Parts processing apparatus

A technology for processing devices and parts, applied in positioning devices, feeding devices, grinding drive devices, etc., can solve the problems of easy deviation of grinding, high maintenance cost, inconvenient movement, etc., to improve work efficiency, low maintenance cost, and grinding speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

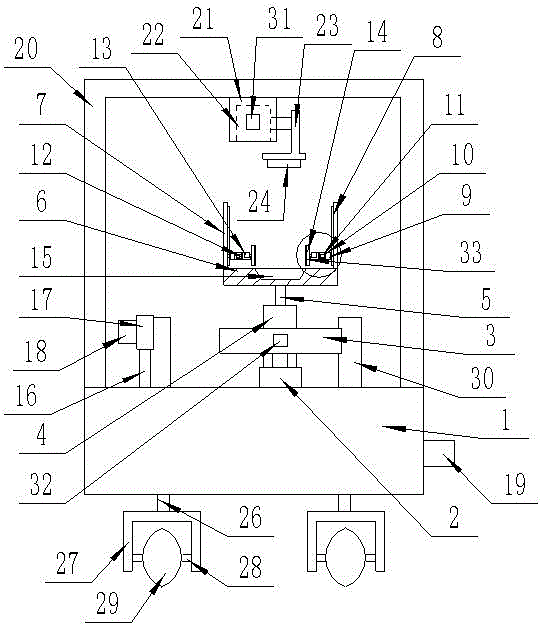

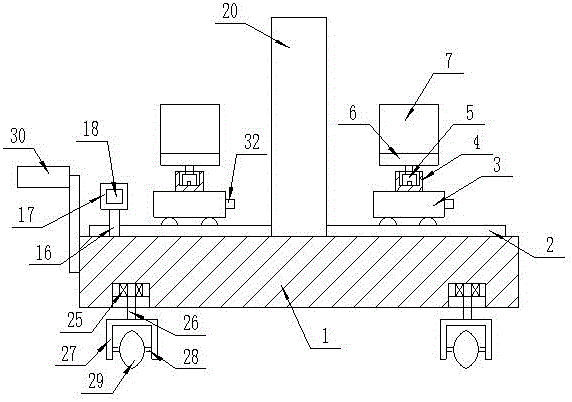

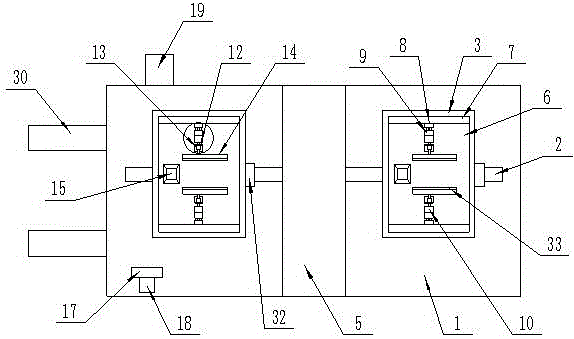

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a parts processing device includes a workbench (1), the upper surface of the workbench (1) is provided with a lifting mechanism, and the lift mechanism is provided on the upper surface of the workbench (1) by a horizontal slide rail ( 2), a plurality of electric trolleys (3) arranged on the horizontal slide rail (2), an installation block (4) arranged on the upper surface of each electric trolley (3), processed on each installation block (4) The installation groove at the center of the surface, the hydraulic cylinder (5) arranged on the inner lower surface of each installation groove with the telescopic end upward, the carrier plate (6) arranged on the telescopic end of each hydraulic cylinder (5), and the carrier plate (6) arranged on each A set of vertical mounting plates (7) on the upper surface of each carrier plate (6), a vertical slide rail (8) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com