A processing equipment suitable for ball valve spool

A processing equipment and spool technology, applied in metal processing equipment, mechanical equipment, valve devices, etc., can solve the problems of inconvenient processing, low processing efficiency, troublesome operation, etc., to prevent grinding dead angle, improve grinding effect, and simple processing operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

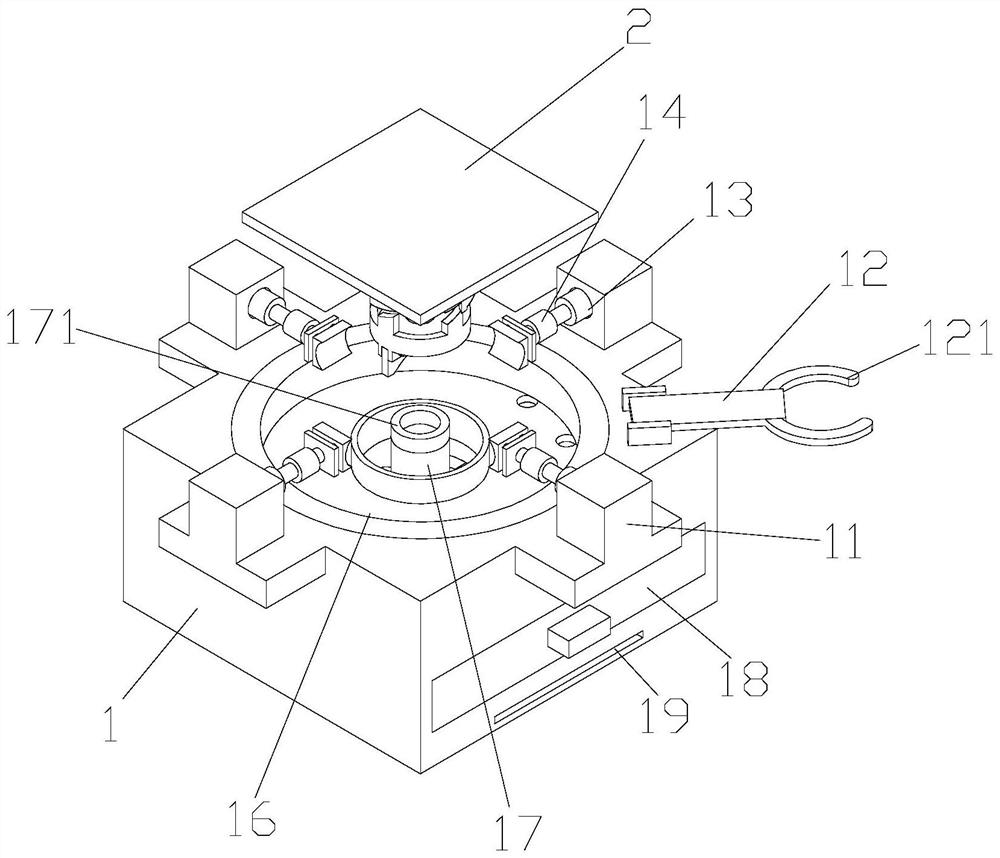

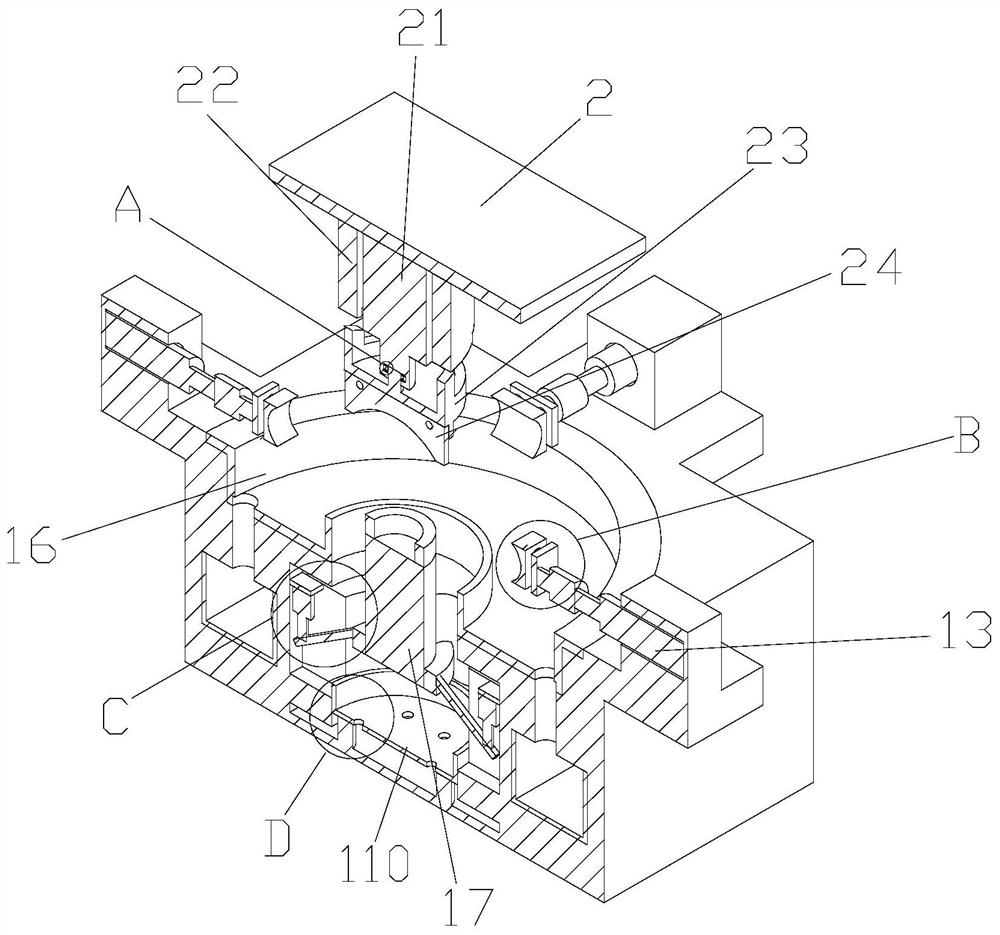

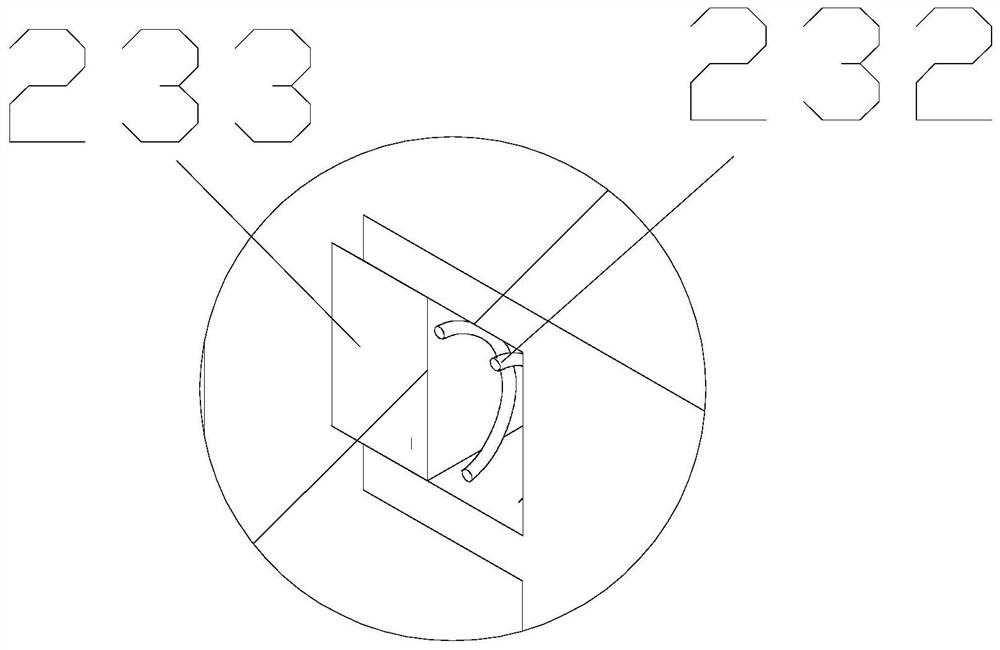

[0026] Such as Figure 1-10As shown, a processing equipment suitable for a ball valve spool includes a processing table 1 and a mounting plate 2 arranged above the processing table 1, the processing table 1 is provided with a mounting block 11, and on the mounting block 11 An installation cavity is provided, and a fixed component is arranged in the installation cavity. The bottom of the installation plate 2 is provided with a first cylinder 21, and a file 24 is provided on the piston rod of the first cylinder 21. The bottom of the file is provided with a The matching arc groove makes the file fit better with the surface of the valve core; the processing table 1 is provided with a first movable chamber, and a support rod 17 is arranged in the first movable chamber, and the support rod 17 There is a friction pad 171 on the top, the friction pad is made of rubber, the friction pad is a ring structure, the diameter of the friction pad is smaller than the diameter of the valve core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com