Patents

Literature

205results about "Filing/rasping devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transmitting and receiving messages through a customizable communication channel and programming model

InactiveUS7200676B2Filing/rasping devicesMultiprogramming arrangementsComputer hardwareMessage passing

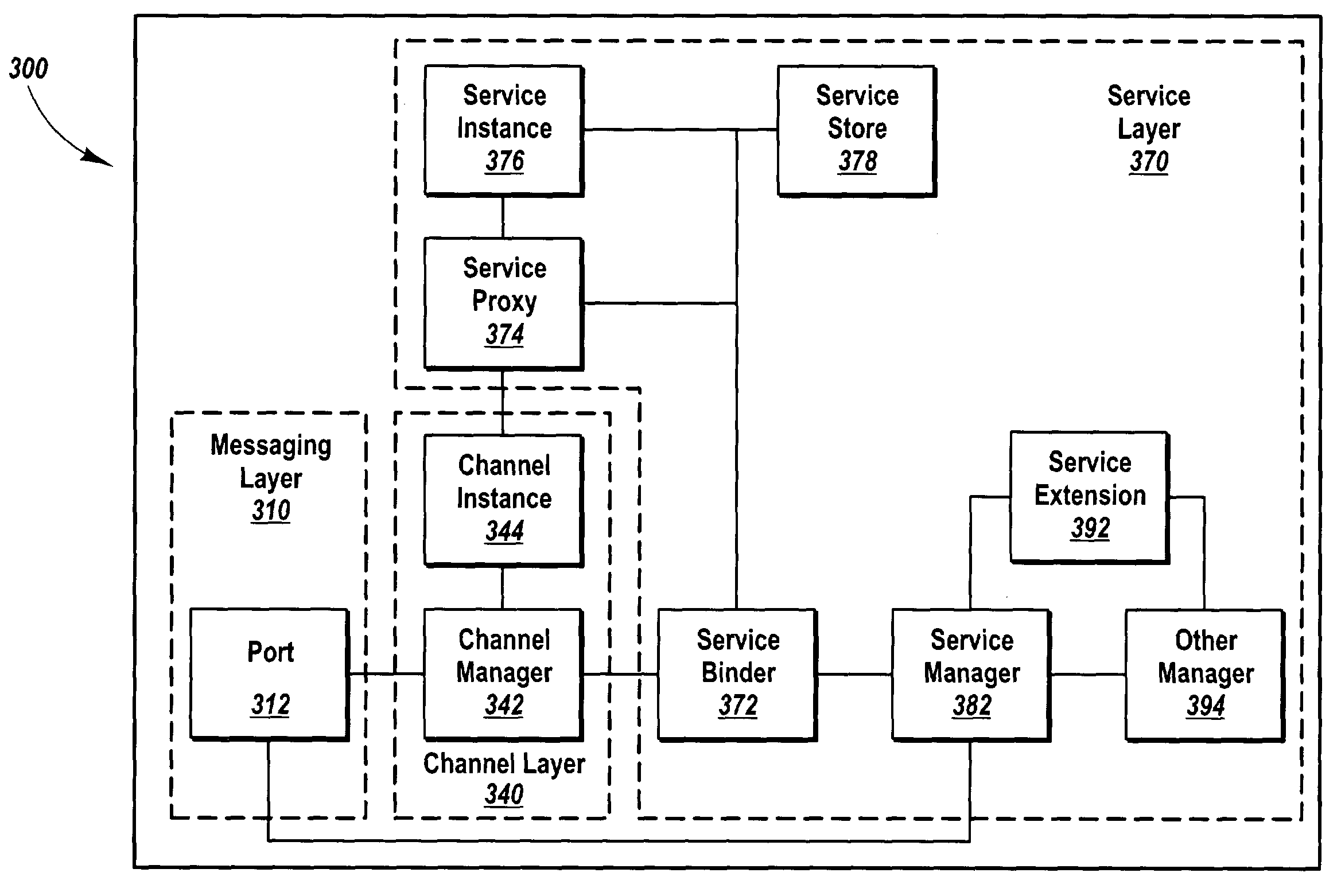

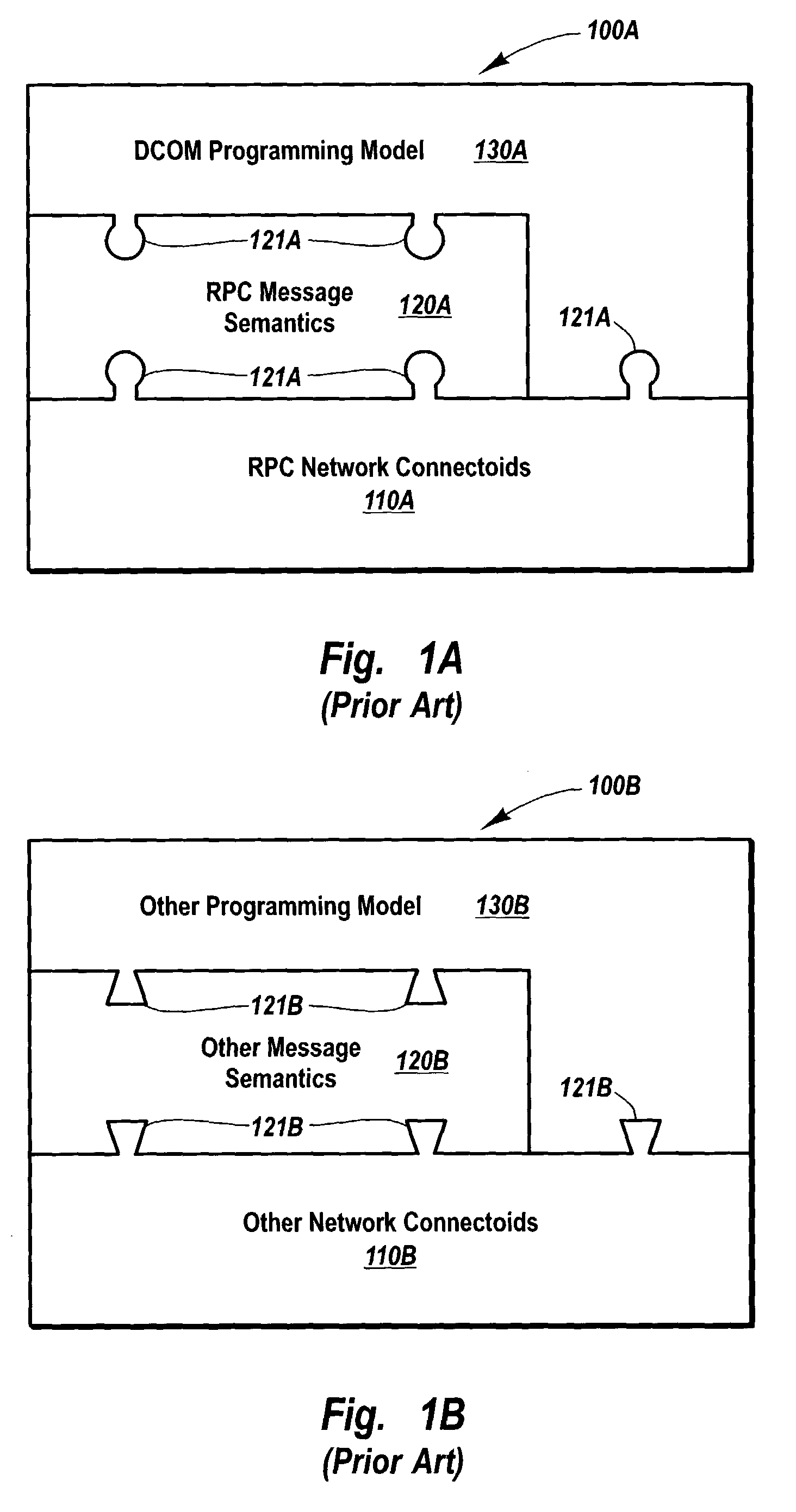

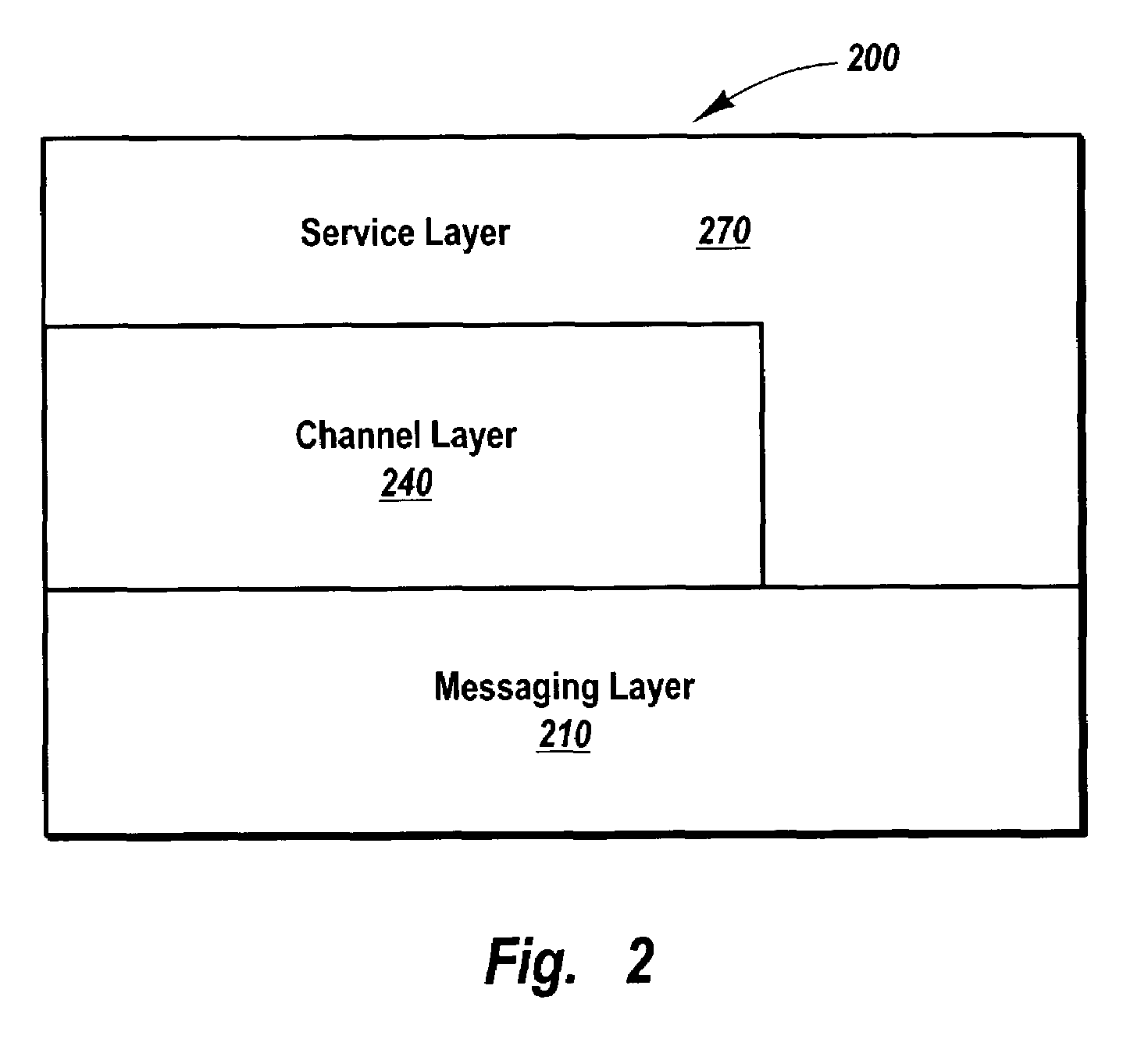

Methods, systems, and computer program products for abstracting processing layers within a messaging infrastructure so that changes or enhancements can be made to the infrastructure while retaining existing functionality. Message transport implementations are abstracted within a message layer, allowing other layers within the infrastructure to interact with messages in a more structured fashion, largely independent of message transport. Transport examples include named pipes, Transmission Control Protocol (TCP), HyperText Transfer Protocol (HTTP), Simple Mail Transfer Protocol (SMTP), etc. A channel layer above the message layer abstracts message exchange implementations, allowing other layers within the infrastructure to send and receive messages in a more structured fashion, largely independent of the message exchange semantics of a specific implementation. Message exchange examples include datagrams, dialogs, monologs, queues, and the like. Above the channel layer and message layer, a service layer abstracts the binding implementations that bind message exchange implementations to user code implementations.

Owner:MICROSOFT TECH LICENSING LLC

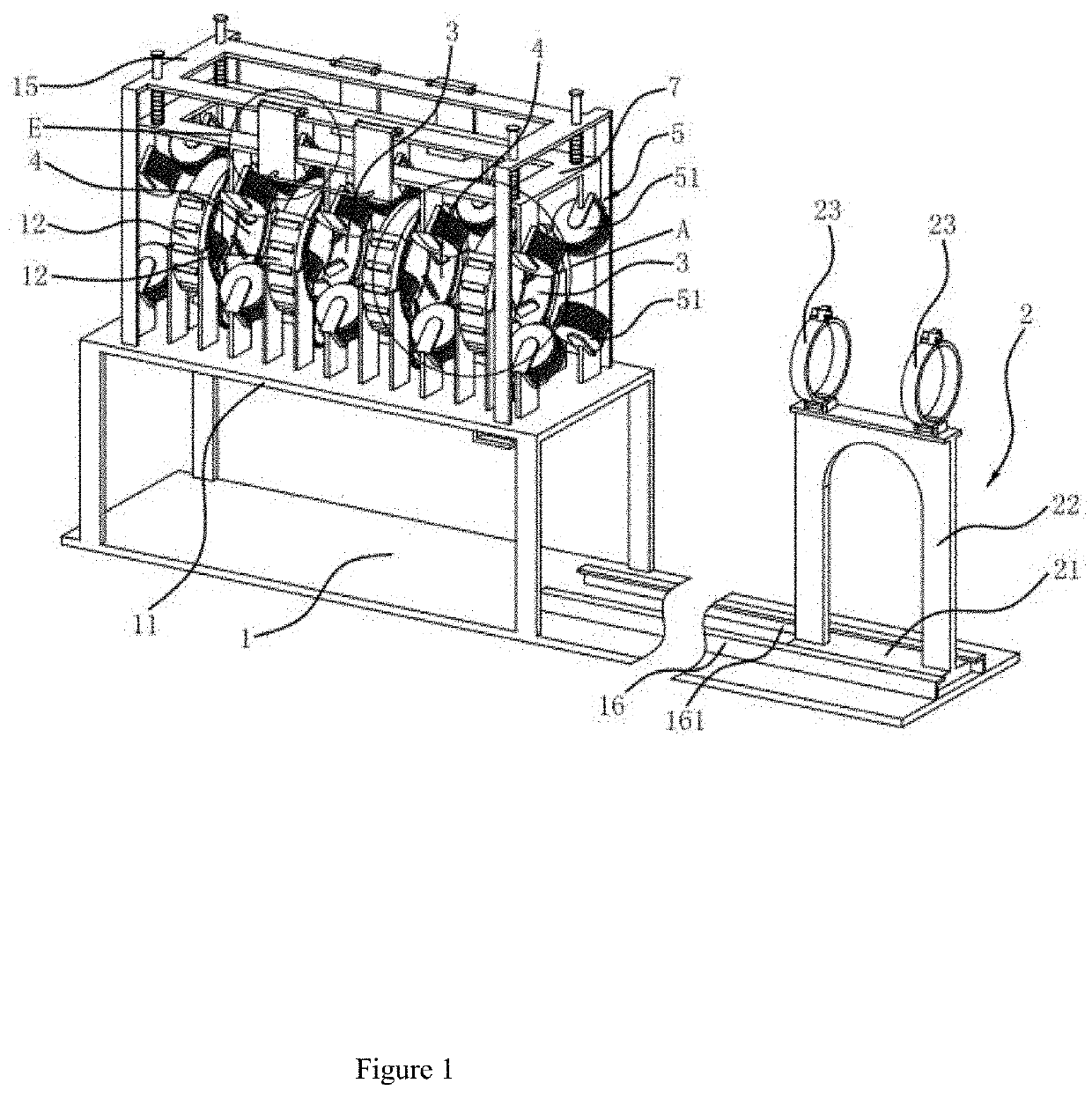

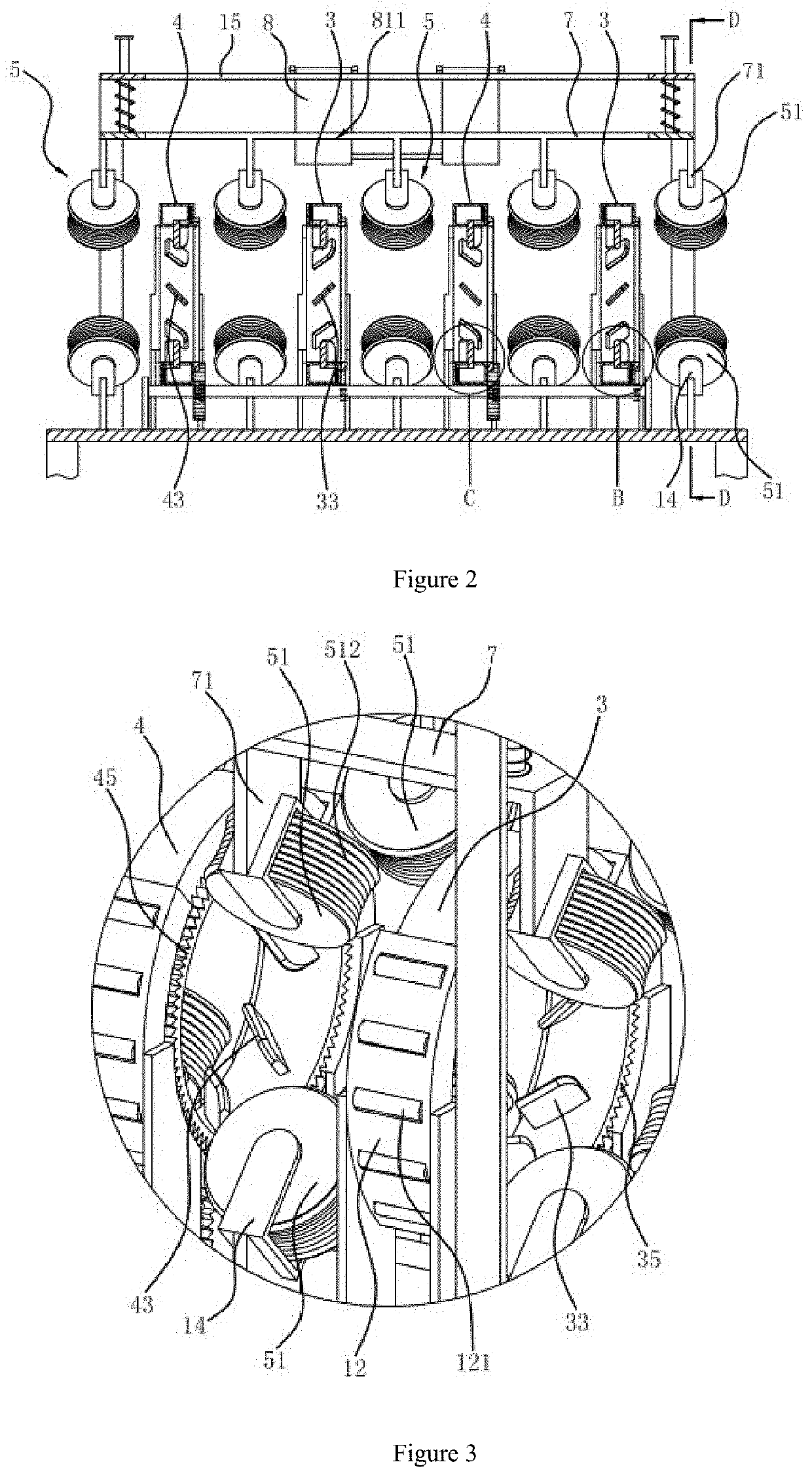

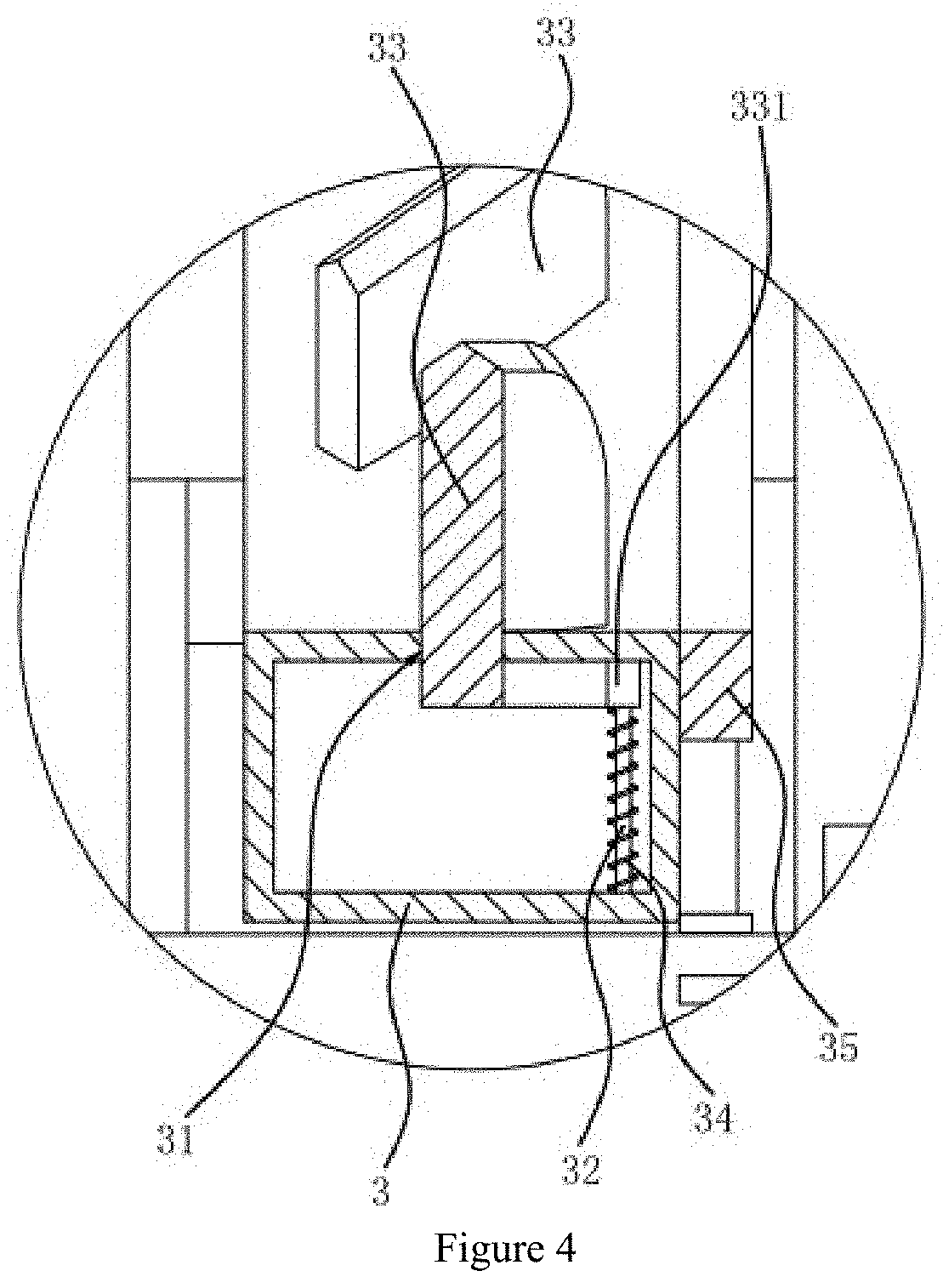

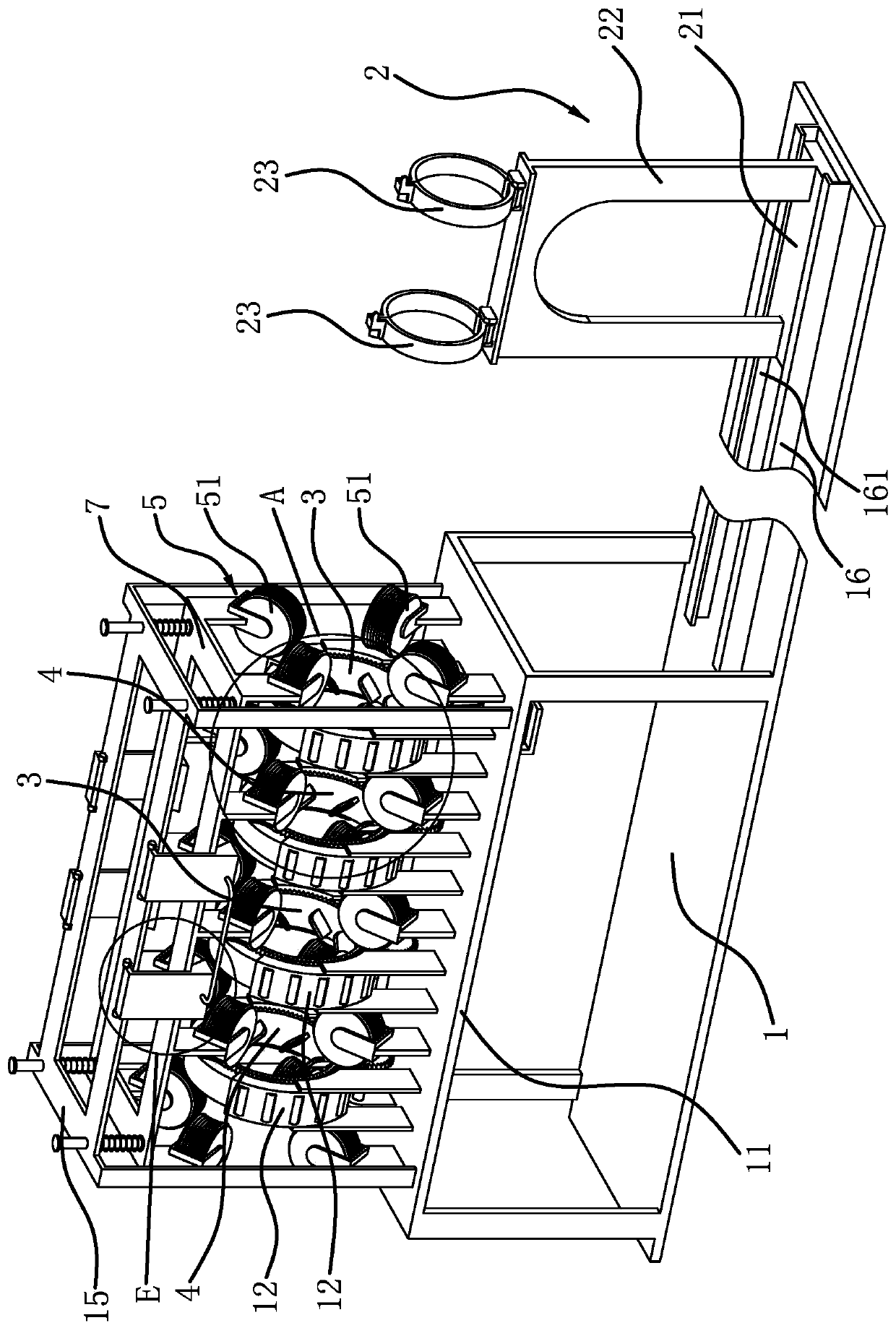

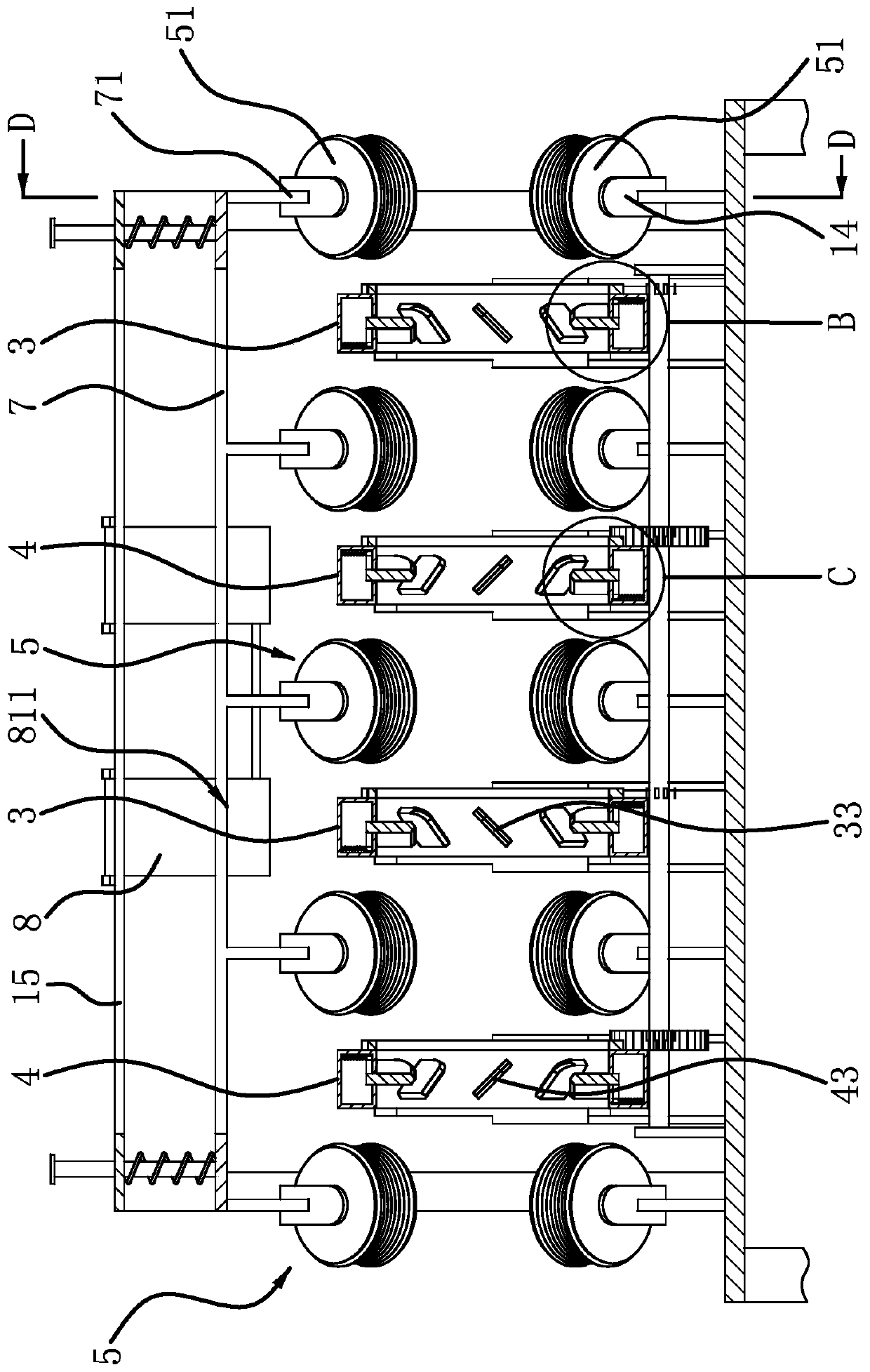

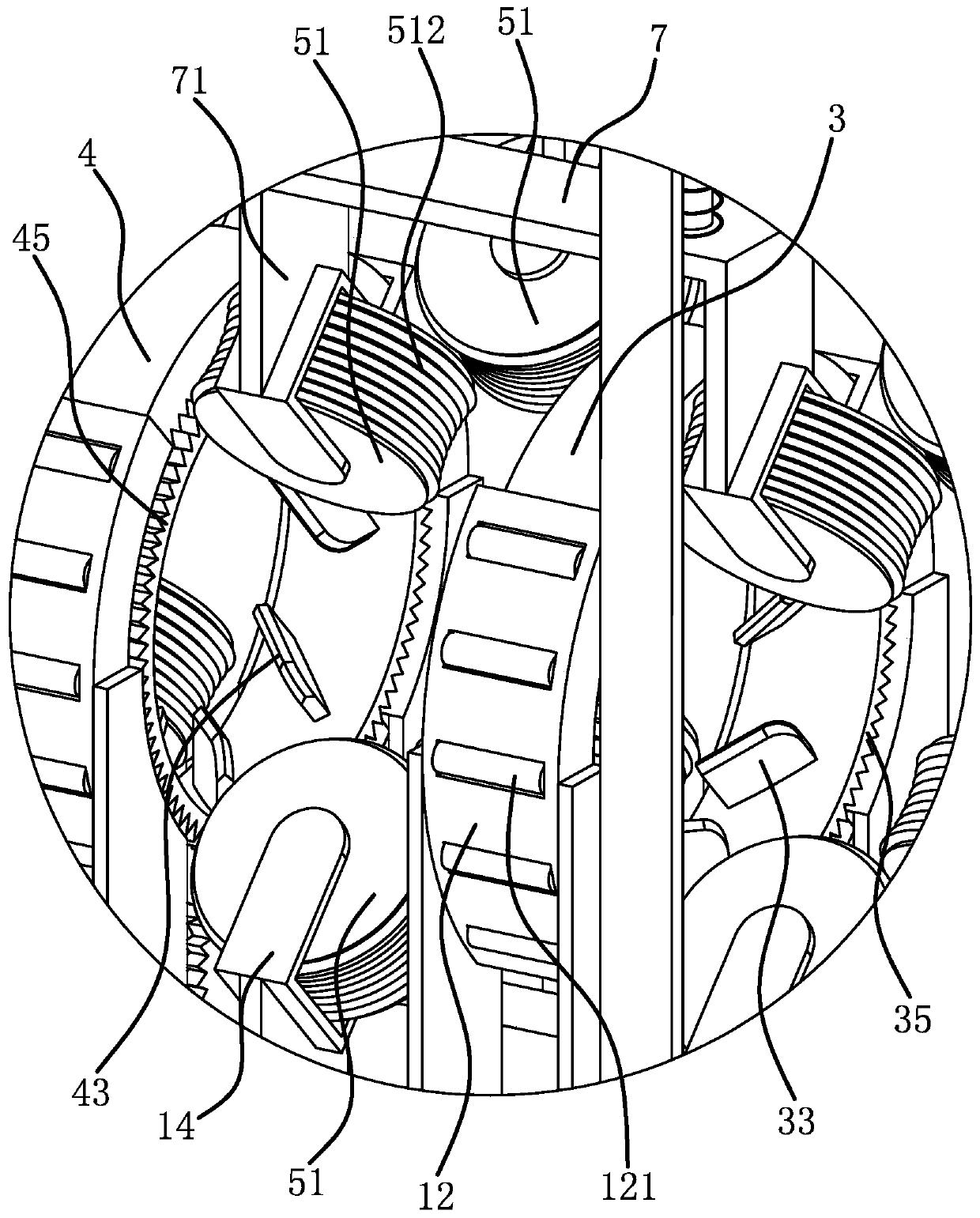

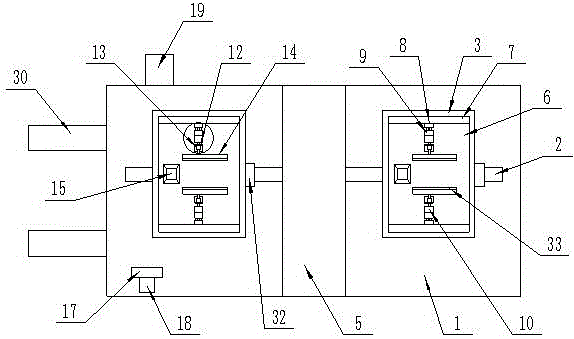

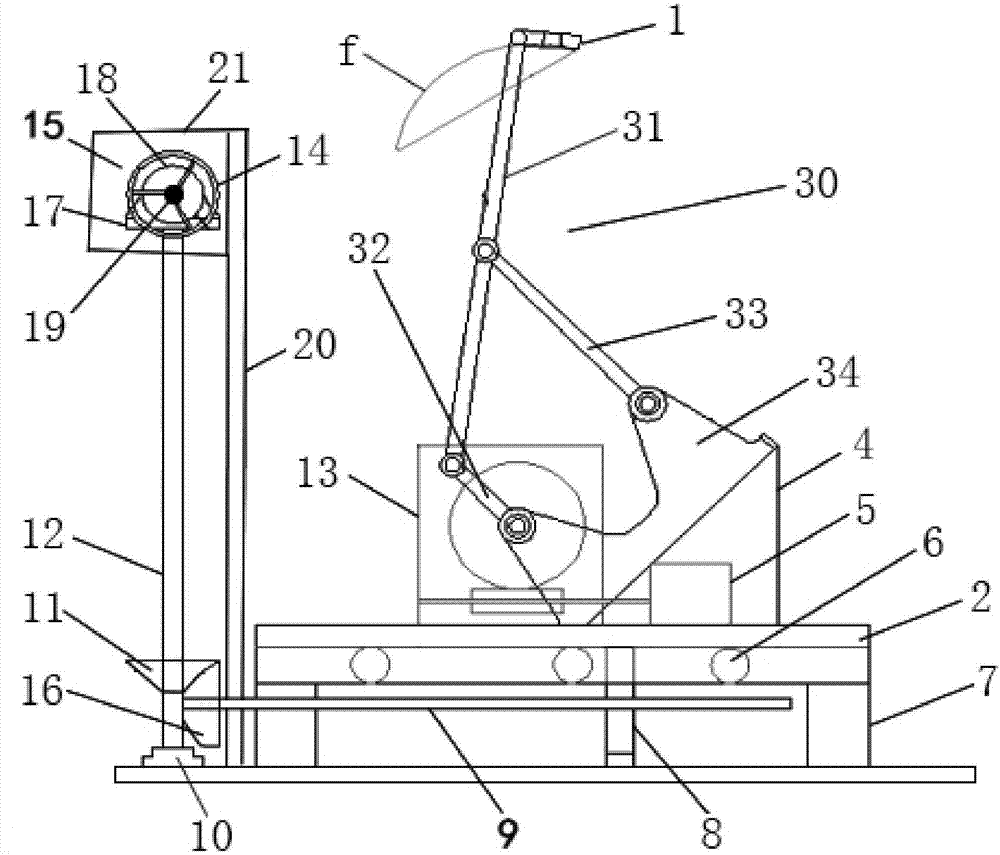

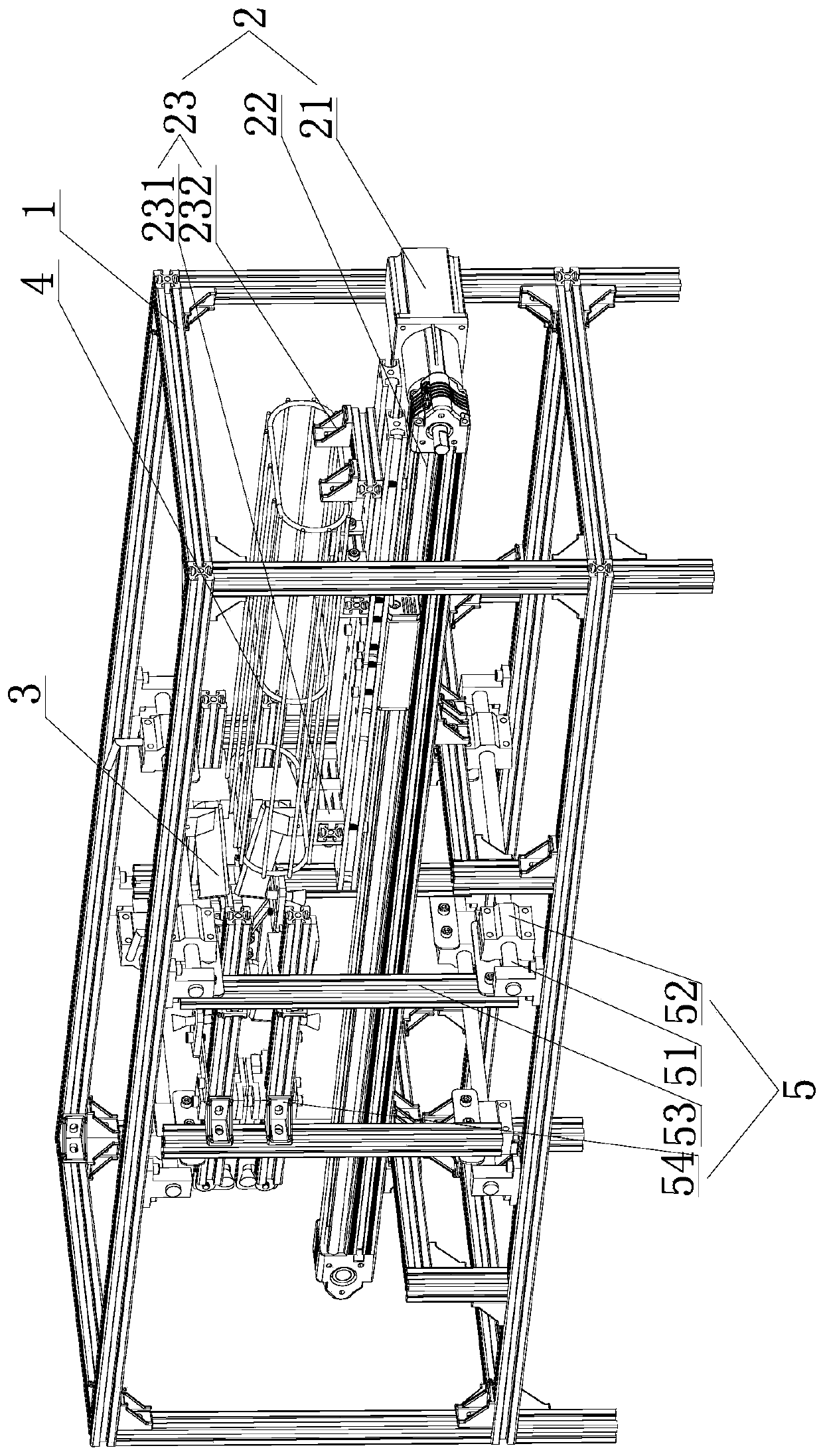

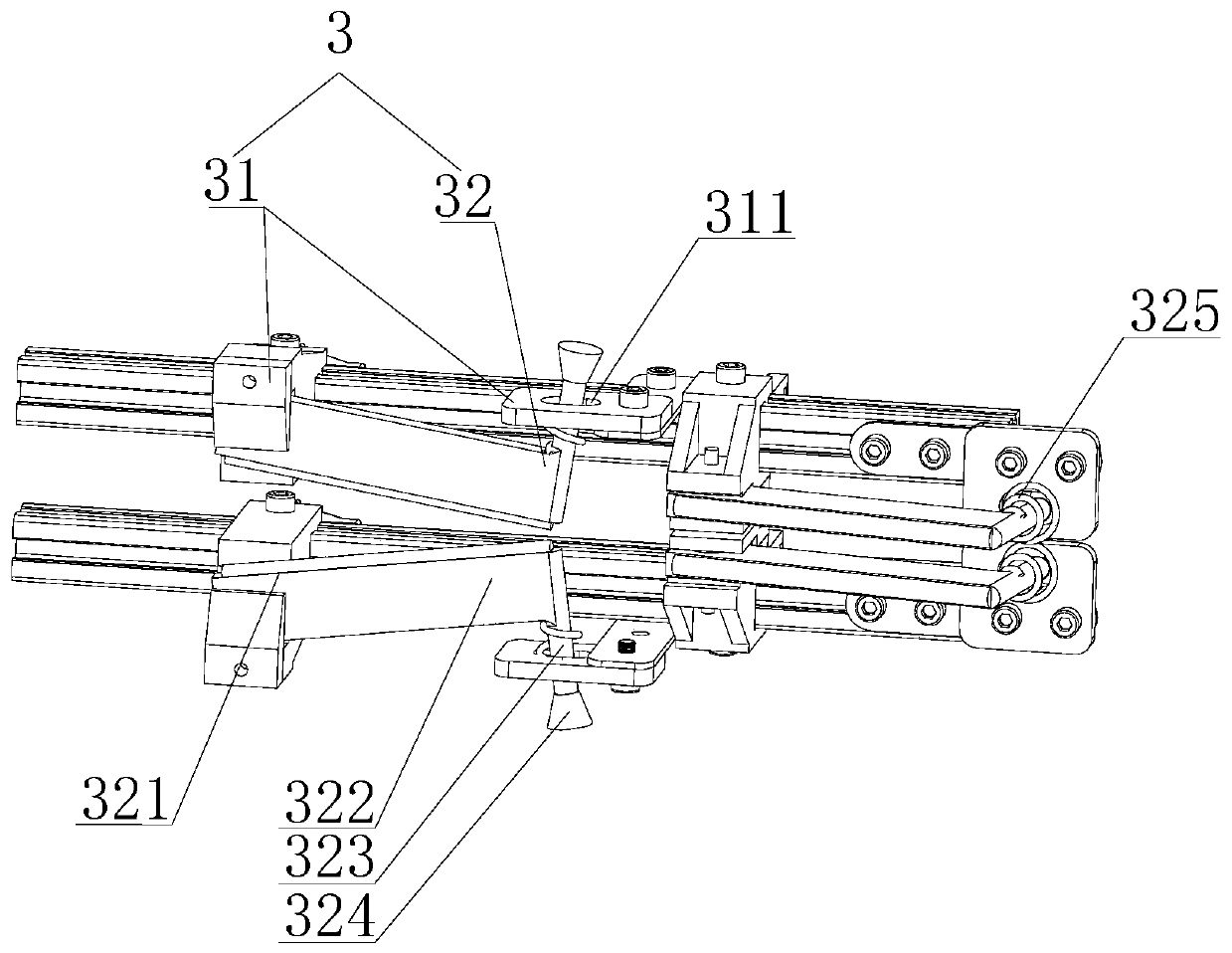

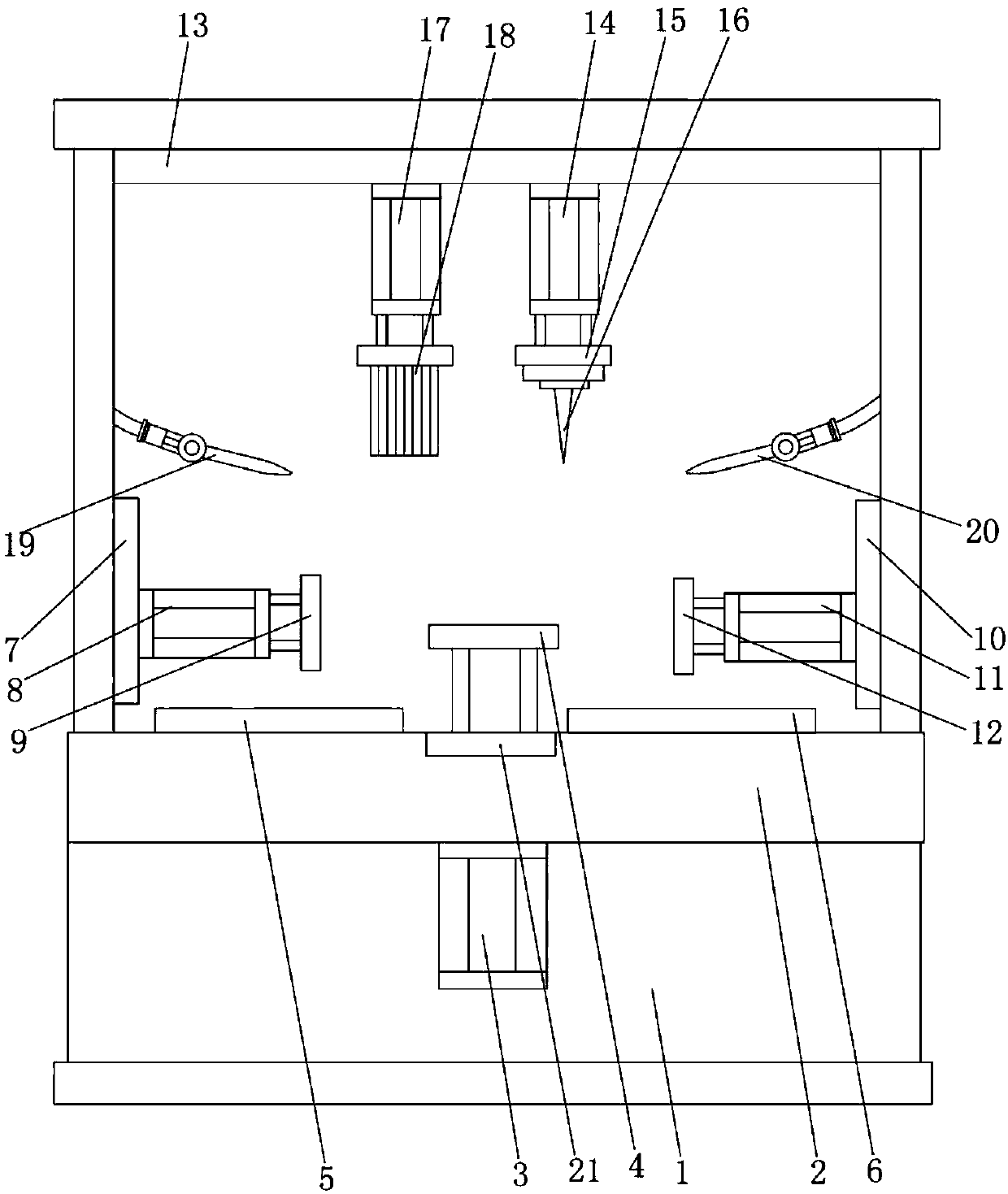

Descaling apparatus for steel tubes of the building scaffold

InactiveUS20210131126A1Good effectMaterial pushing manually more easyRevolution surface grinding machinesGrinding drivesArchitectural engineeringManual handling

This invention discloses a descaling apparatus for steel tubes of the building scaffold, belonging to the technical field of construction equipment, which solves the existing problems with low quality in rust-removal of the steel tube of the building scaffold, and the descaling apparatus for steel tubes of the building scaffold comprises a bottom panel (1), a working table (11), a pushing base (2) on the bottom panel (1) along a length direction, several of forward rust-scraping rings (3) and several of reverse rust-scraping rings (4) on the working table (11), several of forward scrapers (33) on the forward rust-scraping rings (3), several of reverse scrapers (43) on the reverse rust-scraping rings (4), a driving member on the working table (11), several sets of rolling assemblies (5) on the working table (11); this invention has a better rust-removal effect and is more labor-saving when in manual operation.

Owner:ZHUANG QIANHAN

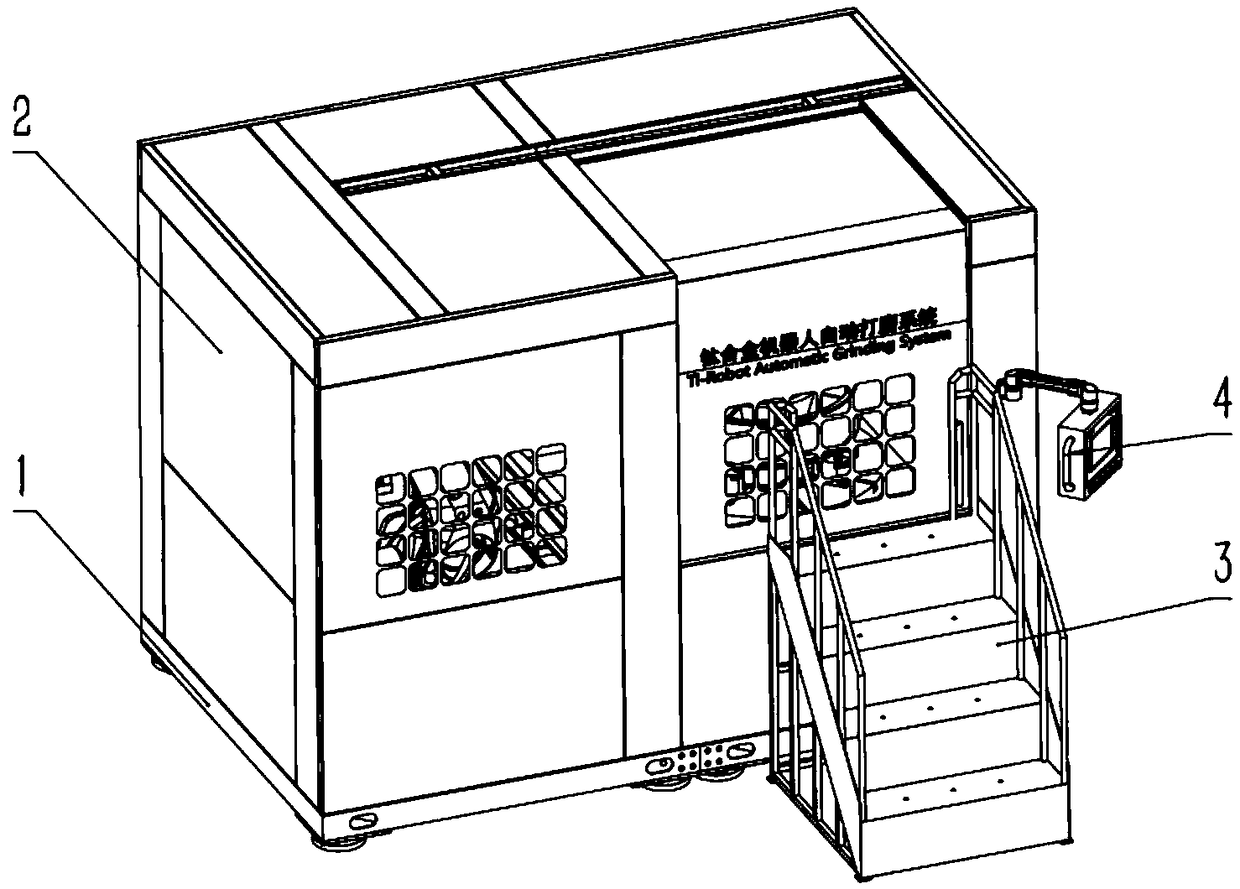

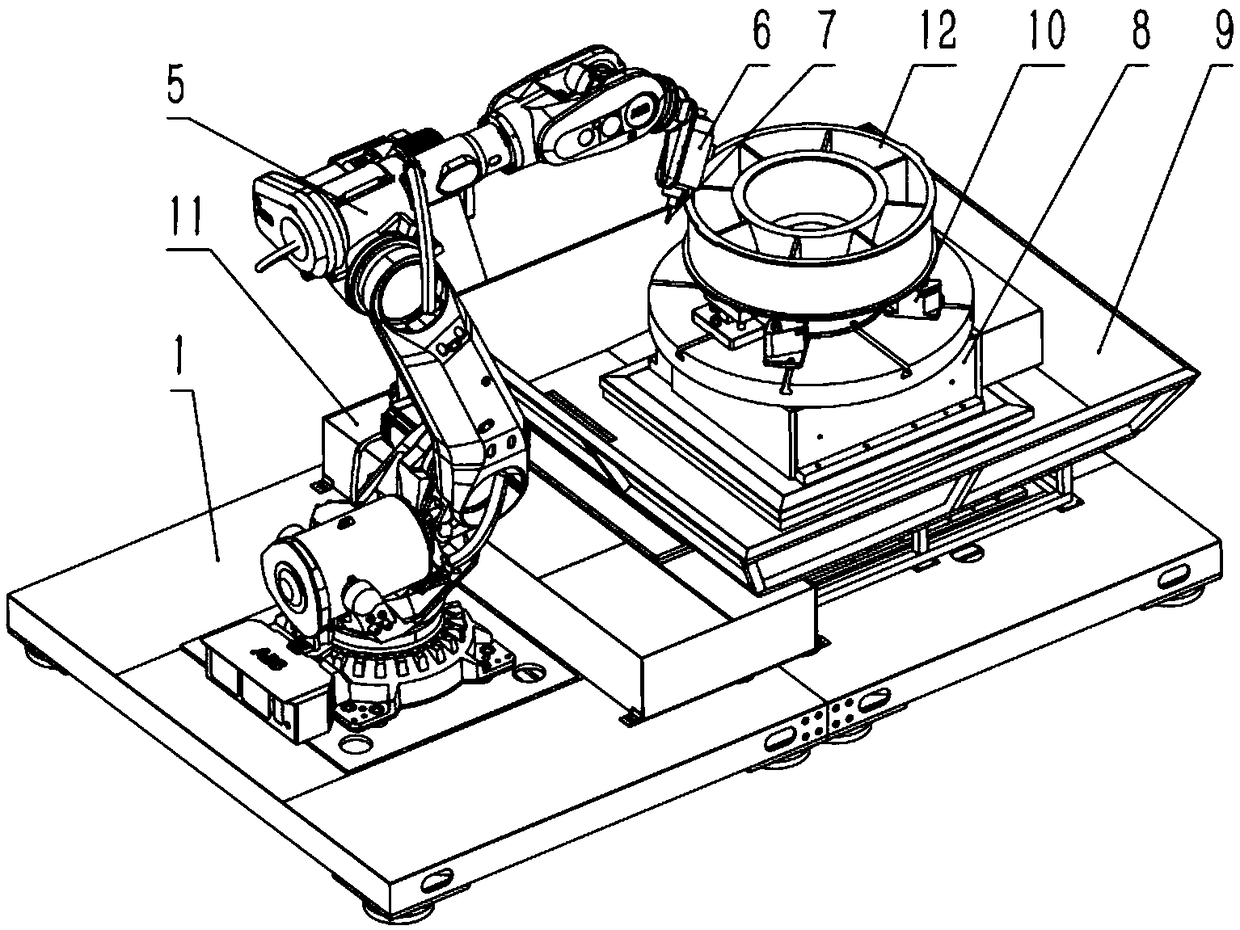

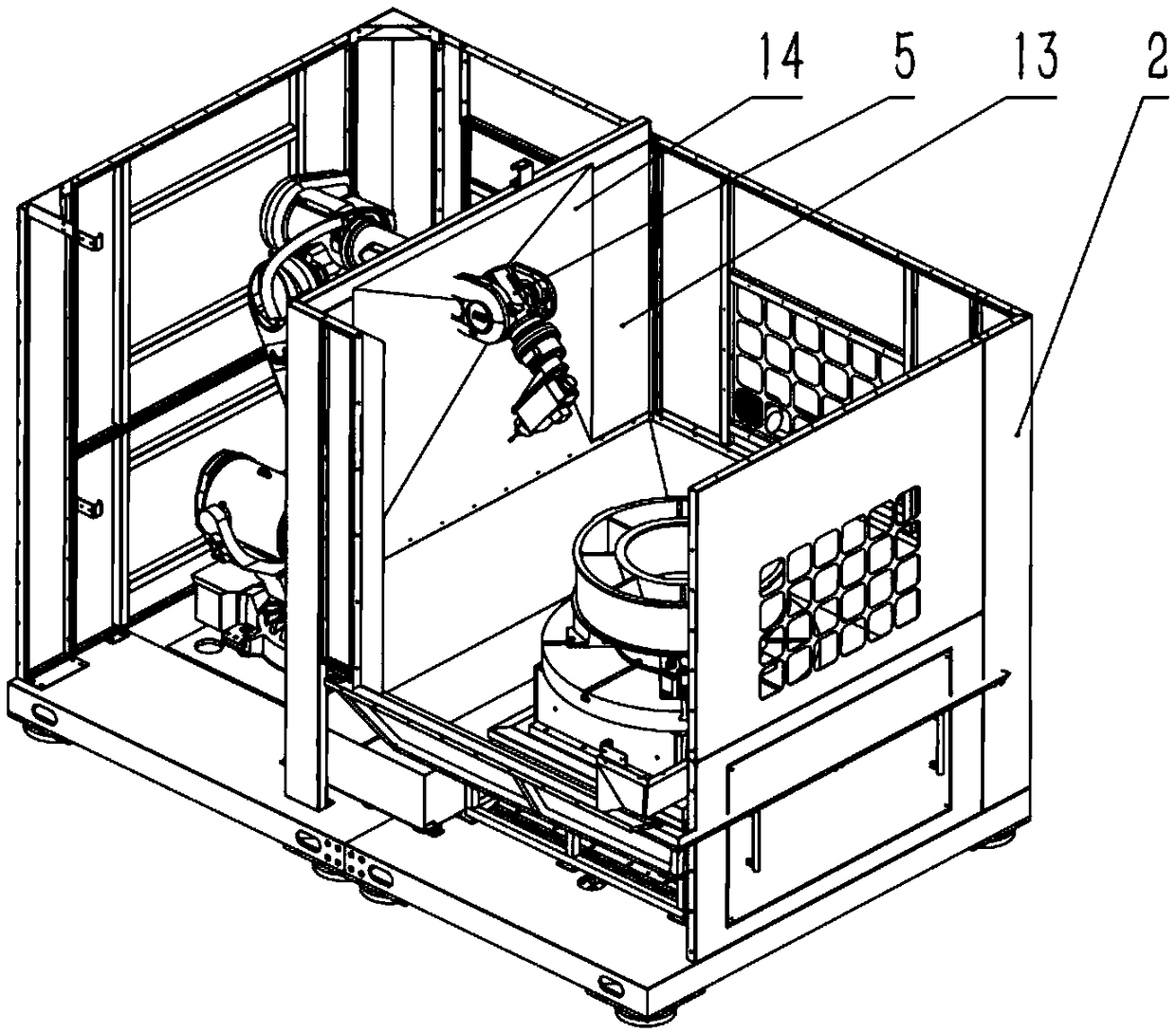

Automatic grinding and polishing process for titanium alloy annular casting

ActiveCN109365793ARealize automatic grinding and polishing operationsExtend your lifeFiling/rasping devicesManipulatorTitanium alloyMachining

The invention provides an automatic grinding and polishing process for a titanium alloy annular casting. An automatic grinding and polishing system for the titanium alloy annular casting mainly comprises a base, an outer cover, an industrial robot, an electric main shaft, a rotating workbench, a positioning clamp, a water tank, a cooling chip removal machine, a PLC and a display screen. The titanium alloy annular casting is positioned and clamped on the surface of the rotating workbench through the clamp; the robot clamps the electric main shaft to move according to a certain trajectory so that the grinding and polishing work of the titanium alloy annular casting is realized, moreover, multiple kinds of sensors are adopted for cooperation to adjust a machining path so as to adapt to the complicated contour and shape difference of a part, therefore, the automatic grinding and polishing system for the titanium alloy annular casting has a wide application prospect in titanium alloy annular casting machining, the production efficiency can be improved, and considerable benefits can be brought to enterprises.

Owner:WUHAN UNIV OF TECH

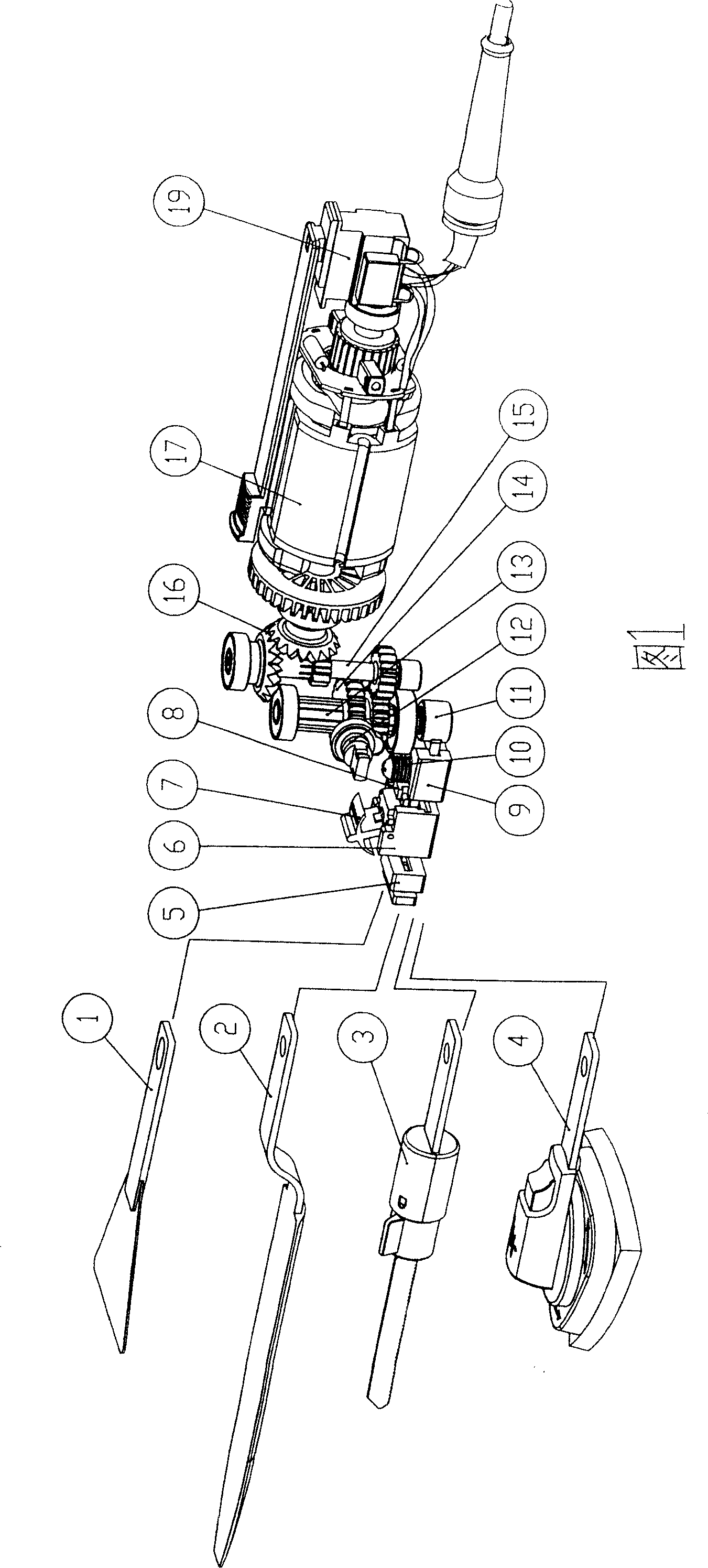

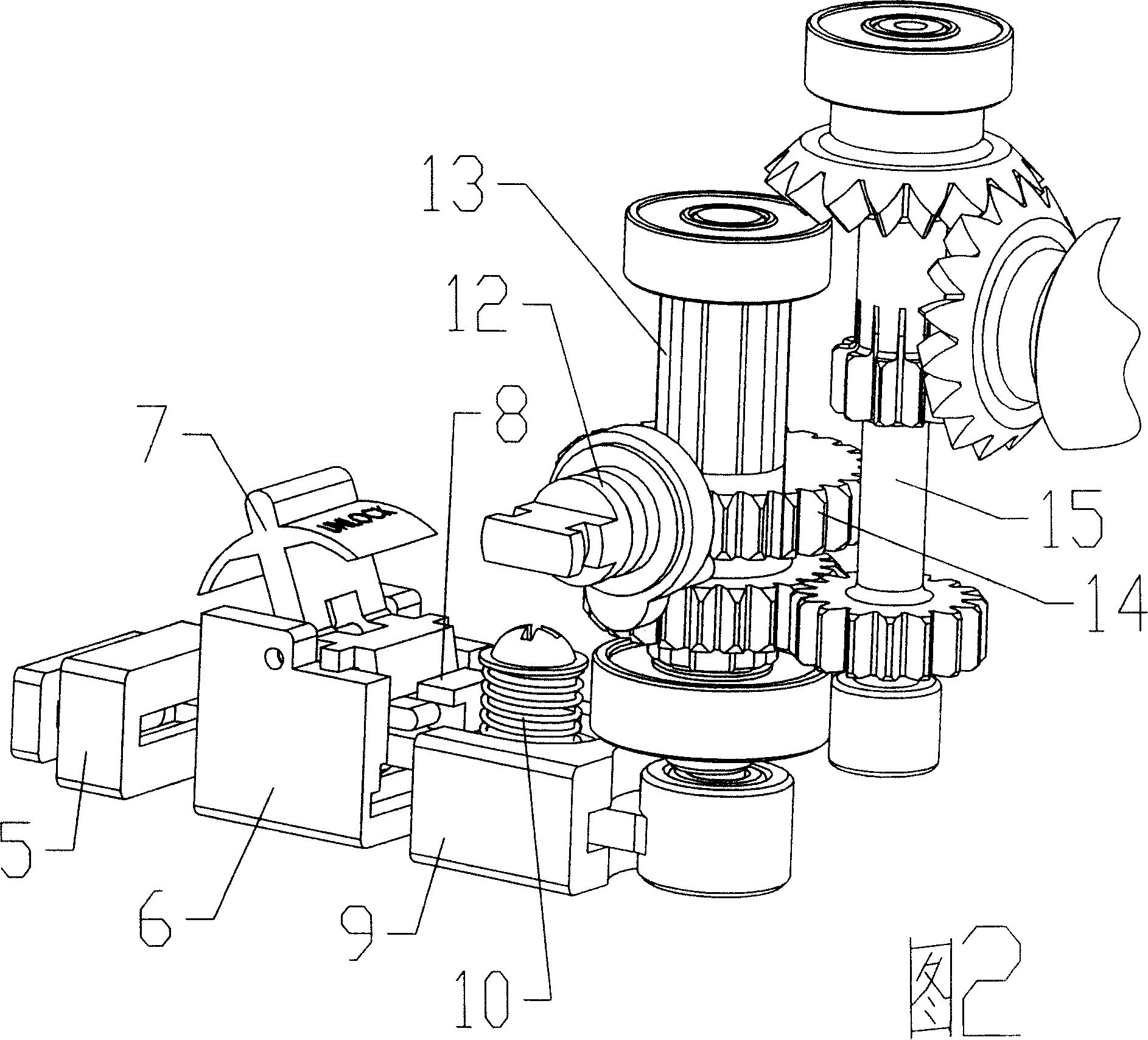

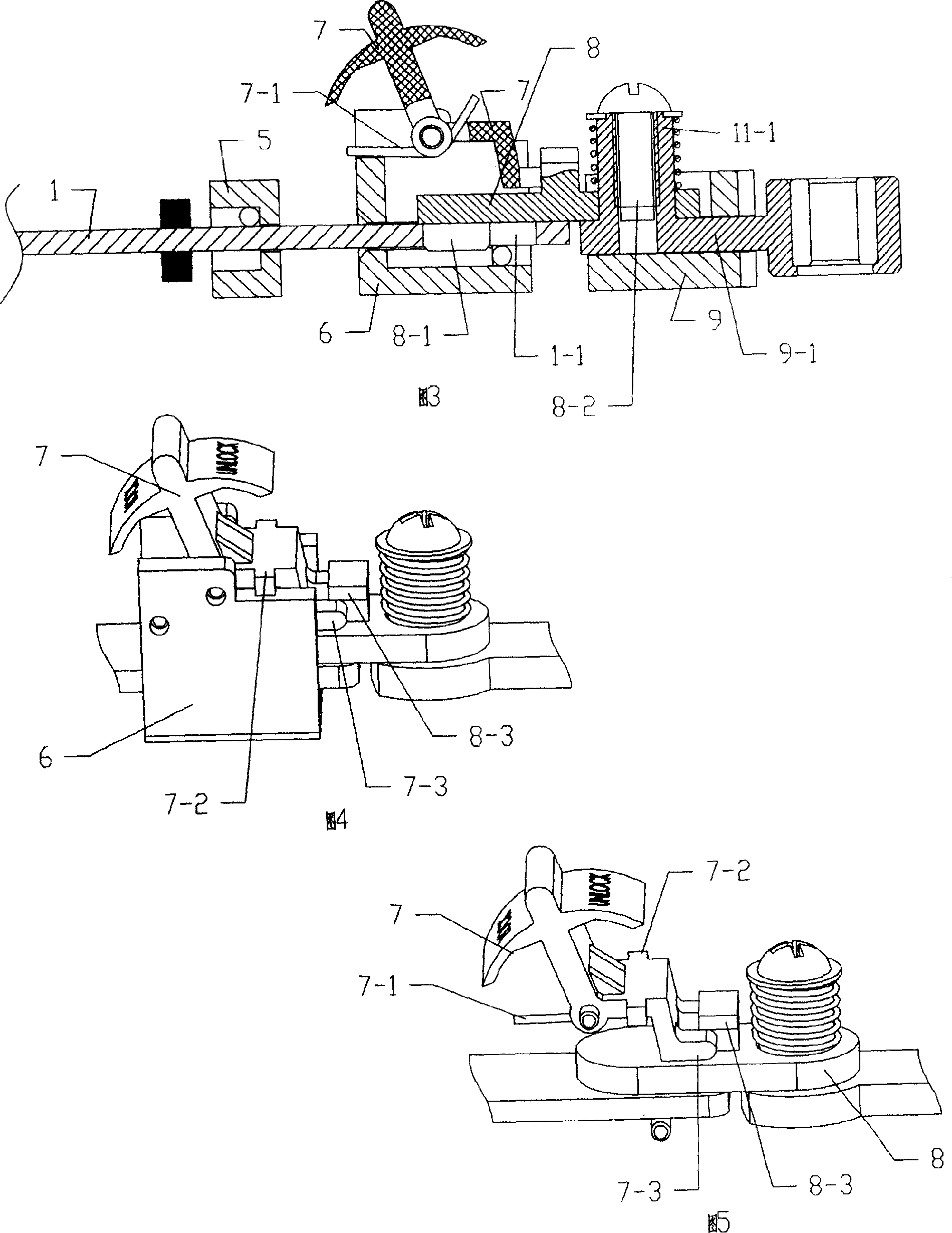

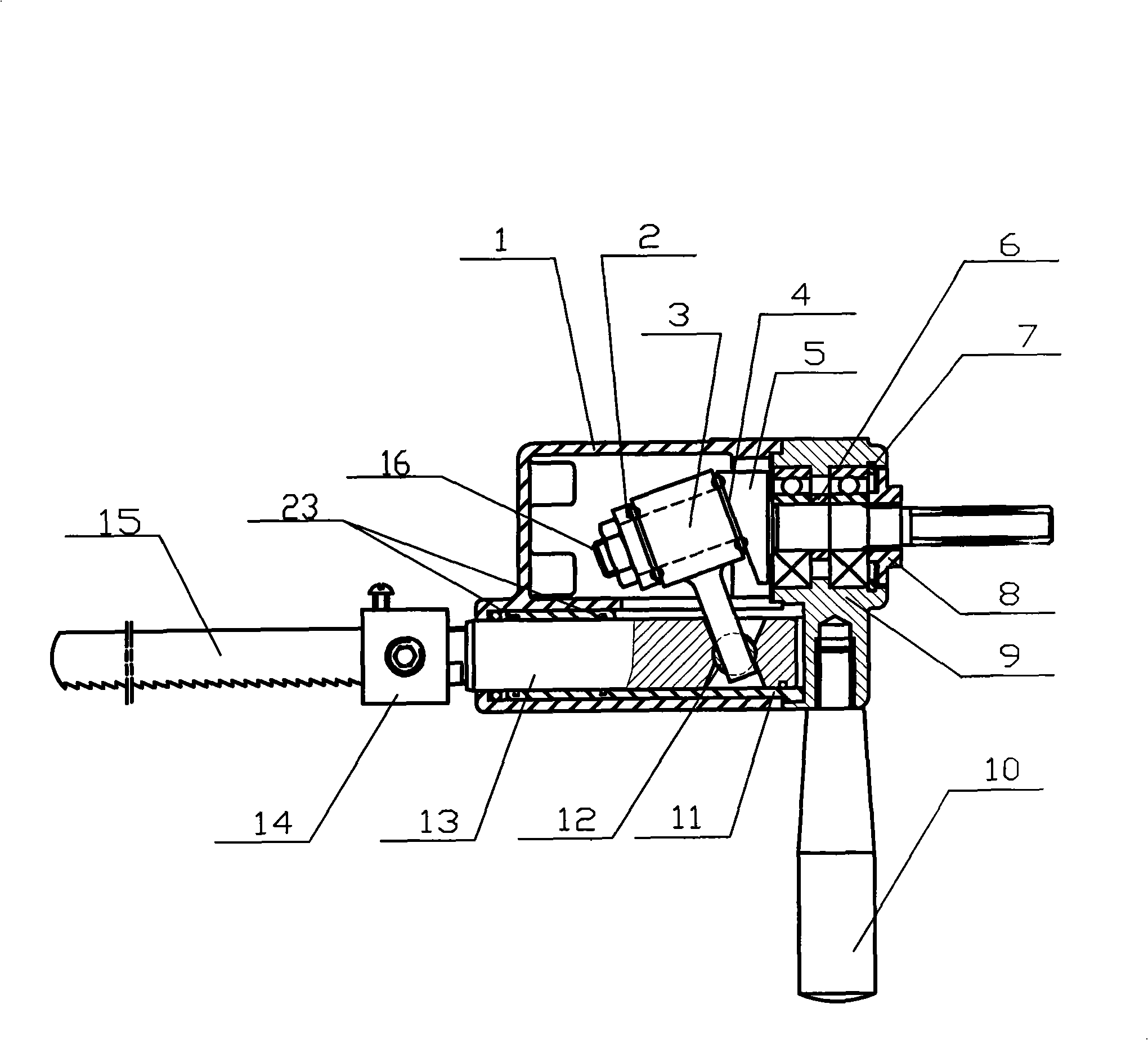

Multi-functional electric tools

The invention provides an electric tool in reciprocating model which can change cutting tools. The electric tool can realize the functions of shoveling, sanding, sawing and filing through the cutting tools being changed. A cutting tool (1) is connected with a reciprocating linear motion mechanism, which is connected with a power mechanism through a speed change mechanism, through a cutting tool loading and unloading mechanism; the back end of the handle of the cutting tool (1) is provided with a hole (1-1); the cutting tool loading and unloading mechanism comprises a front cutting tool holder (5), a back cutting tool hold (6) and a sliding plate (8); the handle of the cutting tool is connected with the front cutting tool holder (5), the back cutting tool holder (6) in sliding along the axial direction of the cutting tool; the front end of the sliding plate (8) is provided with a boss (8-1) extending to the hole (1-1) and is connected with the reciprocating linear motion mechanism in sliding along the axial line of the hole (1-1). The cutting tool can be locked through the boss one the sliding plate hooking the hole (1-1) at the back end of the tool. When the sliding plate slides along the axial line of the hole (1-1) and the boss (8-1) detaches from the hole (1-1), the cutting tool can be get out and be changed.

Owner:CHANGZHOU SAIDI ELECTRIC MFG +1

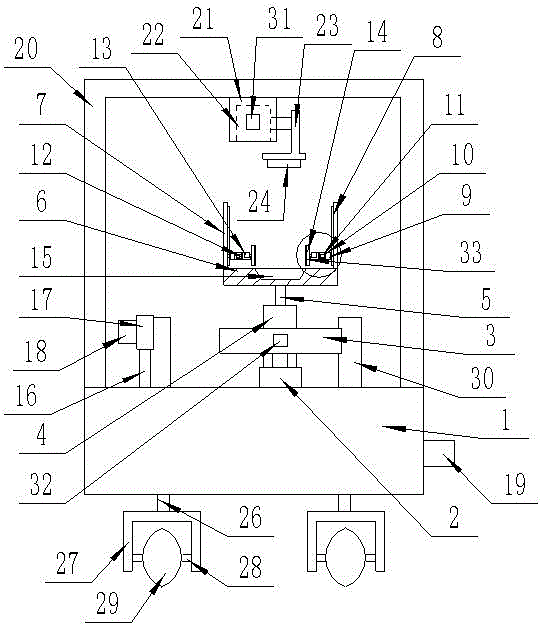

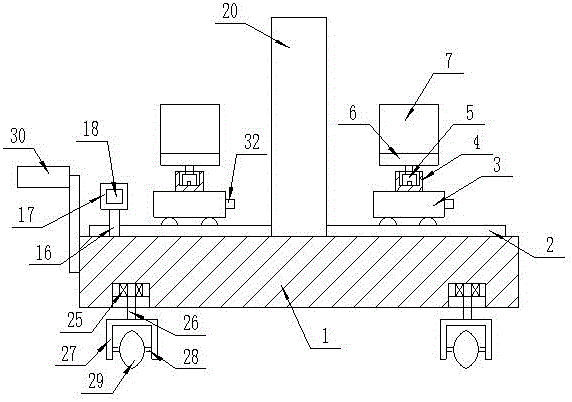

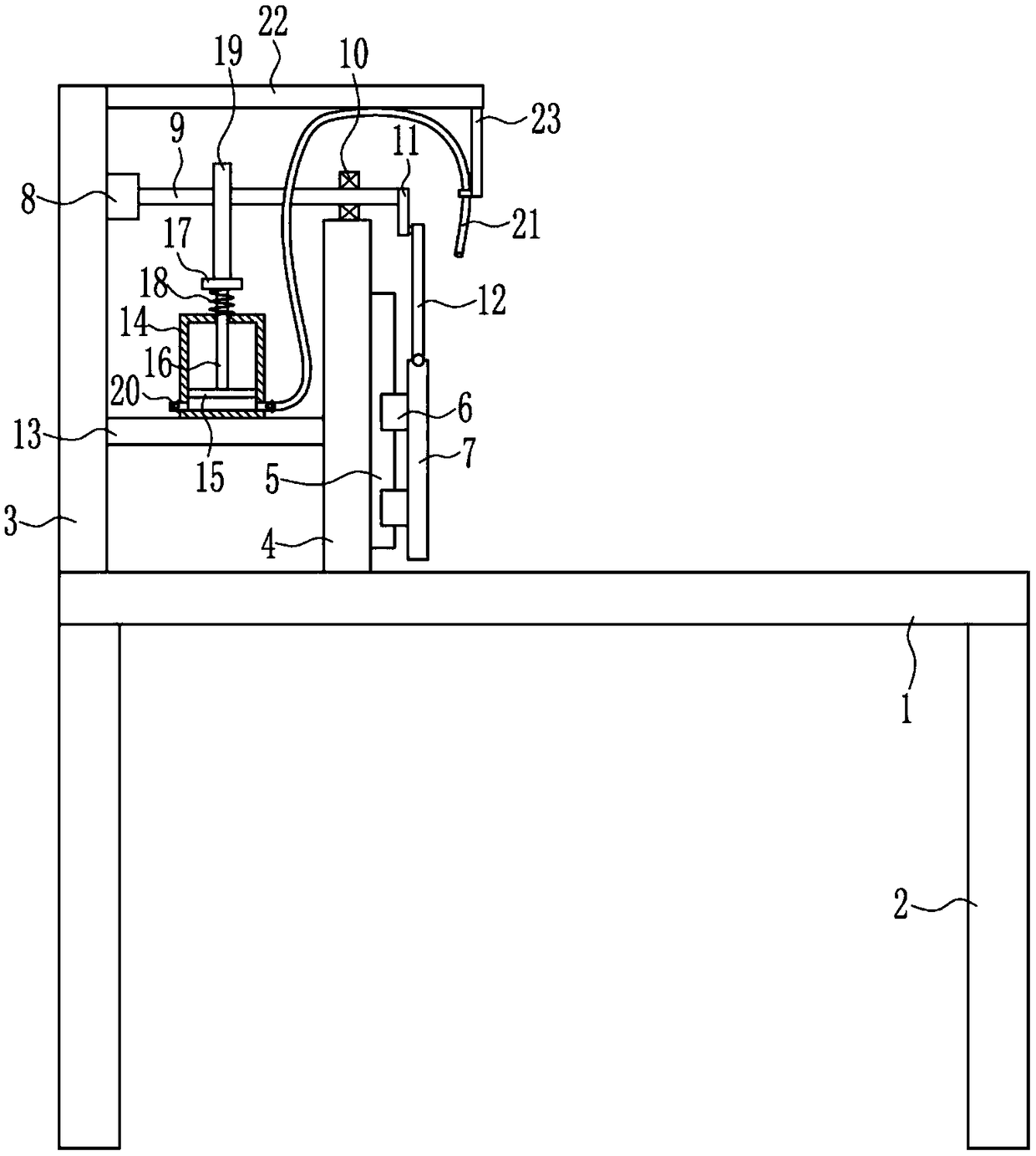

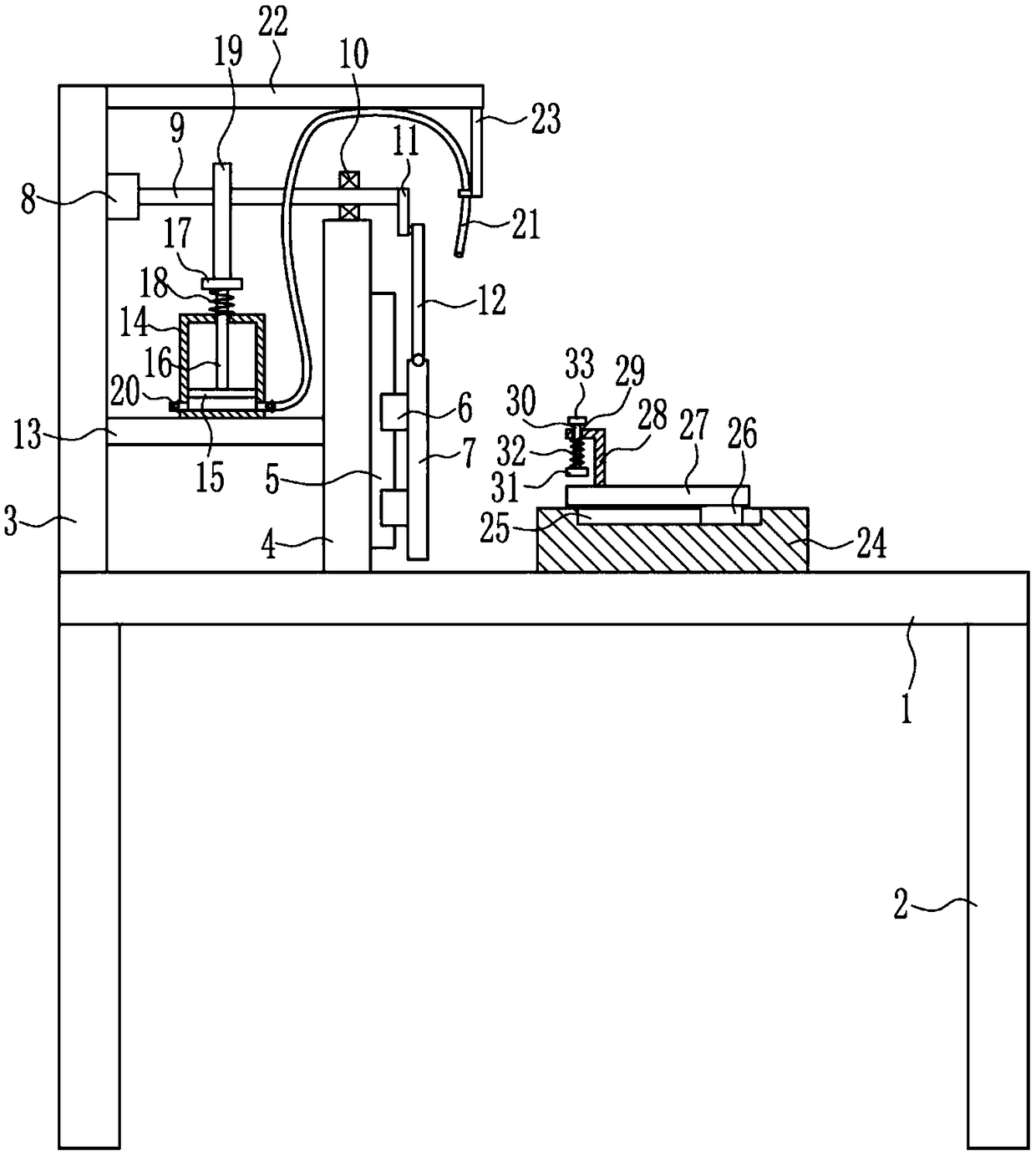

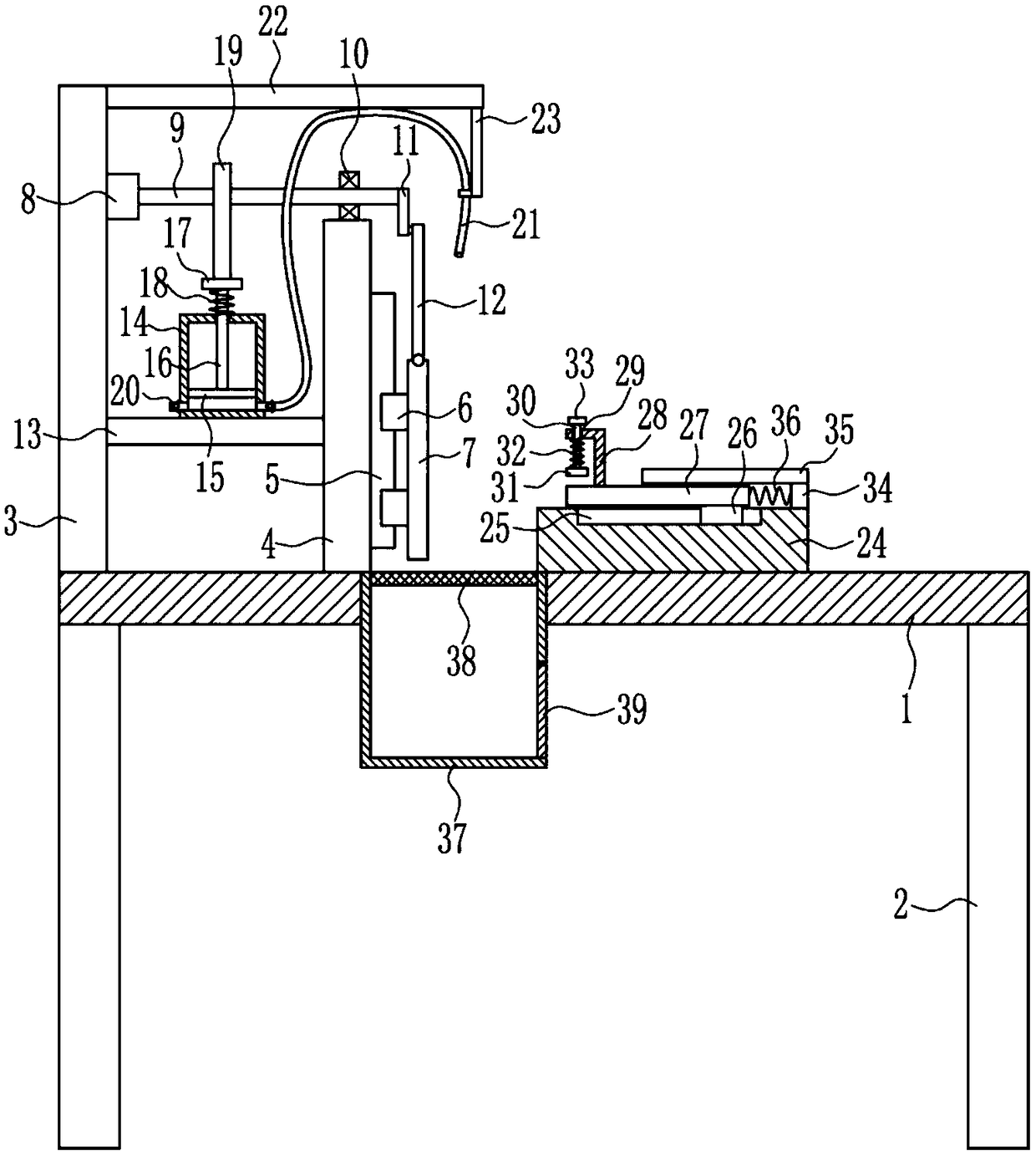

Building scaffold steel pipe rust removal device

ActiveCN111230222AImprove rust removal effectAvoid the phenomenon of circumferential rotationRevolution surface grinding machinesGrinding drivesWorkbenchSteel tube

The invention provides a building scaffold steel pipe rust removal device, and belongs to the technical field of building equipment. The device solves the problems that an existing scaffold steel pipeis poor in rust removal quality. The building scaffold steel pipe rust removal device comprises a bottom plate and a workbench, wherein a pushing base is arranged on the bottom plate in a sliding mode, a plurality of forward rust scraping rings and a plurality of reverse rust scraping rings are rotationally connected to the workbench, a plurality of forward scrapers are arranged on the inner sideface of each forward rust scraping ring in the circumferential direction, a plurality of reverse scrapers are arranged on the inner side face of each reverse rust scraping ring in the circumferentialdirection, the workbench is provided with a driving piece capable of driving the forward rust scraping rings and the reverse rust scraping rings to synchronously and reversely rotate, the workbench is further provided with a plurality of rolling assemblies, and each rolling assembly comprises at least two rolling wheels used for abutting against and supporting the lower portion of a steel pipe and at least two rolling wheels capable of being pressed on the upper portion of the steel pipe. The building scaffold steel pipe rust removal device is better in rust removal effect and is more labor-saving in manual operation.

Owner:广州耀方脚手架工程有限公司

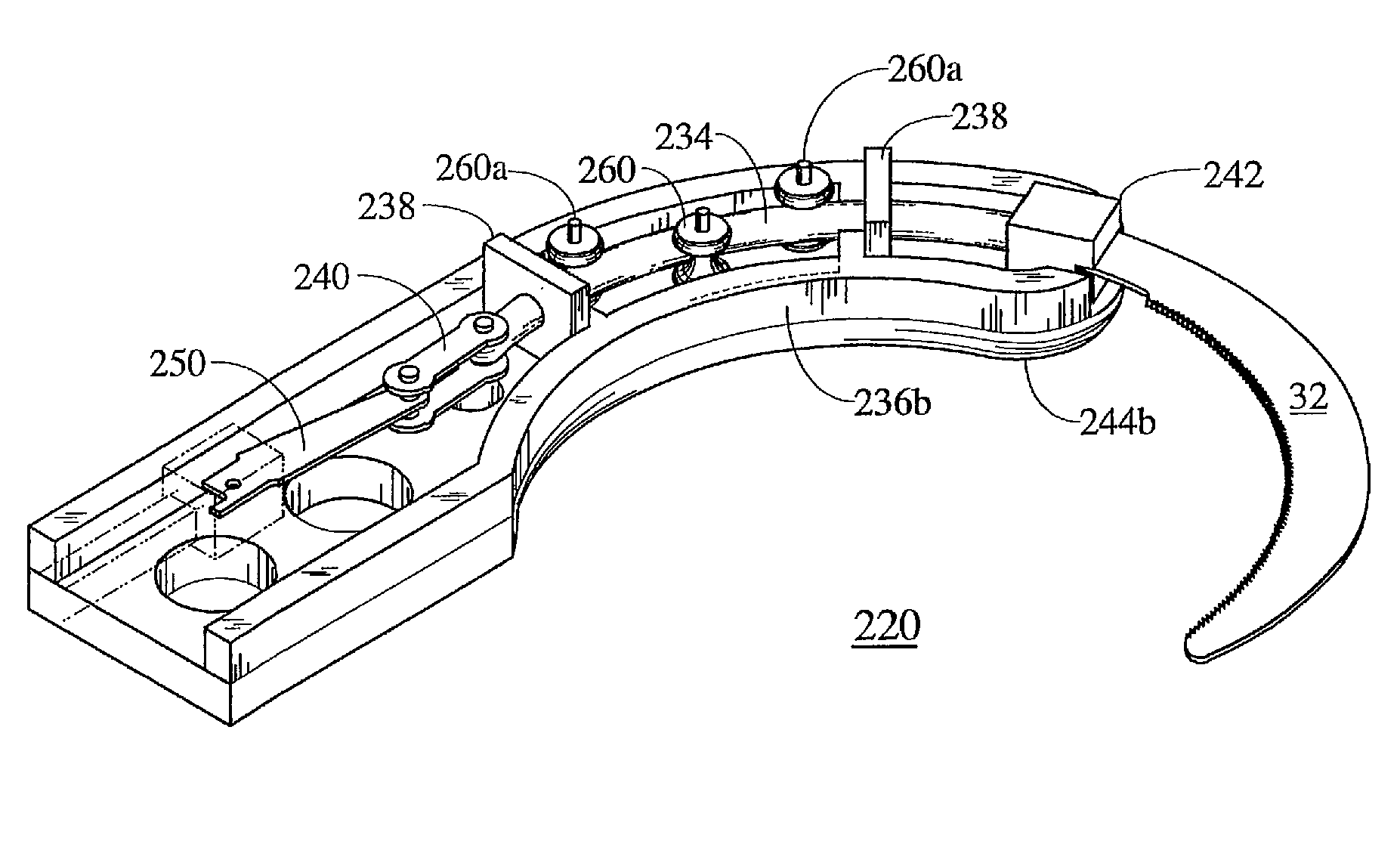

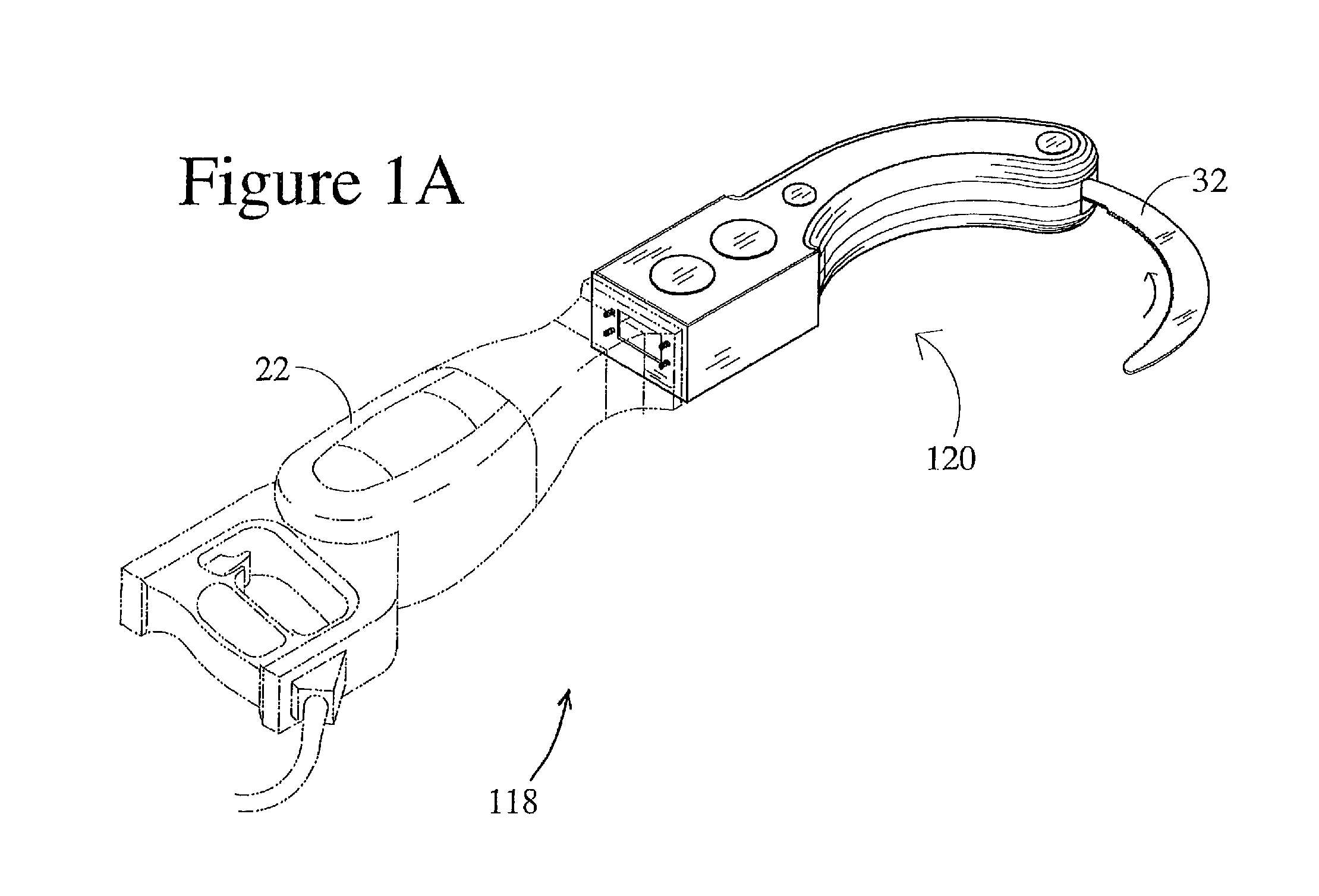

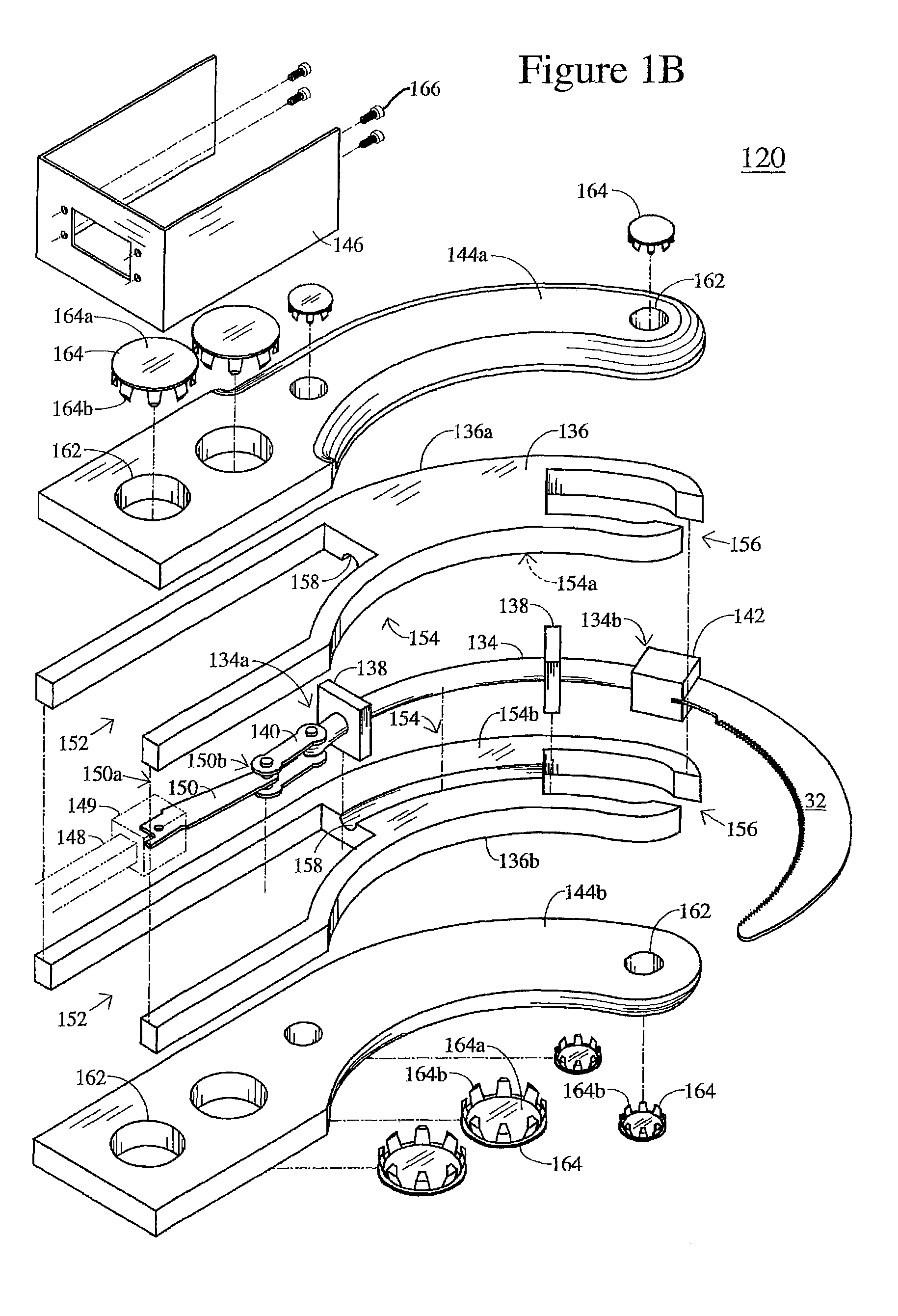

Reciprocating tool

InactiveUS8261455B2Easy to operateEasy accessMetal sawing devicesFiling/rasping devicesReciprocating motionEngineering

An arcuate action tool attachment is adapted to receive an input and to convert that input into reciprocating output motion along an arcuate path. The tool may be adapted to be combined with an existing linear reciprocating device or a rotary device, or the tool may comprise a single unit including a linear reciprocating device or a rotary device. The tool may be fitted with one or more curved or arc-shaped accessories, such as saw blades or the like, that reciprocate along the arcuate paths that may have substantially the same radius of curvature as the accessory.

Owner:HENRICKSON ERIK P

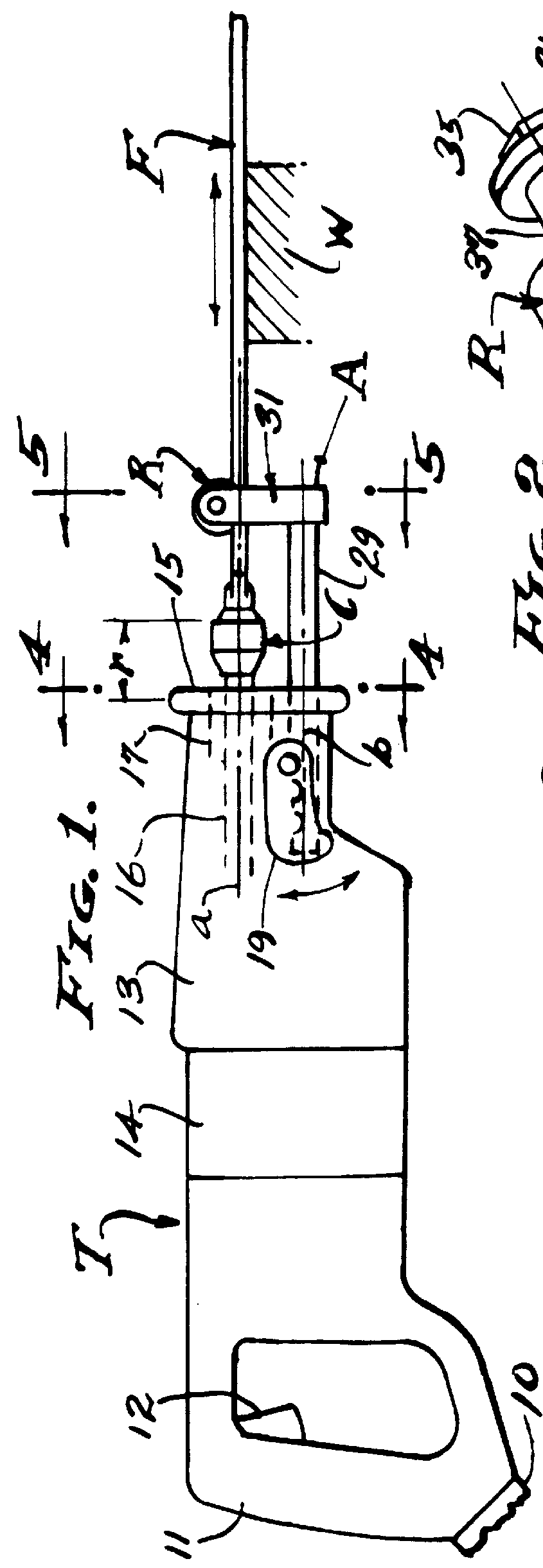

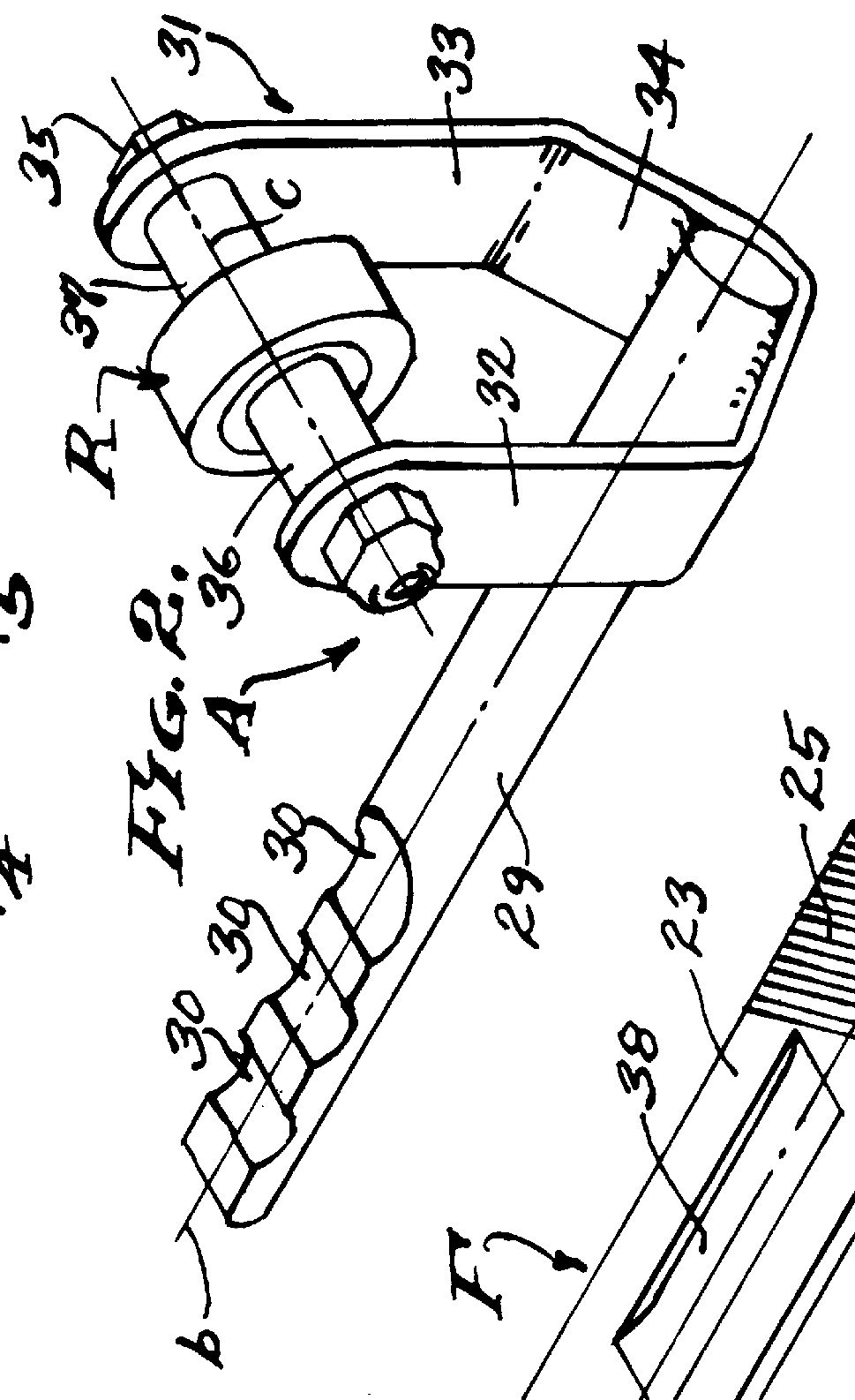

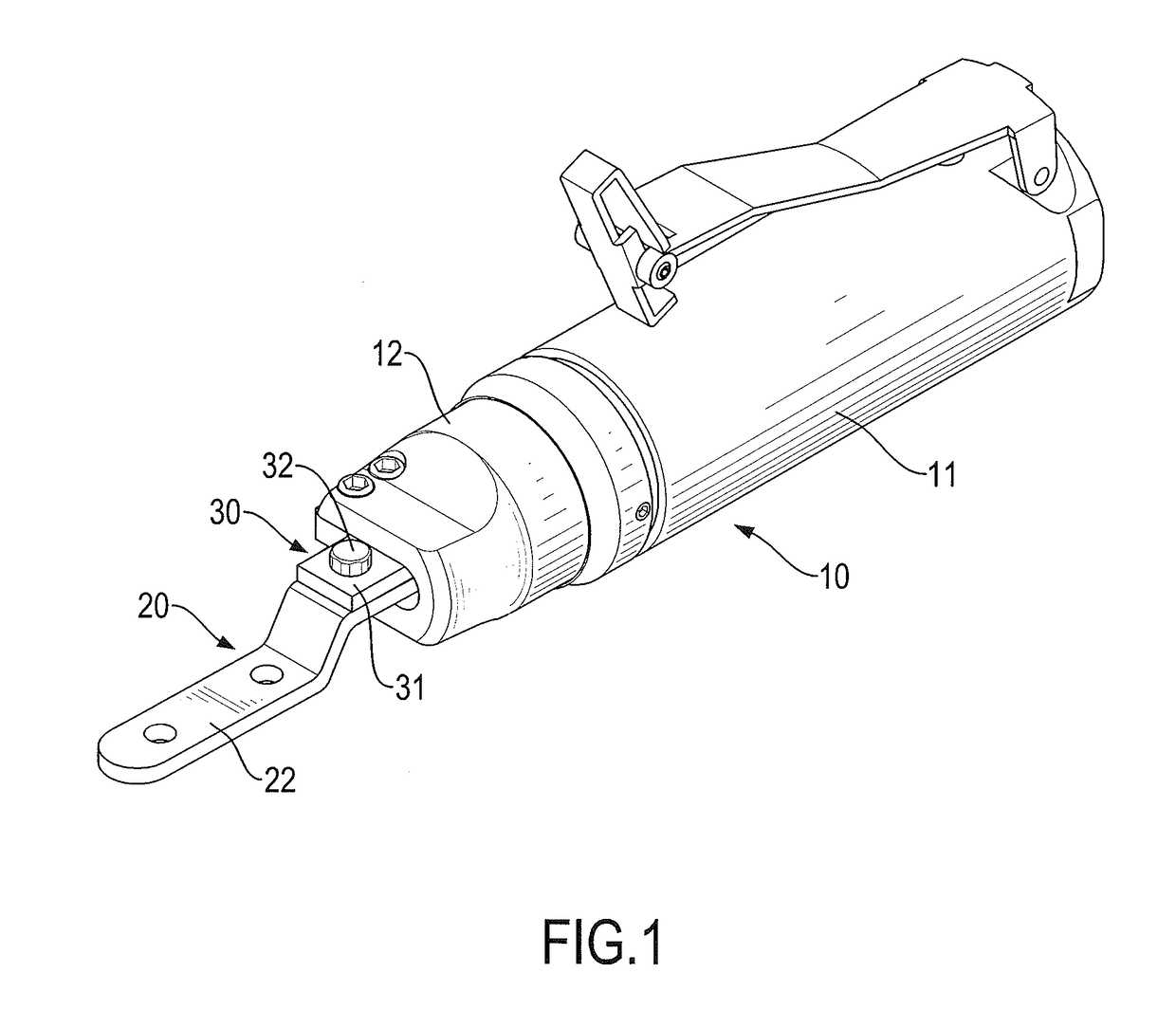

File adapter for power saw tool

A motor driven power hand tool and adapter reciprocating a modified hand file in pressured engagement with a work piece by manipulating a lever resistance intermediate the opposite ends of a file which becomes a second class lever operating with a fulcrum at its reciprocally driven end and with work force applied at its other end, the invention residing in the adapter that guides the file as an aftermarket device and in combination with the power hand tool.

Owner:FUSCO IVALEE

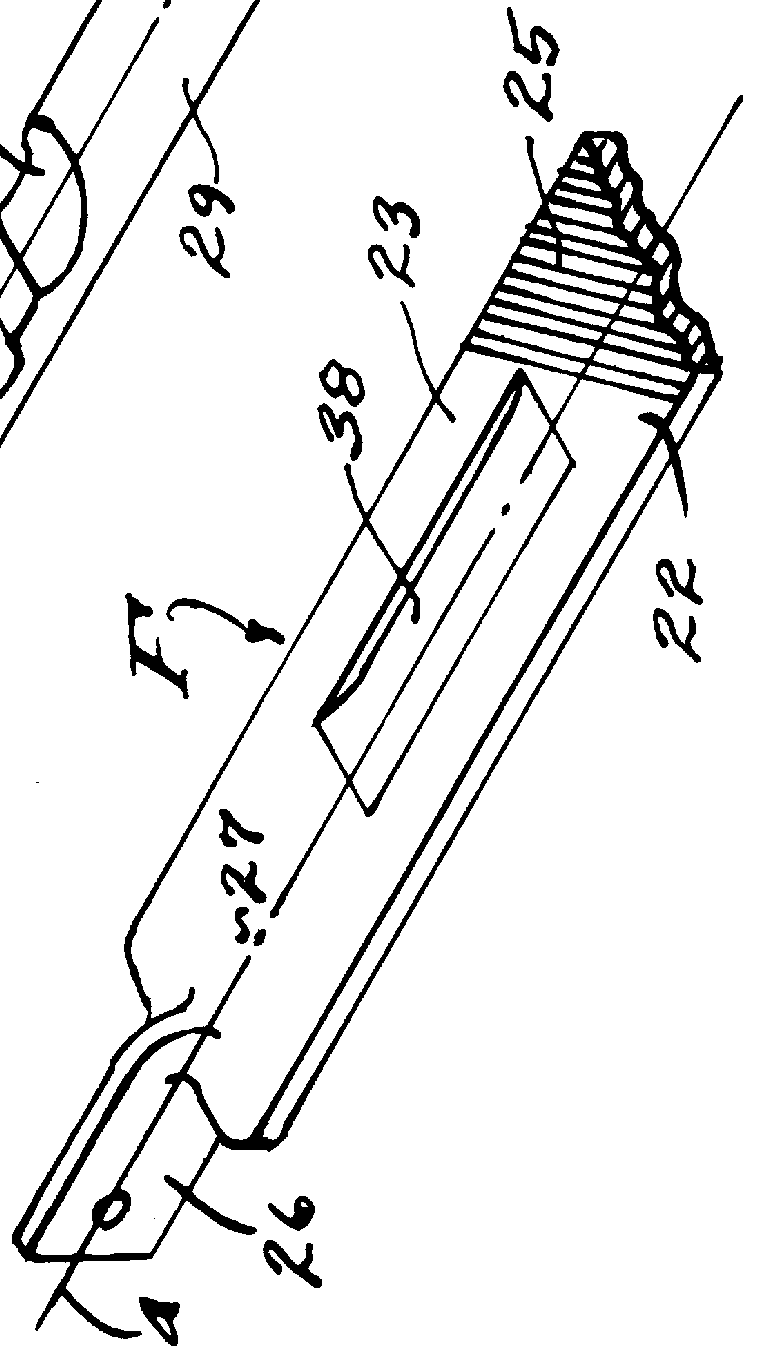

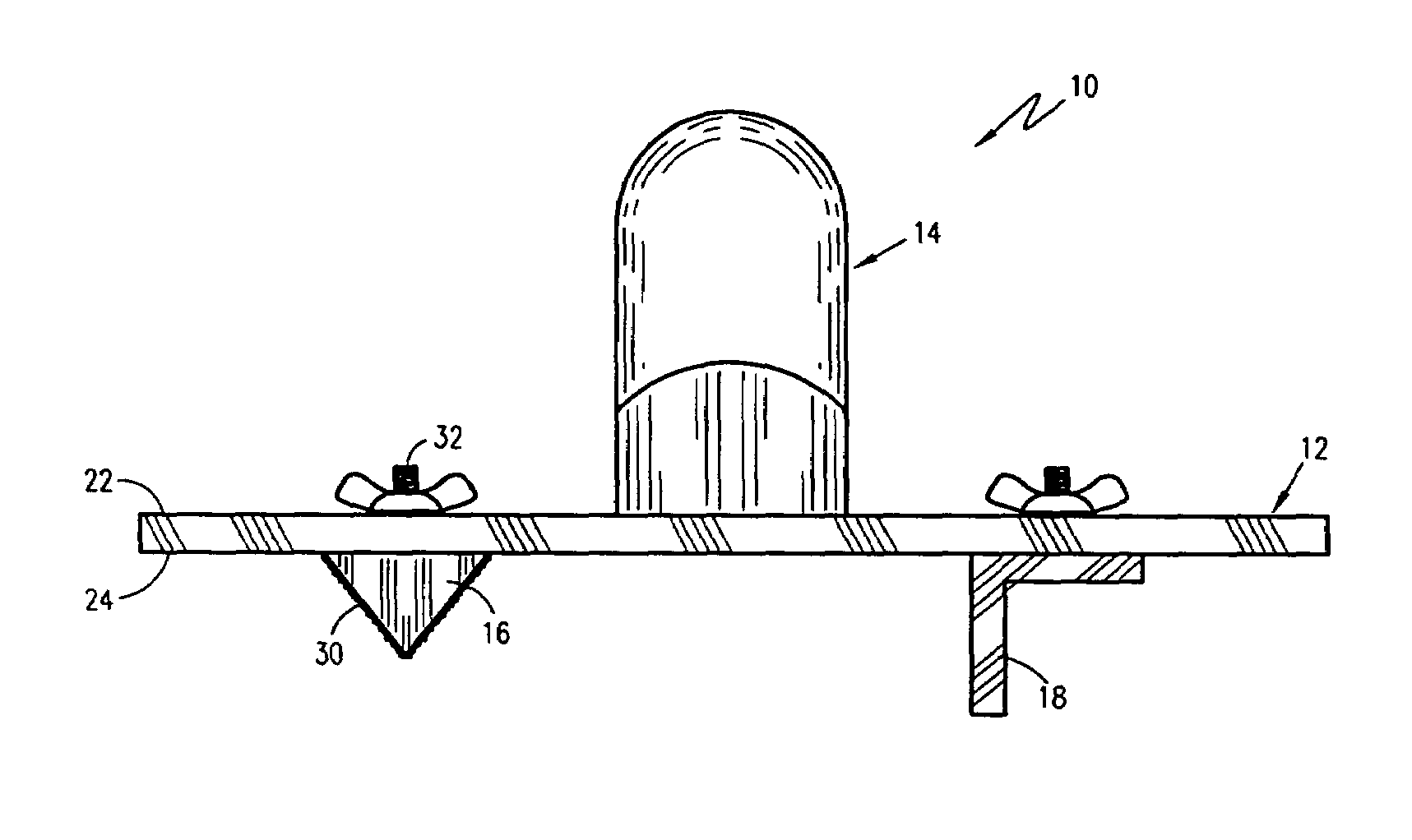

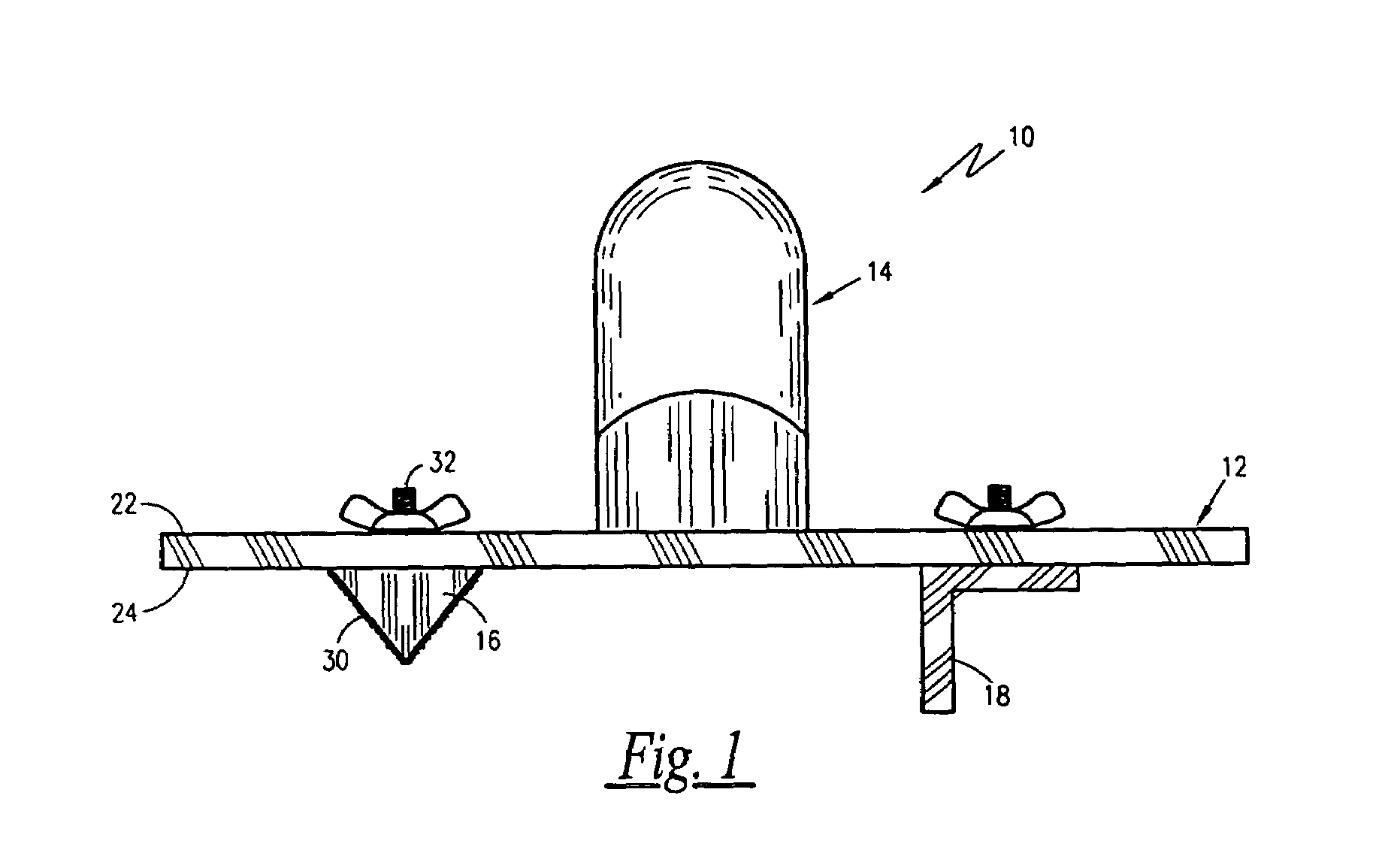

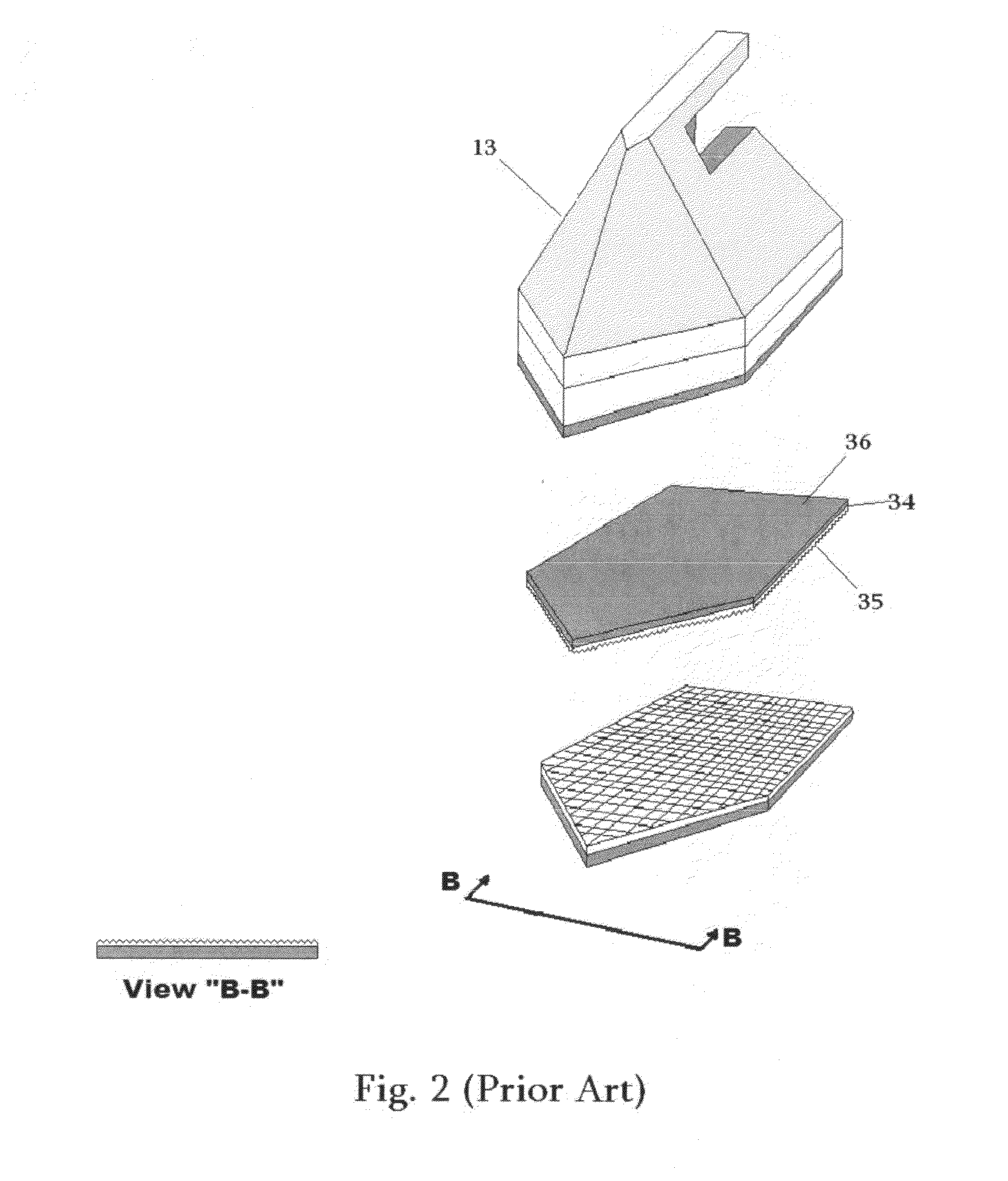

Hand rasp with groove blade and adjustable guide for scoring construction material

ActiveUS6905290B1Improve versatilitySmoothly start scoringMulti-purpose machinesFlat surfacing machinesRaspAnterior surface

An improved hand rasp comprises a planar plate with an anterior surface and an opposing posterior surface. An ergonomic handle is affixed to the anterior surface of the plate. A groove blade is removably affixed to the posterior surface of the plate by attachment means. The groove blade may have a variety of geometric configurations and varying in width and depth to accommodate the imagination of the user or designer. The groove blade includes an abrasive surface on the exterior surface of the groove blade. A guide is also removably affixed to the posterior surface of the plate by attachment means, positioned parallel to the groove blade. The guide is adjustable about apertures formed in the plate to position the guide closer to or farther away from the groove blade.

Owner:CASCIATO JR ANDREW

Parts processing apparatus

ActiveCN106425730AEasy to operateReduce maintenance costsGrinding carriagesGrinding drivesHydraulic cylinderEngineering

The invention discloses a parts processing apparatus, comprising a worktable; the upper surface of the worktable is provided with a lifting mechanism; the upper surface of each carrying plate is provided with a retaining cavity between each group of vertical mounting plates; the upper surface of the worktable is provided with a vertical rod in front of a transverse slide rail, the upper surface of the vertical rod is provided with a second vertical mounting plate, the front surface of the second vertical mounting plate is provided with a controller, the rear surface of the worktable is provided with a mains supply connector, the power junction end of a controller is connected to the mains supply connector through a wire, and the output end of the controller is connected respectively to an electric cart, a hydraulic cylinder, a second electric cart, an electric push rod and a miniature rotary motor through wires. The parts processing apparatus has the advantages that maintenance cost is low, semiautomatic rotational fixed polishing provides high polishing speed, labor is freed, work efficiency is improved, the apparatus is convenient to move, convenient to use and high in novelty.

Owner:嘉兴晟友机械科技有限公司

Multifunctional converter of electrical drill

InactiveCN101342694AMetal sawing devicesFiling/rasping devicesReciprocating motionElectric machinery

The present invention discloses an electric drill multifunctional converter. A transmission gear consists of a rocker, a swing stem, a slide bar and a collet which are connected orderly. One end of the rocker is filled in and fastened at an assembling hole of an electric drill bit. The transmission gear is used for changing the rotation of the motor shaft of the electric drill into the straight reciprocating motion of the collet. A cutter installed at the collet can be a saw blade, a razor blade, a file, and the like, so the electric drill has the functions of electric tools, such as an electric saw, an electric file, etc.

Owner:姚耕

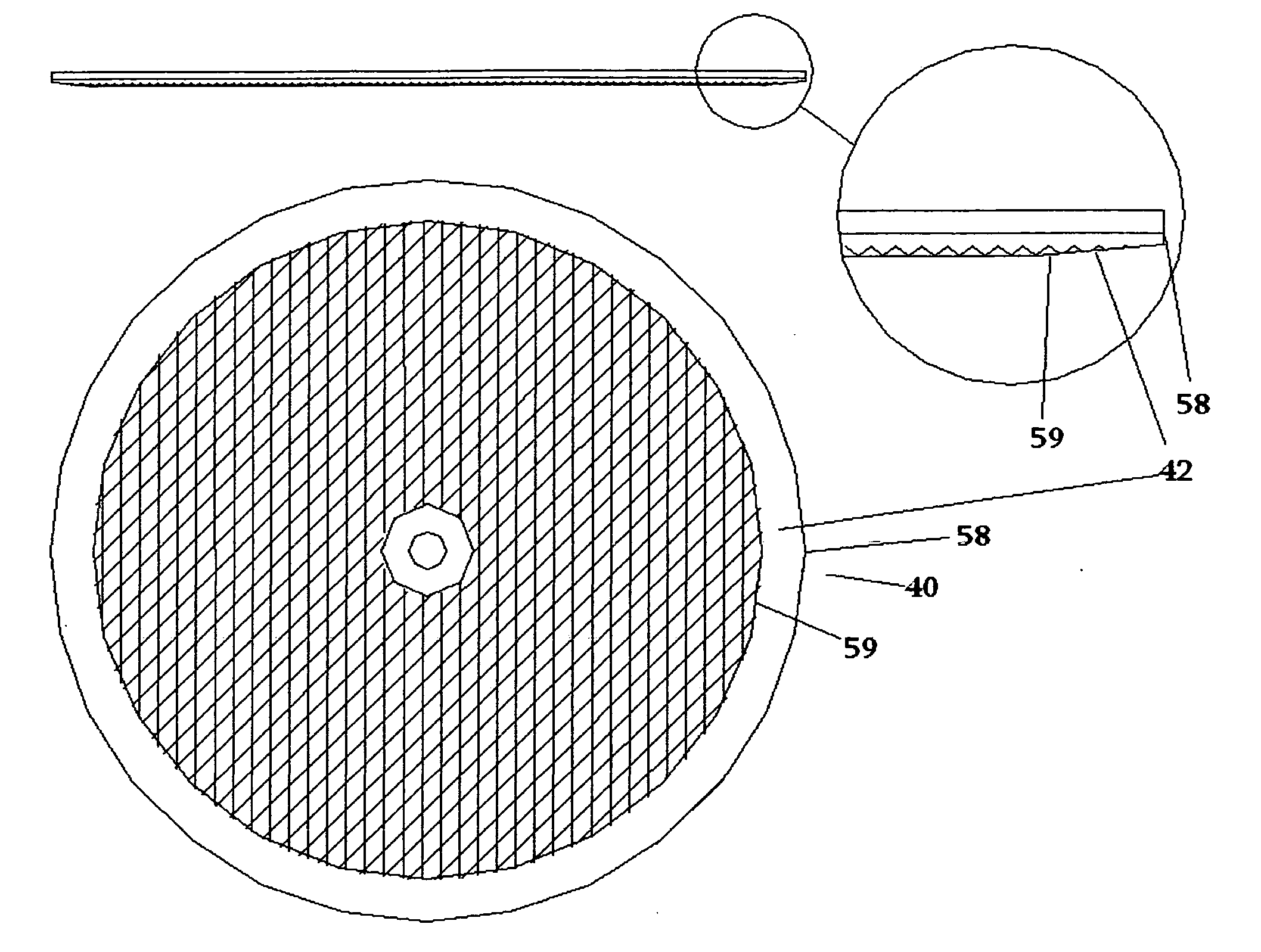

Device for smoothing the surfaces of hard or soft materials

InactiveUS20080171496A1Few clogging problemEasy to slideOven incrustations prevention/removalFiling/rasping toolsSanderEngineering

The present invention is a finishing plate and method of fabricating a finishing plate. The finishing plate can be fabricated to various shapes, and can be used with various surfacing machines. In a preferred mode, the present invention is a disc cutting plate which can be used with a random orbital sander, and can be used to replace traditional abrasive sheets such as sandpaper. The present invention can be used in smoothing various materials including wood, painted wood, plastic, and various metals.

Owner:GELFUSO RUSSELL

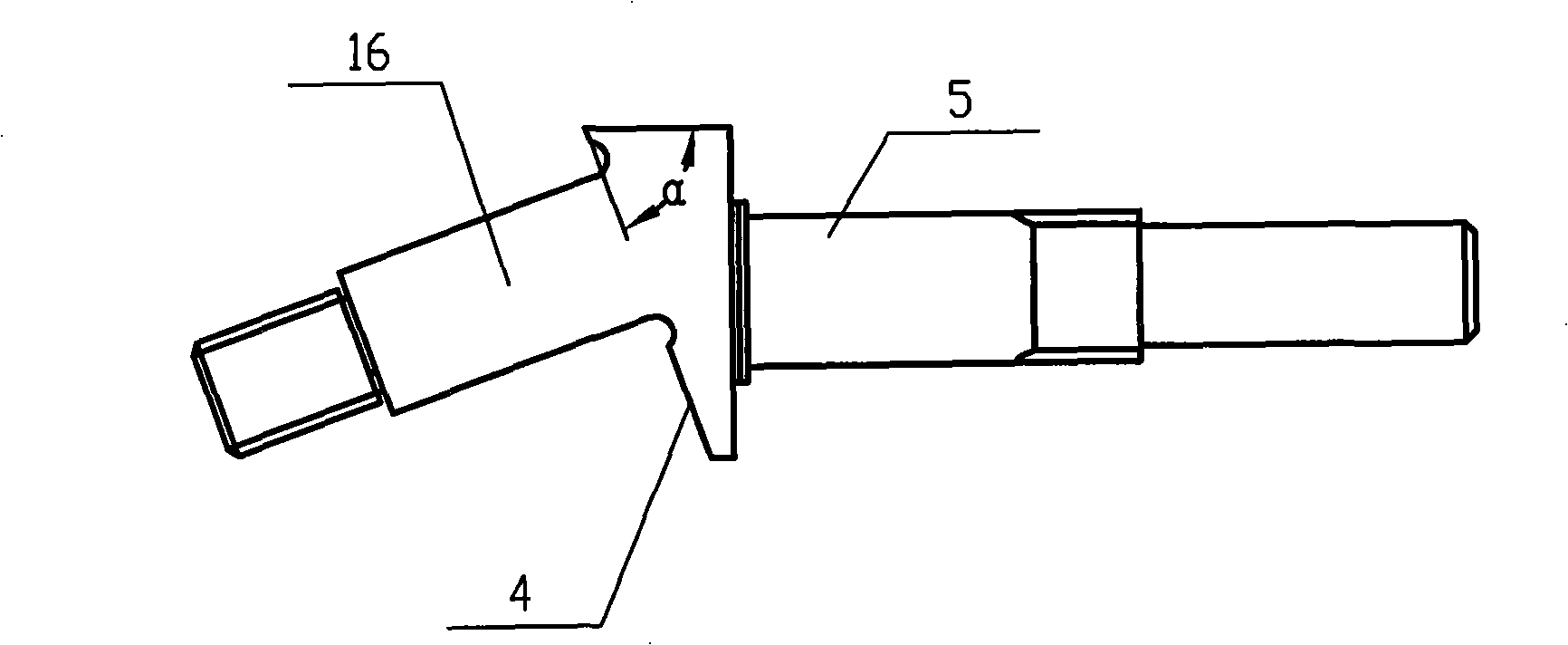

Edge burr grinding machine for highway guardrail

ActiveCN107498114AReduce labor burdenFiling/rasping devicesLarge fixed membersEngineeringMechanical engineering

The invention discloses an edge burr grinding machine for a highway guardrail. A grinding mechanism is arranged on a working platform, wherein an adjusting mechanism is connected to the grinding mechanism and used for adjusting the grinding mechanism to enable the grinding mechanism to reciprocate in the length direction of the working platform; a driving mechanism is arranged on the grinding mechanism and used for driving the grinding mechanism to grind; the grinding mechanism comprises a bottom plate, an inclined platform and a crank connecting rod assembly; the inclined platform is fixed to the bottom plate; the crank connecting rod assembly is fixed to the inclined surface of the inclined platform; a file is arranged at one end, far away from the inclined platform, of the crank connecting rod assembly; the driving mechanism is connected to the crank connecting rod assembly to achieve D-shaped moving track of the file; the moving track includes an arc-shaped section, and a straight line section which is positioned below the arc-shaped section; the straight line section is parallel to a slope surface of the inclined platform. With the adoption of the machine, burrs on a cutting section of the highway guardrail subjected to cutting can be efficiently grinded with high accuracy, so that the workload is decreased.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

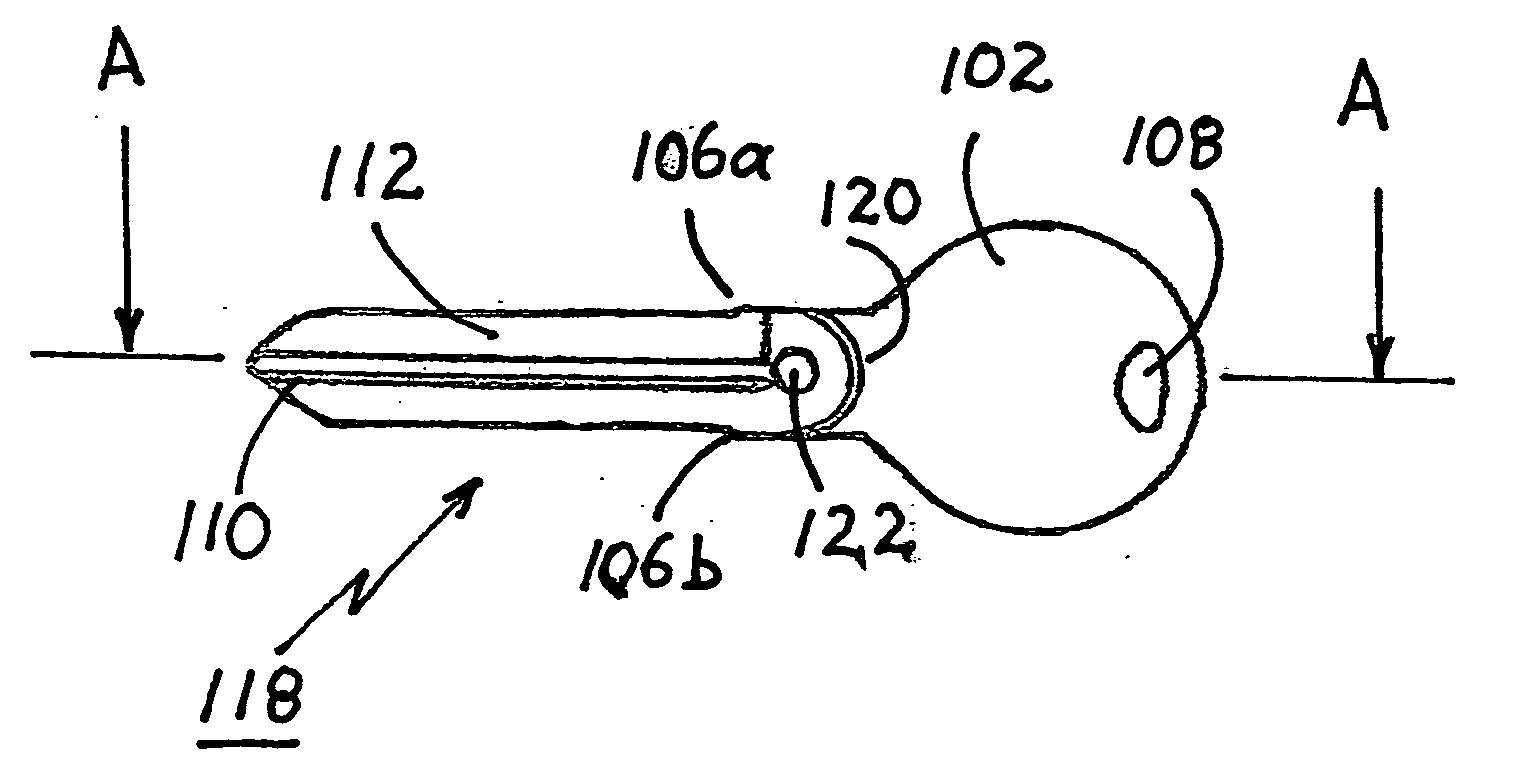

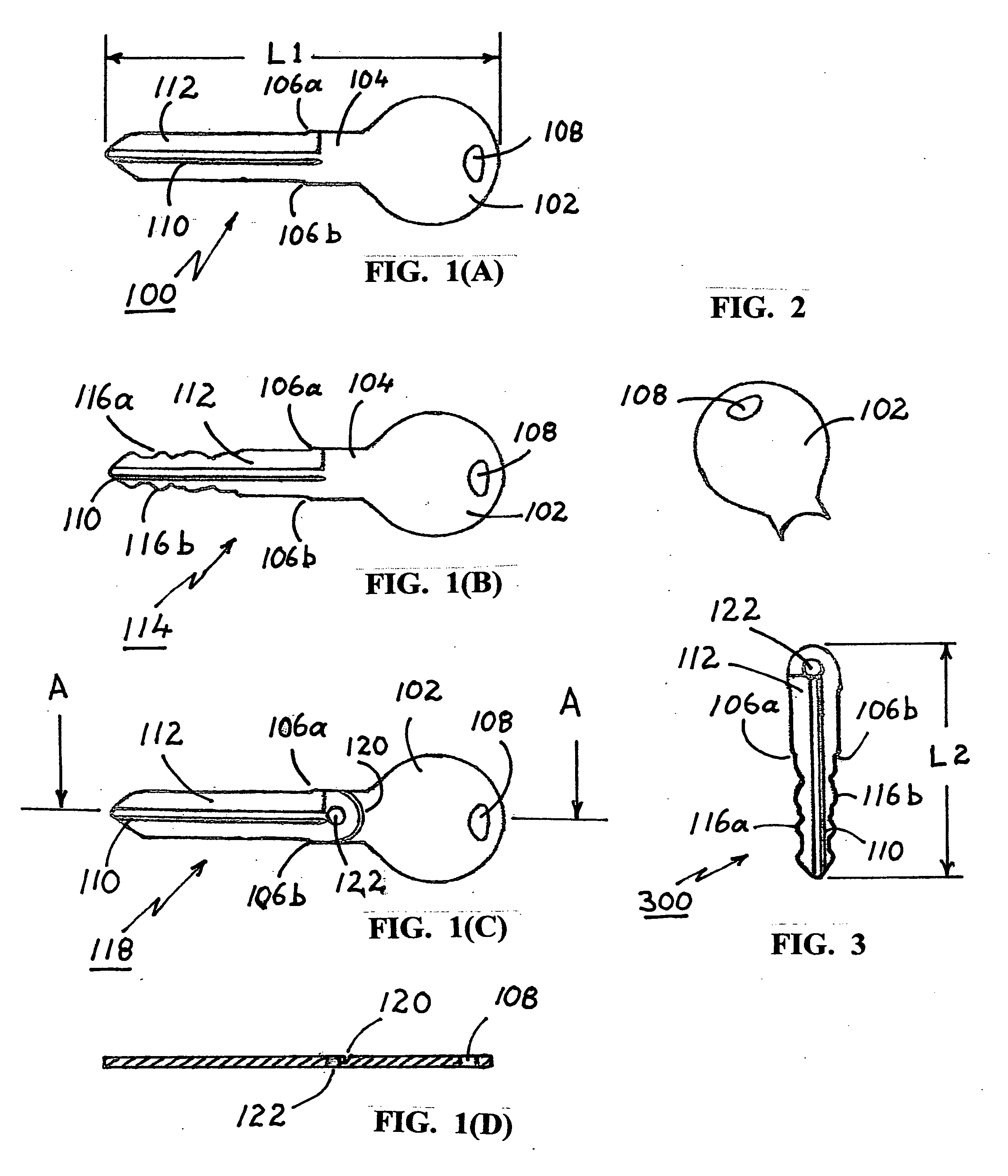

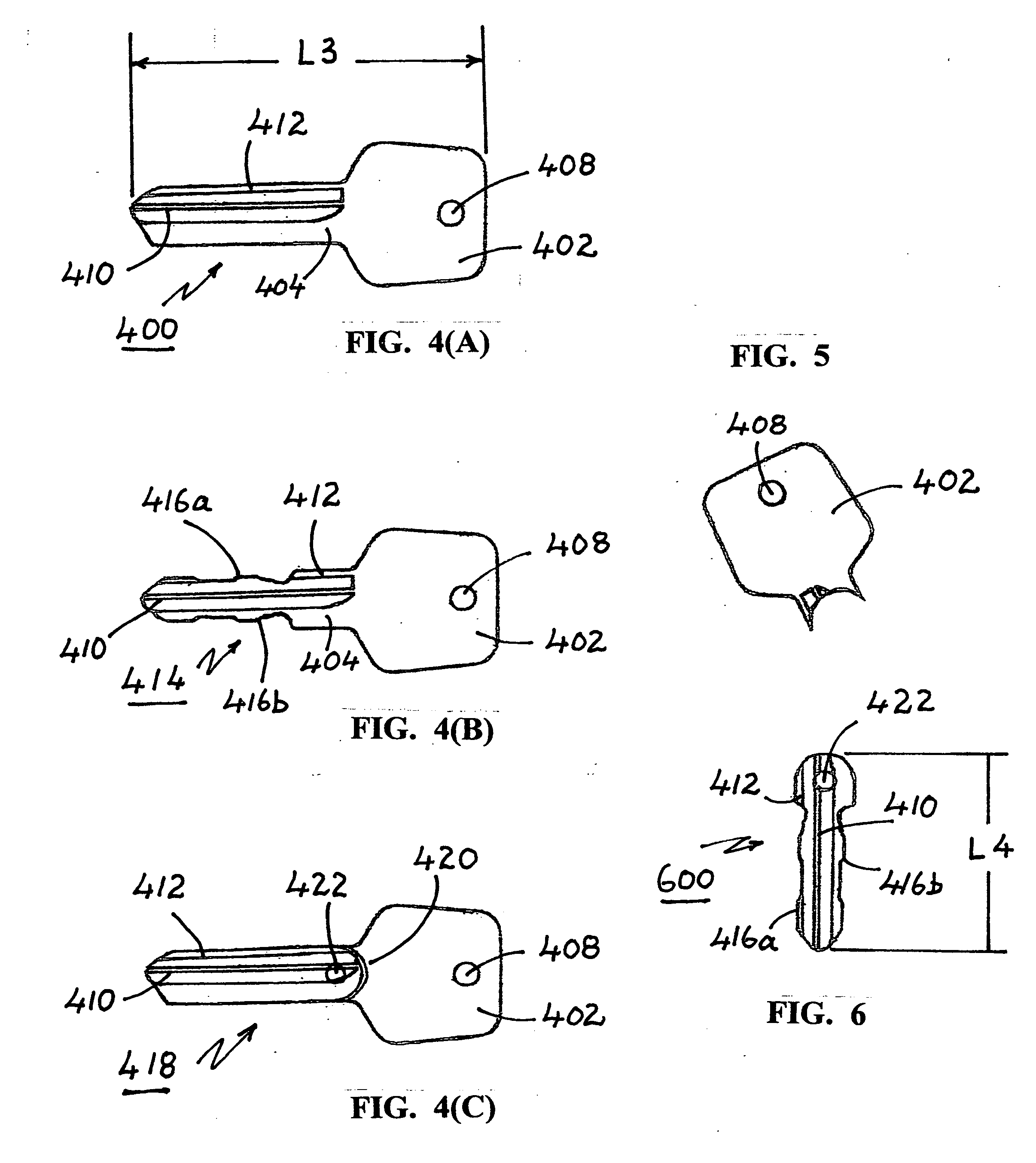

Minimalized keys and blanks for same

Owner:NIRMEL CHITTARANJAN N

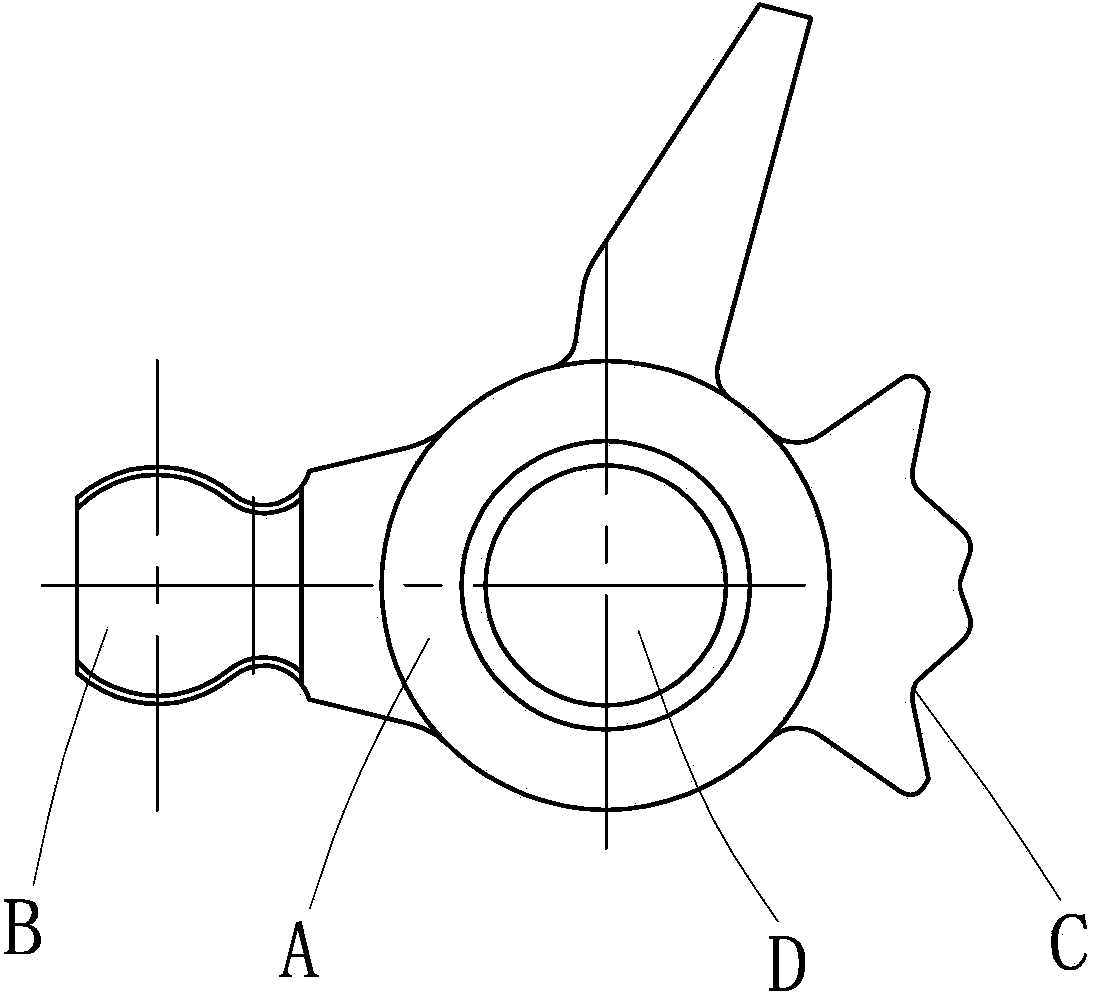

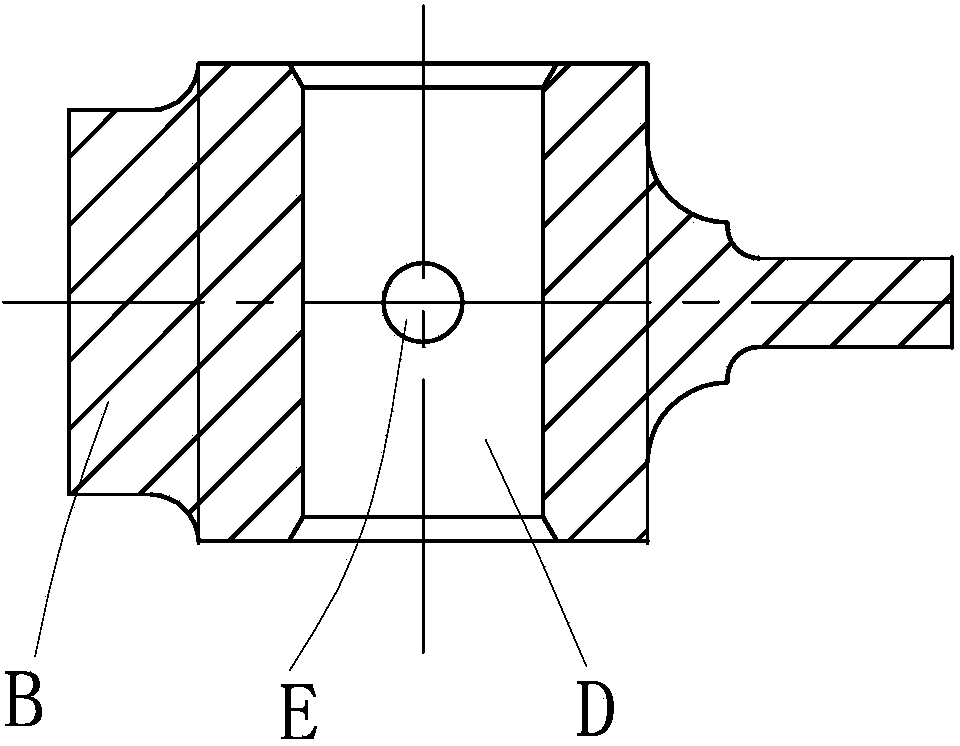

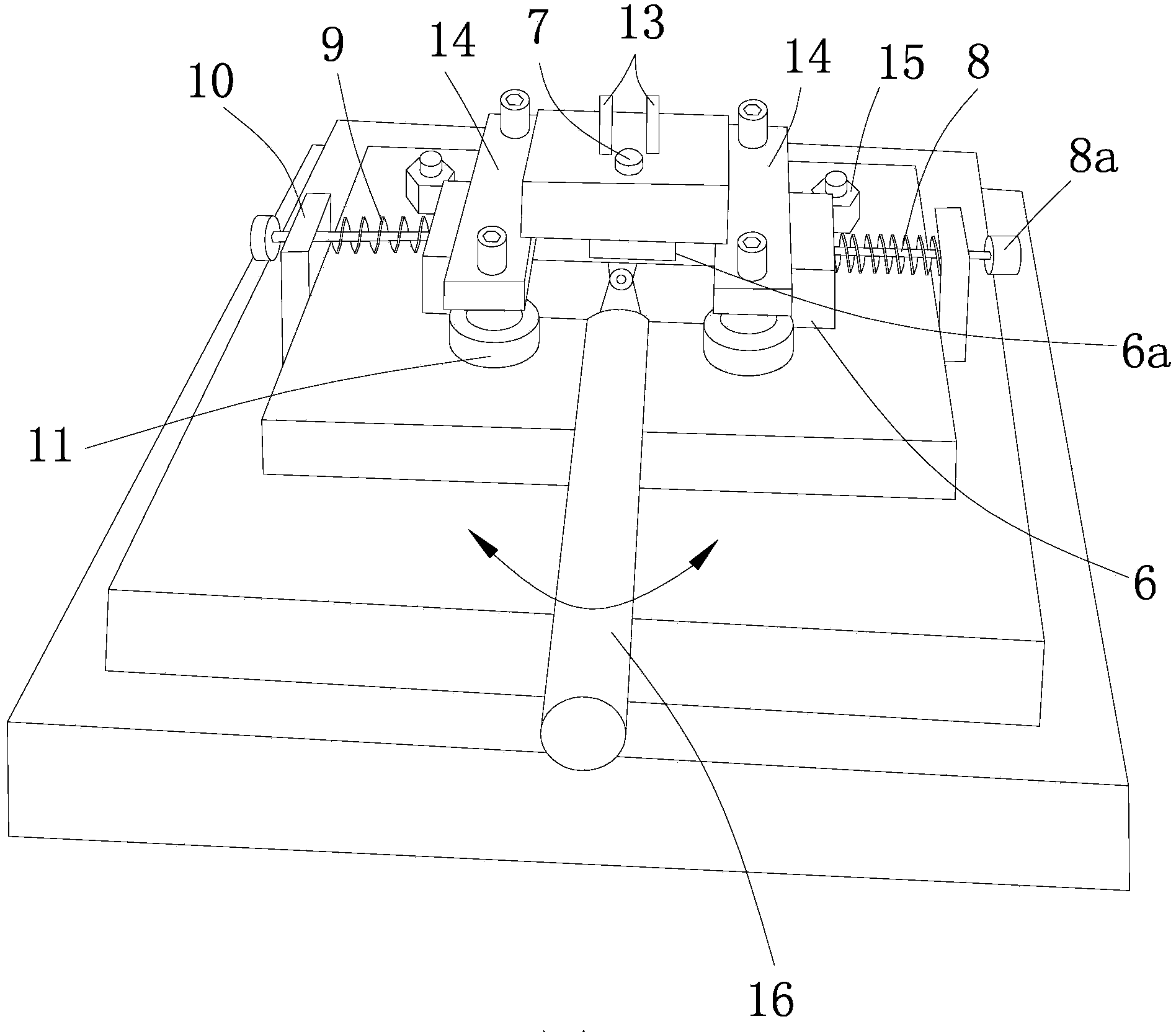

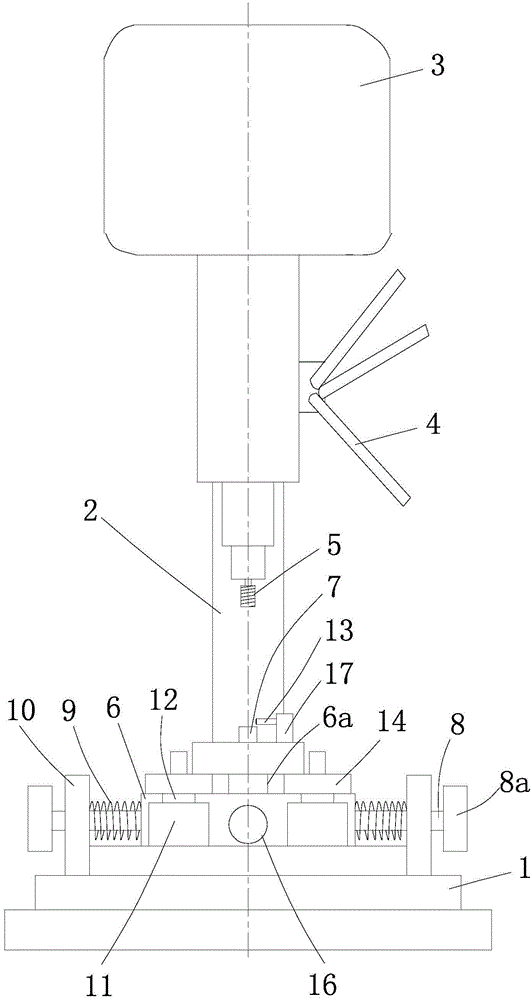

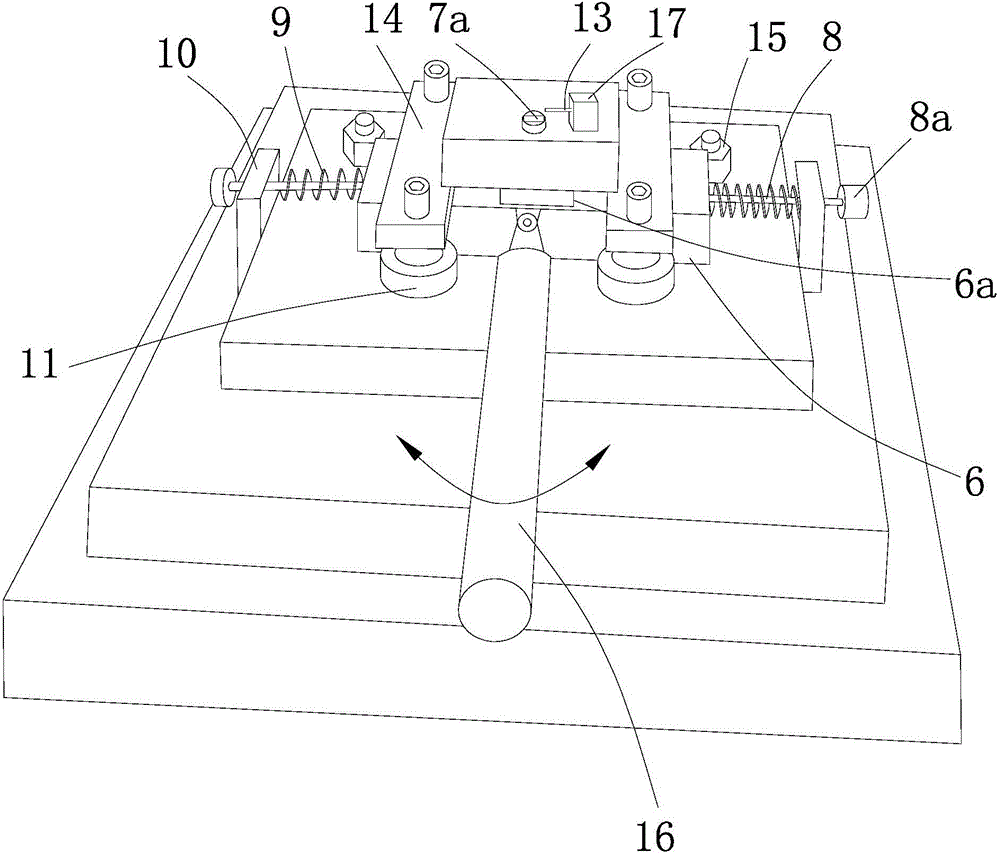

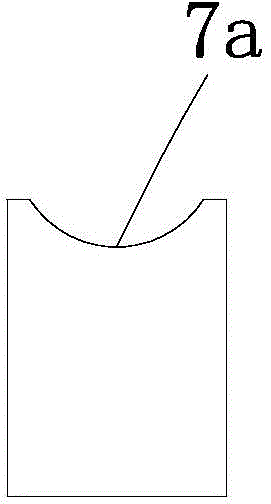

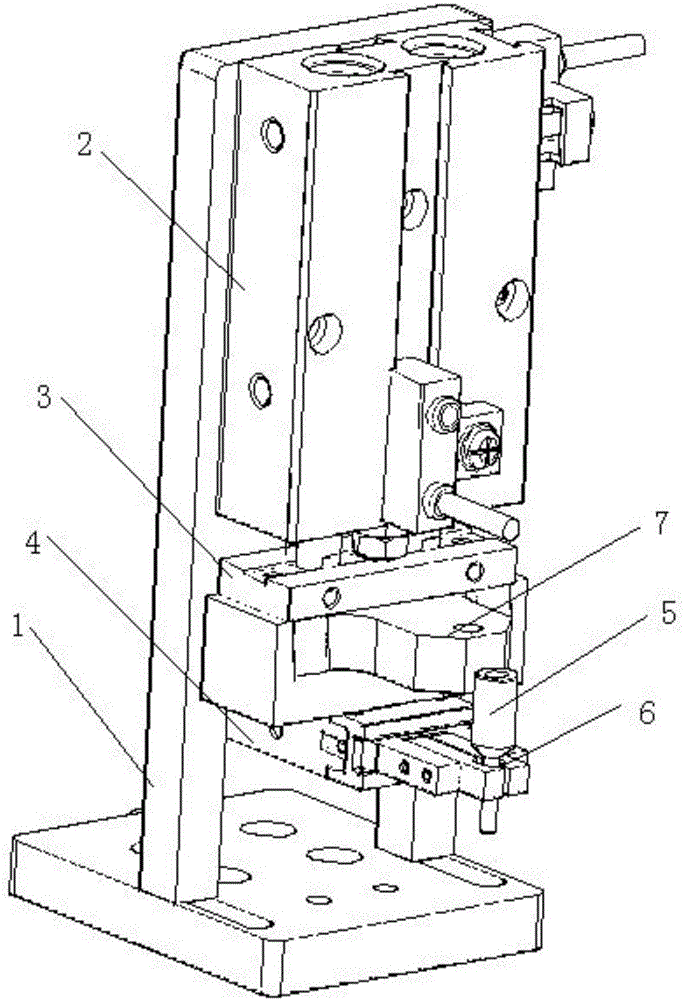

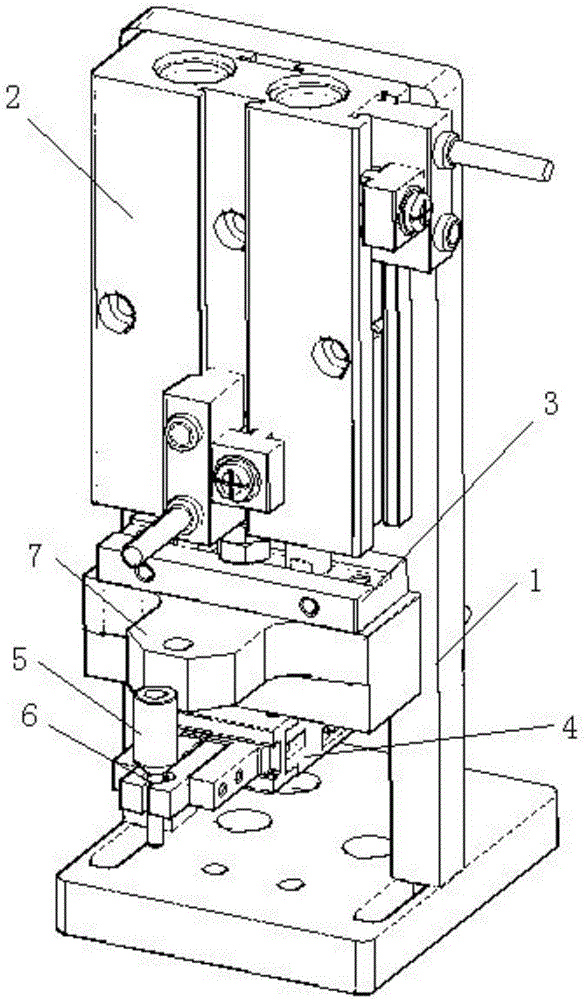

Burr removing tool for inner end of positioning pin hole of gear shifting swing rod of automobile transmission

The invention discloses a burr removing tool for an inner end of a positioning pin hole of a gear shifting swing rod of an automobile transmission. The burr removing tool comprises a working table and a sliding supporting plate; an automobile swing rod sleeve cylinder and automobile swing rod anti-rotating blocks are fixedly arranged above the sliding supporting plate; a manual swing rod is hinged to the middle position of the front side wall of the sliding supporting plate; the left side and the right side of the sliding supporting plate are each provided with a connecting rod which extends left and right; each connecting rod is sleeved with a return spring. The outer side of each connecting rod is provided with a supporting block for supporting the corresponding connecting rod; the front side and the rear side of the sliding supporting plate are each provided with two bearings; the bearings are arranged at intervals in a left and right manner to guide left and right moving of the sliding supporting plate; and the left side and the right side of the neck of the sliding supporting plate are each provided with a limiting plate for limiting left and right moving of the sliding supporting plate. The burr removing tool is novel in conception, ingenious in design, convenient to operate and high in automation degree; the production efficiency and product consistency are remarkably improved; and the burr removing tool has the wide popularization value.

Owner:重庆市广角机械制造有限公司

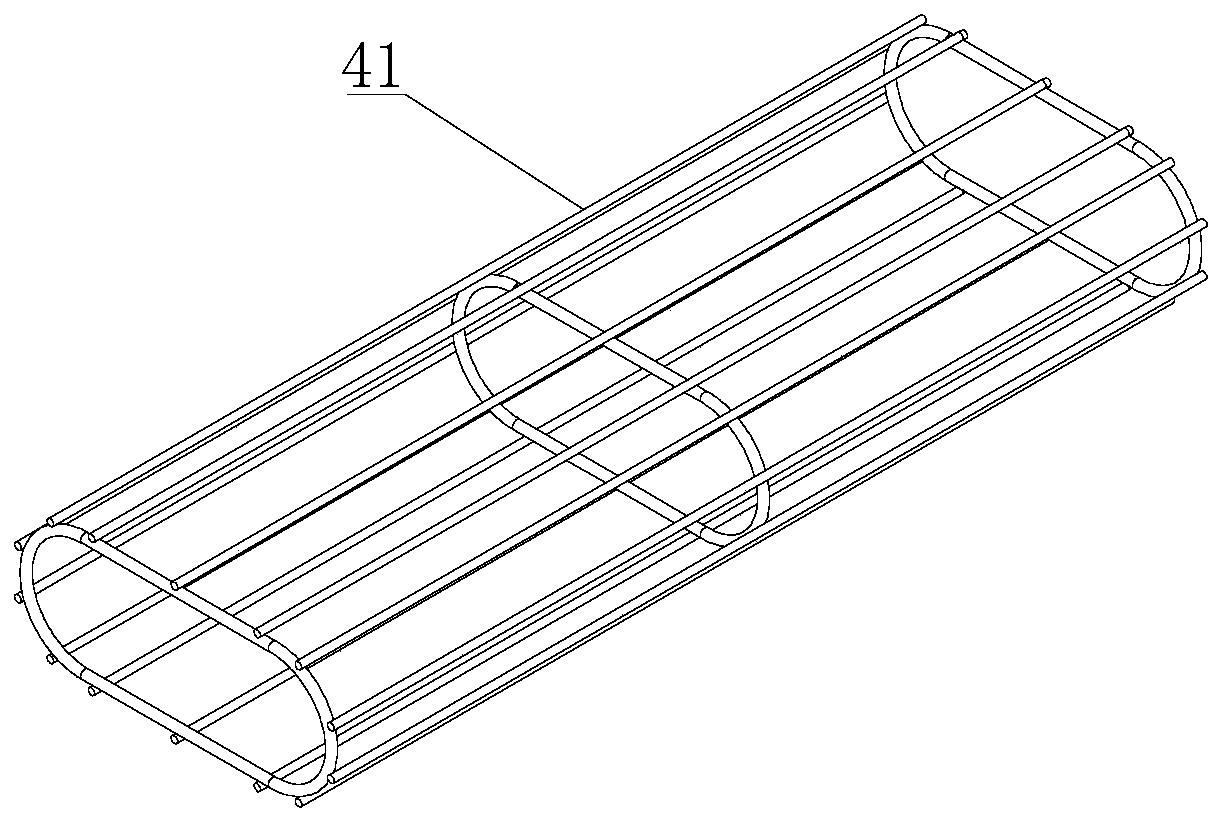

Bag cage deburring device

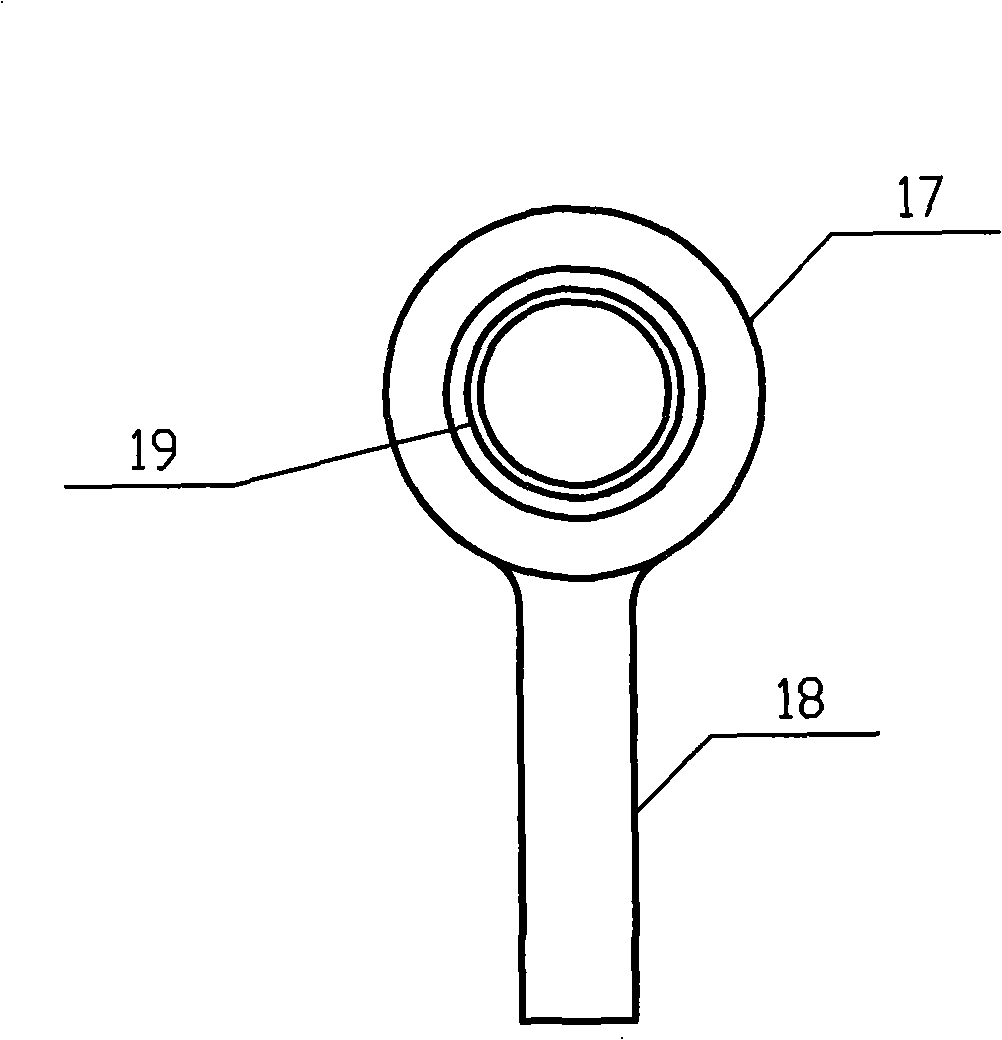

ActiveCN110270904AImprove fitPolished complete and thoroughEdge grinding machinesGrinding carriagesElastic componentReciprocating motion

The invention relates to the technical field of deburring, in particular to a bag cage deburring device used for polishing burrs at the surfaces of supporting ribs of a bag cage. The device comprises a supporting frame, a bag cage transmission mechanism and a polishing assembly; the bag cage transmission mechanism is installed on the supporting frame so as to control the bag cage to reciprocate in the direction of the supporting ribs; the polishing assembly is installed on the supporting frame and comprises a polishing strip and a polishing support, the first end of the polishing strip is connected to the polishing support through a knuckle bearing, the second end of the polishing strip is elastically connected to the grinding support, the polishing strip comprises a polishing edge for polishing the bag cage, and the polishing strip is configured to enable the initial state of the polishing edge of the bag cage to be inclined relative tot he supporting ribs of the bag cage. In the bag cage feeding process, the polishing strip is pushed by elasticity supplied by the elastic component for polishing, and by arranging the knuckle bearing, polishing is more complete and thorough.

Owner:JIMEI UNIV

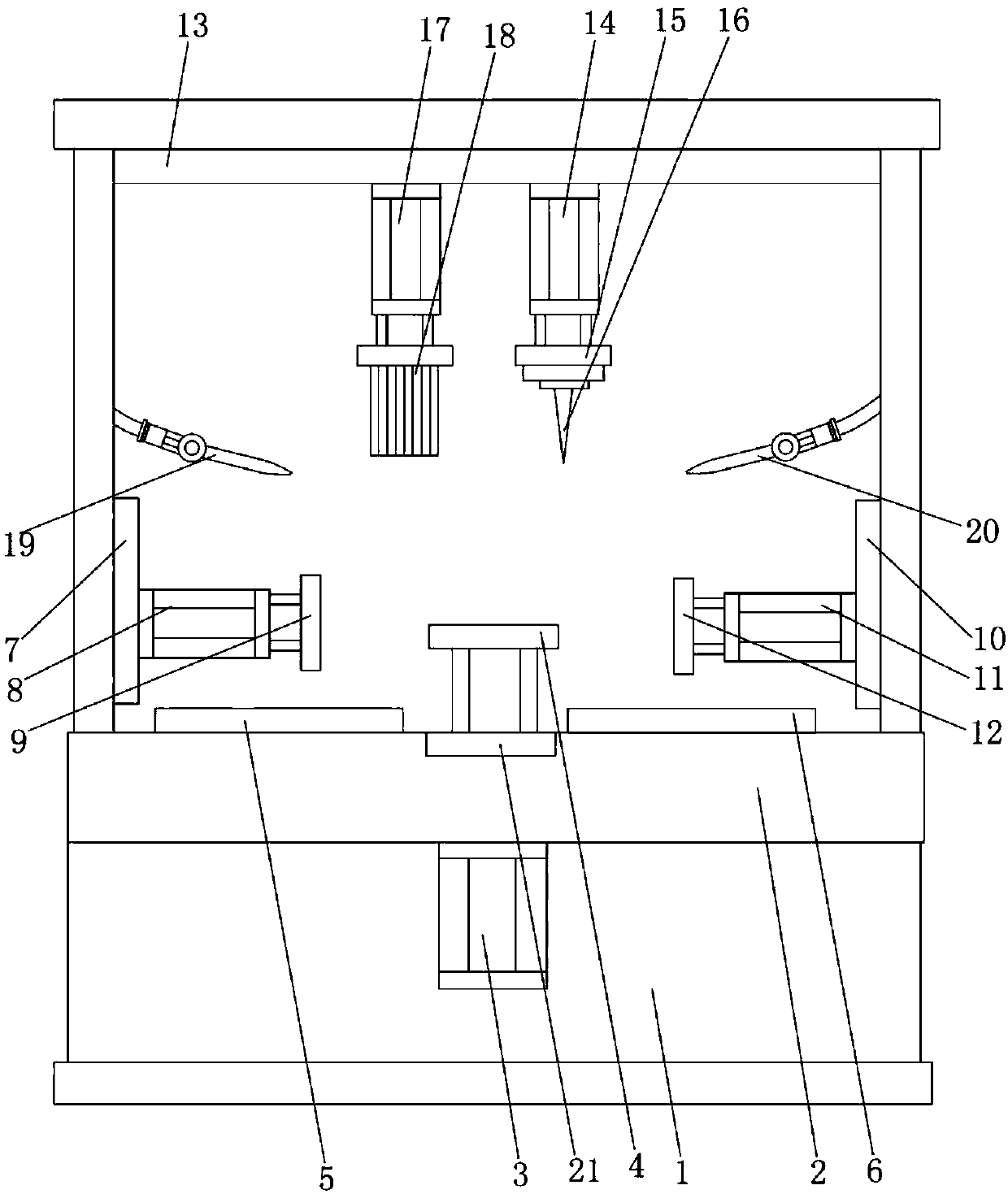

Automatic machining equipment for air compressor

InactiveCN109955066AEasy hole processingImprove processing efficiencyFiling/rasping devicesOther manufacturing equipments/toolsGas compressorPulp and paper industry

The invention belongs to the field of air compressor production equipment, and particularly relates to automatic machining equipment for an air compressor. The automatic machining equipment is characterized in that a base air cylinder is installed on the lower portion of a machine frame platform, the base air cylinder is connected with a base plate, a first magnet plate and a second magnet plate are installed on the machine frame platform, one end of a first push tightening air cylinder is installed on a first push tightening air cylinder sliding guide rail, the other end of the first push tightening air cylinder is connected with a first push tightening plate, one end of a second push tightening air cylinder is installed on a second pushing tightening cylinder sliding guide rail, the other end of the second push tightening air cylinder is connected with a second push tightening plate, one end of a file air cylinder is installed on a file air cylinder sliding guide rail, the other endof the file air cylinder is connected with a file rotating base, a file is installed on the file rotating base, one end of a brush air cylinder is installed on the file air cylinder sliding guide rail, the other end of the brush air cylinder is connected with a brush, and the brush is located above the base plate.

Owner:天津双合盛自行车有限公司

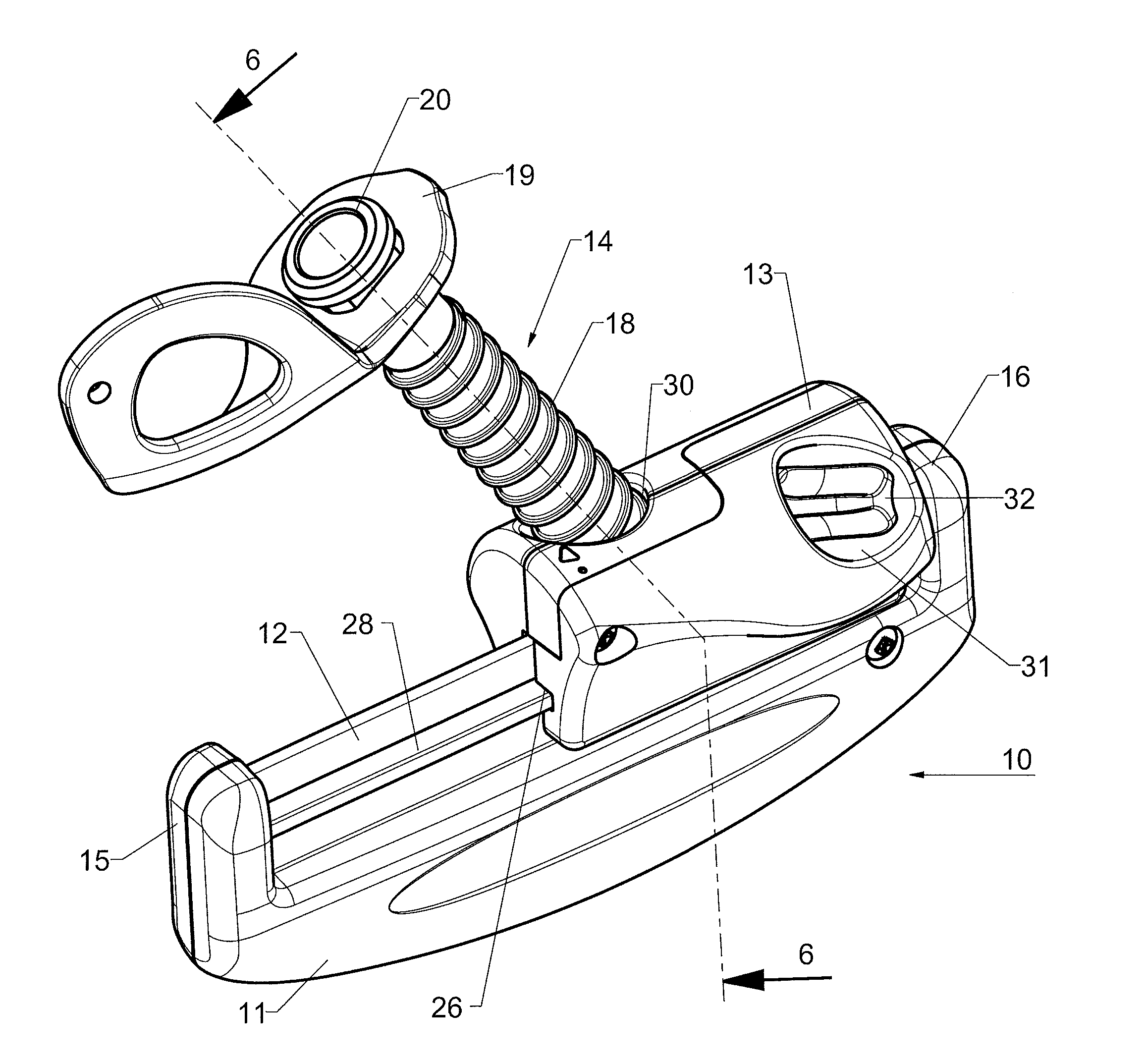

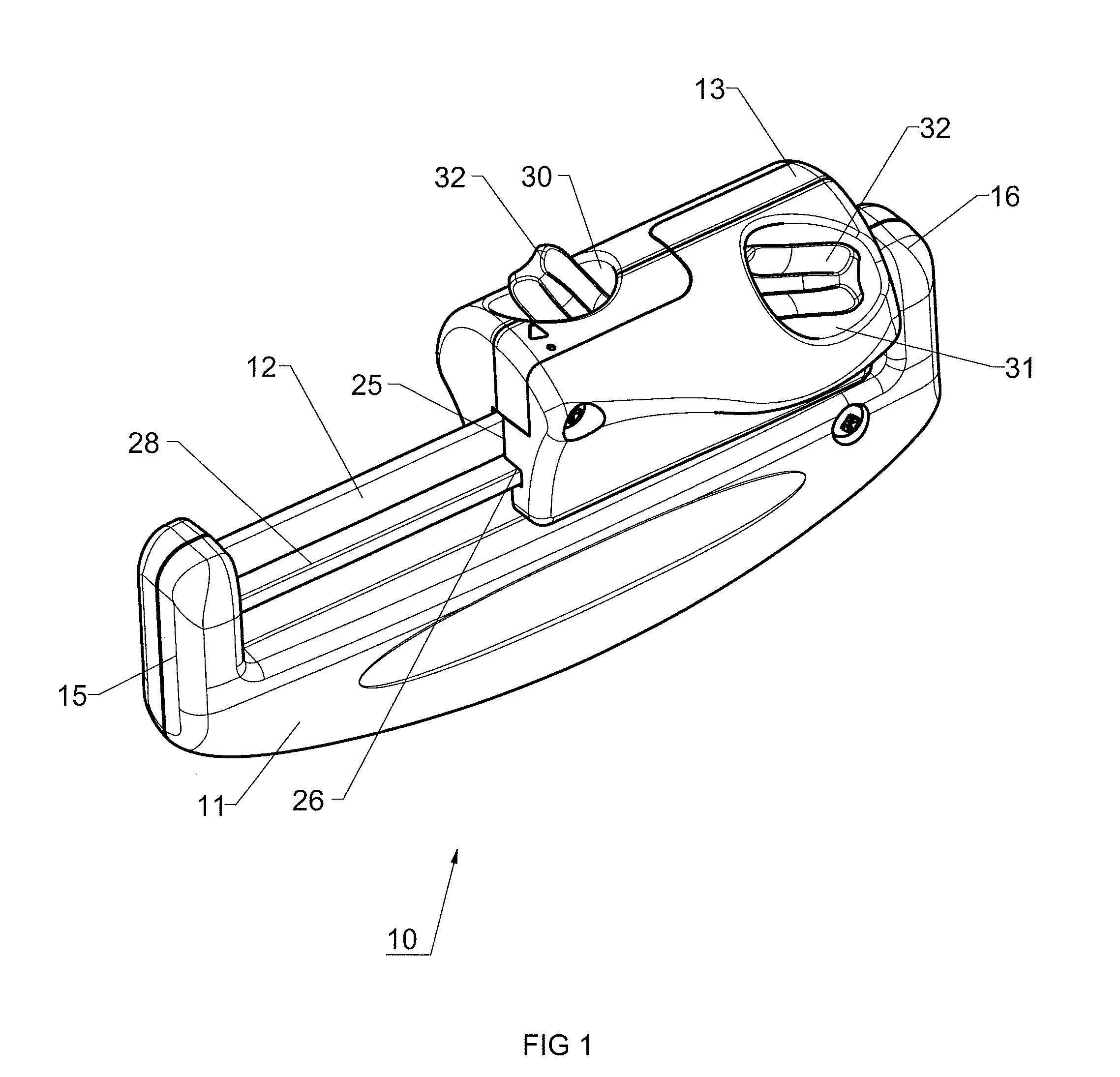

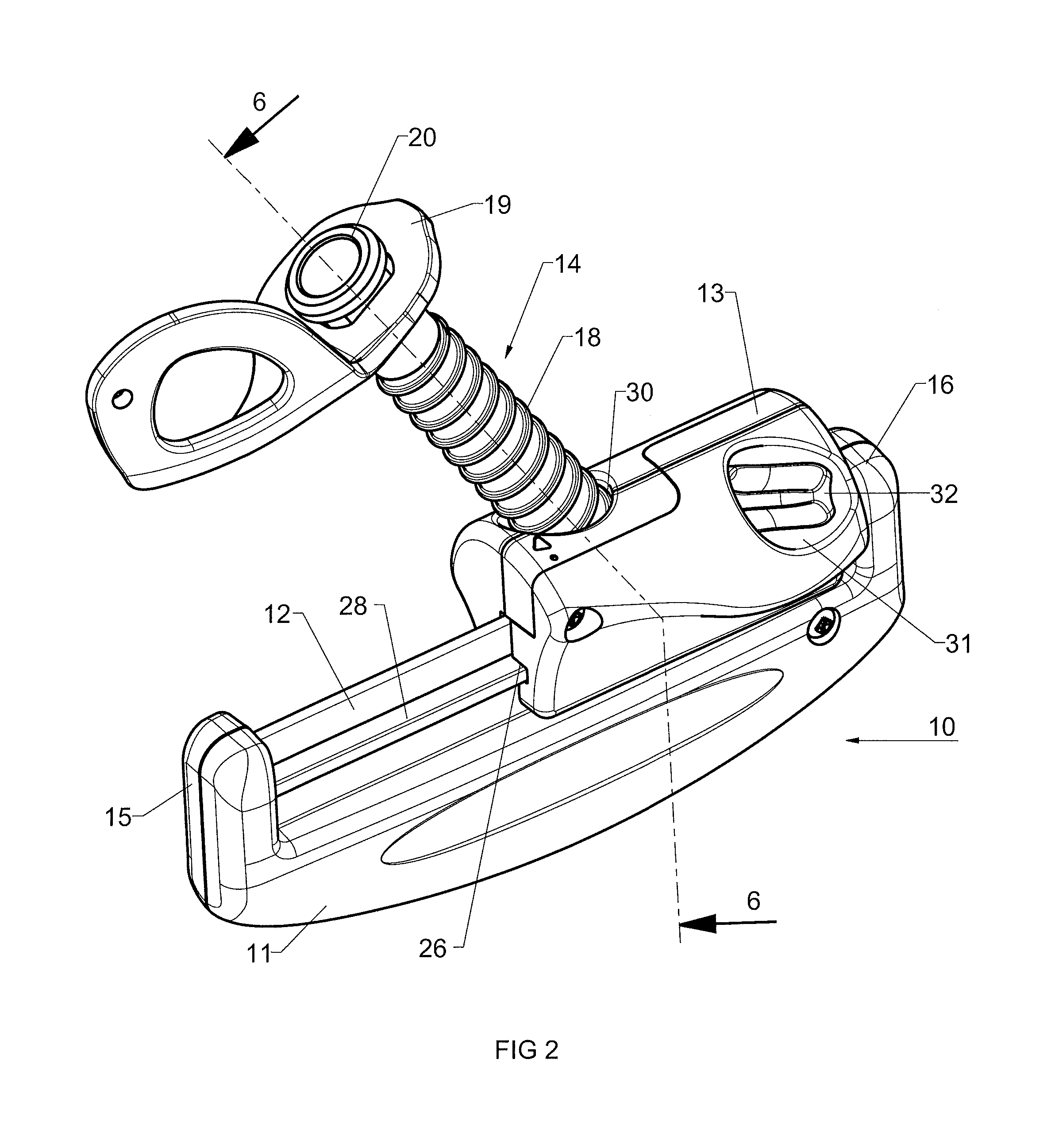

Ice screw sharpener

ActiveUS20140099169A1Easy to handleMaintain performanceFiling/rasping devicesMountaineeringEngineeringKnife blades

A sharpener for an ice screw with a tubular shank and a bit, comprising:a fixed sharpening support equipped with a file in the form of an elongate blade,a positioning slide of the ice screw at predefined angles with respect to the file, said slide being able to move in translation astride the two opposite surfaces of the file,and guiding and stopping means of the bit in the slide comprising at least one opening for inserting the shank and a securing stud salient from the associated opening.

Owner:ZEDEL CORP

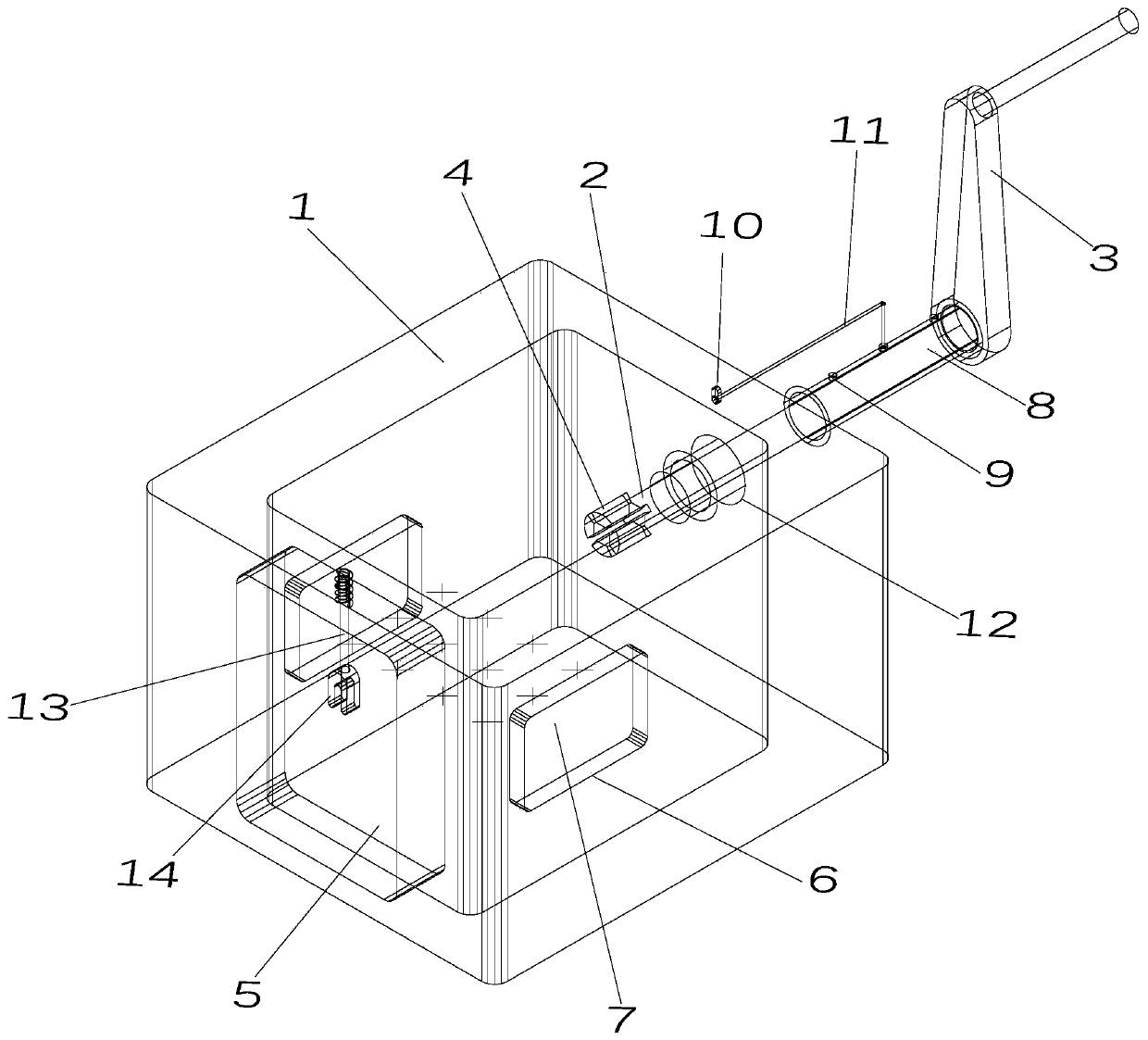

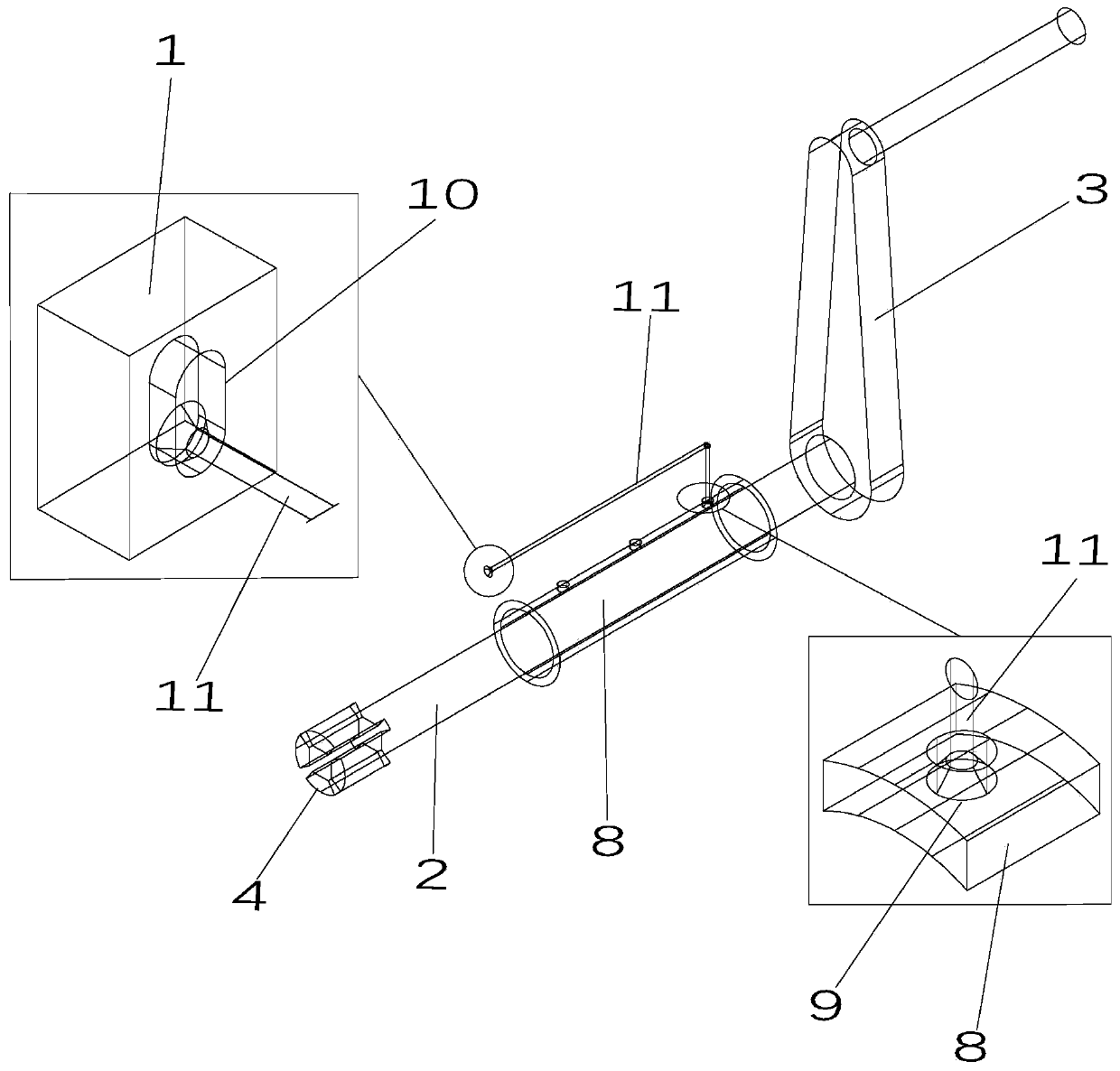

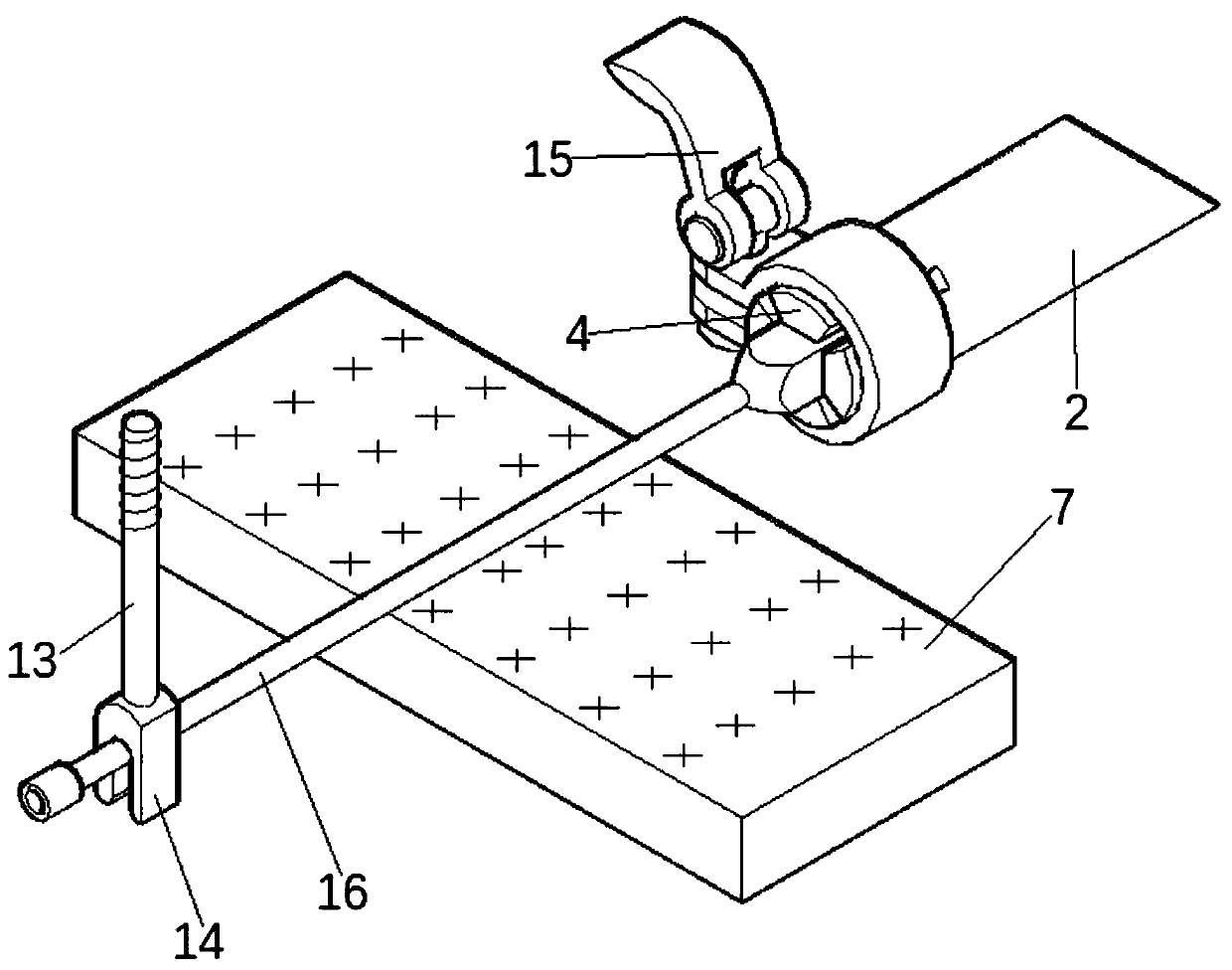

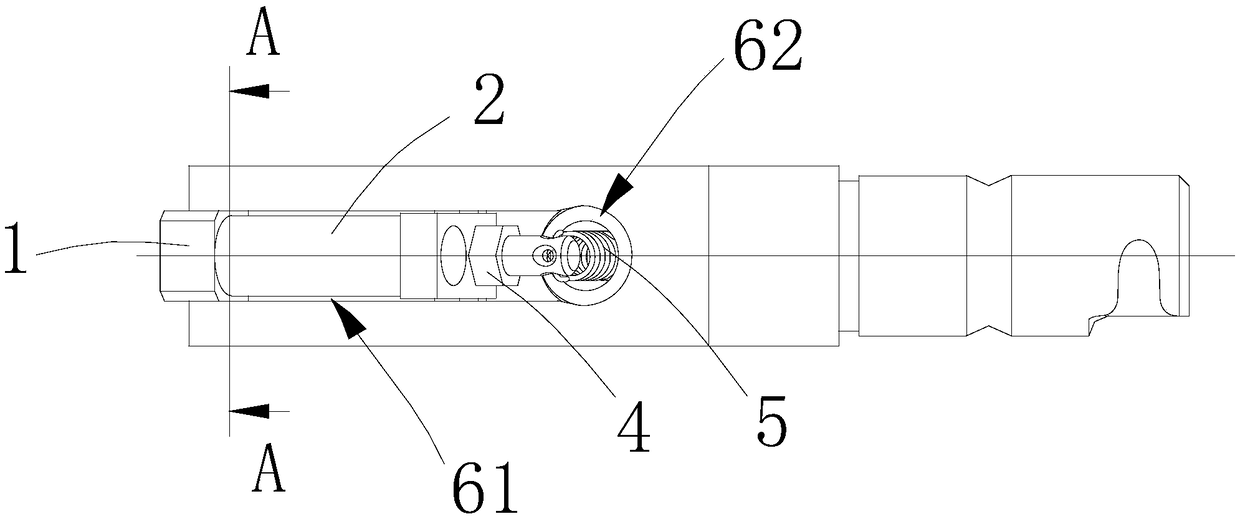

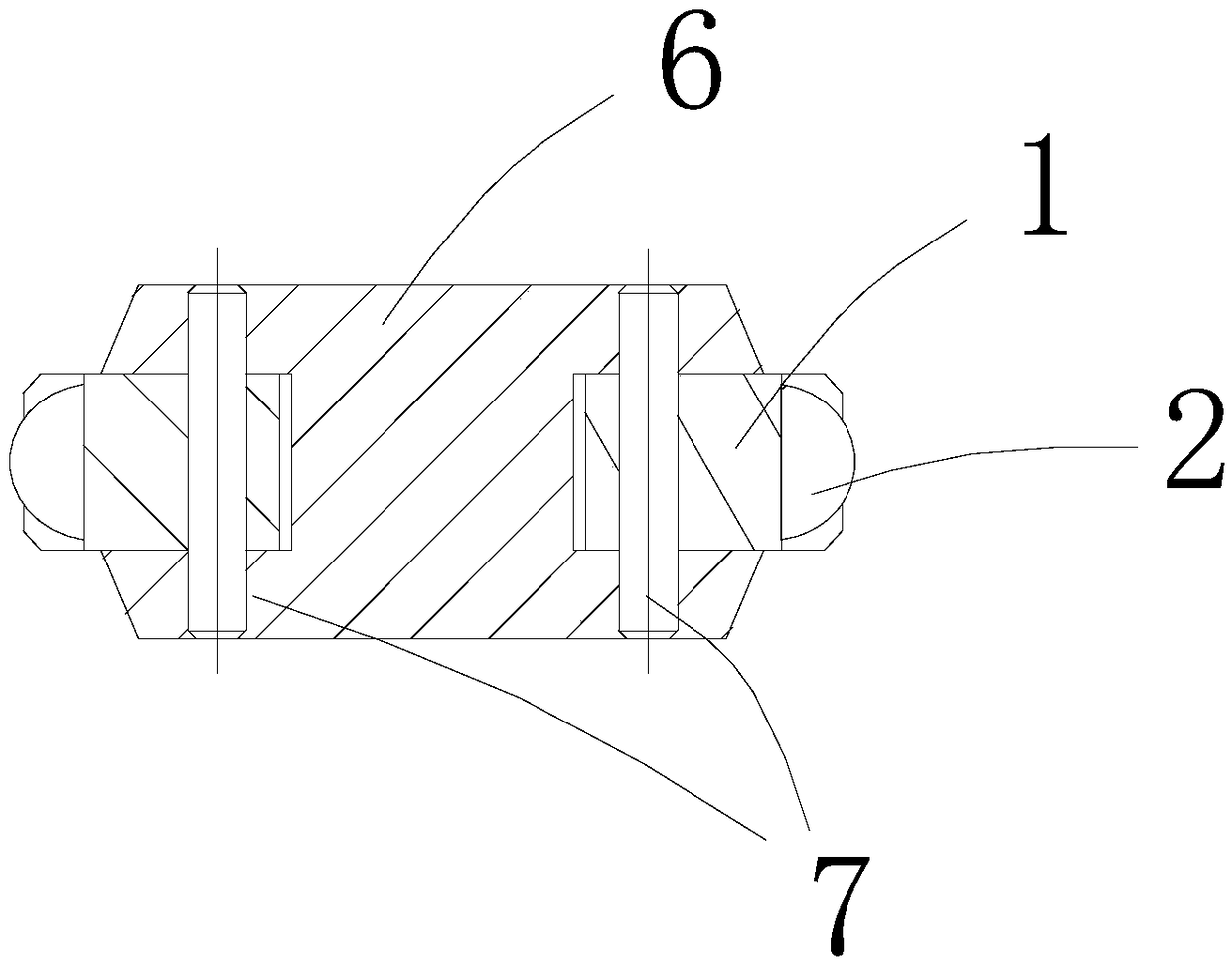

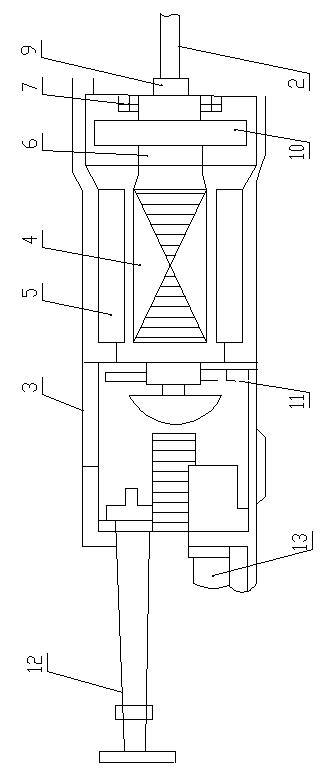

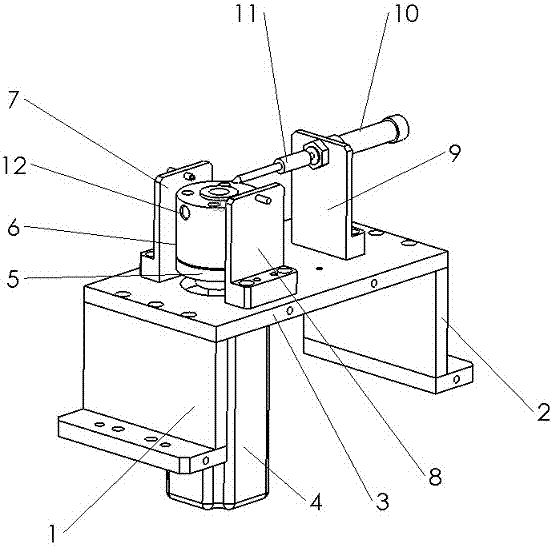

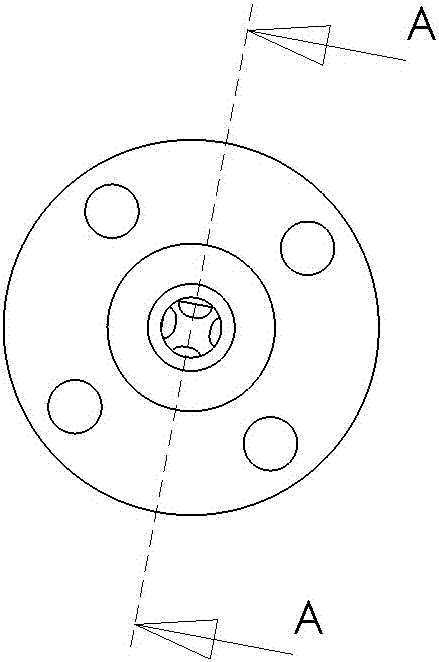

Device capable of rasping cylindrical surface of bar at low speed

ActiveCN111360328AImprove filing efficiencyLine rate is smallWork clamping meansFiling/rasping devicesBar stockOxygen Measurement

The invention discloses a device capable of rasping a cylindrical surface of a bar at a low speed. The device comprises a box body with an opening in the top end; a rotating shaft with one end protruding outwards is arranged horizontally in the box body; one end, positioned outside the box body, of the rotating shaft is connected with a handrail; a positioning mechanism is arranged on the rotatingshaft between the handrail and the outer wall of the box body; one end, positioned in the box body, of the rotating shaft is coaxially connected with a four-jaw ferrule; an accommodating opening is formed in the side wall of the box body directly facing the four-jaw ferrule; a restraining structure is arranged in the accommodating opening; a pair of placement openings are correspondingly formed in the side walls of the box body on two sides of the rotating shaft; and a pair of raspers is jointly erected in the pair of placement openings. The device capable of rasping the cylindrical surface of the bar at the low speed greatly reduces the labor intensity, the damage index and the grinding uniformity of manual rasping, also improves the bar rasping efficiency and avoids the oxygen measurement result distortion.

Owner:中航金属材料理化检测科技有限公司

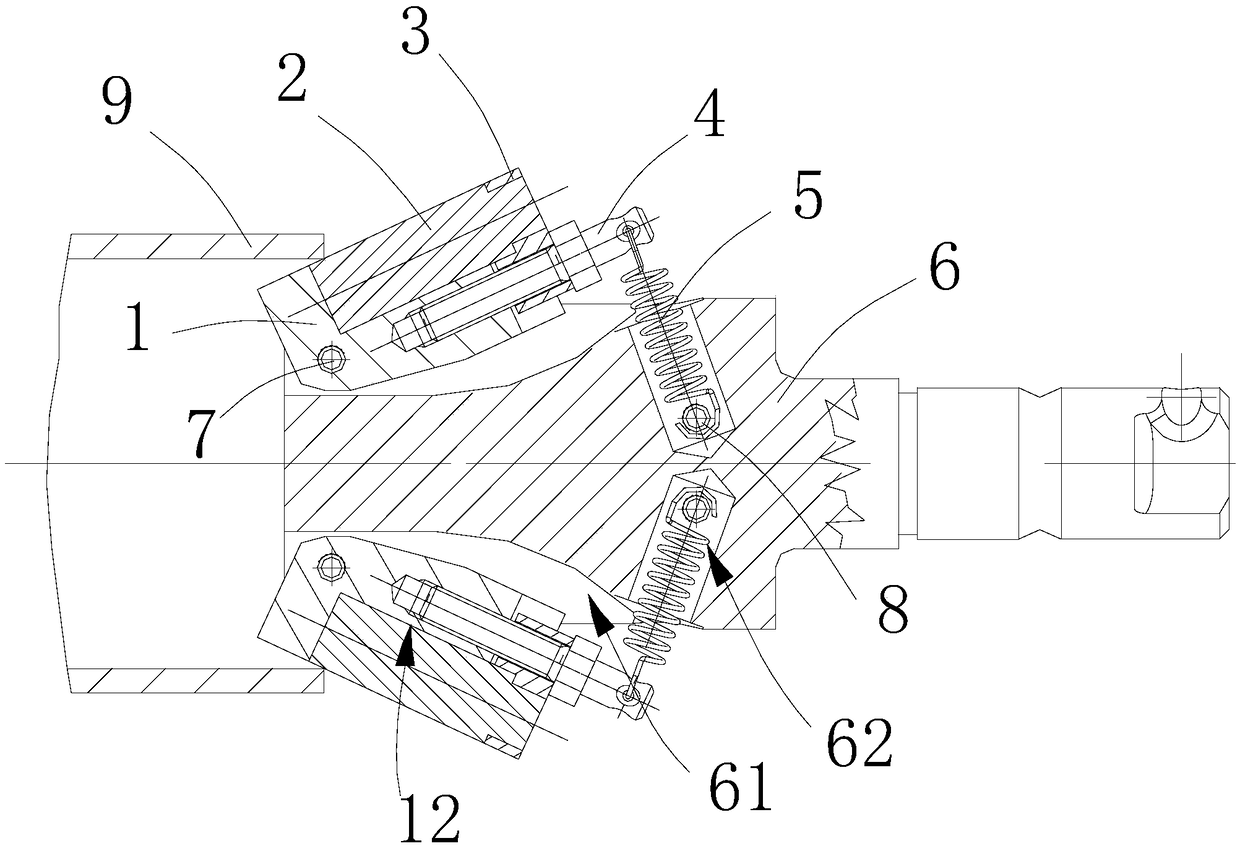

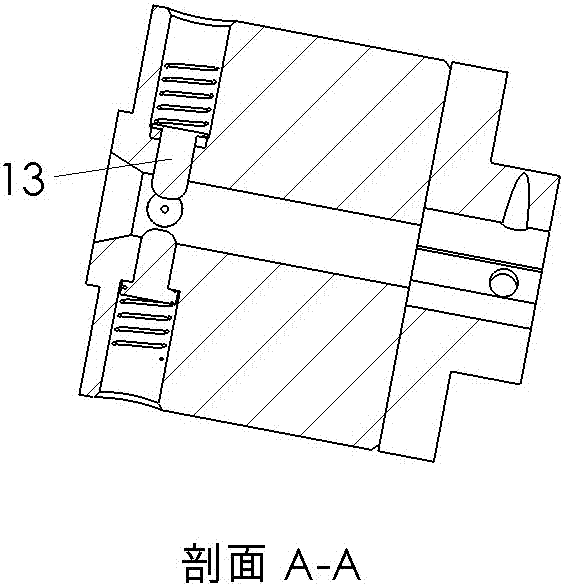

Tubular part orifice deburring device

ActiveCN109262066APrevent crushingEfficient and effective removalFiling/rasping devicesWorking pressureEngineering

The invention discloses a tubular part orifice deburring device. The tubular part orifice deburring device comprises a file module, a spring and a mounting member capable of rotating around the axis of a tubular part; the end surface of the mounting member, which faces towards the orifice of the tubular part, is provided with a tool groove extending the axial direction of the tubular part; one endof the file module, which faces toward the orifice of the tubular part, extends into the tool groove and is hinged to the mounting member at a hinge point, one end of the file module, which backs tothe orifice of the tubular part, extends out of the tool groove and is fixedly connected to one end of the spring, and the other end of the spring is fixedly connected with the mounting member; the file module can swing around the hinge point, and inside the tool groove a yielding space for the file module to swing around the hinge point is formed. When the tubular part orifice deburring device isin work, the spring drives the file module to produce working pressure onto the orifice of the tubular part; due to the fact of being capable of flexibly rotating around the hinge point inside the tool groove and with the spring providing the rotating force, the file module can ensure high-efficiency and effective removal of burrs of the orifice of the tubular parts and meanwhile avoid hard scratching of the tubular part.

Owner:LANDING GEAR ADVANCED MFG

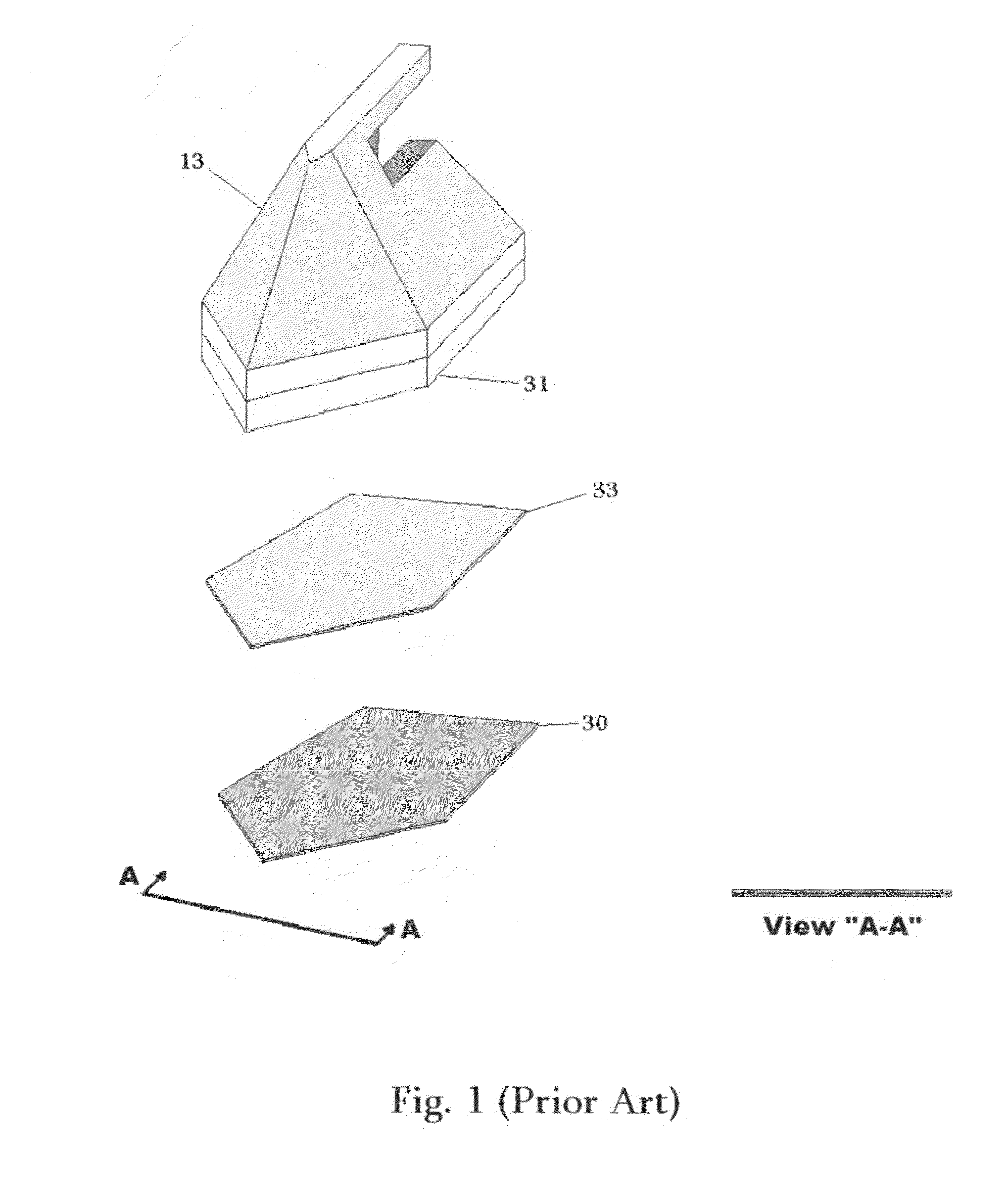

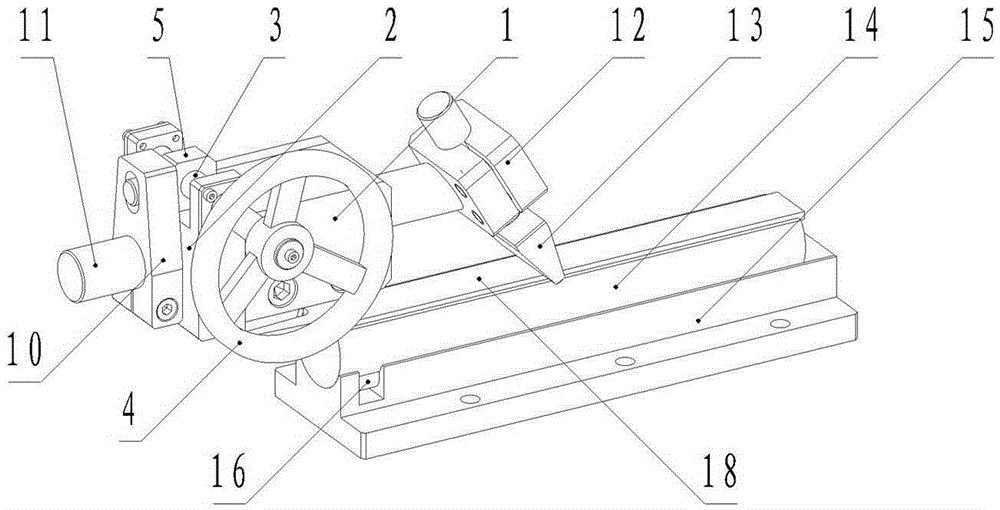

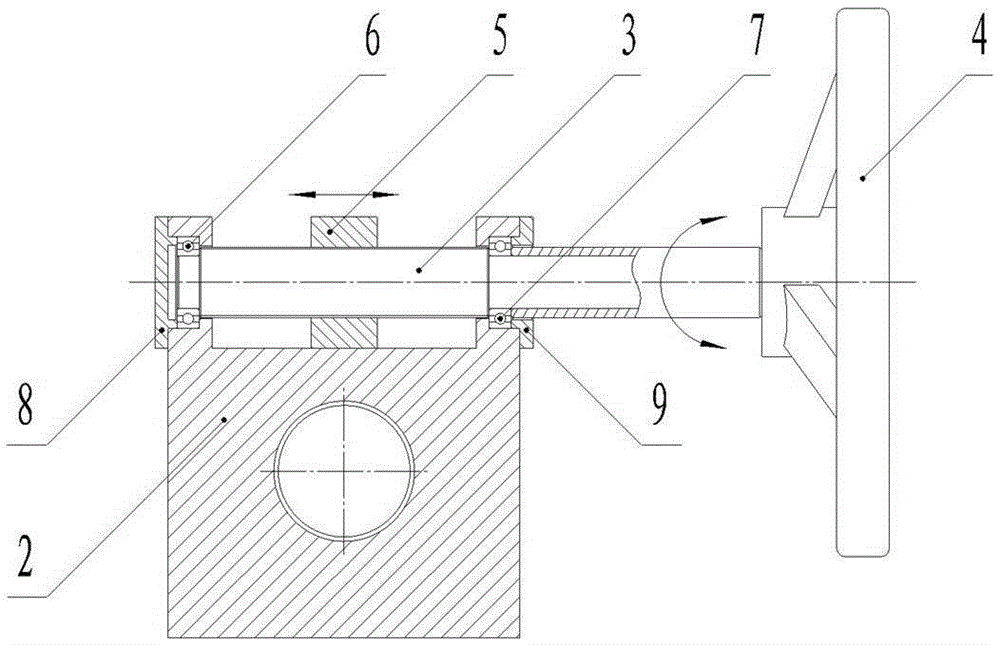

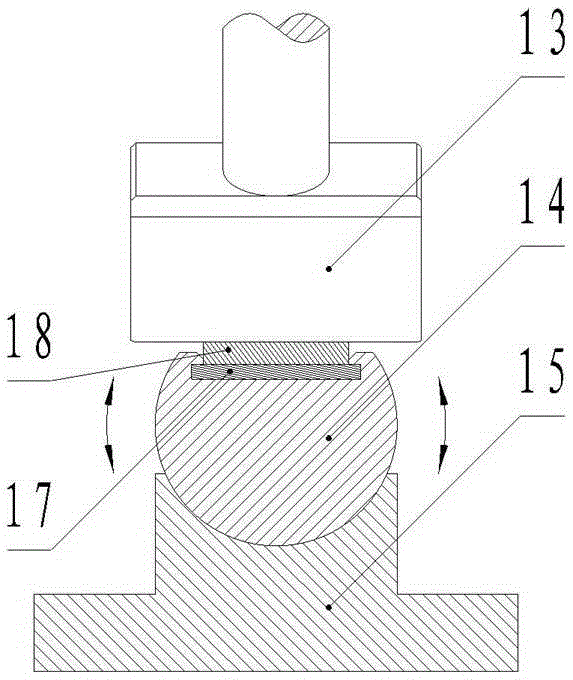

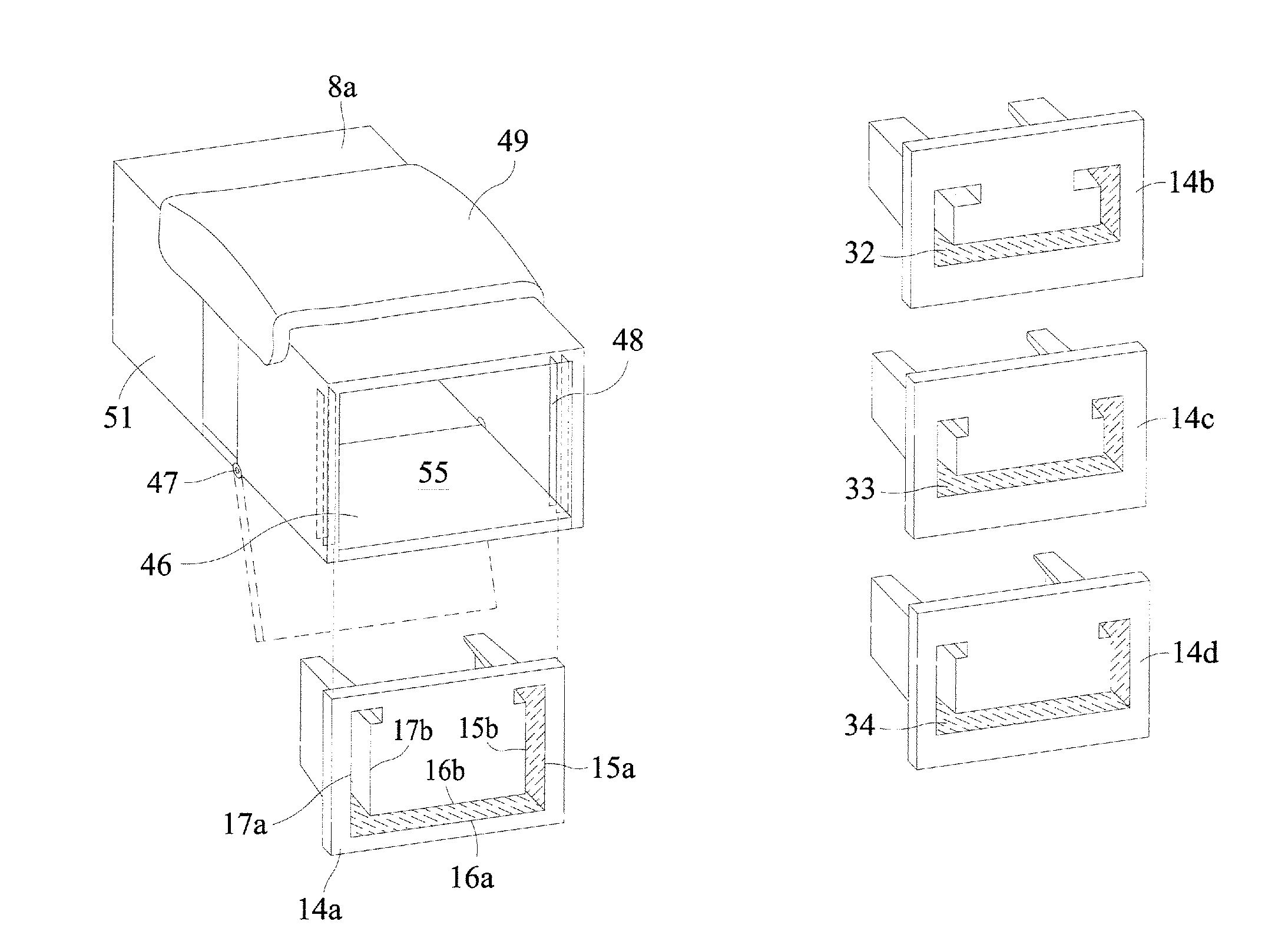

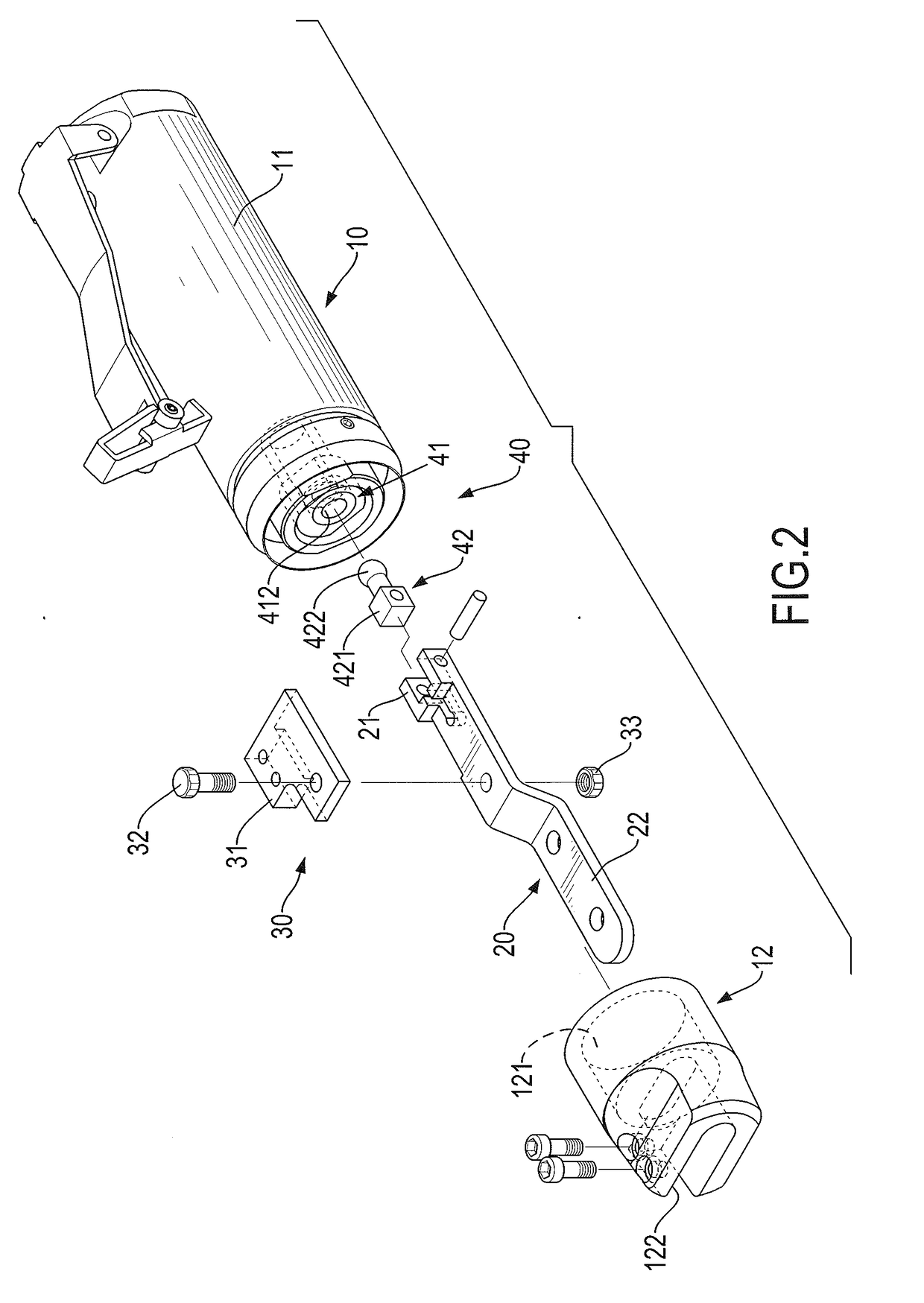

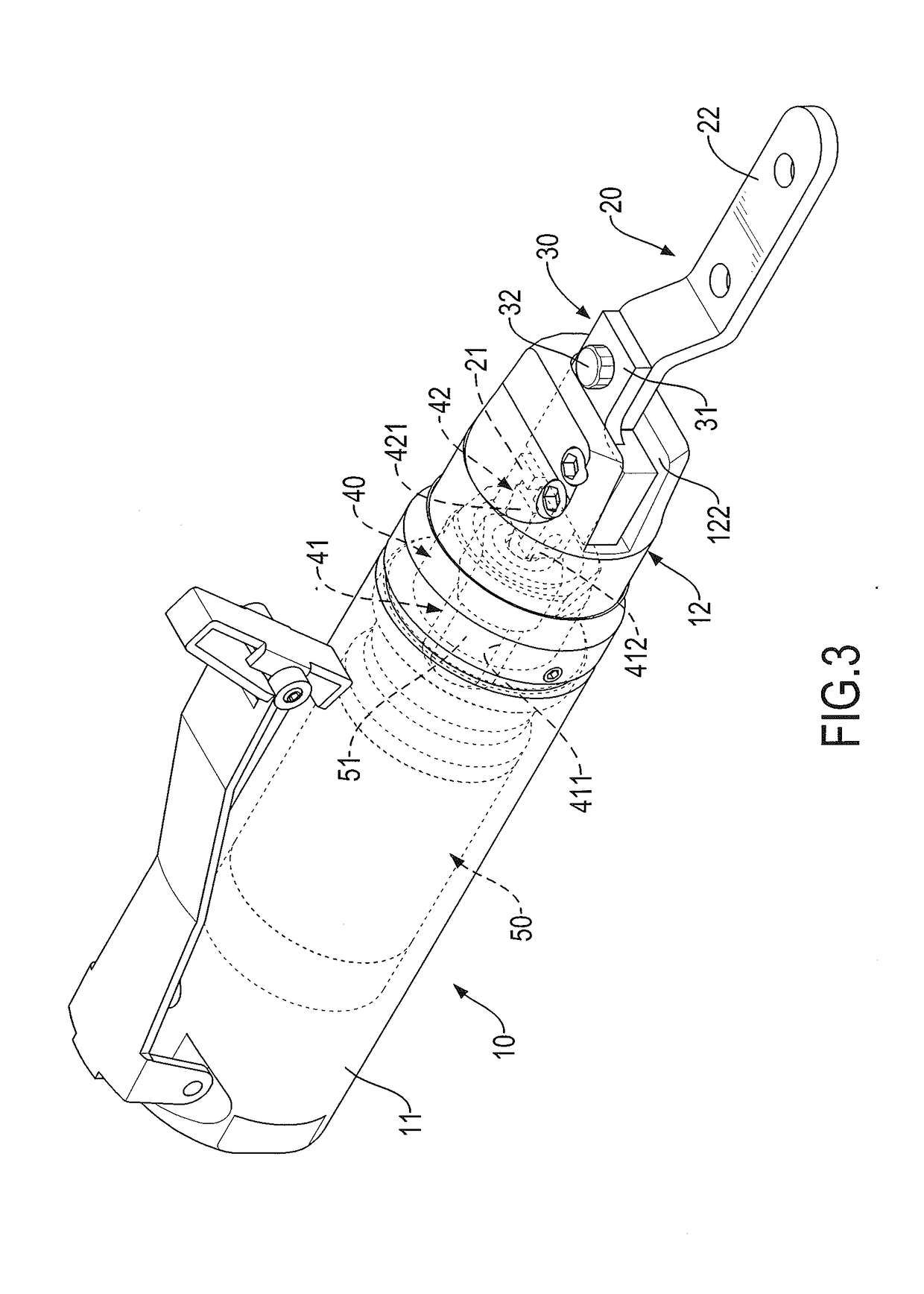

Roll angle self-adaptive adjusting clamp

ActiveCN105290819AEasy to adjustImprove processing efficiencyFiling/rasping devicesPositioning apparatusInverted-T shapeEngineering

The invention provides a roll angle self-adaptive adjusting clamp. A roll clamping block is fixedly connected with a machine tool body; an adjusting screw seat is fixed to the roll clamping block; an adjusting screw is installed in the middle of the adjusting screw seat; a hand wheel is connected with one end of the adjusting screw; an adjusting nut and the adjusting screw are connected in a thread matched mode; one end of a roll swing arm is connected with a roll shaft; the other end of the roll swing arm is connected with a small shaft of the adjusting nut; the roll shaft horizontally penetrates through a clamping hole of the roll clamping block; one end of the roll shaft is connected with the roll swing arm; the other end of the roll shaft is connected with a presser foot clamping block; the lower portion of an inverted T-shaped presser foot tightly presses the upper plane of a file; the length direction of the long side of the lower portion of the inverted T-shaped presser foot is parallel to the axis of the adjusting screw; the file is arranged on a clamp platform, and a base plate is cushioned between the file and the clamp platform; a clamp base is fixedly connected to a machine tool workbench; the clamp platform is arranged above the clamp base.

Owner:中国兵器装备集团自动化研究所有限公司

Multi-surface object end manual filing tool

ActiveUS20150283632A1Safe and quick mannerLess timeEdge grinding machinesFiling/rasping devicesEngineering

Owner:URSULIAK TARAS

Equipment for removing burrs on surfaces of mechanical parts

InactiveCN108620675AAffect removal effectImprove removal efficiencyFiling/rasping devicesMaintainance and safety accessoriesMarine engineeringPiston

The invention relates to equipment for removing burrs, in particular to equipment for removing burrs on the surfaces of mechanical parts. The equipment for removing the burrs on the surfaces of the mechanical parts is high in burr removal efficiency and thorough in removal effect. According to the technical scheme, the equipment for removing the burrs on the surfaces of the mechanical parts comprises a transverse plate, supporting legs, a bracket, a vertical plate, a sliding rail, first sliding blocks, a file, a motor, a rotating shaft, a bearing seat, a rotating rod, a swinging rod, a mounting plate, a cylinder body, a piston and the like. The supporting legs are correspondingly connected to the left and right sides of the bottom of the transverse plate. The bracket and the vertical plateare connected to the left side of the top of the transverse plate. The bracket is positioned on the left side of the vertical plate, and the sliding rail is installed on the right side of the vertical plate. According to the equipment for removing the burrs on the surfaces of the mechanical parts, the burrs on the surfaces of the mechanical parts are removed by the file moving up and down, and the piston moving up and down drives air to be blown out from the end of an air pipe, so that debris generated during burr removal is blown off, the debris is prevented from affecting burr removal efficiency, and the more thorough removal effect is achieved.

Owner:胡志能

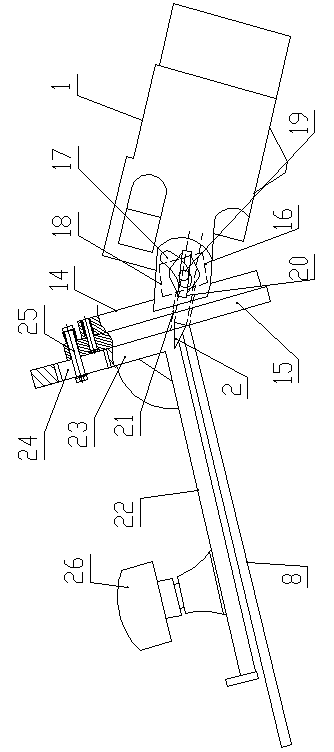

Mechanism special for removing burrs in transverse through hole of cylinder part

The invention discloses a mechanism special for removing burrs in a transverse through hole of a cylinder part. The mechanism comprises a workbench, a support pillar, a driving motor, a manual turntable, a hard alloy rotating file and a sliding support plate, wherein a workpiece sleeving cylinder, a horizontal cylinder and a workpiece rotation prevention ejector rod are fixedly arranged above the sliding support plate; a manual swinging rod is hinged to the front sidewall of the sliding support plate; a connecting rod which extends leftwards and rightwards is arranged on each of the left and right sides of the sliding support plate; a resetting spring is arranged on each connecting rod in a sleeving manner; a support block is arranged on the outer side of each connecting rod, and is used for supporting the connecting rod; left and right bearings for guiding the leftward and rightward movement of the sliding support plate are arranged at an interval on each of the front and rear sides of the sliding support plate; a limiting plate for limiting the leftward and rightward movement of the sliding support plate is arranged on each of the left and right sides of the neck of the sliding support plate. The mechanism is novel in concept, ingenious in design, convenient to operate and high in automation degree, and has high popularization value, and the production efficiency and the consistency of a product are remarkably improved.

Owner:重庆东威隆诗特科技有限公司

Beveling machine

Owner:JIAOZUO ZHUOLI STAMPING MATERIAL CO., LTD.

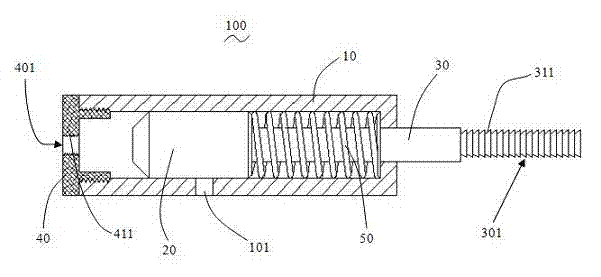

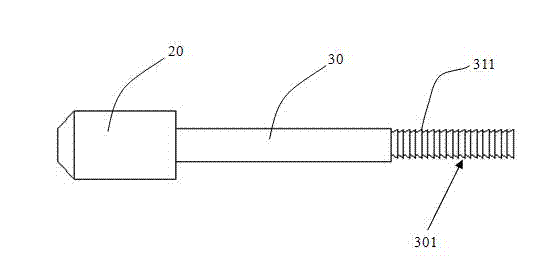

Pneumatic slag removing device

InactiveCN102728892AImprove adaptabilityReduce labor intensityFiling/rasping devicesSlagReciprocating motion

The invention provides a pneumatic slag removing device, which comprises a cylinder, a piston and a piston rod, wherein the piston rod is fixedly connected with the piston and extends out of the cylinder, a rear end cover and a spring; the cylinder is fixedly connected with the rear end cover; the side wall of the cylinder is provided with an exhaust hole; an air inlet is formed in the center of the rear end cover; the spring is arranged around the piston rod and positioned in the cylinder; two ends of the spring are respectively clamped by the piston and the cylinder; and a file head is arranged at one end of the piston rod, which is far away from the piston. According to the pneumatic slag removing device, the piston rod is driven to longitudinally reciprocate through longitudinal reciprocating motion of the piston in the cylinder, and iron slag at slits is removed through the cylindrical file head at the end of the piston rod, so that the slag removing efficiency is remarkably improved, the labor intensity of workers is reduced, and adaptability of the pneumatic slag removing device is also improved.

Owner:WUXI CITY UNITE PETRO CHEM EQUIP

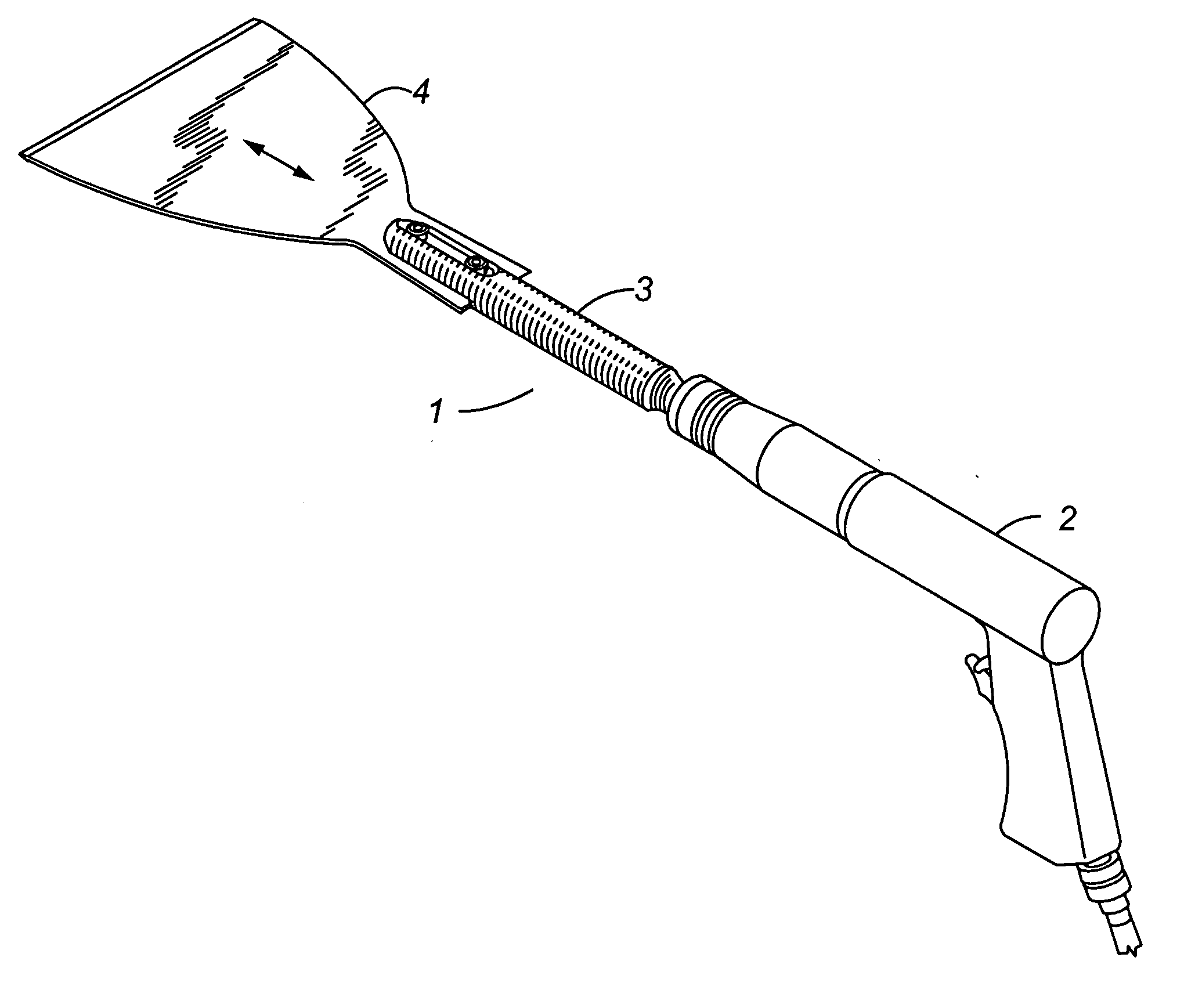

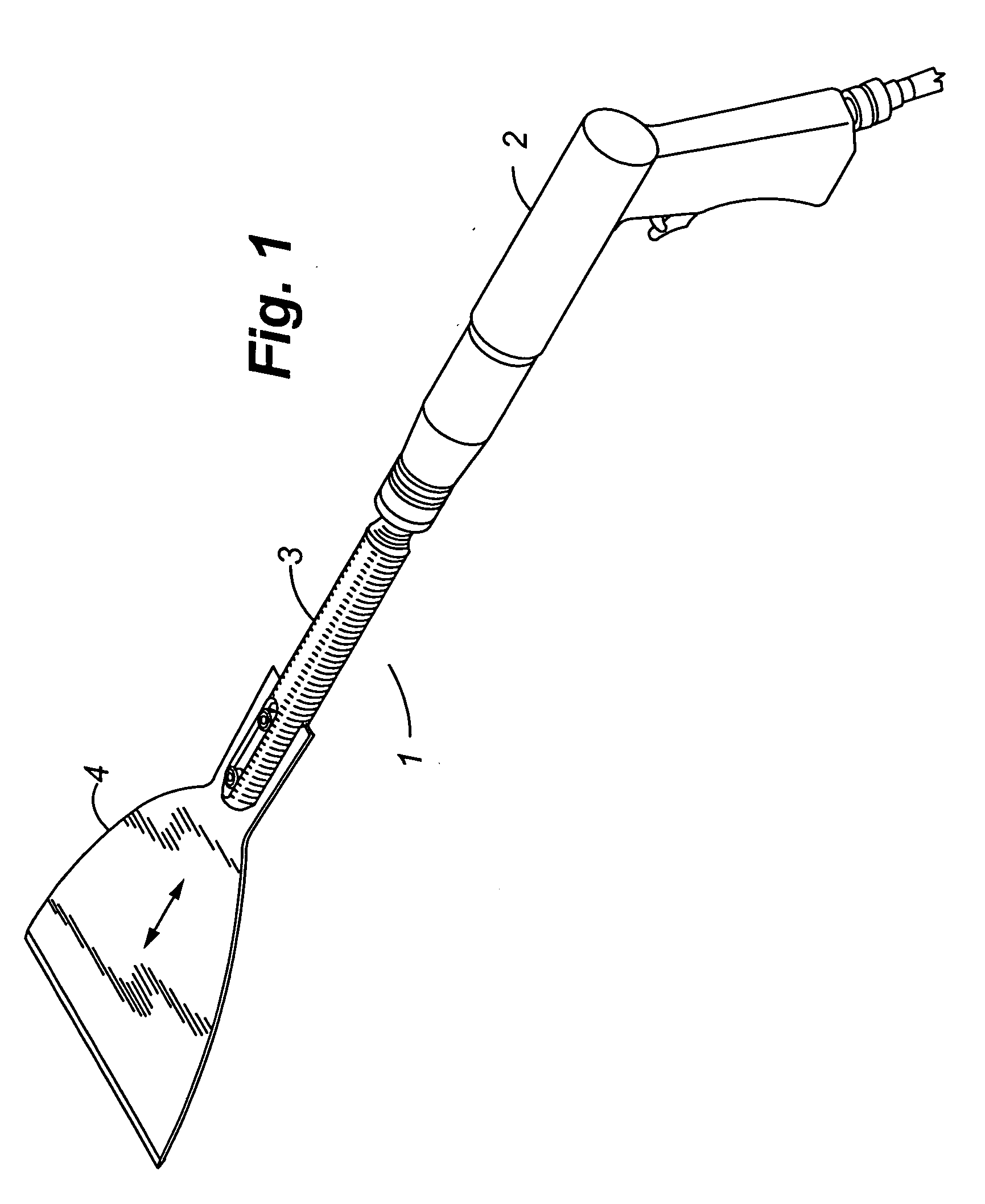

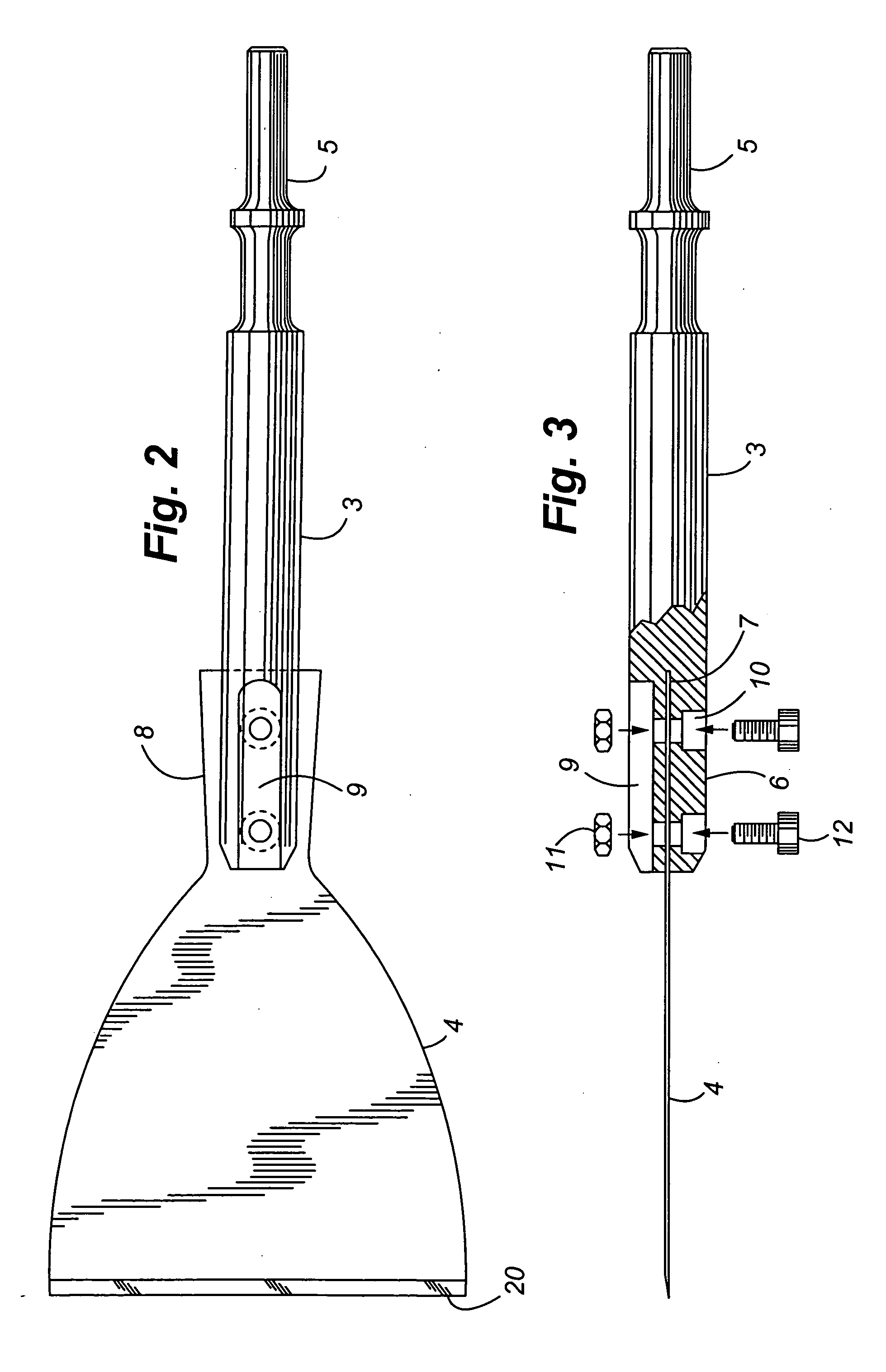

Cutting assembly for removing a windshield and method relating to same

InactiveUS20050126359A1Clean incisionEngine sealsHollow article cleaningReciprocating motionEngineering

The cutting assembly functions to sever the urethane bed bonding a windshield to a vehicle. The assembly comprises a reciprocating air gun connected with a cutting blade by a shaft. The blade has a straight front cutting edge about 4 inches in width. The blade is reciprocated in and out of the bed to sever it.

Owner:CRYSTAL GLASS CANADA

Iron-chip removing machine

The invention provides an iron-chip removing machine. The iron-chip removing machine comprises a machine frame. A punching machine is mounted on the upper portion of the machine frame. A machine core is arranged on the upper portion of the punching machine, and a punch is arranged on the lower portion of the punching machine. A clamp is mounted below the punching machine. A fixing hole used for containing a workpiece is formed in the head of the clamp. A metal block protruding towards a side face is mounted on the punch. The metal block is located over the clamp. After the punch is pressed downwards, the side face of the metal block is tightly attached to the side face of the workpiece. The iron-chip removing machine is used for removing iron chips on the specific portion of the workpiece in a mechanical punching mode, and is simple in structure, high in efficiency and suitable for polishing the metal workpiece.

Owner:苏州金牛精密机械有限公司

Device and method for machining three-dimensional impeller blade welding groove through robot

ActiveCN112757307ASolving Adaptive Machining ProblemsLow costProgramme-controlled manipulatorFiling/rasping devicesNumerical controlImpeller

The invention discloses a device and method for machining a three-dimensional impeller blade welding groove through a robot, and belongs to the technical field of robot automatic machining. The device comprises the industrial robot, a force control measurement module, a machining tool quick-change module, a machining tool and a workbench. The machining method comprises the steps of impeller blade characteristic curve extraction, sorting and discretization, central axis generation and extraction, cover plate line generation and discretization, machining allowance calculation, impeller blade welding groove frame setting and adjustment, cutting tool coordinate system calibration, workpiece coordinate system calibration, machining track automatic production, in-situ measurement based on force control mode, and feed allowance determining based on online control of machining removal amount. The automatic machining and removal of the impeller welding groove by the robot can be realized, compared with a five-axis numerical control machining machine tool, the device and method provided by the invention are low in cost, good in adaptability and very high in flexibility, and then the self-adaptive machining problem of the impeller welding groove is well solved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

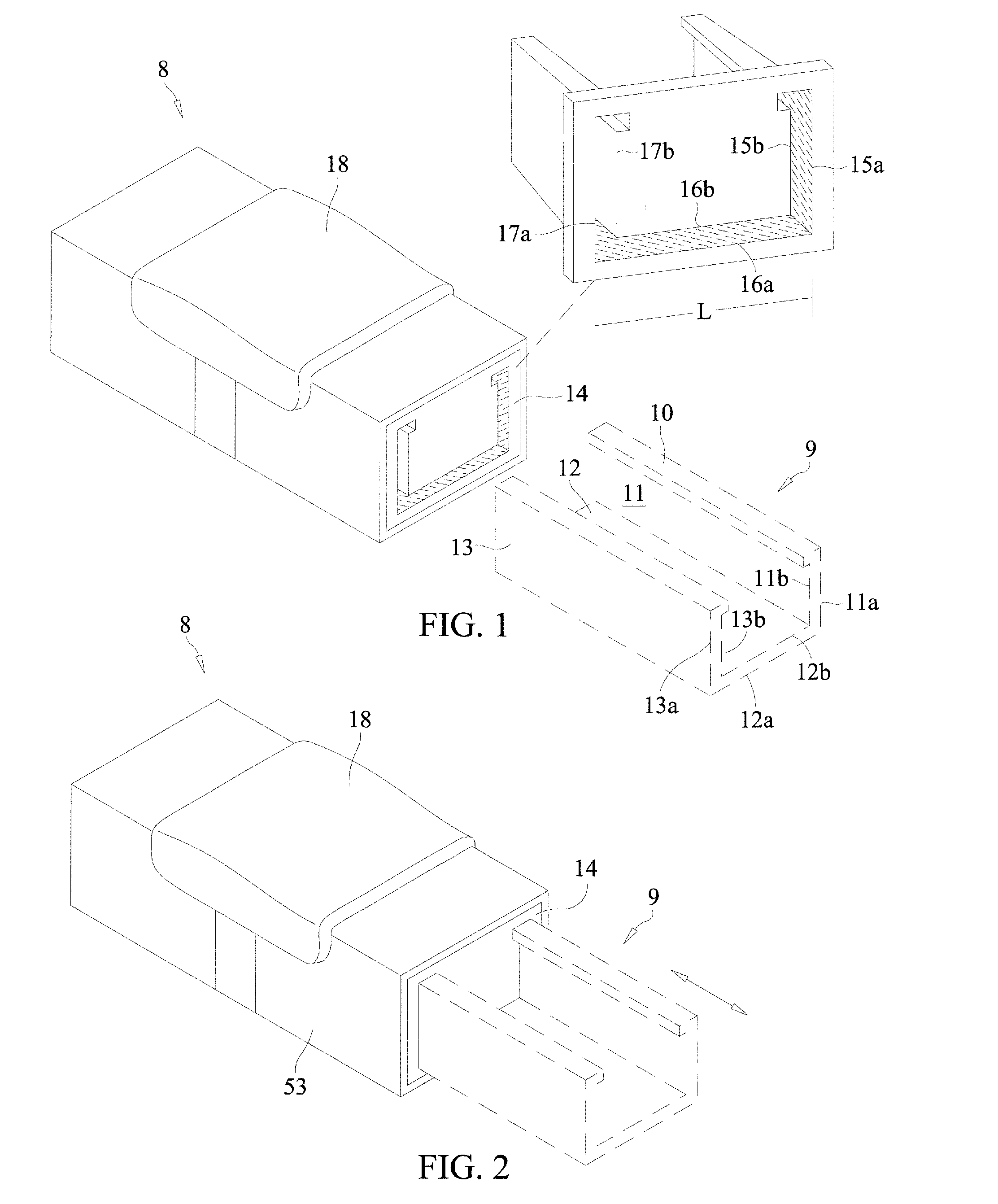

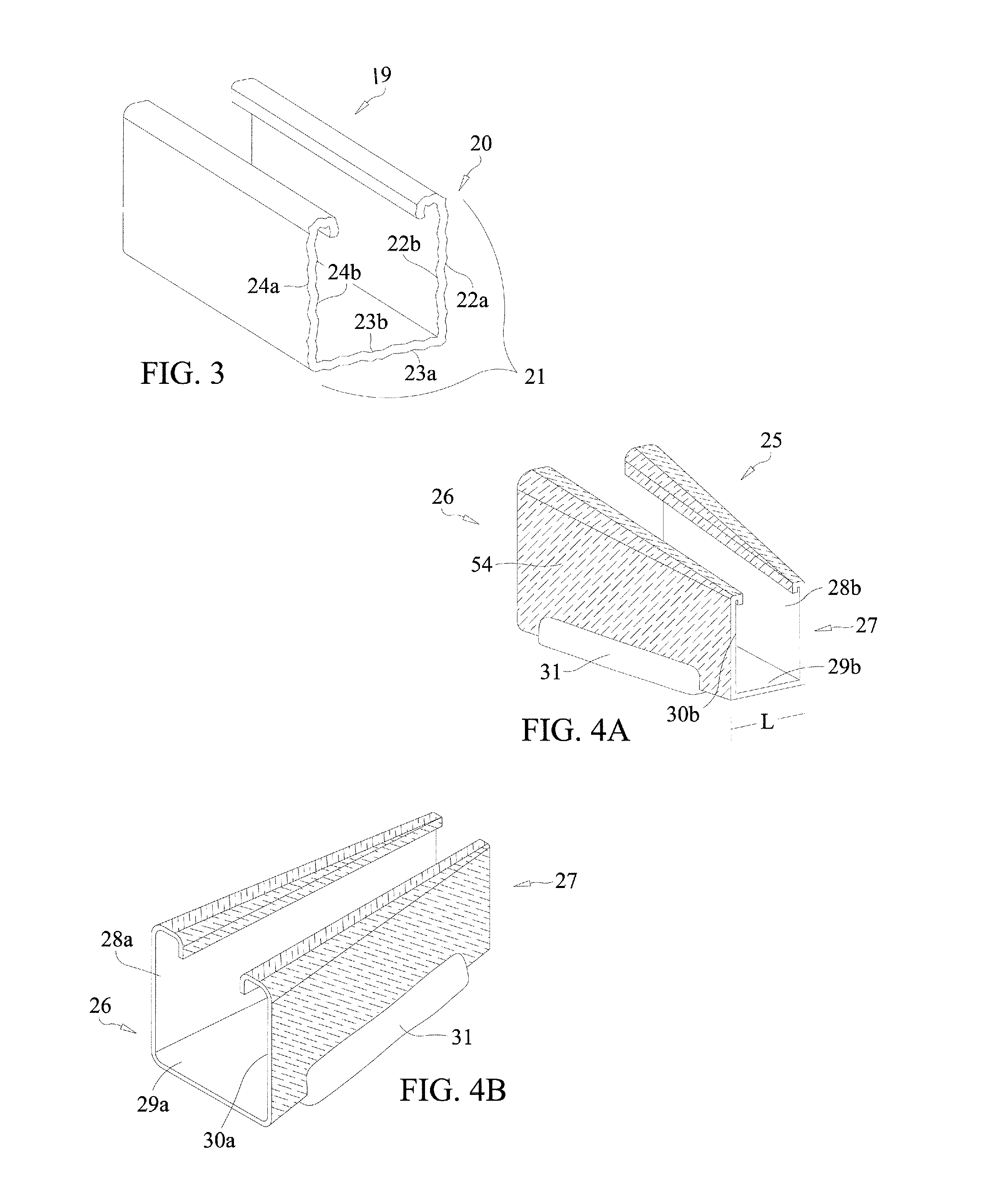

Air File

InactiveUS20190039200A1Simple structureReduce energy consumptionMetal sawing devicesGrinding drivesEngineeringBall joint

An air file has a body, a fastening member, and a driving assembly. The body has a handle and a front cover connected to the handle. The fastening member is swingably assembled to the front cover and has a pivoting end and a connecting end. The pivoting end of the fastening member is inserted inside the front cover. The connecting end of the fastening member extends out of the front cover. The driving assembly is mounted inside the body and has an eccentric shaft and a swinging unit. The eccentric shaft is connected to a driving device and has an eccentric hole facing to the front cover. The swinging unit has a pivoting portion and a ball joint. The pivoting portion is pivotally connected to the pivoting end of the fastening member. The ball joint is engaged in the eccentric hole of the eccentric shaft.

Owner:LIAW JIAN SHIOU

Coarse grinding device

InactiveCN107262827AReduce failurePlay the role of elastic top tightFiling/rasping devicesMetal working apparatusEngineeringMechanical engineering

The invention discloses a rough grinding device, which comprises a first support plate, a second support plate is arranged behind the first support plate, a bottom plate is arranged above the first support plate and the second support plate, and a rotating motor is arranged on the lower surface of the bottom plate. The upper end of the rotating motor is provided with a connecting plate, the upper end of the connecting plate is provided with a placement block, the left side of the placement block is provided with a first vertical plate, the right side is symmetrically provided with a second vertical plate, the rear of the placement block is provided with a cylinder mounting plate, and behind the cylinder mounting plate The part on the surface is provided with a polishing cylinder, the front end of the polishing cylinder is provided with a polishing rod, and the side walls around the block are provided with a pressure rod mounting hole, and a pressure rod is provided in the pressure rod mounting hole; in general, the present invention has the advantages of simple structure, easy use The advantages of convenience, small size and easy handling.

Owner:孟卫兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com