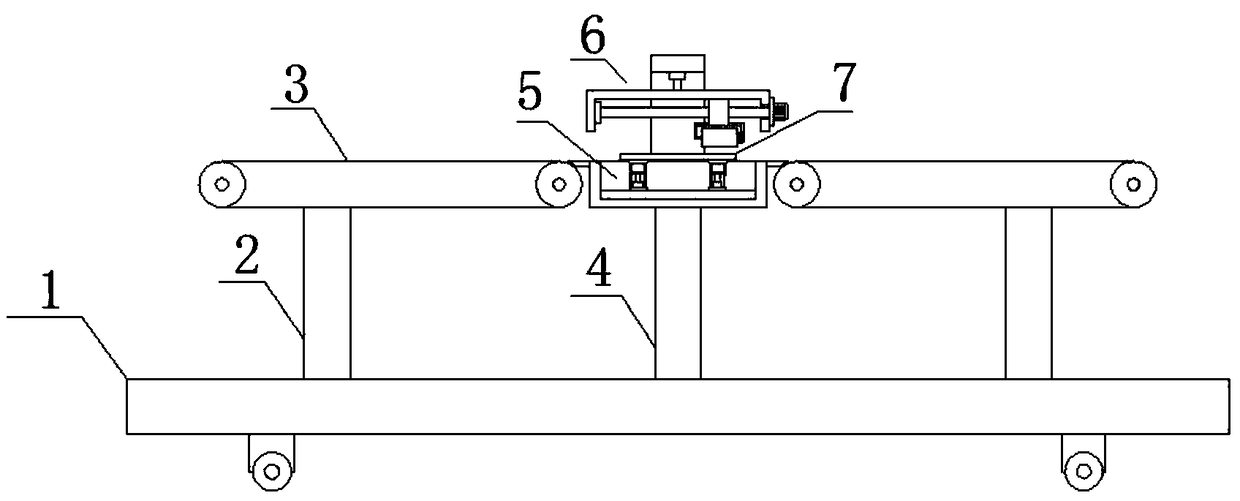

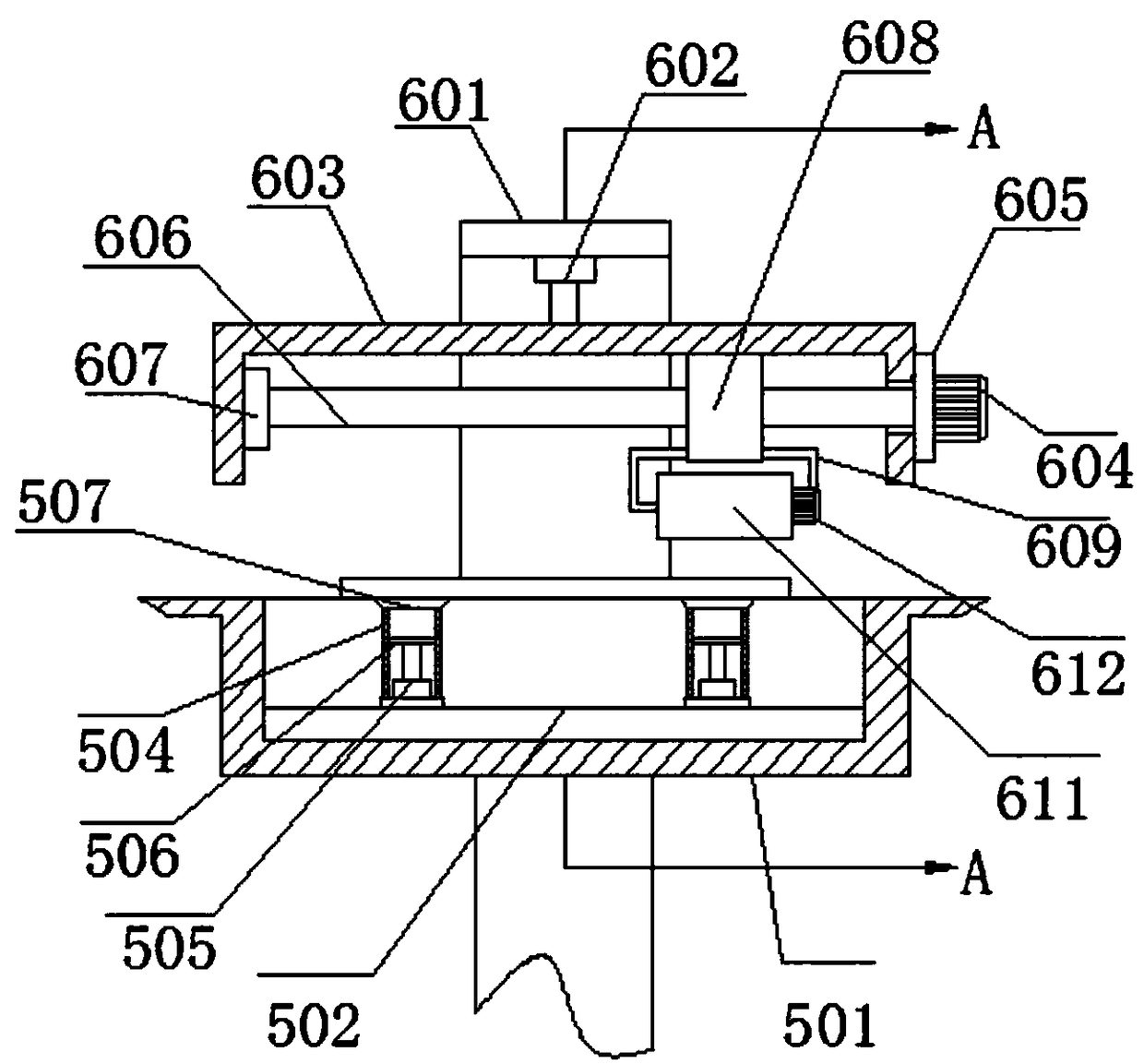

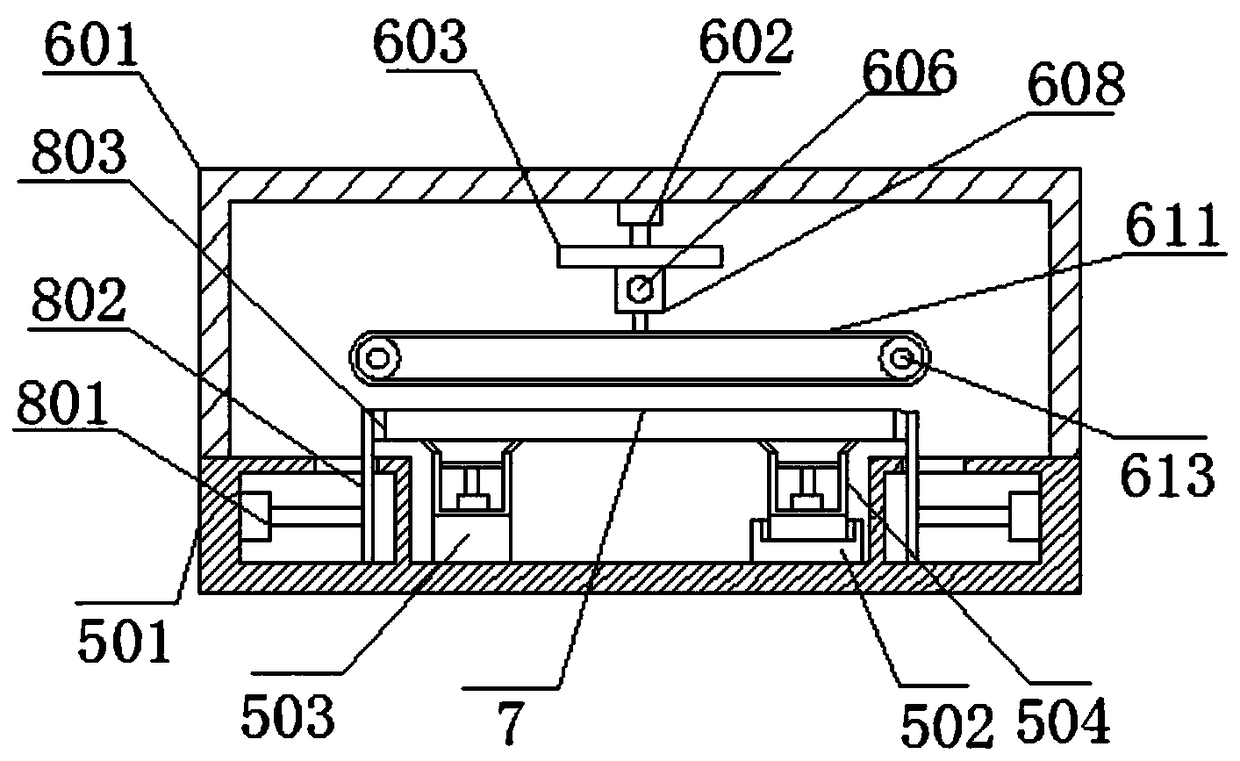

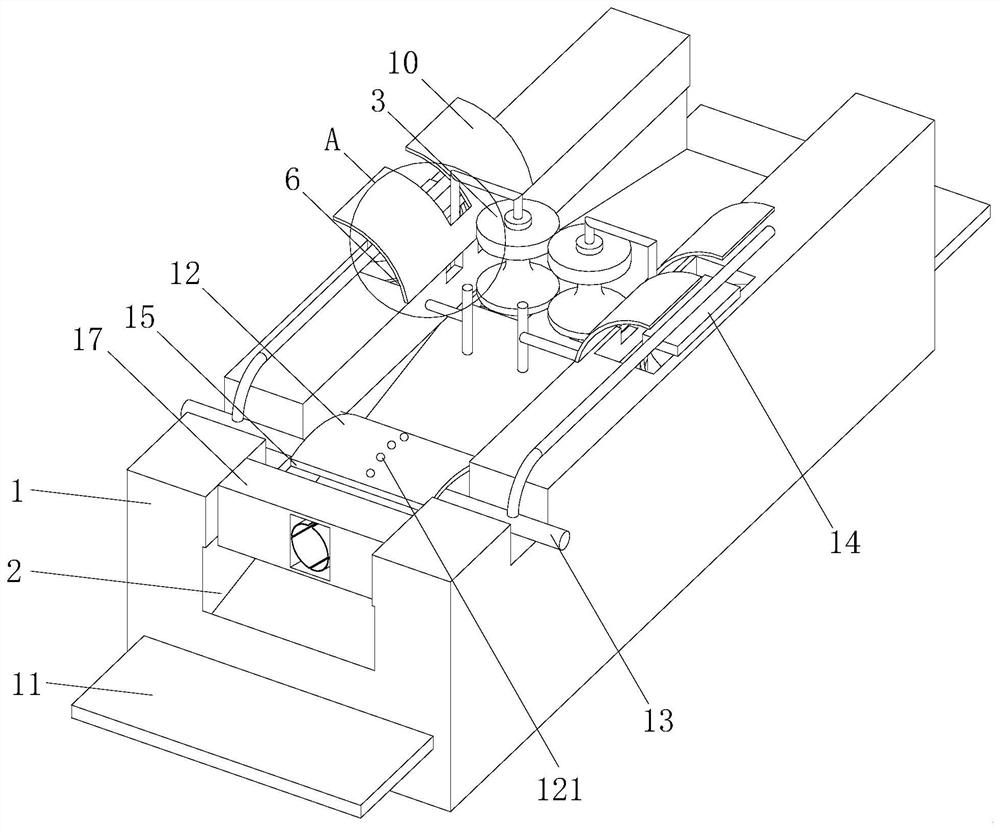

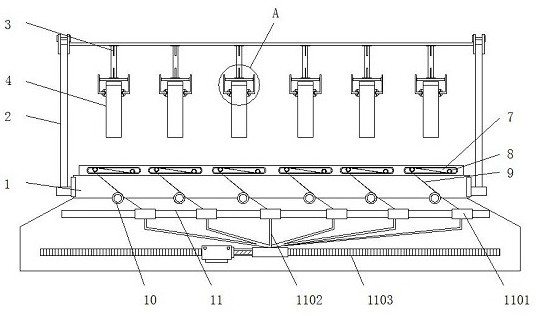

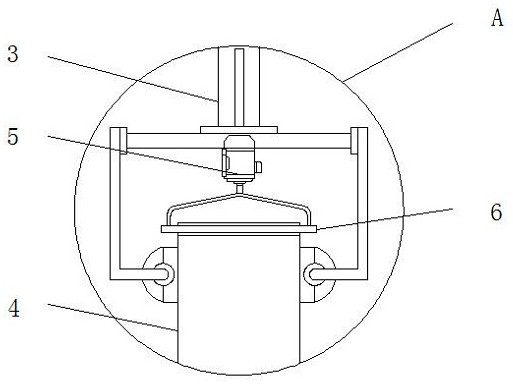

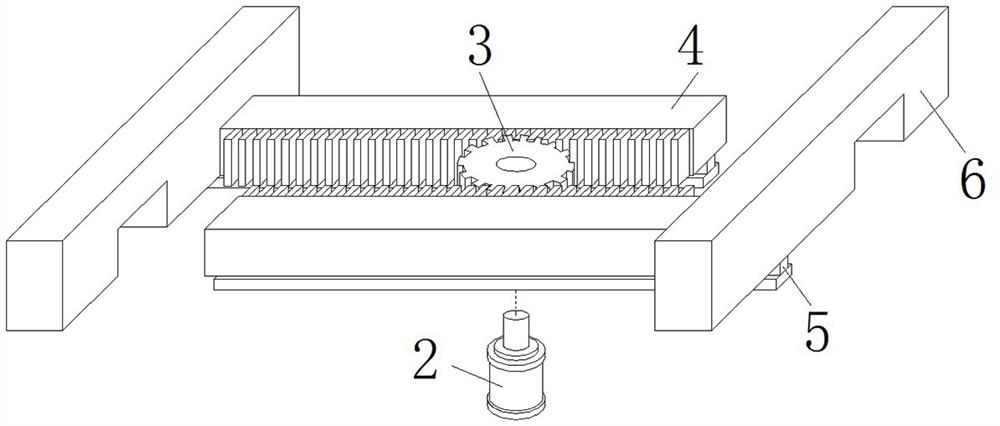

Integrated circuit copper-clad plate surface polishing device

InactiveCN109382738ALabor savingReduce labor costsPrinted circuit manufactureGrinding work supportsEngineeringCopper

The invention discloses an integrated circuit copper-clad plate surface polishing device. The polishing device comprises a base, two brackets, two conveying devices and a support plate; the two brackets are fixedly connected to the upper end of the base, the two conveying devices are fixedly connected to the brackets, and the support plate is fixedly connected to the middle of the upper end of thebase. Through the conveying devices, copper-clad plates are not required to be manually placed on a polishing device body one by one during polishing so that manual work can be reduced, the labor cost is reduced, and the work efficiency is improved; through the cooperation between a reciprocating screw and a polishing sleeve, the surfaces of the copper-clad plates can be completely polished to avoid polishing of dead corners, so that the polishing effect is improved; the copper-clad plates are firmly sucked by suckers to achieve a fixing effect; meanwhile, by cooperating with a clamping device, the copper-clad plates are fixed before polishing to avoiding the situation that the polishing effect is affected by slippage during polishing.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

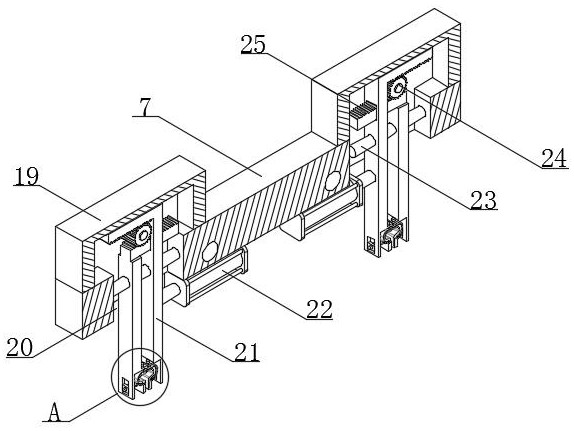

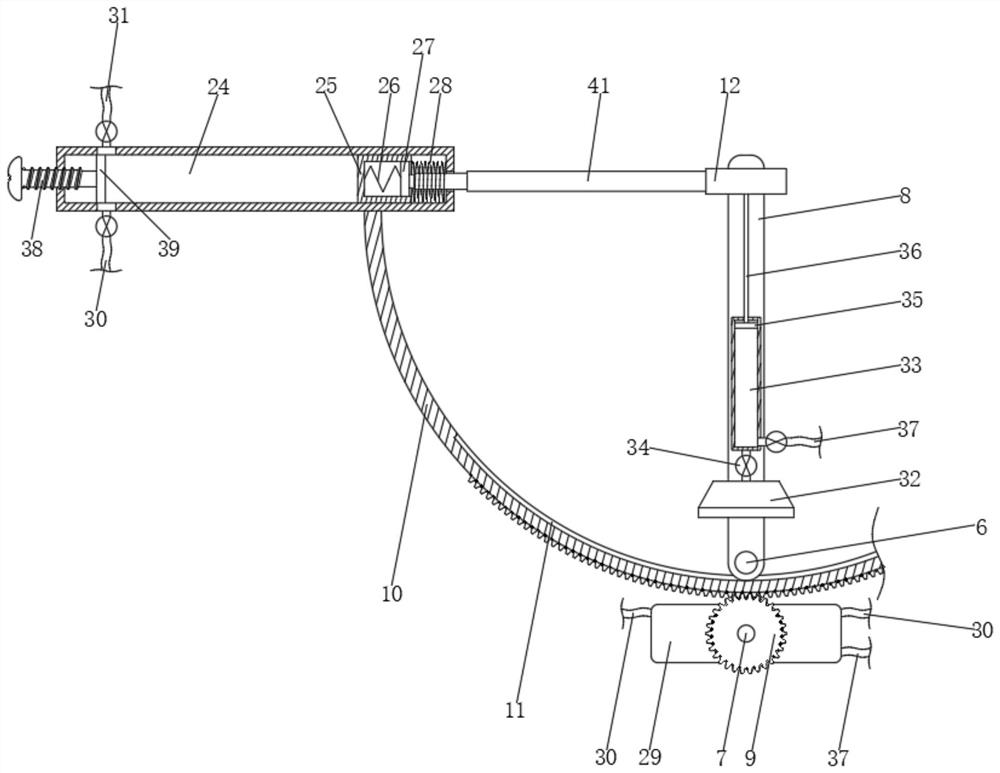

Hanging bracket supporting workpiece centerless grinding machine

InactiveCN104191322AFlexible adjustment of grinding positionEasy to recycleRevolution surface grinding machinesGrinding/polishing safety devicesEngineeringMechanical engineering

The invention provides a hanging bracket supporting workpiece centerless grinding machine. The hanging bracket supporting workpiece centerless grinding machine comprises a base, a horizontal machine platform, a rotary shaft, a sliding machine platform, a first threaded rod, a workpiece supporting frame, a first tool rest, a second threaded rod, an adjustment wheel, a supporting part, a second tool rest, a third threaded rod and a grinding wheel, wherein the horizontal machine platform is installed on the base in a horizontally rotary mode through the rotary shaft, the supporting part is installed on the base, the sliding machine platform is installed on the horizontal machine platform in a sliding mode and can longitudinally slide on the horizontal machine platform by adjusting the first threaded rod, the workpiece supporting frame is composed of a first supporting rod, a second supporting rod, a third supporting rod, a first hanging arm and a second hanging arm, the first supporting rod and the second supporting rod are installed on the sliding machine platform in parallel, a first end and a second end of the third supporting rod are installed at the top end of the first supporting rod and the top end of the second supporting rod respectively, and the top end of the first hanging arm and the top end of the second hanging arm are installed on the third supporting rod in a rotary mode. The hanging bracket supporting workpiece centerless grinding machine avoids the situation that grinding chippings are accumulated on the bottom of a workpiece so that the surface of the workpiece can not be ground smooth.

Owner:芜湖中驰机床制造有限公司

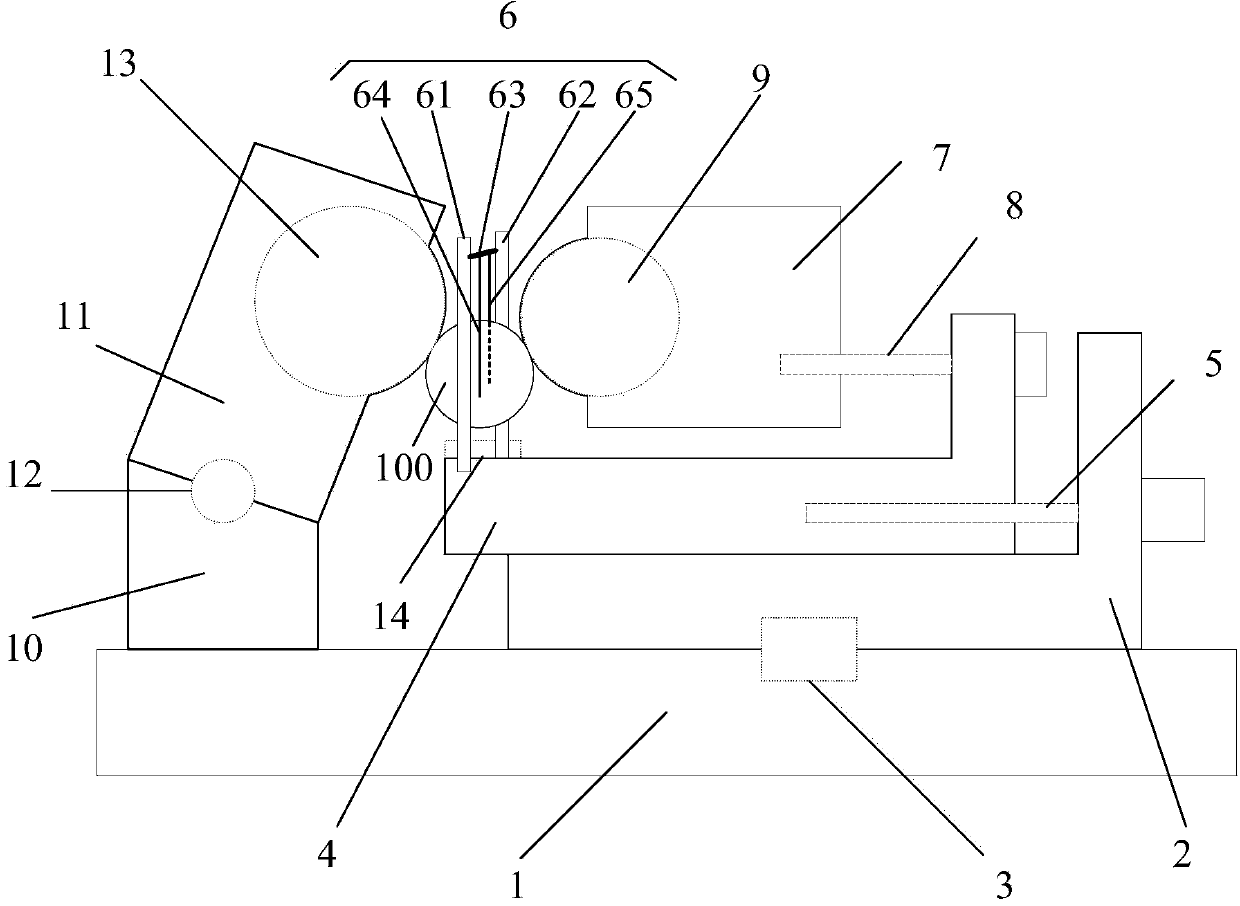

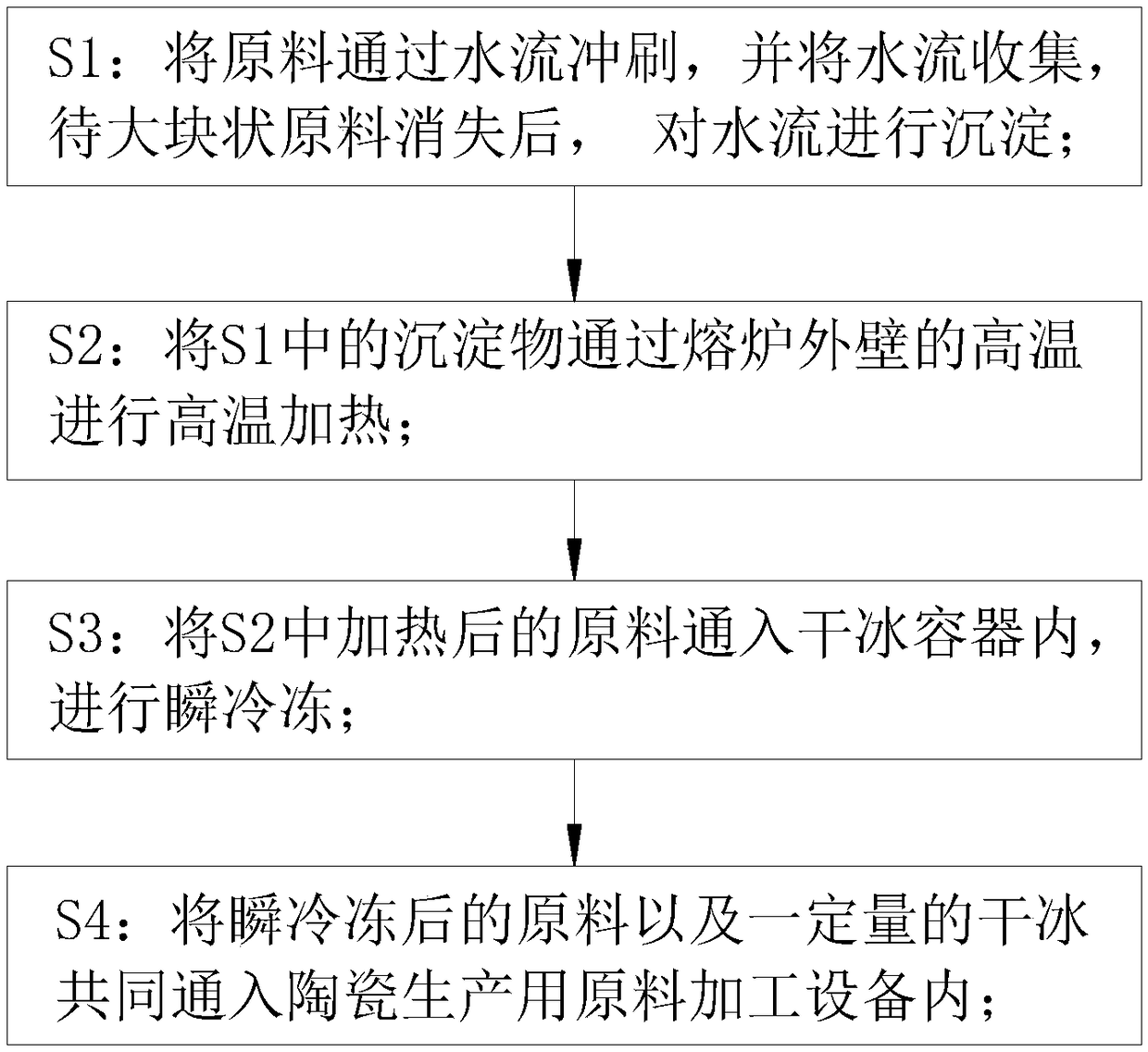

Raw material processing technology for ceramic production

The invention belongs to the technical field of ceramic production, in particular to a raw material processing technology for the ceramic production. The raw material processing technology for the ceramic production comprises the steps that raw materials are washed by water flow, the water flow is collected, and the water flow is precipitated after large block raw materials disappear; the precipitate is heated at high temperature through the high temperature of the outer wall of a melting furnace, and water in the raw materials is evaporated through the high temperature heating; then the heated raw materials are introduced into a dry ice container to carry out instantaneous freezing, and the block raw materials in the raw materials are crushed; and the instant frozen raw materials and a certain amount of dry ice are jointly introduced into a raw material processing device for the ceramic production, wherein the dry ice effectively prevents the device from generating heat when grindingand crushing the raw materials, the service life of the device is prolonged, and the dry ice is gasified when the raw materials are mixed with water to generate carbon dioxide gas to assist in stirring, so that the mixing is more sufficient. According to the raw material processing technology for the ceramic production, the operation is convenient, the crushing efficiency is high, the service lifeis prolonged, the raw materials are fully mixed, and the phenomenon that the raw materials adhere to the surface of the device and the precipitation is not occur .

Owner:徐州亚苏尔高新材料有限公司

Mechanical part polishing device convenient to adjust

InactiveCN108637859AEasy to cleanEasy to adjustGrinding wheel securing apparatusGrinding carriagesSurface smoothnessElectrical and Electronics engineering

The invention discloses a mechanical part polishing device convenient to adjust. The mechanical part polishing device comprises a frame, limiting plates and a drawer; first connection rods are installed on the upper surface of the interior of the frame and connected with a second connection rod through first connection blocks; the limiting plates are connected with the second connection rod through second connection blocks, grooves are reserved in the limiting plates, and the limiting plates are connected with the frame through third connection rods; fixed blocks are installed on the third connection rods; a first elastic telescopic rod is located at the bottom of the second connection rod and connected with a polisher through a first motor; and the left side and the right side of the inner surface of the frame are both connected with second motors. The mechanical part polishing device convenient to adjust can be conveniently adjusted according to the sizes and shapes of mechanical parts, polishing dead corners are avoided, in addition, the polisher can be required to replace according to the surface smoothness of the parts, and dust generated after polishing can be conveniently removed.

Owner:利辛县鹏博机电设备有限公司

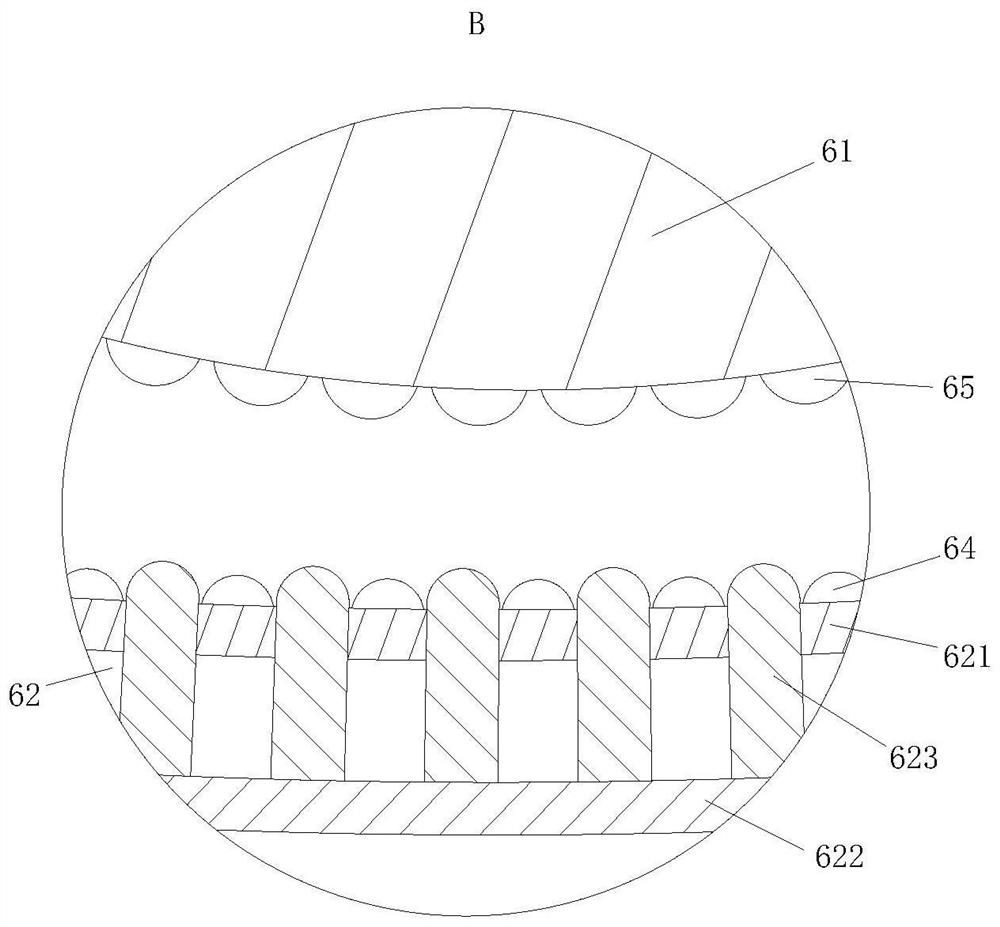

Rubber hose polishing device

InactiveCN113579866AAvoid grinding cornersImprove sanding effectRevolution surface grinding machinesGrinding drivesPolishingCeramic materials

The invention discloses a rubber hose polishing device, and relates to the technical field of rubber product production. The rubber hose polishing device comprises a device body, a polishing channel is formed in the center of the top of the device body, and two rotary polishing rollers are arranged in the polishing channel. According to the rubber hose polishing device, the two rotary polishing rollers on the device body can polish the surface of a rubber hose in the surface treatment process, and in the polishing process, the two rotary polishing rollers can move towards the two sides under the pushing effect of the rubber hose, and then rubber hoses with different diameters can be polished. Meanwhile, the elastic force from elastic pieces of the two rotary polishing rollers can extrude the rubber hose so that the rubber hose can deform, the rubber hose can be tightly attached to the rotary polishing rollers so that polishing dead corners caused by deformation of the rubber hose can be prevented, and the polishing effect can be improved through the extrusion force between the rubber hose and the rotary polishing rollers.

Owner:陆海平

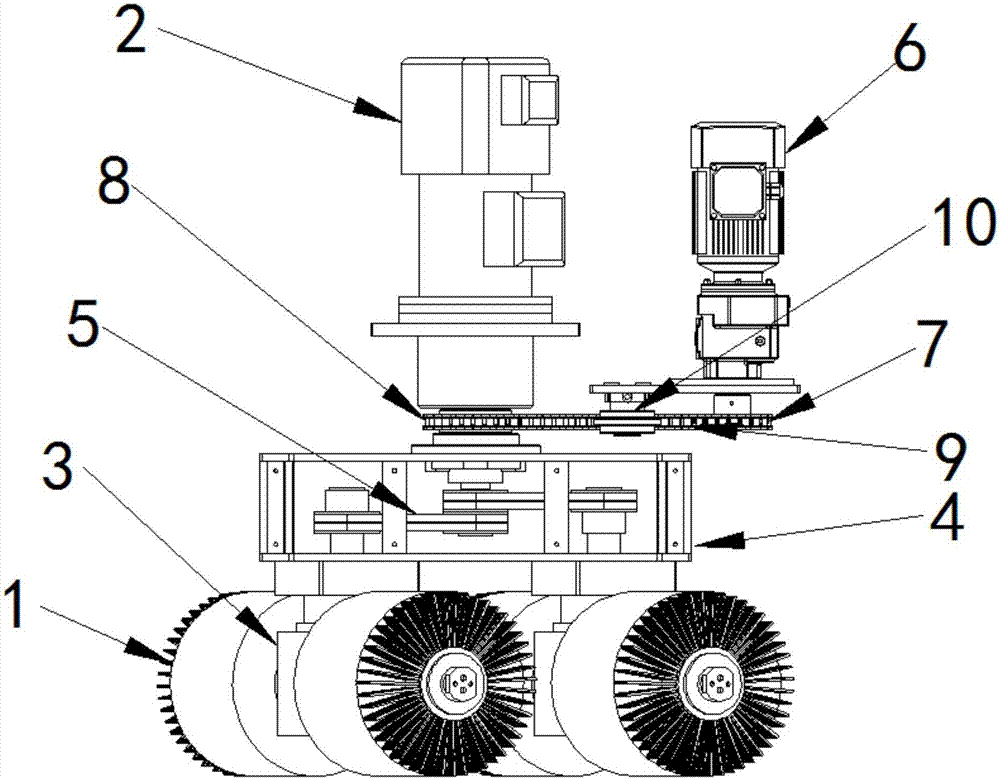

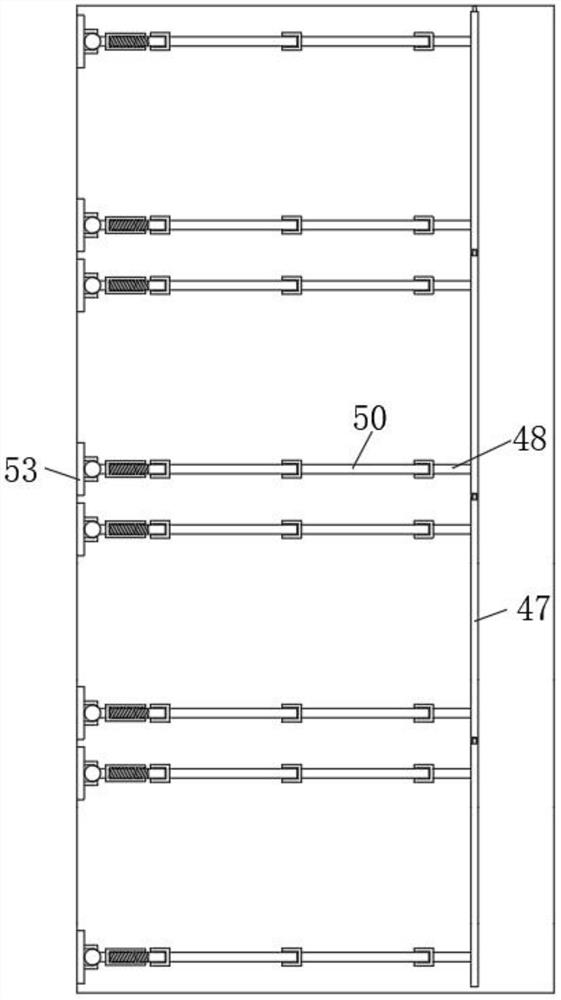

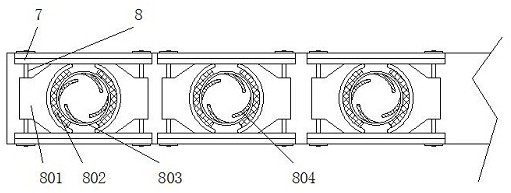

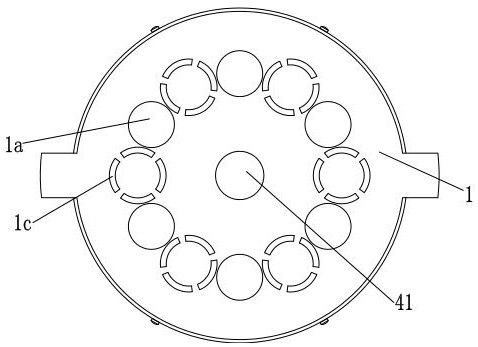

High-efficiency roller brush grinding mechanism

PendingCN107225463AImprove grinding efficiencyAvoid grinding cornersEdge grinding machinesGrinding drivesPhysicsElectric machinery

Provided is a high-efficiency roller brush grinding mechanism. The high-efficiency roller brush grinding mechanism comprises roller brush sets, a roller brush rotation driving mechanism and a roller brush revolution driving mechanism. The roller brush sets comprise the front roller brush set and the rear roller brush set. The front roller brush set and the rear roller brush set both comprise two roller brushes. Every two roller brushes are connected through a rotating shaft. The roller brush rotation driving mechanism comprises a support, a rotation motor and a steering device, wherein the rotation motor and the steering device are arranged on the support. In specific work, the steering device can be driven by the rotation motor to rotate so as to drive the roller brushes to achieve rotation. The roller brush revolution driving mechanism comprises a revolution motor, and the revolution motor is connected through a drive mechanism to drive the support to rotate around a rotation motor output shaft. The roller brushes rotate automatically to grind workpieces continuously, and polishing efficiency is high. Meanwhile, the revolution motor drives the support to rotate, so that the roller brushes are driven to revolute on the surfaces of the workpieces, all the parts of the workpieces can be ground, polishing dead corners are avoided, and the effect is thorough. The high-efficiency roller brush grinding mechanism is compact in structure and small in space occupation.

Owner:苏州尚品科技有限公司

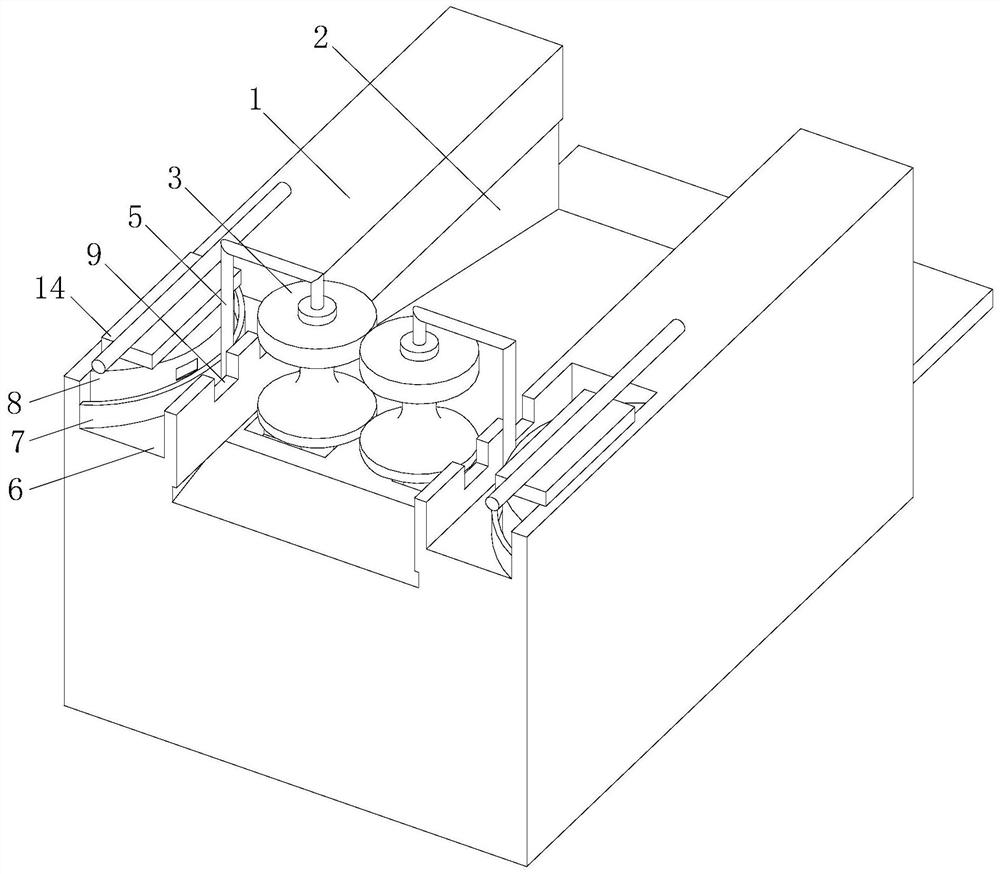

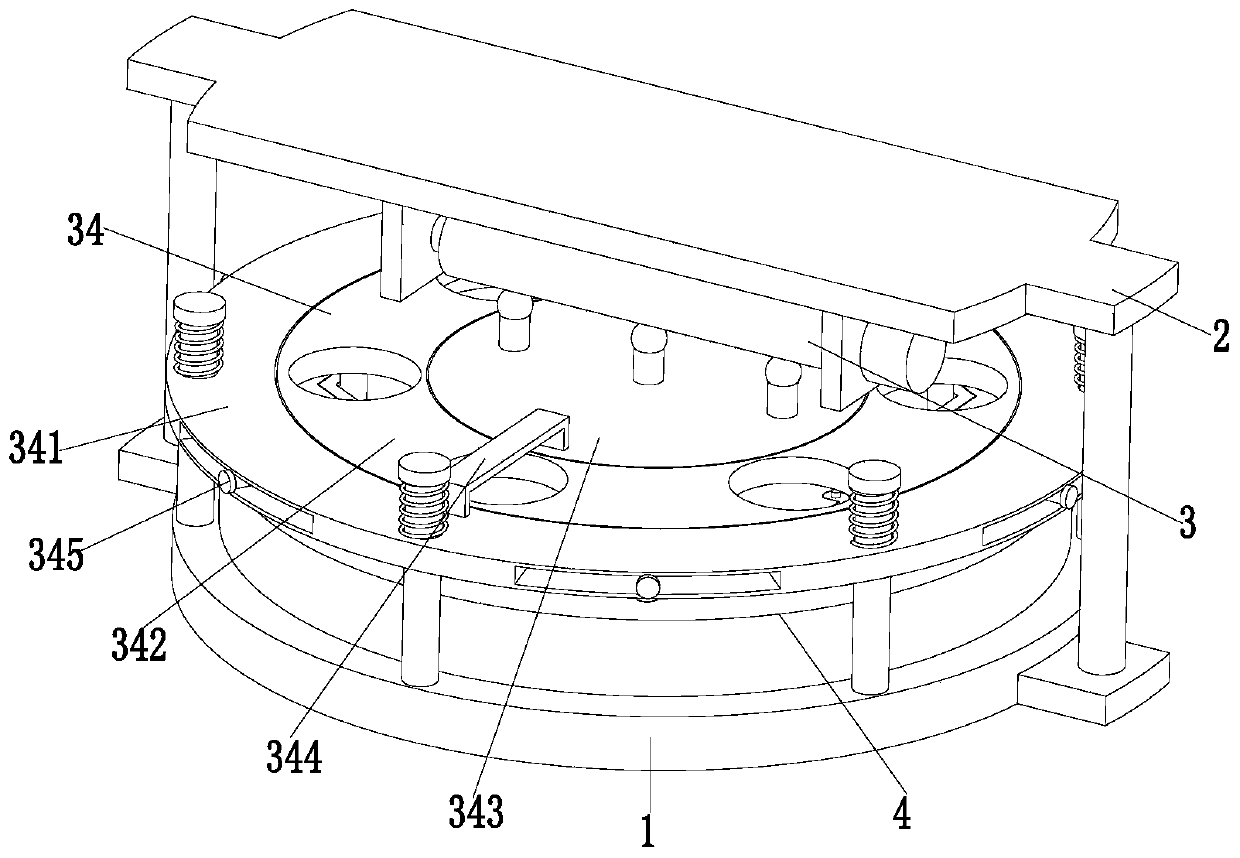

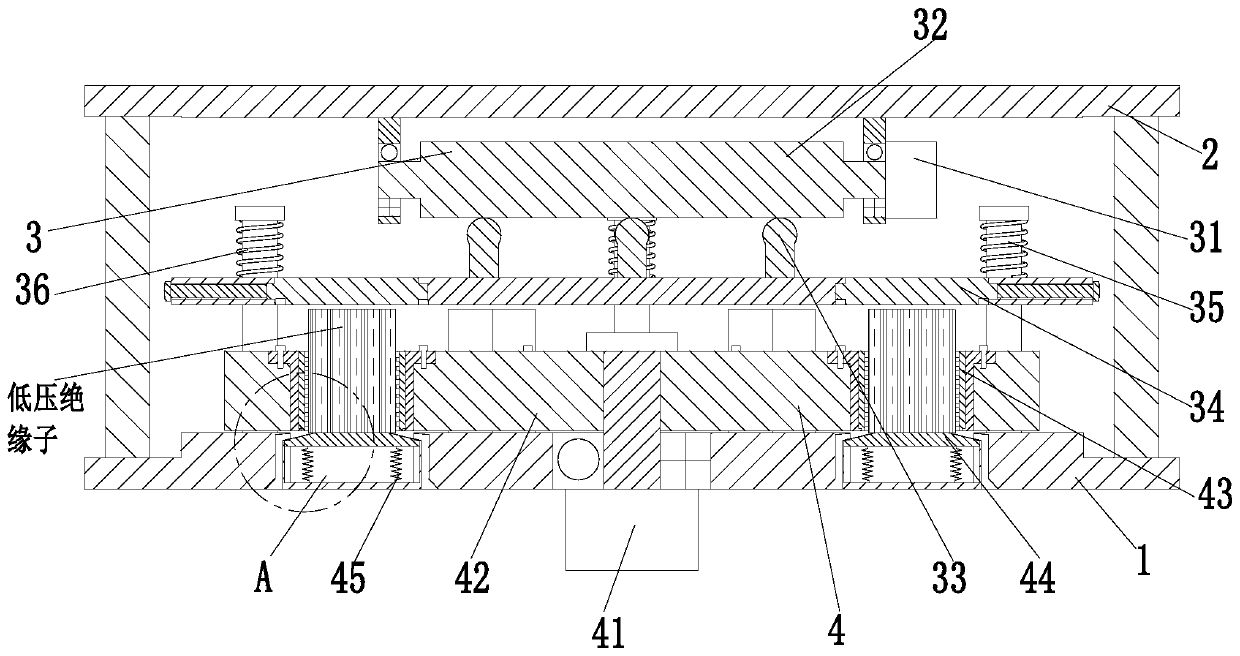

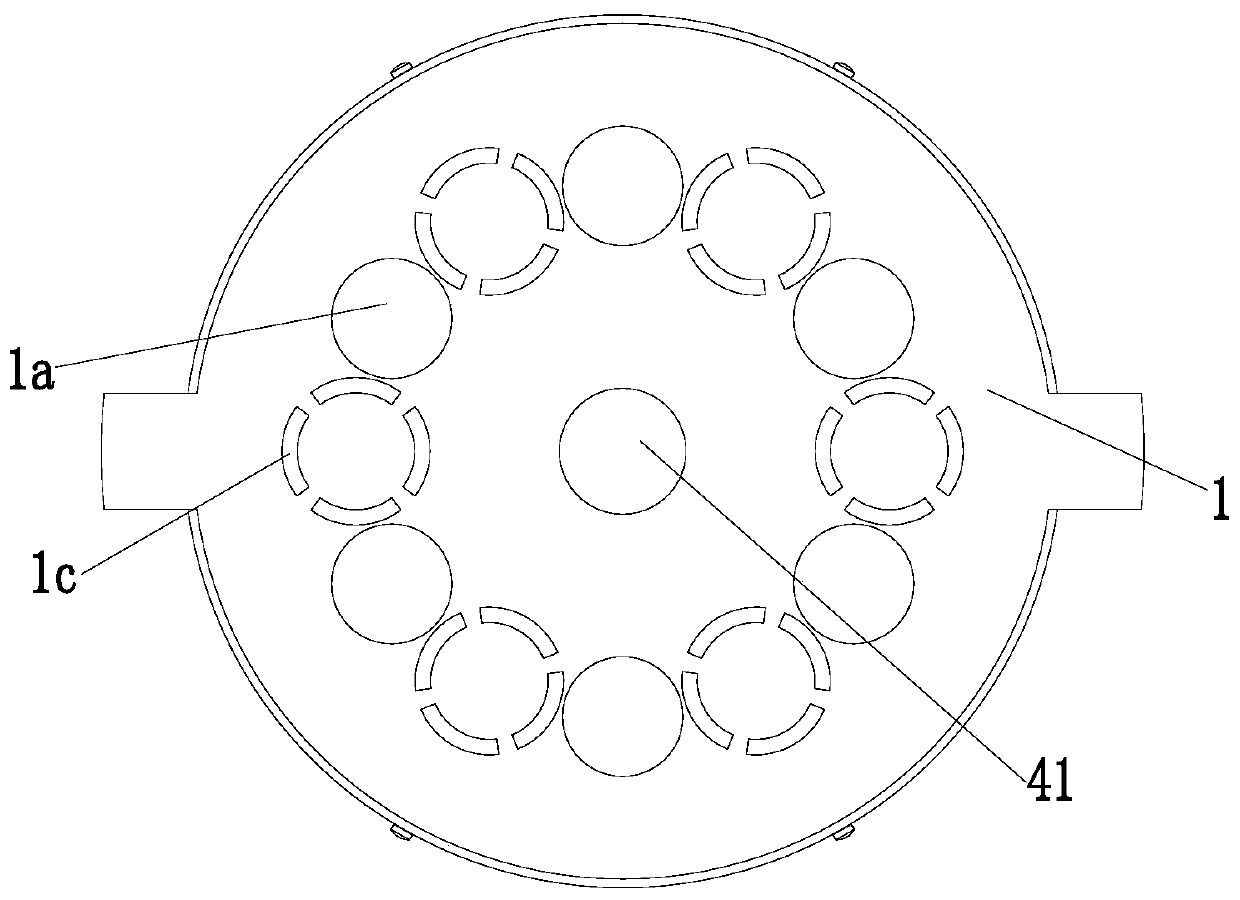

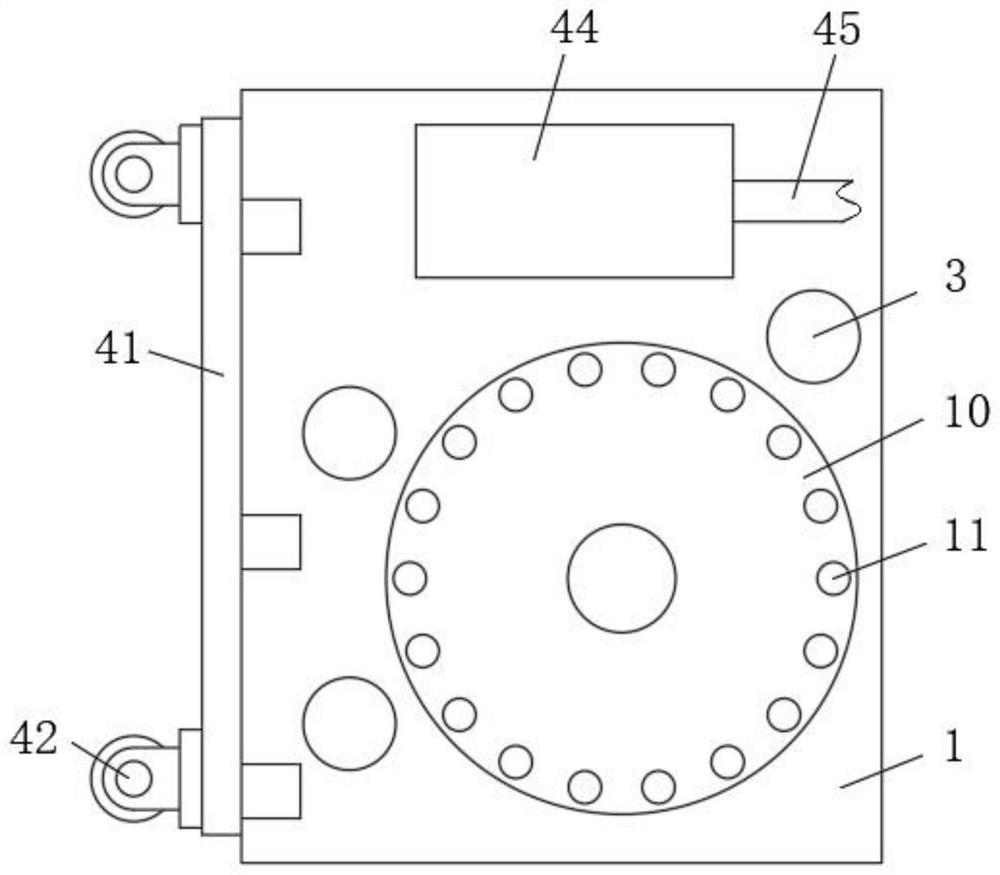

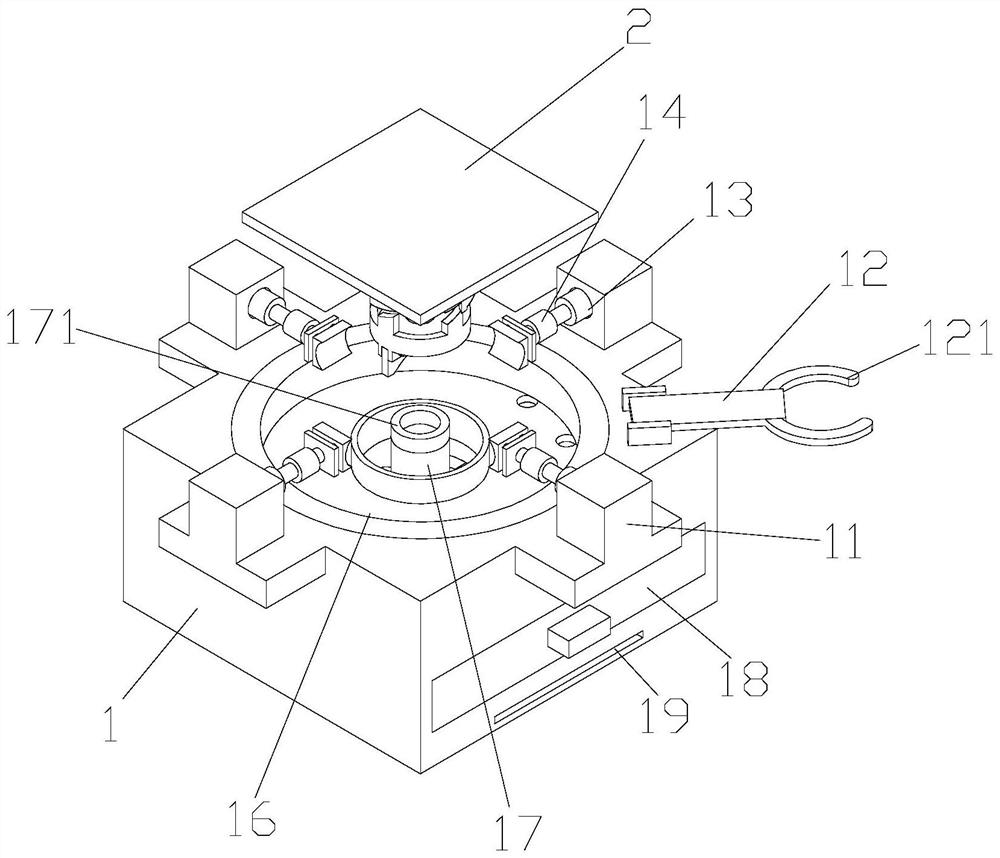

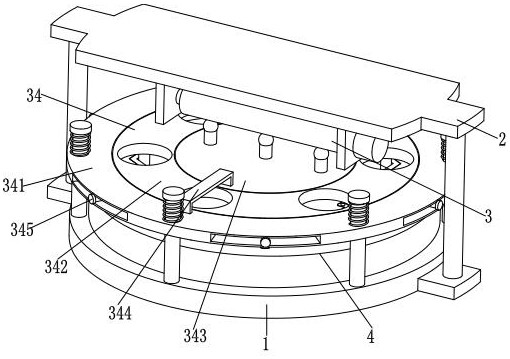

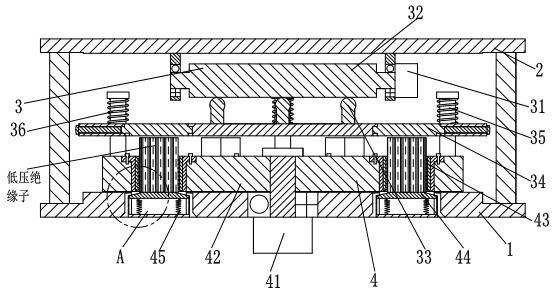

Forming manufacturing machining machine and machining method for low-voltage insulator

ActiveCN111531444AReduce fixation stepsImprove grinding efficiencyGrinding machinesGrinding work supportsStructural engineeringManufacturing engineering

The invention relates to a forming manufacturing machining machine and a machining method for a low-voltage insulator. The forming manufacturing machining machine comprises a fixing table board, a mounting frame, a pushing pressing mechanism and a material placing mechanism, wherein the upper end of the fixing table board is provided with the mounting frame, the lower end of the mounting frame isprovided with the pushing pressing mechanism, the lower end of the pushing pressing mechanism is tightly attached to the upper end of the material placing mechanism, the material placing mechanism ismounted on the fixing table board, blanking openings and material placing grooves are uniformly formed in the fixing table board in the circumferential direction of the fixing table board, the blanking openings and the material placing grooves are arranged at intervals, and the blanking openings and the material placing grooves each are of a circular structure. According to the forming manufacturing machining machine, through the common cooperation of the pushing pressing mechanism and the material placing mechanism, the operation of grinding the outer surface of the hexagonal low-voltage insulator is completed; and a grinding frame matched with the shape of the low-voltage insulator is arranged on the material placing mechanism in advance, so that it is guaranteed that the grinding frameis attached to the surface of the low-voltage insulator without repeated position adjustment of the material placing mechanism before grinding, the grinding efficiency is effectively improved, and thegrinding effect is guaranteed.

Owner:永州捷宝电讯塑胶五金有限公司

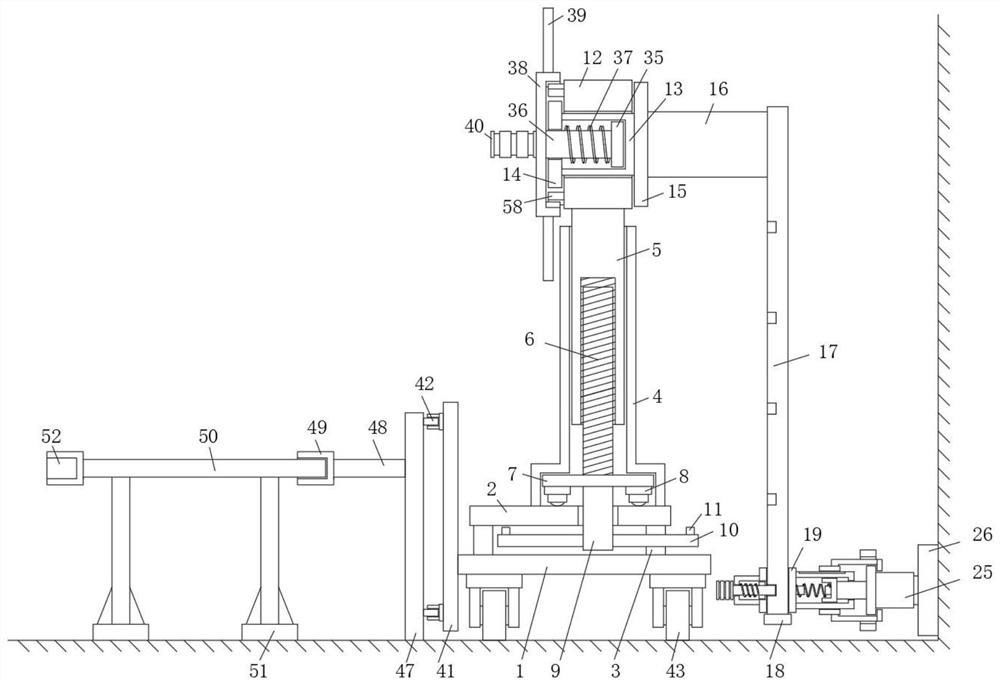

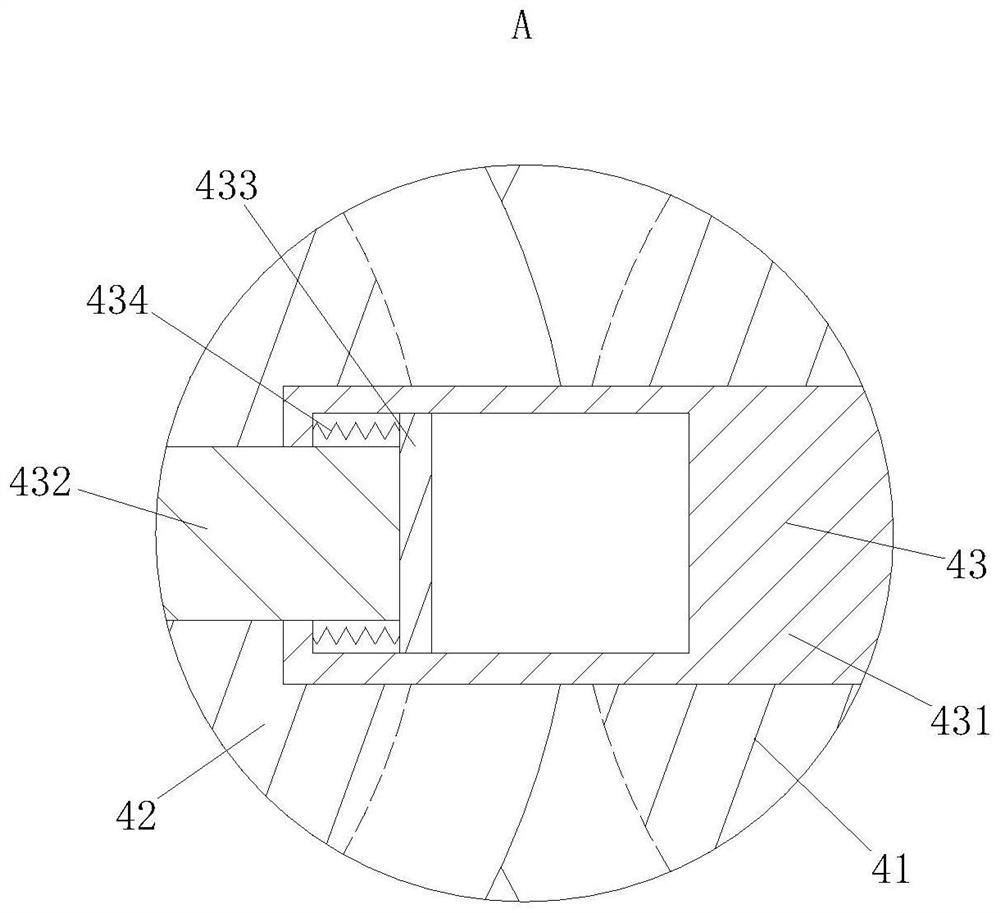

Machining equipment for automobile fittings

PendingCN108705402APolished evenlyAvoid grinding cornersEdge grinding machinesGrinding drivesDrive motorMachining

The invention relates to the field of machining of automobile fittings and discloses machining equipment for the automobile fittings. The machining equipment comprises an operating floor, one side ofthe operating floor is provided with a clamping mechanism, and the clamping mechanism is connected with a drive motor for driving the clamping mechanism to rotate. The operating floor is movably connected with a polishing mechanism, and the polishing mechanism comprises a polishing piece capable of rotating relative to the automobile fittings to be polished and a drive piece for driving the polishing piece to move. By means of the machining equipment for the automobile fittings, the problems that in the prior art, when inner walls of inner holes of the fittings are polished, labor investment is large, and work efficiency is low are solved.

Owner:重庆炅达贸易有限公司

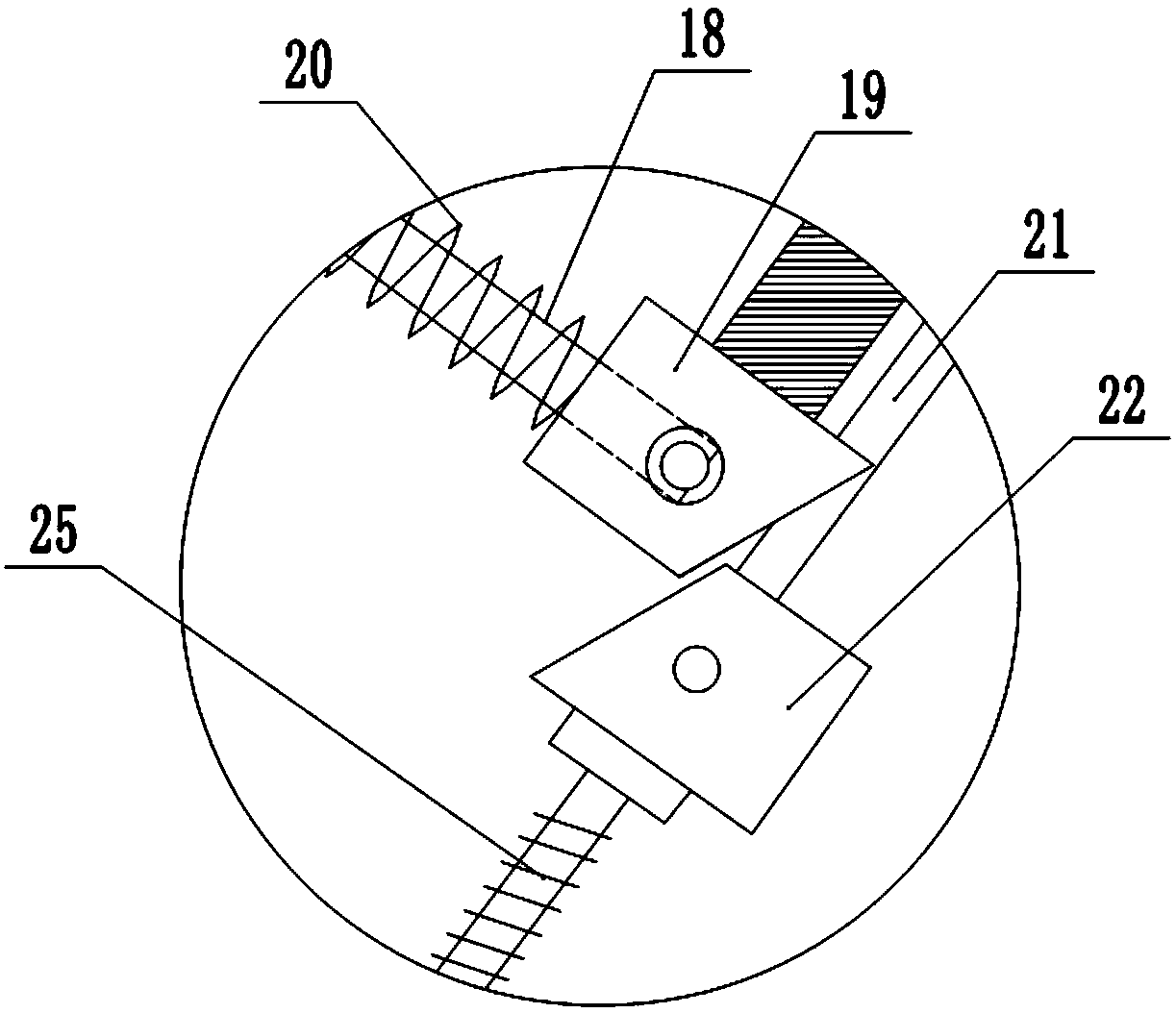

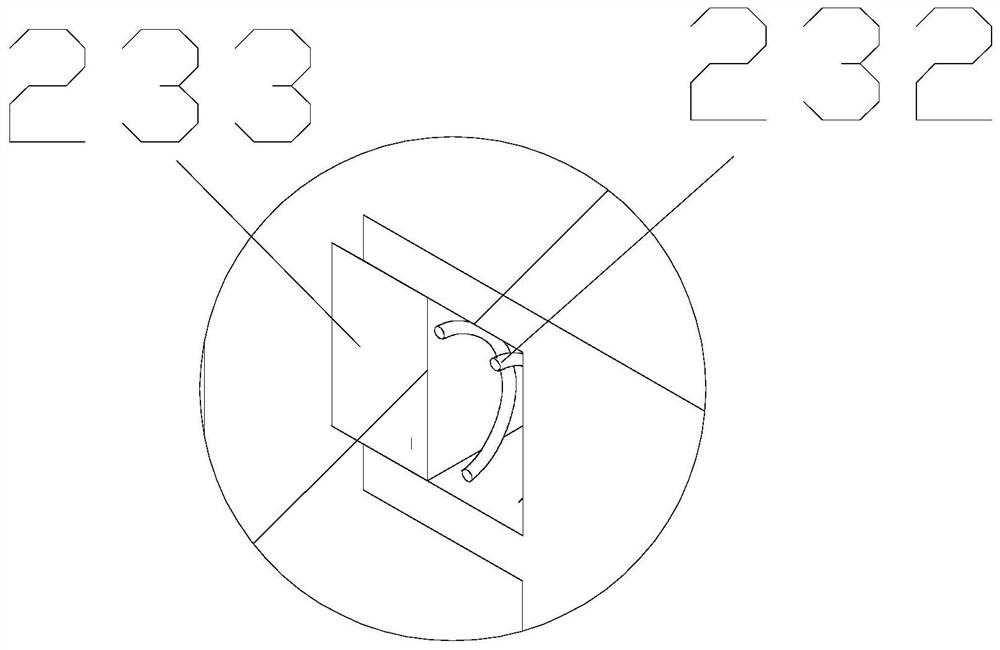

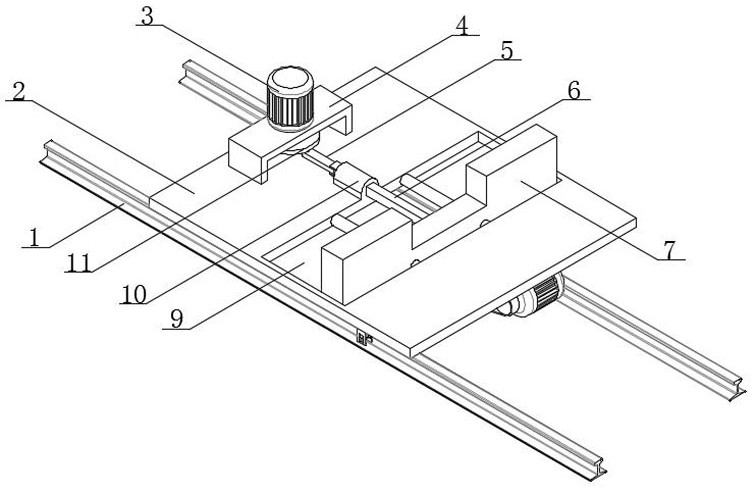

Milling machining device

ActiveCN109605162AAchieve circumferential grindingAvoid grinding cornersEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

The invention relates to the field of mechanical machining, and particularly discloses a milling machining device. The milling machining device comprises a fixing mechanism used for fixing a ring to be ground, the fixing mechanism can drive the ring to rotate, a grinding mechanism is arranged on one side of the fixing mechanism, and comprises a driving assembly and a grinding assembly, the drivingassembly comprises a first rotating shaft and a second rotating shaft, a synchronous belt is connected between the first rotating shaft and the second rotating shaft, a first fixed base and a secondfixed base are fixedly connected to the first rotating shaft and the second rotating shaft, two parallel bending rods are movably connected to the first fixed base, bending parts are arranged on the ends of the two bending rods, the two bending rods can form a rectangular structure, the middles of the two bending rods are movably connected to the second fixed base, and the grinding assembly is movably connected between the ends, away from the first fixed base, of the two bending rods. The problem that in the prior art, when the arc outer wall of a ring workpiece is ground, manual input is large, and the grinding amount is difficulty controlled is solved.

Owner:河南巨人起重机集团有限公司

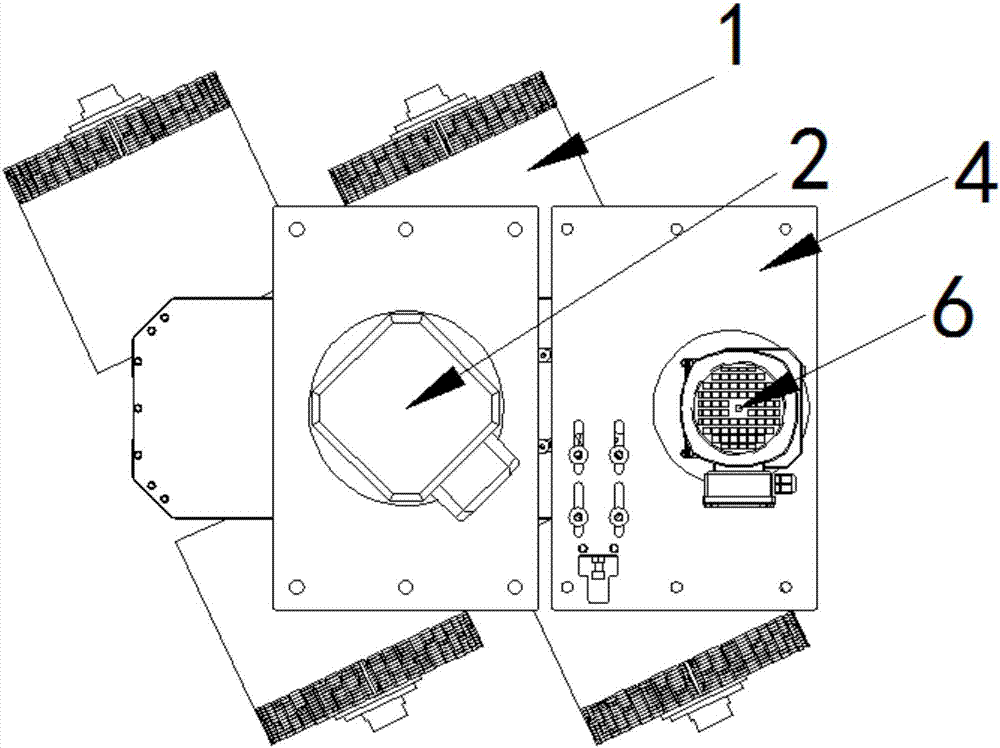

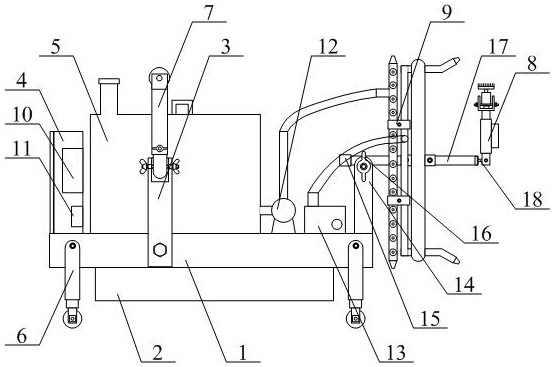

Environment-friendly wall surface smoothing device for building construction and building construction method

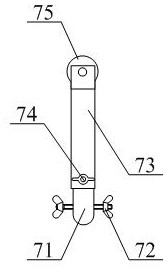

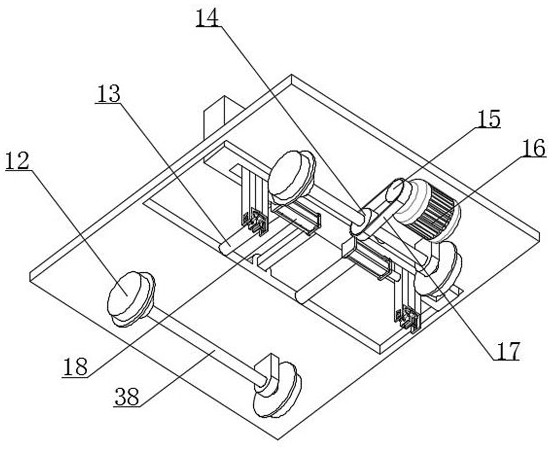

PendingCN113510549AAchieving Squeeze ContactSingle and stable force directionGrinding carriagesGrinding drivesArchitectural engineeringPlanishing

The invention discloses an environment-friendly wall surface smoothing device for building construction and a building construction method. The environment-friendly wall surface smoothing device comprises a smoothing trolley and an abutting plate assembly, the smoothing trolley comprises a trolley plate, and locking universal wheels are installed on the four corners of the bottom of the trolley plate; the environment-friendly wall surface smoothing device is characterized in that a stand is arranged at the top of the trolley plate, supporting legs are arranged between the bottom side of the stand and the trolley plate, a rail vertical pipe is fixedly mounted on the top side of the stand, the rail vertical pipe is of a rectangular pipeline-shaped structure, a rectangular lifting column is vertically and glidingly mounted in the rail vertical pipe, a threaded groove is formed in the bottom of the rectangular lifting column, a threaded column is connected in a threaded mode, a rotating circular plate is fixedly mounted at the bottom end of the threaded column, and a universal ball and a connecting rod are mounted on the bottom side of the rotating circular plate. According to the device, the wall surface smoothing effect is guaranteed, the polishing range is wide, using is more convenient and faster, labor is saved, the application range is wide, the design is reasonable, the structure is stable, and the using requirement of building workers for wall surface flatness treatment in the construction process is met.

Owner:葛泮忠

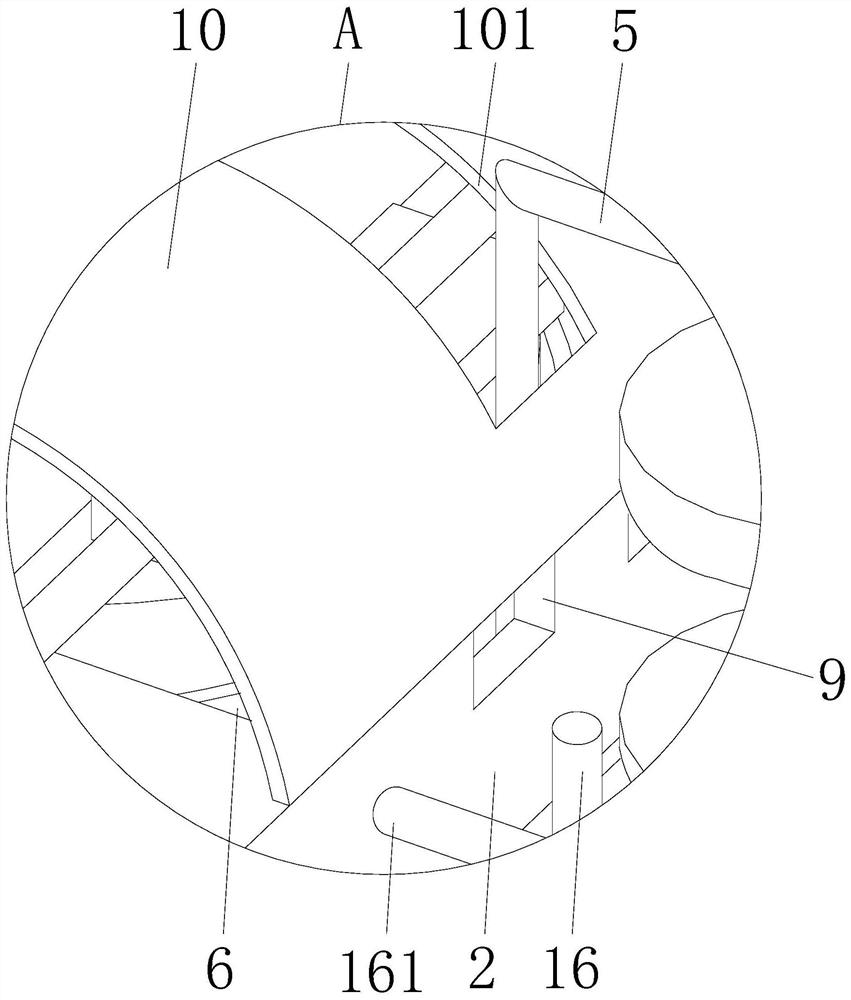

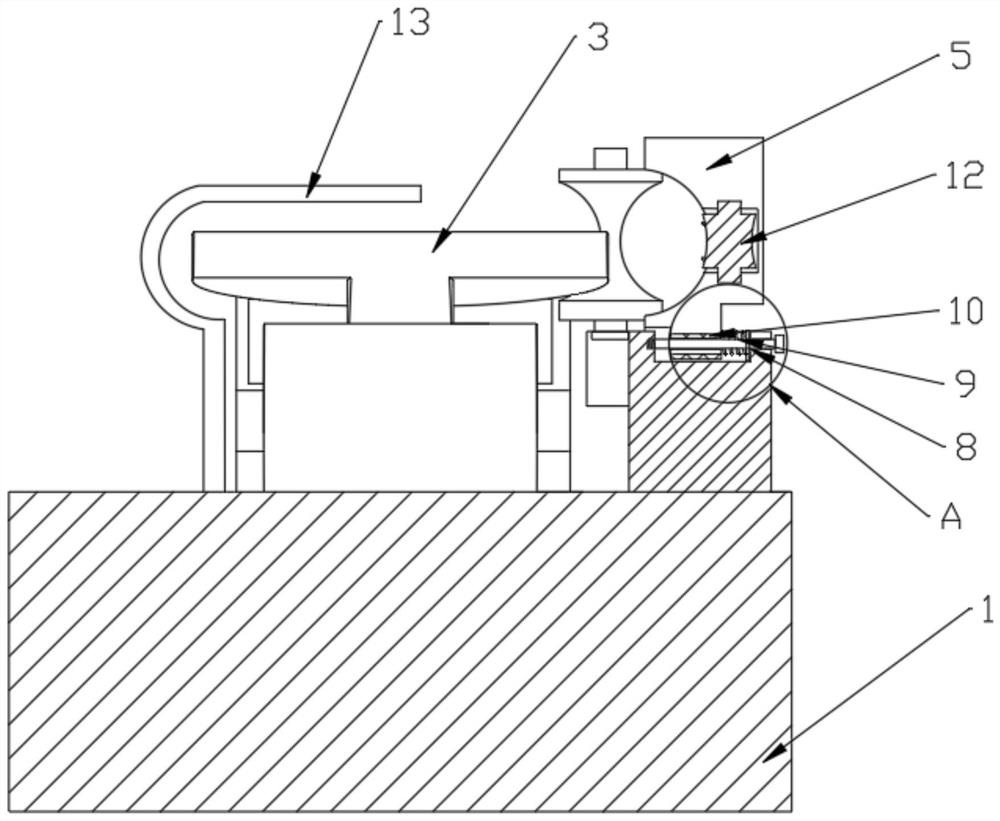

Magnetic abrasive finishing process machine

InactiveCN108747600ATimely dischargeInto fastEdge grinding machinesGrinding carriagesDraining tubeEngineering

The invention discloses a magnetic abrasive finishing process machine. The magnetic abrasive finishing process machine comprises a machine base, a processing box and a rotating magnetic disc, whereinthe machine base comprises a first supporting table and a second supporting table; the processing box is placed on the first supporting table, and the rotating magnetic disc comprises a rotating discand a magnet body; the magnet body is embedded and fixed to the rotating disc, a first motor is installed on the second supporting table, and the rotating disc is fixed to an output shaft of the firstmotor; the processing box comprises a box body and a cover body, a filter plate is arranged in the box body, and the filter plate and the box body are connected through a spring; the filter plate partitions the box body into a processing cavity and a chip removal cavity, a plurality of magnetic abrasives are placed in the processing cavity, and the pore size of filter holes is smaller than the size of the magnetic abrasives; a liquid inlet tube is fixed to the top of the inner wall of the cover body, and a plurality of spray heads are installed on the the liquid inlet tube; a first liquid storage barrel and a second liquid storage barrel are arranged on the sides of the machine base, the first liquid storage barrel is connected with the liquid inlet tube, and the first liquid storage barrel is used for supplying cooling liquid to the liquid inlet tube; and the second liquid storage barrel is connected with the chip removal cavity through a drain tube, and the second liquid storage barrel is used for collecting the cooling liquid and sweeps discharged from the processing box.

Owner:HAINING SHENGXIANG WIRE

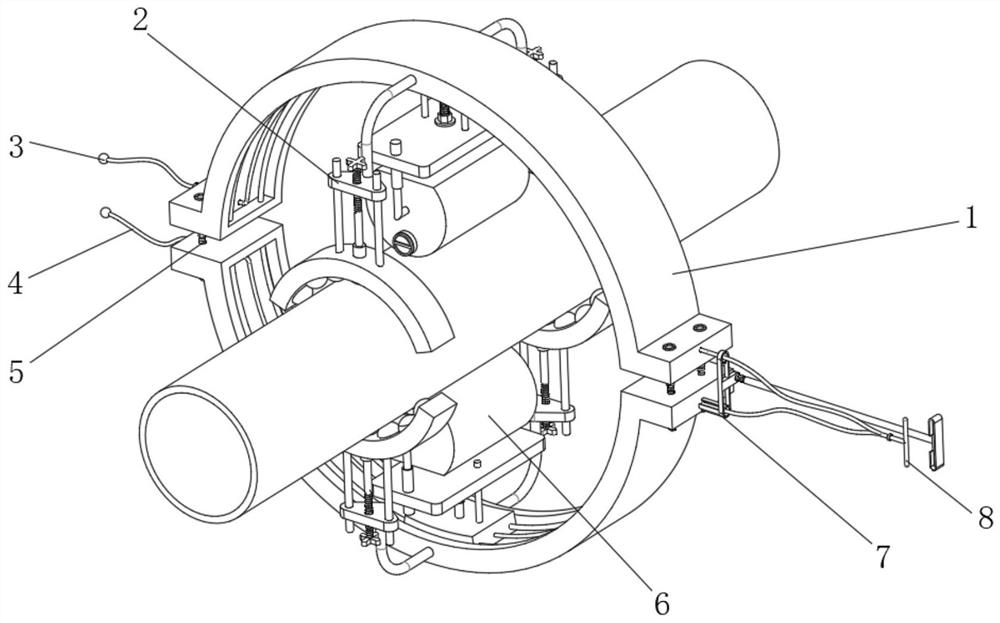

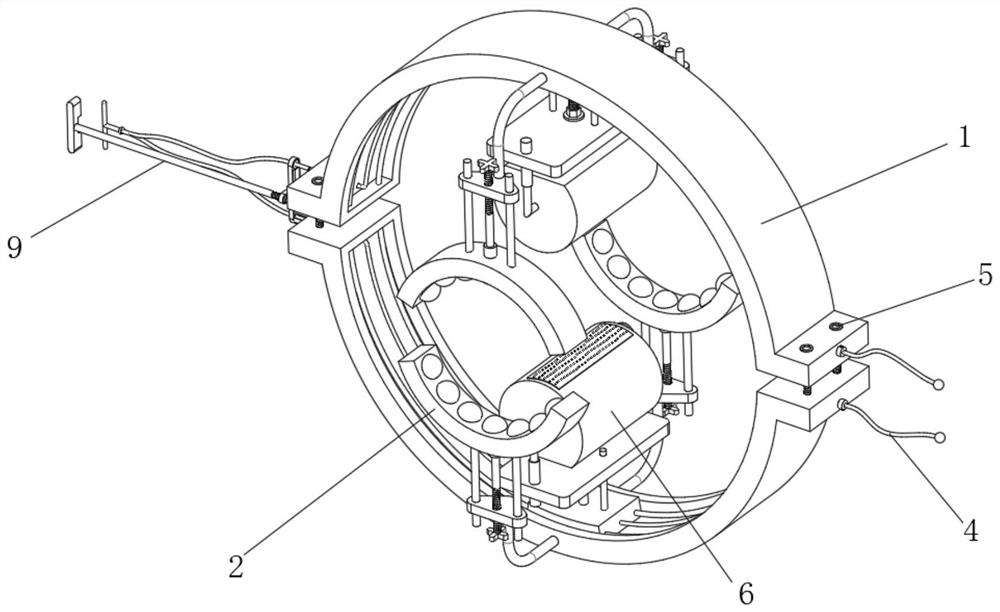

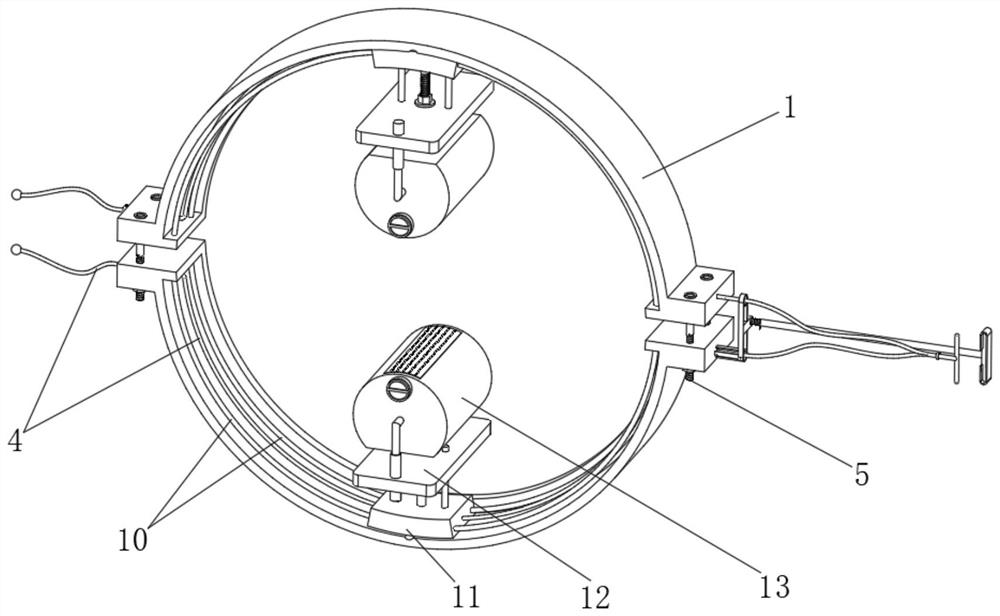

Water conservancy construction pipeline outer surface rust removal device and using method thereof

ActiveCN114083414AEasy to adaptImprove grinding efficiencyGrinding machinesGrinding work supportsCylindrical grindingBolt connection

The invention discloses a water conservancy construction pipeline outer surface rust removal device and a using method thereof, and relates to the technical field of pipeline outer surface rust removal devices. The grinding effect is improved. The device comprises two hoop-shaped mounting frames which are symmetrically arranged, the two hoop-shaped mounting frames are mounted and fixed through connecting bolts, supporting mechanisms are arranged on the two sides of each hoop-shaped mounting frame, and a grinding mechanism is arranged on the inner side of each hoop-shaped mounting frame. The method comprises the following steps that a user places the two hoop-shaped mounting frames on the outer side of a pipeline, and the two hoop-shaped mounting frames are connected and fixed through connecting bolts. Through arrangement of the hoop-shaped mounting frames, the cylindrical polishing part, the elastic rope, the handle and other structures, the elastic rope can be repeatedly dragged through the handle, the sliding base is pulled to slide back and forth along the surface of the arc-shaped guide rod under the elastic cooperation of the elastic rope, and the pipeline is polished through the cylindrical polishing part; and since thegrinding track of the cylindrical grinding part is curved, the device can better adapt to the pipeline surface, and the grinding efficiency and the grinding effect are improved.

Owner:沧州昊海水利工程质量检测有限公司

Multi-axis linkage position adjusting type die casting deburring device

InactiveCN114505747AIncrease freedomImprove the scope of grindingEdge grinding machinesAbrasive machine appurtenancesDie castingStructural engineering

The invention discloses a multi-axis linkage position adjusting type die casting deburring device, and relates to the technical field of die casting deburring, the multi-axis linkage position adjusting type die casting deburring device comprises a feeding assembly, a displacement assembly, a fixing assembly, a lower rack and a thermal explosion assembly, the feeding assembly is fixedly connected with the ground, the lower rack is located on the side edge of the feeding assembly, and the lower rack is also fixedly connected with the ground; the displacement assembly, the fixing assembly and the thermal explosion assembly are fixedly connected with the upper surface of the lower rack. According to the five-axis linkage deburring device, accurate control over the position of the cutter is achieved in a five-axis linkage mode, the degree of freedom of the cutter is improved to a great extent, the grinding application range of the cutter is widened, and the universality of the deburring device is improved. By compensating the local deformation of the grinding sleeve, the stability of the grinding process is greatly improved, and the service life of the cutter is prolonged. Moreover, the compensation amount of the local deformation is linearly controlled through the heating amount of the local deformation, and the compensation precision is also guaranteed.

Owner:哈工大机器人(中山)无人装备与人工智能研究院

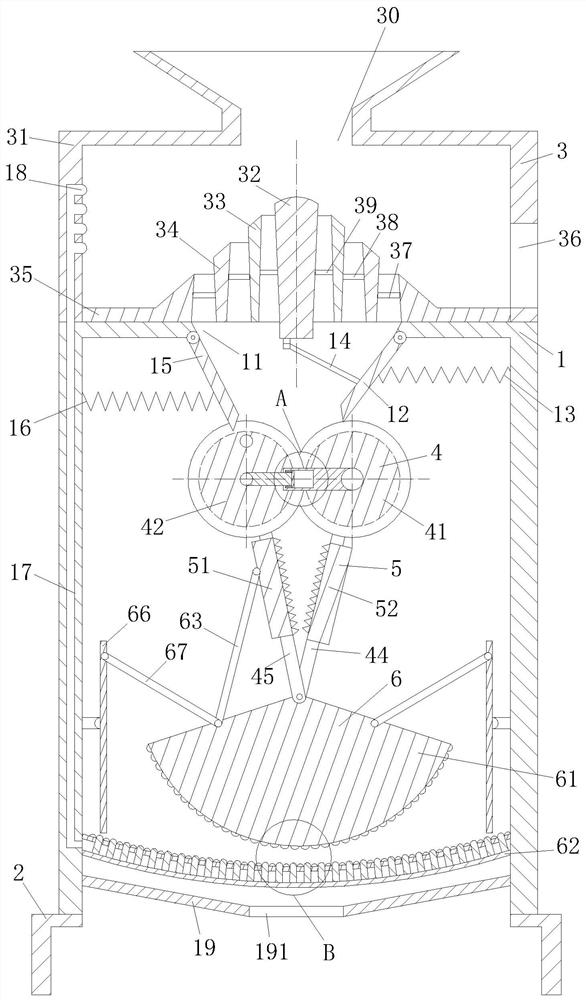

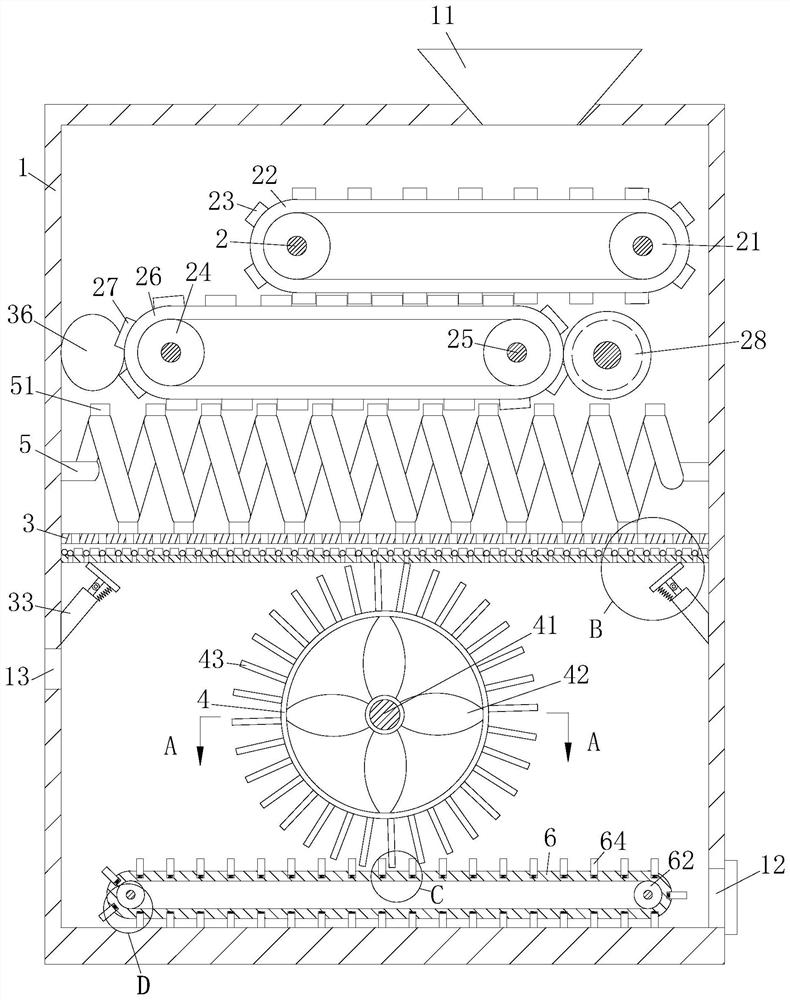

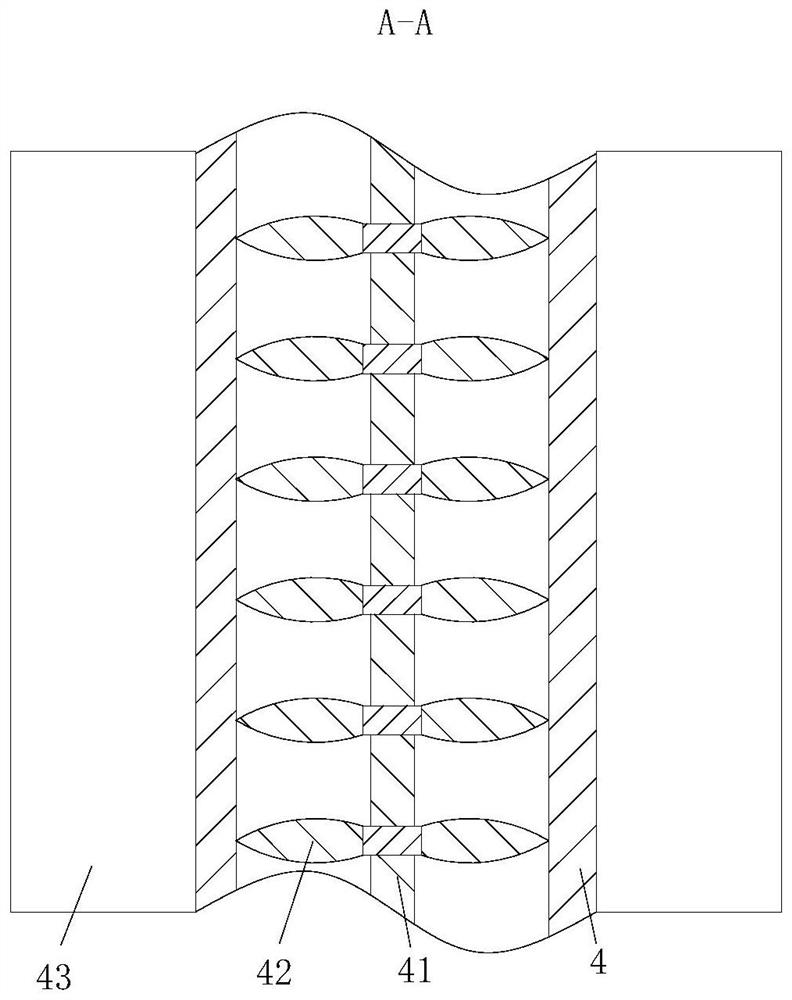

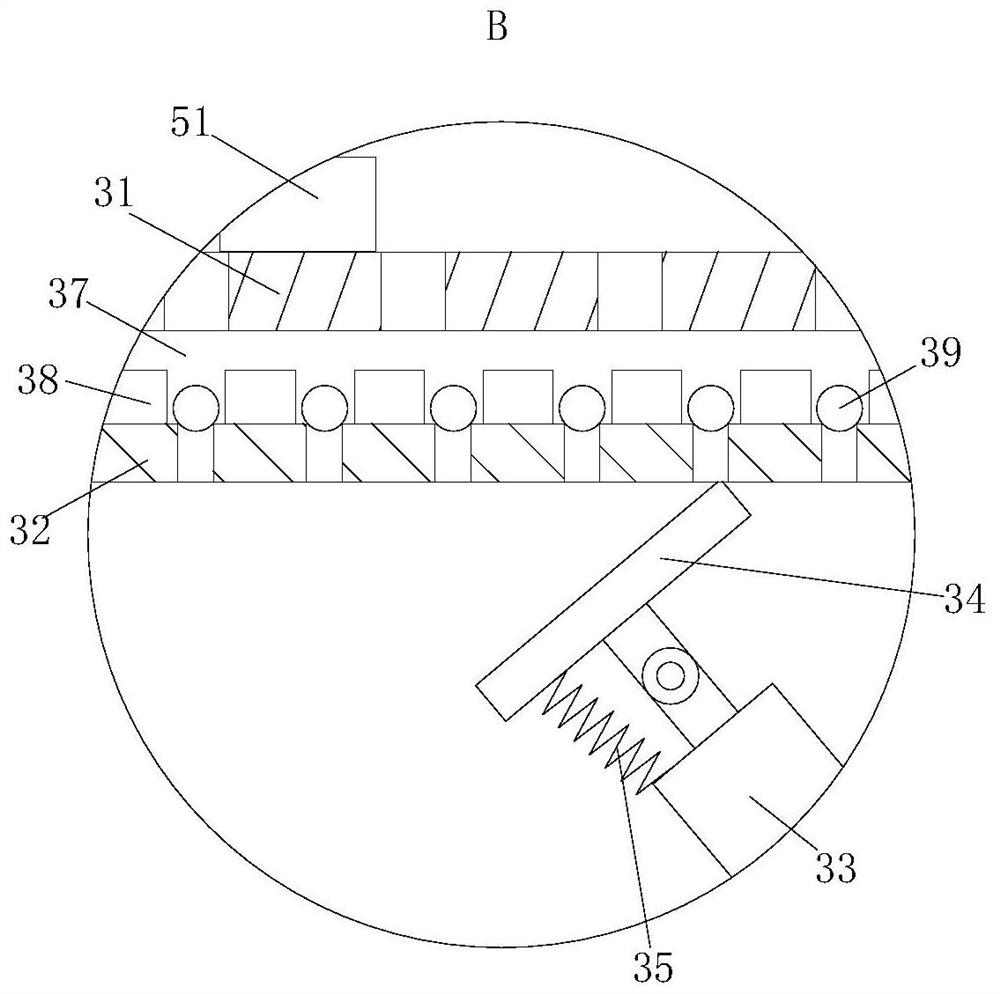

Sand screening and grinding equipment for construction engineering

The invention belongs to the technical field of constructional engineering equipment and particularly discloses sand and stone screening and grinding equipment for constructional engineering. The sandand stone screening and grinding equipment comprises a frame body, a base and a controller. The top of the frame body is provided with a screening unit. A first guiding unit, a second guiding unit and a third grinding unit are arranged inside the frame body. The first grinding unit comprises a first grinding gear and a second grinding gear. A first fixing rod is divided into two parts, a thick rod and a thin rod. The screening unit comprises a screening cabin, a rotating shaft, a first rotating ring, a second rotating ring and a third rotating ring. The second grinding unit comprises a firstgrinding block and a second grinding block. The third grinding unit comprises a third grinding block, a filter plate and a transmission rod. The sand and stone screening and grinding equipment is simple in structure and convenient to use; sand and stone can be screen and ground effectively; and grinding is conducted completely, and the efficiency is high.

Owner:安徽同胜电力科技有限公司

Adjustable suction and application anticorrosion device for internal surface of oil exploitation pipe

ActiveCN111853424APrevent impact on quality of workStable supportCorrosion preventionPipe protection against corrosion/incrustationWireless transmissionProgrammable logic controller

The invention provides an adjustable suction and application anticorrosion device for the internal surface of an oil exploitation pipe. The adjustable suction and application anticorrosion device comprises a chassis, a power box, a first supporting plate, a control box, a coating box, telescopic power pushing frame structures, a rotatable telescopic supporting pipe structure, a detectable rotatingcleaning brush structure, a cleanable spraying frame structure, a programmable logic controller (PLC), a wireless transmission module, a spraying pump, a miniature air pump, a second supporting plate, a rotating motor, a fixing bolt, a supporting pipe and a supporting rotating pipe. The power box is in bolted connection with the middle position of the lower end of the chassis. By arranging the chassis, the first supporting plate, a connecting rod, a telescopic pipe, an adjusting bolt and a rubber wheel, the adjusting bolt is beneficially loosened during working, then the telescopic pipe is pulled up and down, the rubber wheel makes contact with the inner wall of a pipeline, then the adjusting bolt is tightened, support of equipment is facilitated during working, and the situation that during working, the equipment tilts and affects the working quality is prevented.

Owner:山东万盟能源科技有限公司

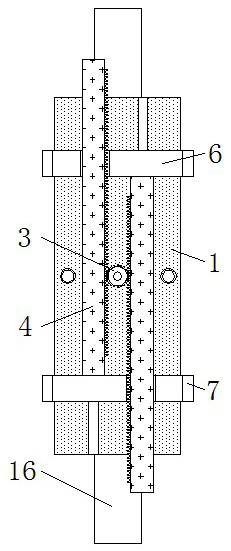

A round rod-shaped metal grinding device

ActiveCN112207640BEasy to applyEasy to polishRevolution surface grinding machinesGrinding work supportsPolishingMetal machining

The present invention is applicable to the technical field of metal processing, and provides a circular rod-shaped metal grinding device, which comprises: a workbench for supporting and installing; a placement frame, which is slidably arranged on the workbench , used to support the round rod-shaped metal to be polished; the grinding disc is used to grind the round rod-shaped metal; the driving part is used to drive the grinding disc to rotate; wherein, the grinding disc and the placing frame are inclined, and the grinding The disk exerts a force inclined along the axial direction of the circular rod-shaped metal on the polished circular rod-shaped metal, so that the circular rod-shaped metal rotates inside the placement frame and is forwarded. The circular rod-shaped metal of the rotating grinding disc has a force inclined to the axis, which plays the role of advancing and deflecting, so that the surface of the circular rod-shaped metal can be polished in all directions, and the device is simplified, and the manufacturing cost is reduced. save resources. The invention has the advantages of simple structure, convenient operation, comprehensive polishing, energy saving, and convenient popularization and implementation.

Owner:苏州铜盟电气有限公司

A processing equipment suitable for ball valve spool

ActiveCN110508873BImprove sanding effectEasy to operatePlug valvesFiling/rasping devicesMachiningPiston rod

The invention discloses a machining device suitable for a ball valve core. The machining device comprises a machining table and a mounting plate arranged on the machining table, wherein a mounting block is arranged on the machining table; a mounting cavity is formed in the mounting block; a fixing component is arranged in the mounting cavity; a first air cylinder is arranged at the bottom of the mounting plate; a file is arranged on a first air cylinder piston rod; a first movable cavity is formed in the machining table; a supporting rod is arranged in the first movable cavity; a friction padis arranged at the top of the supporting rod; the two sets of fixing components are arranged on the machining table; the file can rotate during moving with the first air cylinder piston rod; and an infusion tube is further arranged above the machining table. Through alternate matching of the two sets of fixing components, different faces of a valve body are machined by the file, so that the grinding dead angles are avoided, the grinding effect of the valve core is improved, and therefore, the valve core is simpler and more convenient to machine.

Owner:YUHUAN JIAYU VALVE CO LTD

Centerless grinding machine

InactiveCN104827356AEasy to collectAvoid grinding cornersRevolution surface grinding machinesGrinding/polishing safety devicesCenterless grindingEngineering

The invention provides a centerless grinding machine, comprising a pedestal, a working platform, an installation seat, a protective sleeve, a first clamping component, a grinding component and a second clamping component, wherein the working platform and the protective sleeve are arranged on the base; the installation seat is arranged on the base in a sliding manner; the first clamping component comprises a first base, a first bracket and a telescopic rod; the first base is arranged on the pedestal in the sliding manner; the first bracket is arranged on the first base through the telescopic rod; a workpiece is arranged on the first bracket, and is positioned in the protective sleeve; the second clamping component comprises a second bracket, a supporting rod and an adjusting wheel; the second bracket is arranged on the working platform in the sliding manner; the supporting rod is arranged on the second bracket in the sliding manner; the adjusting wheel is positioned in the protective sleeve, and is positioned above the workpiece; the grinding component comprises a grinding bracket and a grinding wheel; the grinding bracket is arranged on the working platform in the sliding manner; the grinding wheel is arranged on the grinding bracket, and is positioned in the protective sleeve. The centerless grinding machine provided by the invention has the advantage that abrasive dust is conveniently collected and cleaned.

Owner:芜湖中驰机床制造有限公司

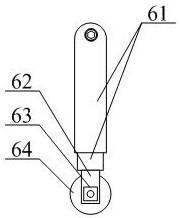

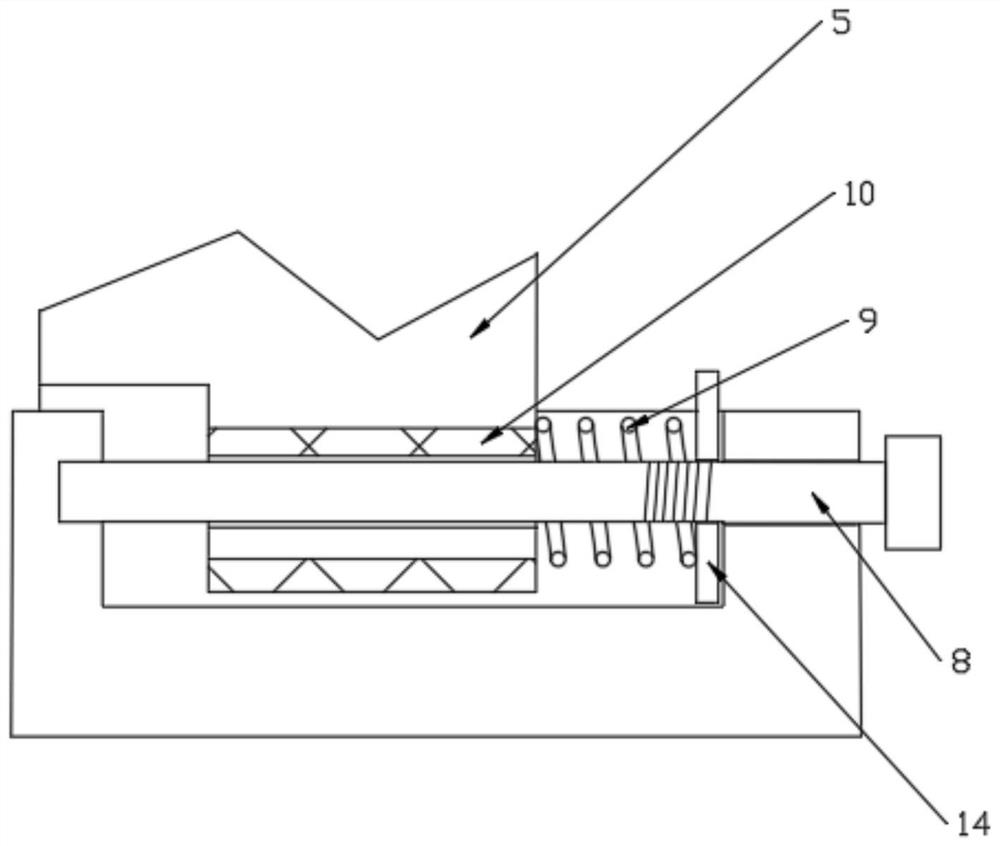

Round rod-shaped metal grinding device

ActiveCN112207640AEasy to applyEasy to polishRevolution surface grinding machinesGrinding work supportsPolishingMetal machining

The invention is applicable to the technical field of metal machining, and provides a circular rod-shaped metal grinding device. The circular rod-shaped metal grinding device comprises a workbench, aplacing frame, a polishing plate and a driving part, wherein the workbench is used for supporting and installing, the placing frame is arranged on the workbench in a sliding mode and used for supporting polished round rod-shaped metal, the polishing plate is used for grinding the round rod-shaped metal, the driving part is used for driving the grinding plate to rotate, the polishing plate and theplacing frame are obliquely arranged, and the polishing plate applies force inclining in the axial direction of the circular rod-shaped metal to the polished circular rod-shaped metal, so that the circular rod-shaped metal rotates inside the placing frame and is conveyed forwards. The rotating polishing plate applies the force inclining towards the axis to the polished circular rod-shaped metal, the force has the effect of advancing and deflecting so that the surface of the circular rod-shaped metal can be ground in all directions, the device is simplified, the production and manufacturing cost is reduced, and resources are saved, the device has the advantages of being simple in structure, convenient to operate, comprehensive in polishing, energy-saving and convenient to popularize and implement.

Owner:苏州铜盟电气有限公司

Railway track maintenance rust mark polishing device

The invention discloses a railway track maintenance rust mark polishing device, and relates to the technical field of track 1 polishing. The device comprises a walking frame erected on a track, a reciprocating device fixed to the top of the walking frame, a power device fixed to the bottom of the end, opposite to the reciprocating device, of the walking frame, a movable groove formed in the center of the top face of the walking frame and a grinding device movably connected into the movable groove. The grinding device comprises a cross beam and grinding pieces located below the cross beam and clamped on the two sides of the track, movable rods are fixedly connected to two side plates of the movable groove in parallel, the cross beam is movably connected to the movable rods in a sleeving mode, and adjusting grooves are formed in the two ends of the movable cross beam. According to the railway track maintenance rust mark polishing device, through cooperative arrangement of the fixing rod and the polishing piece, in the using process of the device, the fixing rod can be used for clamping the polishing piece and a track and completely attaching the polishing piece to the track, comprehensive polishing can be conducted on the track, and polishing dead corners are avoided.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

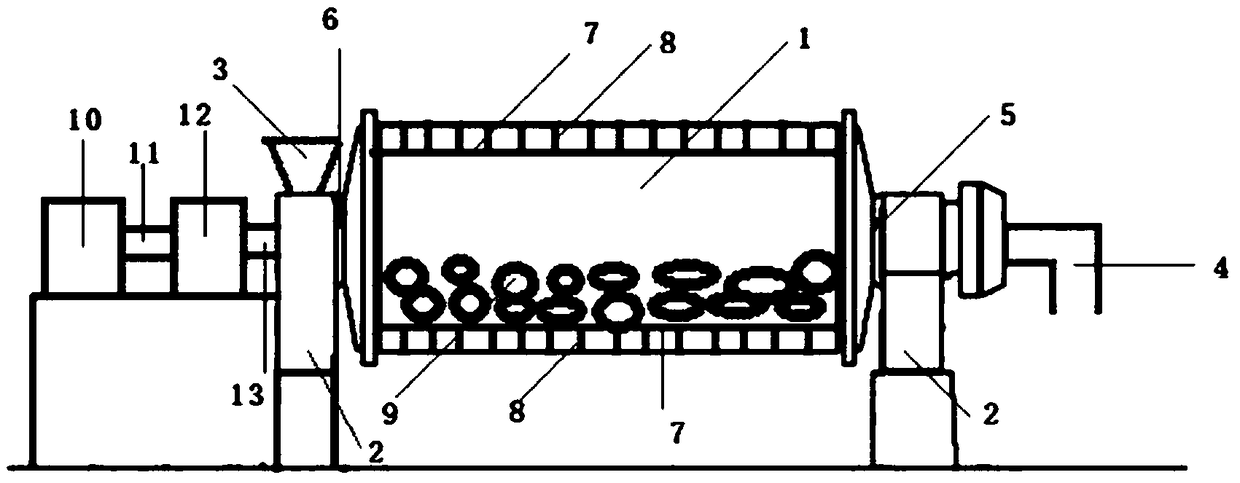

Grinding mechanism for pulverized coal production

PendingCN113413993AAvoid grinding cornersImprove grinding effectDrying solid materialsGrain treatmentsElectric machineryCoal

The invention discloses a grinding mechanism for pulverized coal production. A first supporting rod and a second supporting rod drive a grinding roller to rotate around the central axis of a rotary drum, and meanwhile the grinding roller rotates automatically, and thus pulverized coal is fully ground. A power oil cylinder drives a translation rod to move up and down, and a connecting rod structure formed among the translation rod, a transverse rod, a transmission rod, a vertical rod and a third supporting rod is used for driving a scraping plate to move downwards to abut against the pulverized coal. The scraping plate rotates around the central axis of the rotary drum along with the second supporting rod, and the scraping plate scrapes the pulverized coal flatly and distributes the pulverized coal evenly, so that the situation that the grinding effect is affected due to accumulation of the pulverized coal is avoided. The problem that in an existing grinding mechanism, drying and grinding are conducted at the same time, and danger exists is solved through a drying device. The drying device drives stirring blades A and stirring blades B to stir through a grinding motor, and the pulverized coal makes full contact with a main electric heating pipe, so that the pulverized coal is evenly heated. A first oil cylinder drives dispersing pieces to rotate, the included angle between the dispersing pieces and the stirring pieces A is adjusted, and therefore the pulverized coal makes full contact with the dispersing pieces.

Owner:镇江市蓝火环保能源有限公司

Polishing device convenient size adjustment for water purifier filter element machining

PendingCN113997133AAdjust inner sizeExtended replacement timeRevolution surface grinding machinesGrinding drivesElectric machineStructural engineering

The invention discloses a polishing device convenient for size adjustment for water purifier filter element processing, and relates to the technical field of water purifier filter element processing. The polishing device convenient for size adjustment for water purifier filter element processing comprises a base, a bracket is fixed above the base, a hydraulic rod is mounted above the bracket, a sleeve is arranged below the hydraulic rod, a motor is installed between the sleeve and the hydraulic rod, a lantern ring is connected to the bottom of the motor, a sliding way is arranged on the surface of the base, a rolling shaft is installed in the sliding way, and a pull wire is connected to the surface of the rolling shaft. The polishing device convenient for size adjustment for water purifier filter element processing is provided with the sleeve, and the sleeve is formed by connecting a plurality of sections of sleeves together, so that the sleeve can be detached; and the sleeve with the most serious abrasion on a bottom layer is replaced above the whole sleeve, so that the replacement time can be prolonged.

Owner:东莞市正通机电设备设计有限公司

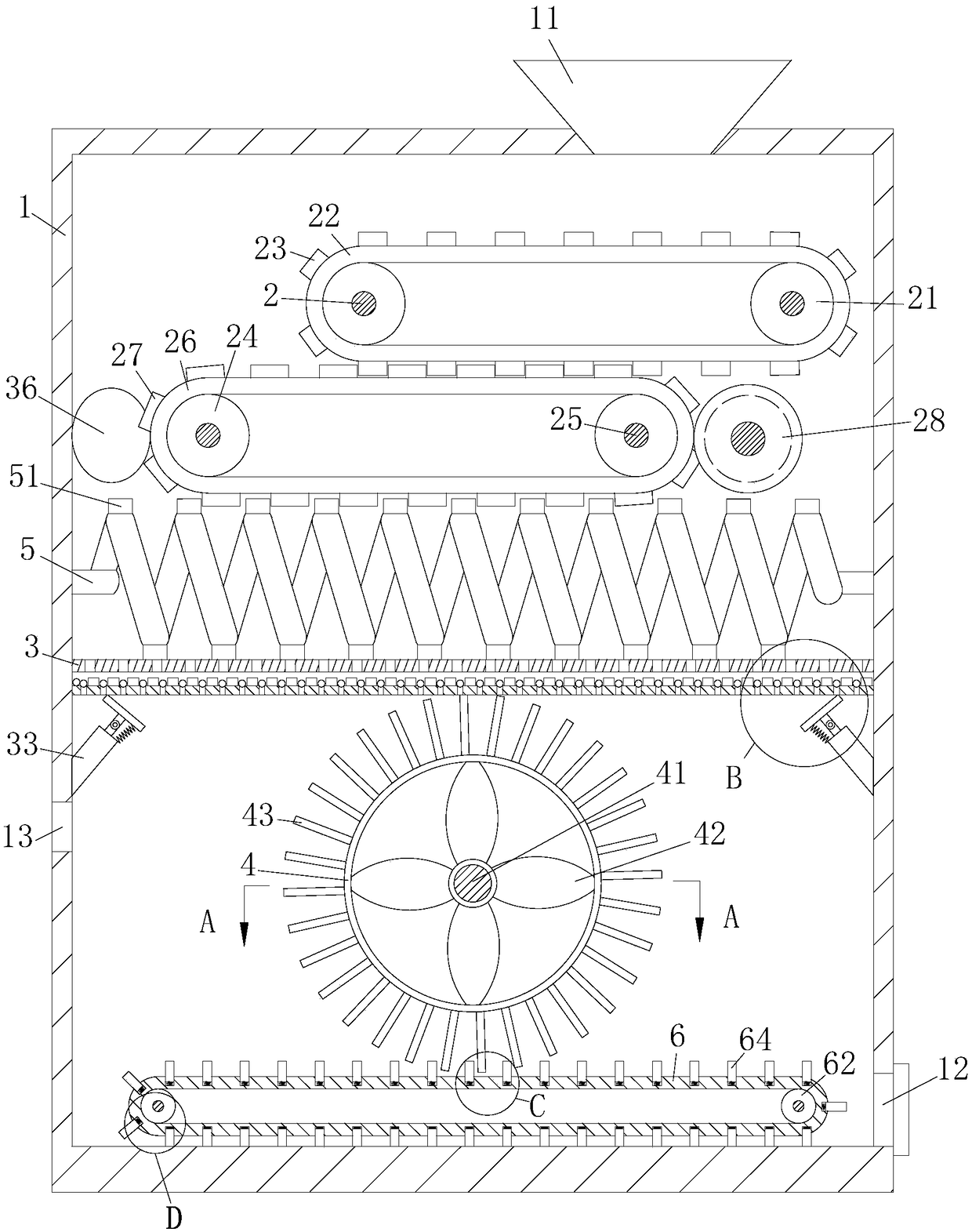

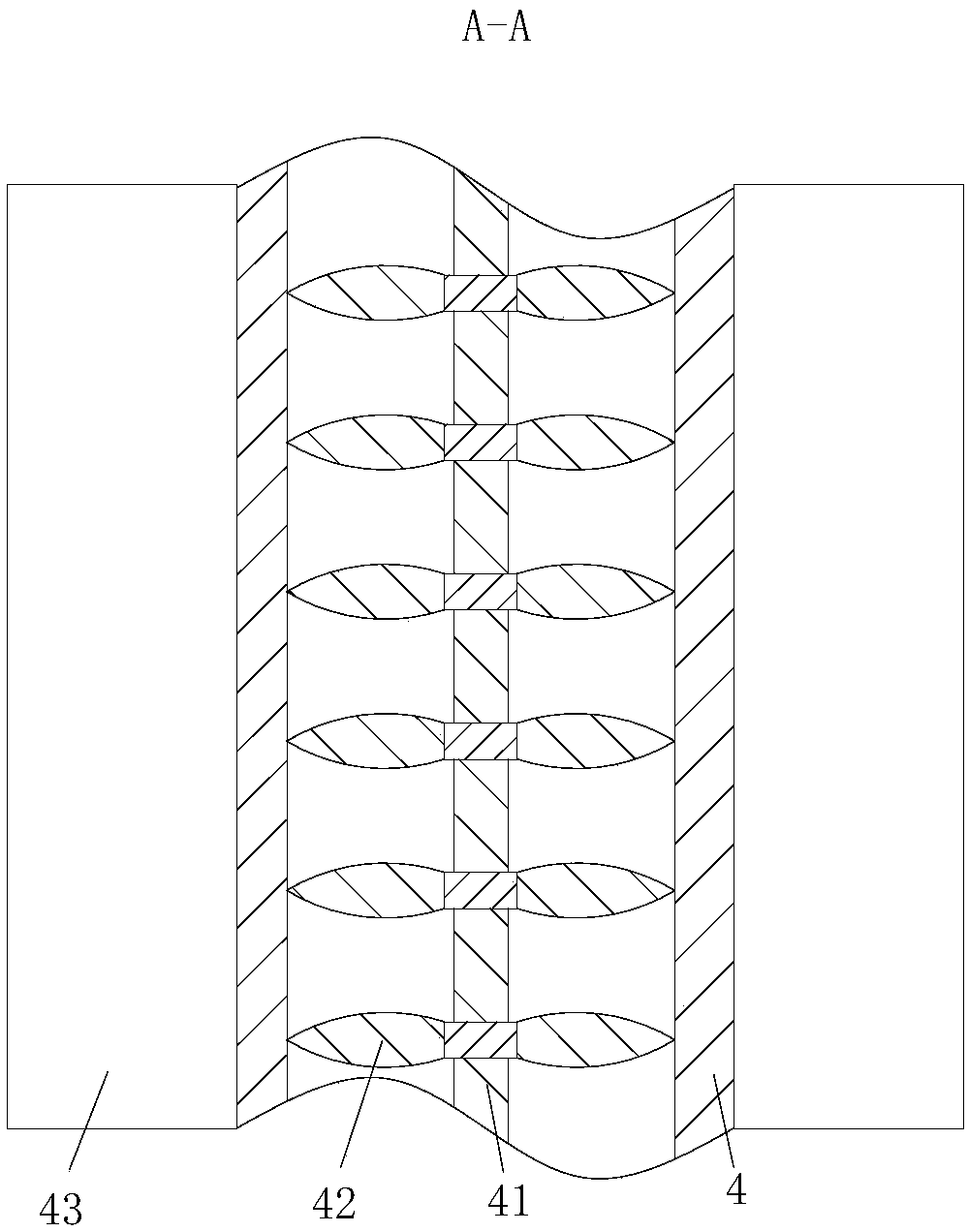

Raw material processing equipment for ceramic production

Owner:浙江龙昱机械科技有限公司

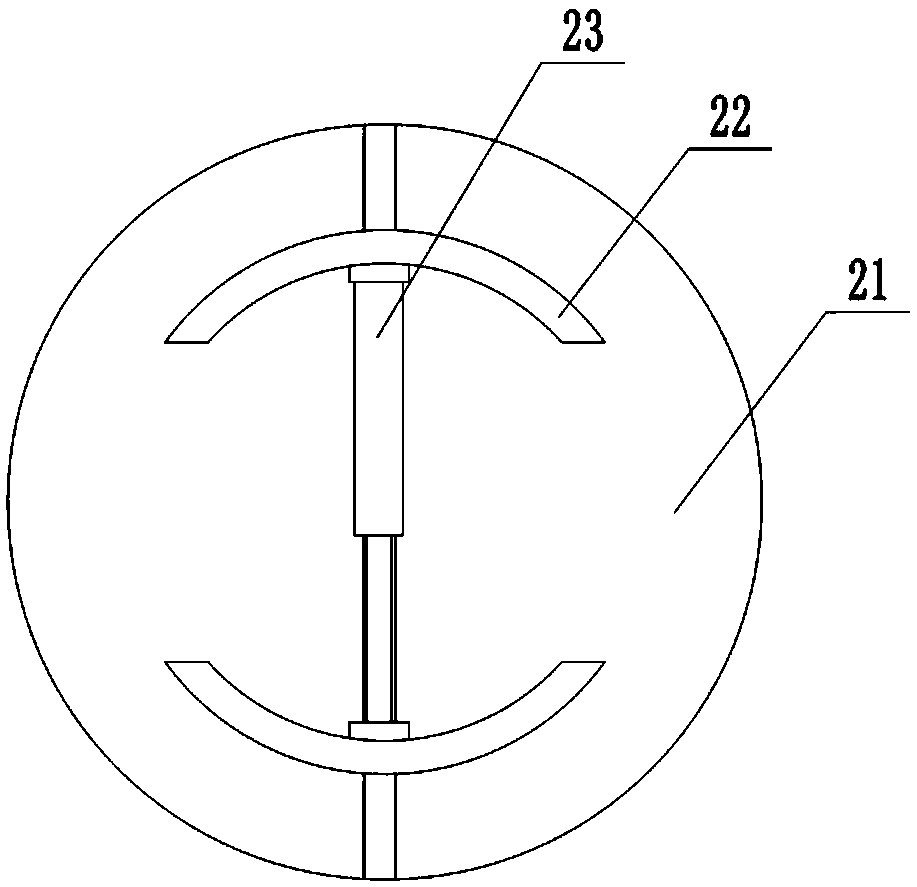

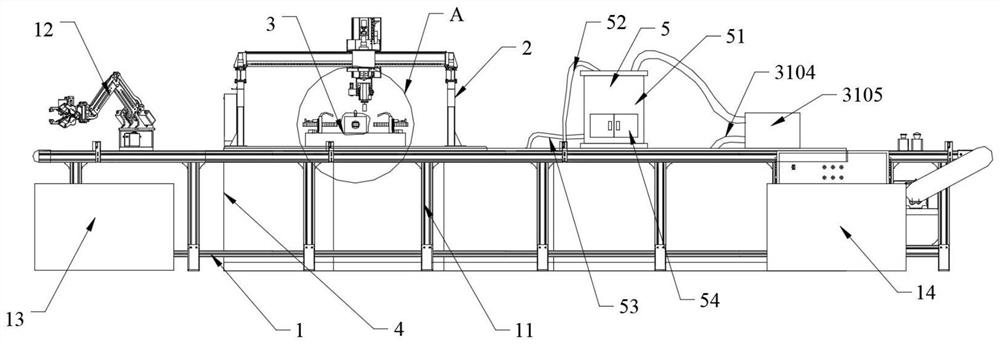

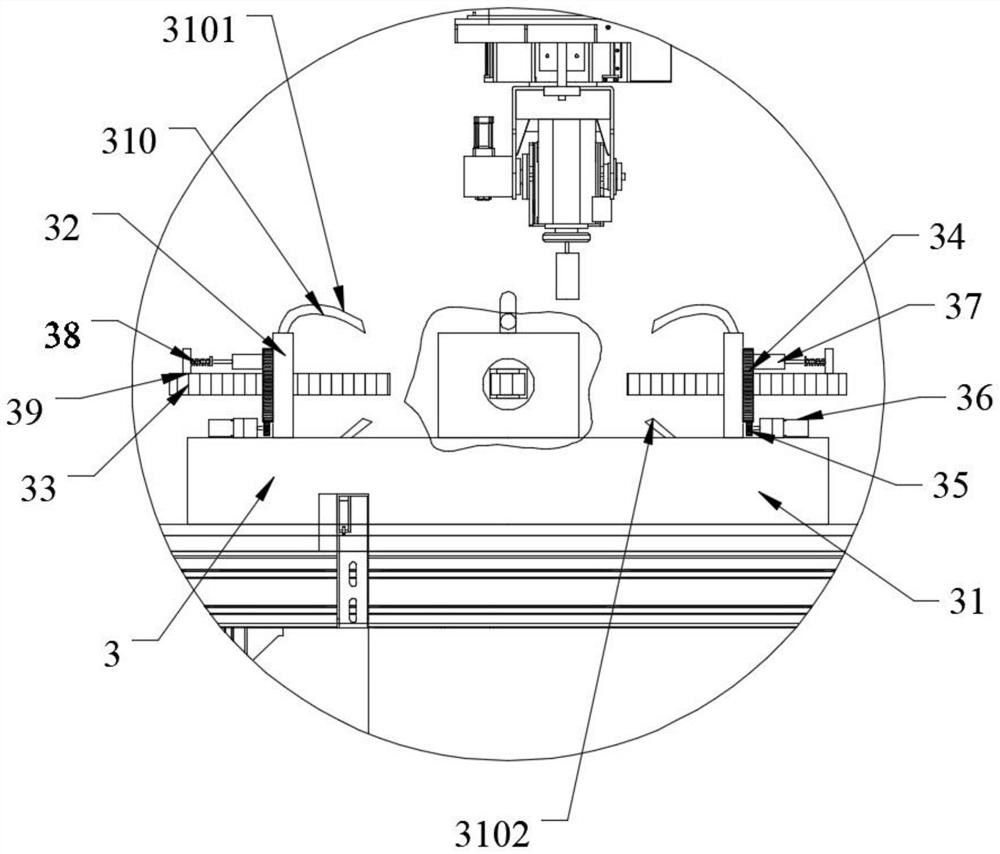

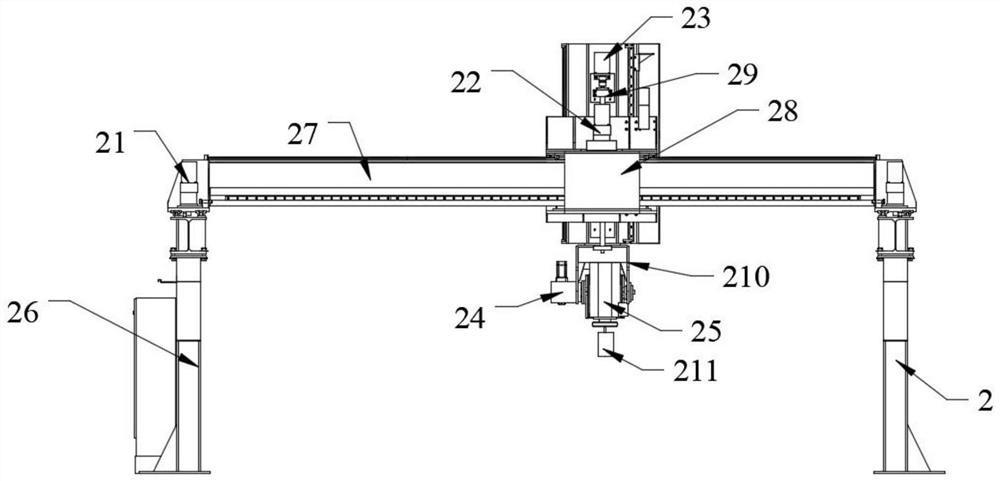

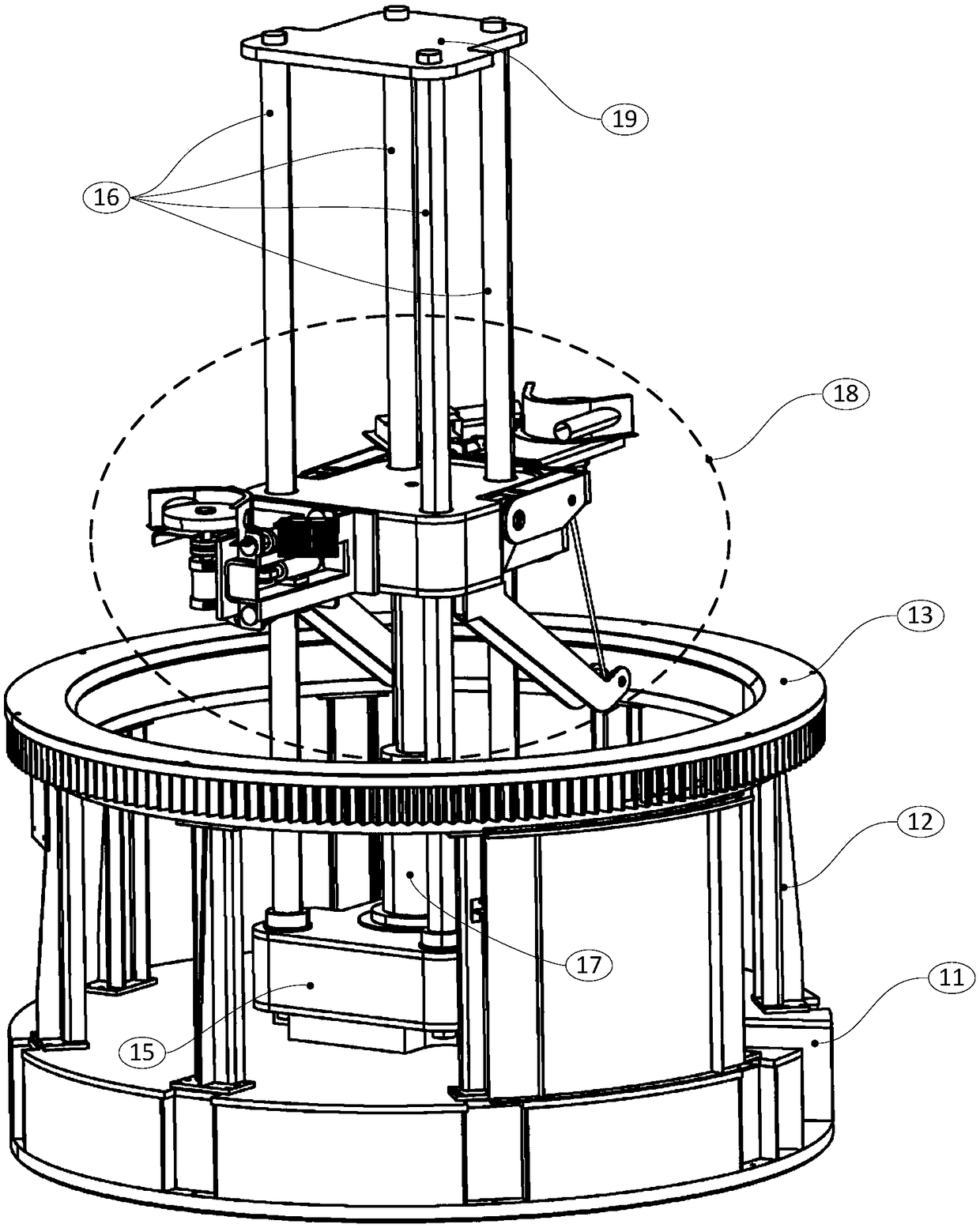

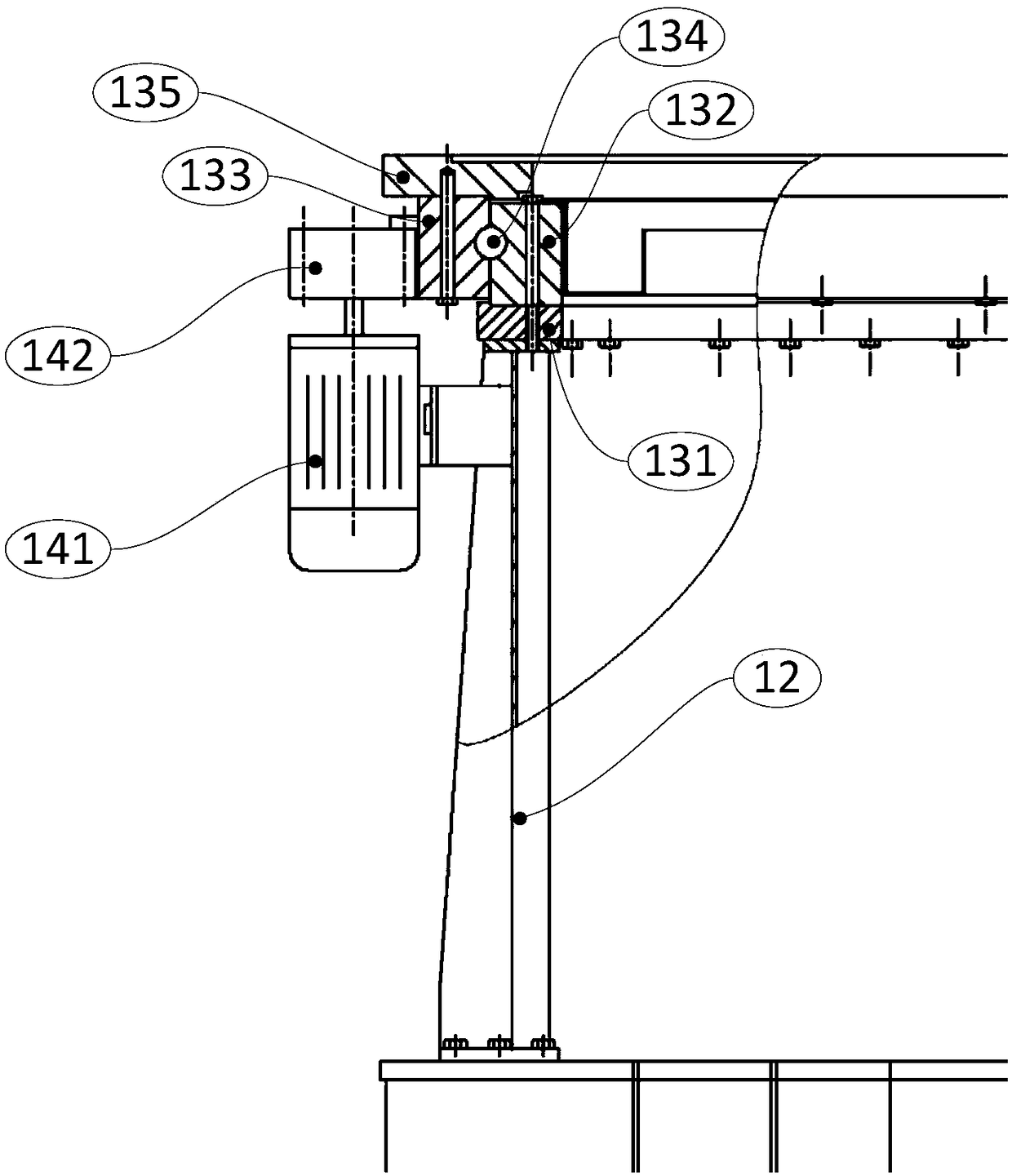

Full-automatic polishing machine for furnace drum

PendingCN109048601AAvoid grinding cornersGuaranteed uptimeGrinding carriagesGrinding machinesEngineeringMechanical engineering

The invention discloses a full-automatic polishing machine for a furnace drum. The full-automatic polishing machine comprises a base, a rotary working table, a lifting guide mechanism and a working mechanism, wherein the rotary working table is in a circular ring shape and is supported and fixed on the base through a plurality of support columns; the rotary working table is driven to rotate horizontally through a rotary driving device; the lifting guide mechanism comprises a lifting oil cylinder and a linear guide rail; and the working mechanism comprises a lifting platform, a fixed grinding and polishing machine head and a swing grinding and polishing machine head, the lifting platform is arranged on the linear guide rail in a sliding fit mode, the bottom of the lifting platform is connected with the output end of the lifting oil cylinder, and the fixed grinding and polishing machine head and the swing grinding and polishing machine head are installed on the left side and the right side of the lifting platform. The full-automatic polishing machine for the furnace drum is stable and reliable in structure and operation, is suitable for machining of drum type reaction furnaces, and is capable of avoiding grinding dead corners, and realizing three working procedures of grinding, mechanical polishing and electrochemical polishing through one-time hoisting.

Owner:江阴市天利化工机械有限公司

Efficient grinding machine for metal product hole machining

ActiveCN113334212AEfficient grindingImprove grinding efficiencyGrinding drivesGrinding machinesGear wheelEngineering

The invention discloses an efficient grinding machine for metal product hole machining, and relates to the technical field of grinding machines. The efficient grinding machine comprises a bottom plate, two side grinding plates, an upper grinding plate, a driving component for driving a workpiece to rotate, a first linkage component which drives the upper grinding plate to transversely move in a reciprocating mode and is in transmission connection with a gear, and a second linkage component which drives the two side grinding plates to vertically move in a reciprocating mode and is in transmission connection with the driving component; and when the upper grinding plate moves towards any side grinding plate, the grinding plate moves downwards and avoids the upper grinding plate. The efficient grinding machine has the effect of multi-directional grinding under the condition of the same grinding time, the grinding efficiency is higher through the workpieces and the side grinding plates which move relatively and are different in movement form, and then the production efficiency is improved.

Owner:乐清市仁惠电气有限公司

Device and method for repairing damaged part of cable

PendingCN114597828AGuaranteed smoothEffective clampingApparatus for repairing insulation/armouring cablesElectronic waste recyclingHydraulic cylinderPolishing

The invention discloses a damaged part repairing device for a cable, which comprises a material box, an outer supporting plate, a conveying pipe, a hydraulic cylinder, a second driving motor and a double-shaft motor, and is characterized in that the material box is internally provided with a first driving motor, and the material box is filled with a repairing material; the outer supporting plate is connected to the outer side of the material box in a sliding mode. The conveying pipe is fixed at the bottom of the material box; an adjusting mechanism is installed at the output end of the first driving motor and comprises an adjusting wheel, an adjusting plate, a limiting strip and a first connecting plate. According to the damaged part repairing device for the cable and the repairing method, cables of different models can be effectively clamped, the structure is stable, the stability of the whole device can be guaranteed, the position of the clamping mechanism can be conveniently adjusted according to the size of the damaged part, different damages can be effectively and automatically repaired, practicability is high, polishing can be conducted after the damaged part is filled, and the repairing efficiency is improved. The surface flatness of the cable is ensured, the polishing positions are changeable, and polishing dead angles can be avoided.

Owner:翁会兰

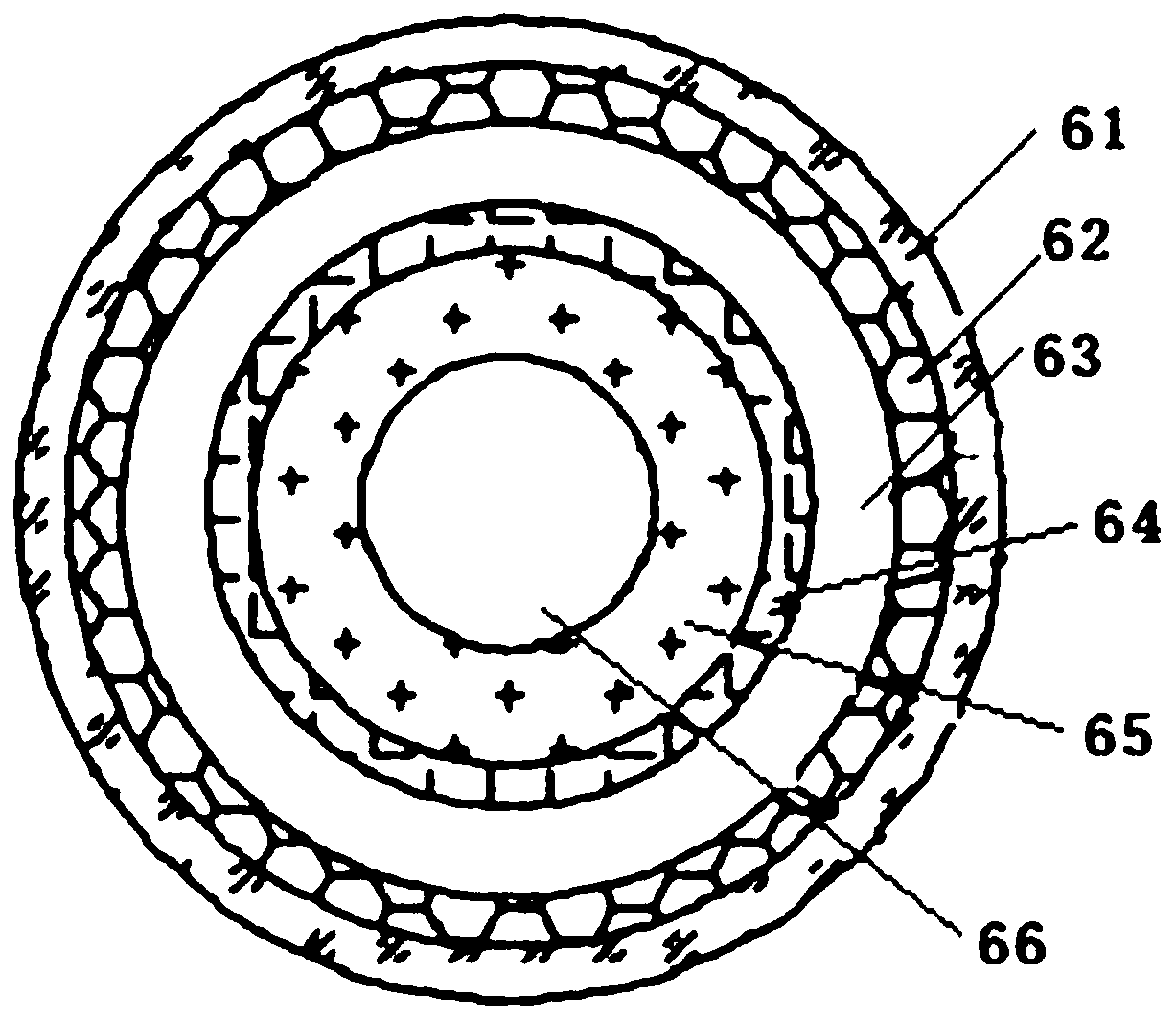

Durable ball mill for building material processing

InactiveCN108906236AExtended service lifeAvoid frequent replacementGrain treatmentsCouplingElectric machinery

The invention provides a durable ball mill for building material processing. The ball mill comprises a ball mill cylinder body, a machine base, a motor, a vibration exciter, an inner lining plate, a sound absorbing layer, a first bearing, a second bearing, a feed port and a discharge port; one end of the vibration exciter is connected to the motor through a universal coupling; the other end of thevibration exciter is connected to the ball mill cylinder body through a flexible coupling; the inner lining plate is arranged in the ball mill cylinder body; the sound absorbing layer is arranged between the inner lining plate and the ball mill cylinder body; one end of the ball mill cylinder body is connected to the first bearing; and the other end of the ball mill cylinder body is connected tothe second bearing. The durable ball mill for building material processing has the advantages that the grinding effect is excellent, and meanwhile, noise generated in the working process of the efficient vibration ball mill is small; and in addition, the abrasion of materials to the ball mill cylinder body can be reduced, and the service life can be prolonged.

Owner:太仓市太丰船舶钢梁建筑有限公司

A low-voltage insulator forming and processing machine and processing method

ActiveCN111531444BReduce fixation stepsImprove grinding efficiencyGrinding machinesGrinding work supportsEngineeringMechanical engineering

The invention relates to a low-voltage insulator forming and processing machine and processing method, including a fixed table top, a mounting frame, a pushing mechanism and a material placement mechanism. The lower end of the pressing mechanism is closely attached to the upper end of the feeding mechanism, and the feeding mechanism is installed on the fixed table, and the fixed table is evenly opened along its circumferential direction with a blanking port and a feeding trough, and the blanking port and the feeding trough are arranged alternately , and both the blanking port and the trough are circular in structure. The present invention completes the work of grinding the outer surface of the hexagonal low-voltage insulator through the joint cooperation of the pushing mechanism and the material-setting mechanism. The repeated position adjustment of the material setting mechanism can ensure that the grinding frame is in close contact with the surface of the low-voltage insulator, which effectively improves the grinding efficiency and ensures the grinding effect.

Owner:永州捷宝电讯塑胶五金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com