Raw material processing technology for ceramic production

A processing technology and raw material technology, which is applied in the field of raw material processing technology for ceramic production, can solve the problems of filter blockage, insufficiency, and low crushing efficiency, and achieve the effects of preventing raw material agglomeration, strengthening cooling treatment, and high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

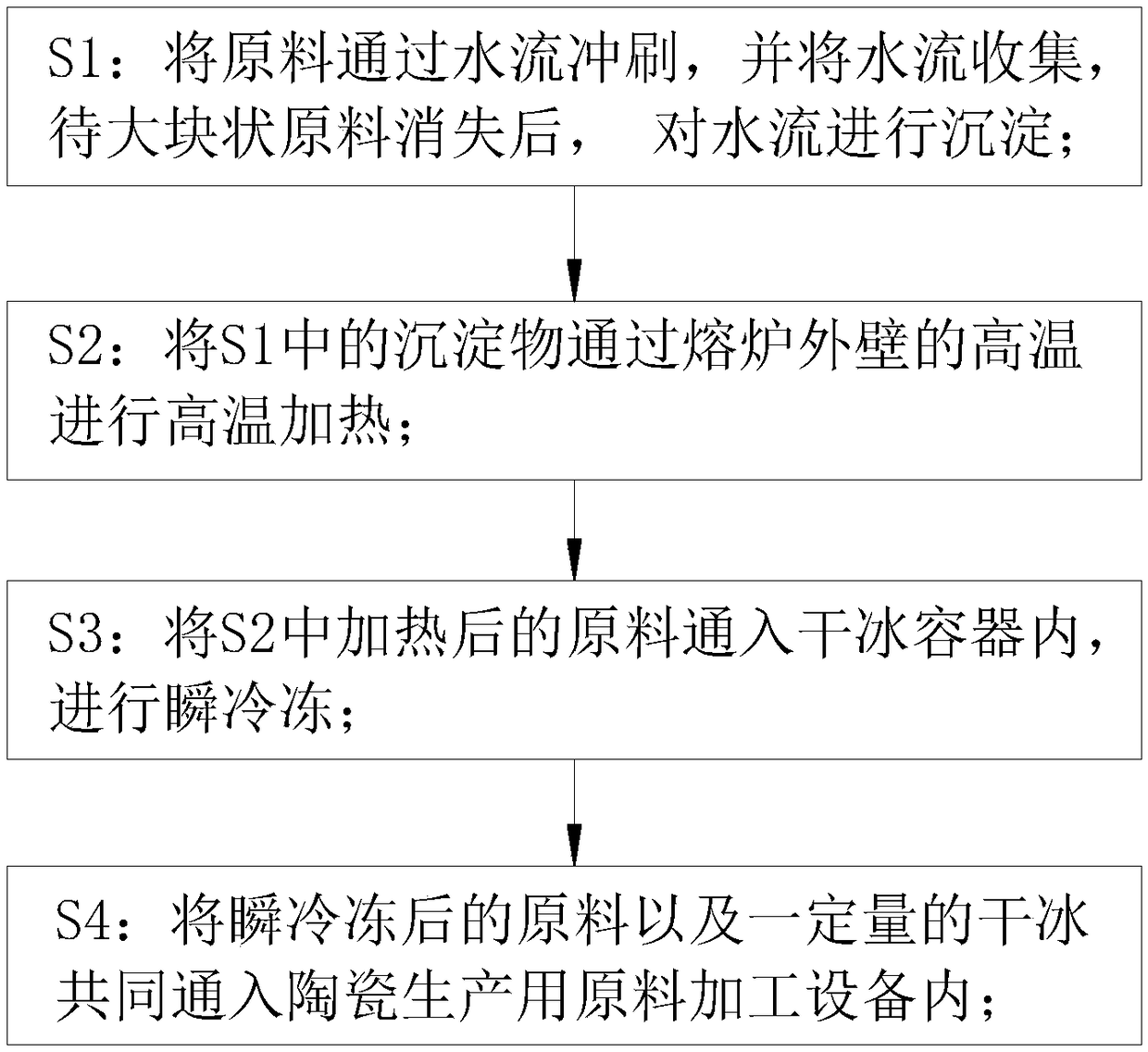

Method used

Image

Examples

Embodiment approach

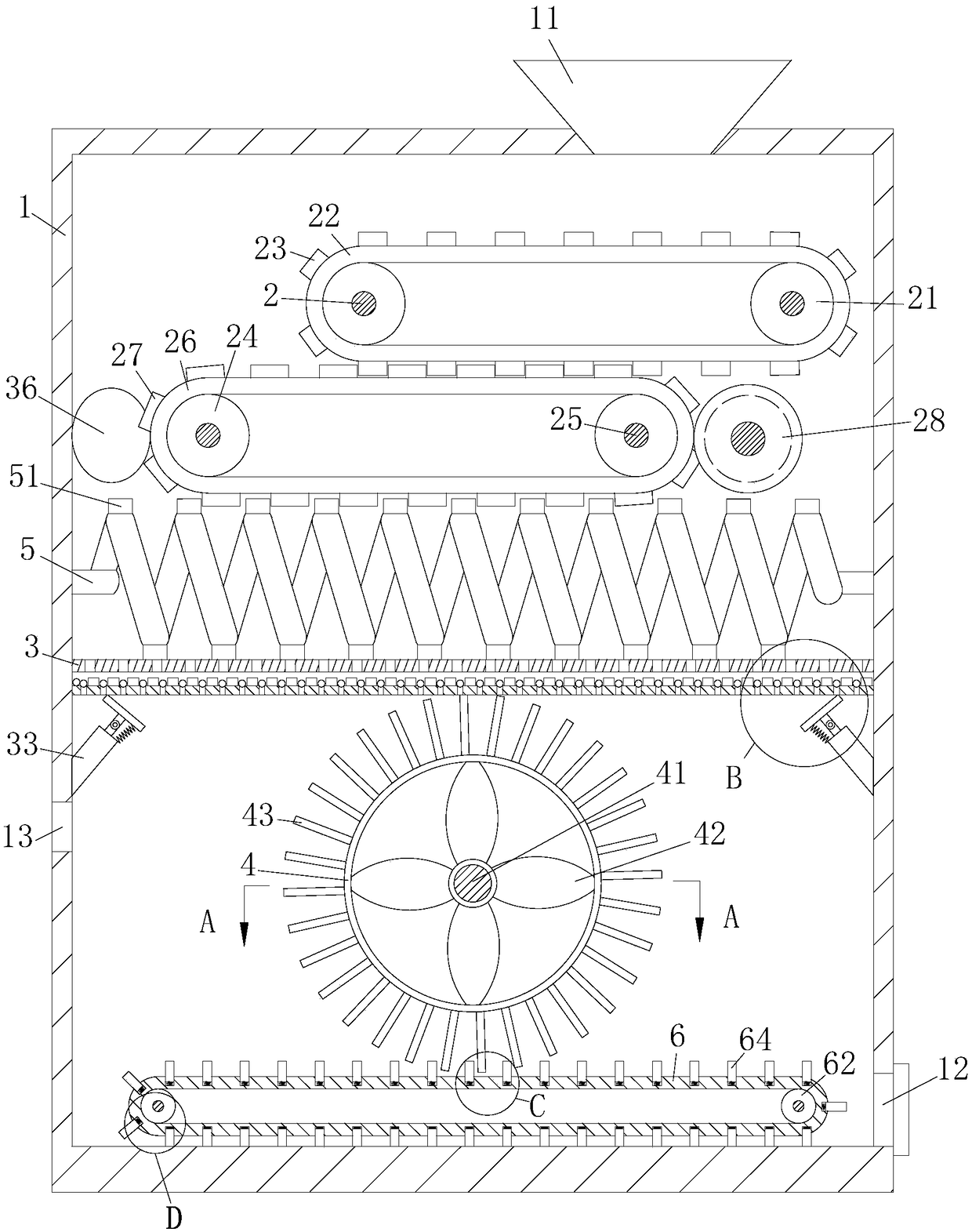

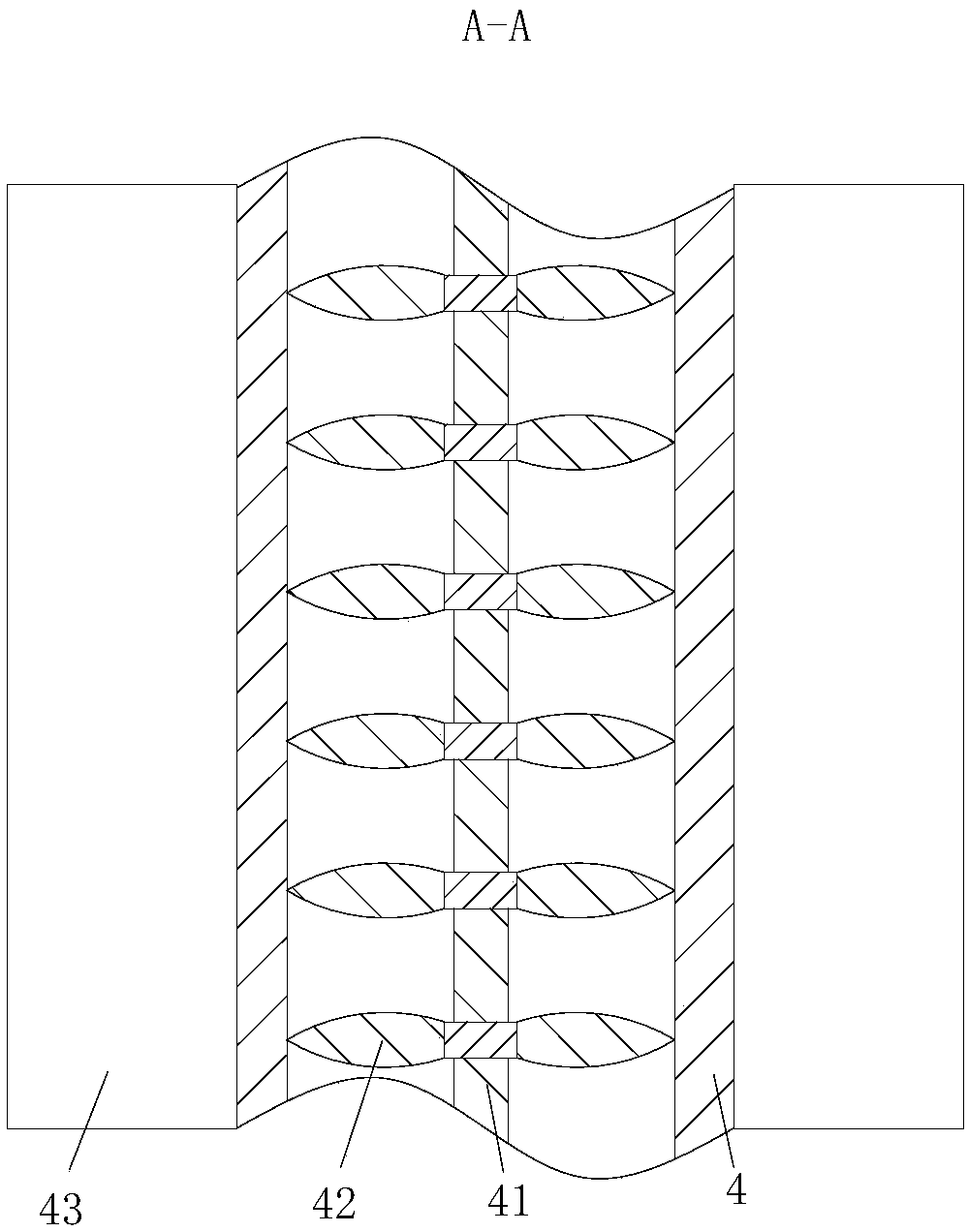

[0037] As an embodiment of the present invention, the frame body 1 is provided with a first spring 5; the two ends of the first spring 5 are respectively rotatably connected to the left and right inner walls of the frame body 1; Between the two belts 26 and the filter plate 3; the surface of the spring bar of the first spring 5 is evenly arranged with grinding sheets 51; the grinding sheets 51 are engaged with the second convex teeth 27, and the grinding sheets 51 contact the upper surface of the filter plate 3 Setting; when in use, the second belt 26 rotates, and the first spring 5 is driven to rotate through the engagement of the second convex tooth 27 and the grinding sheet 51, thereby driving the grinding sheet 51 to rotate, and the process of meshing the grinding sheet 51 with the second convex tooth 27 The raw material can be further squeezed and crushed, and during the rotation of the grinding sheet 51, it intermittently contacts the upper surface of the filter plate 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com