Tubular part orifice deburring device

A technology for removing burrs and parts holes, which is applied in the field of processing parts grinding. It can solve the problems of affecting product quality, increasing the scrap rate, and high labor intensity. It achieves efficient and effective removal, simple and light structure, and avoids hard scratches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

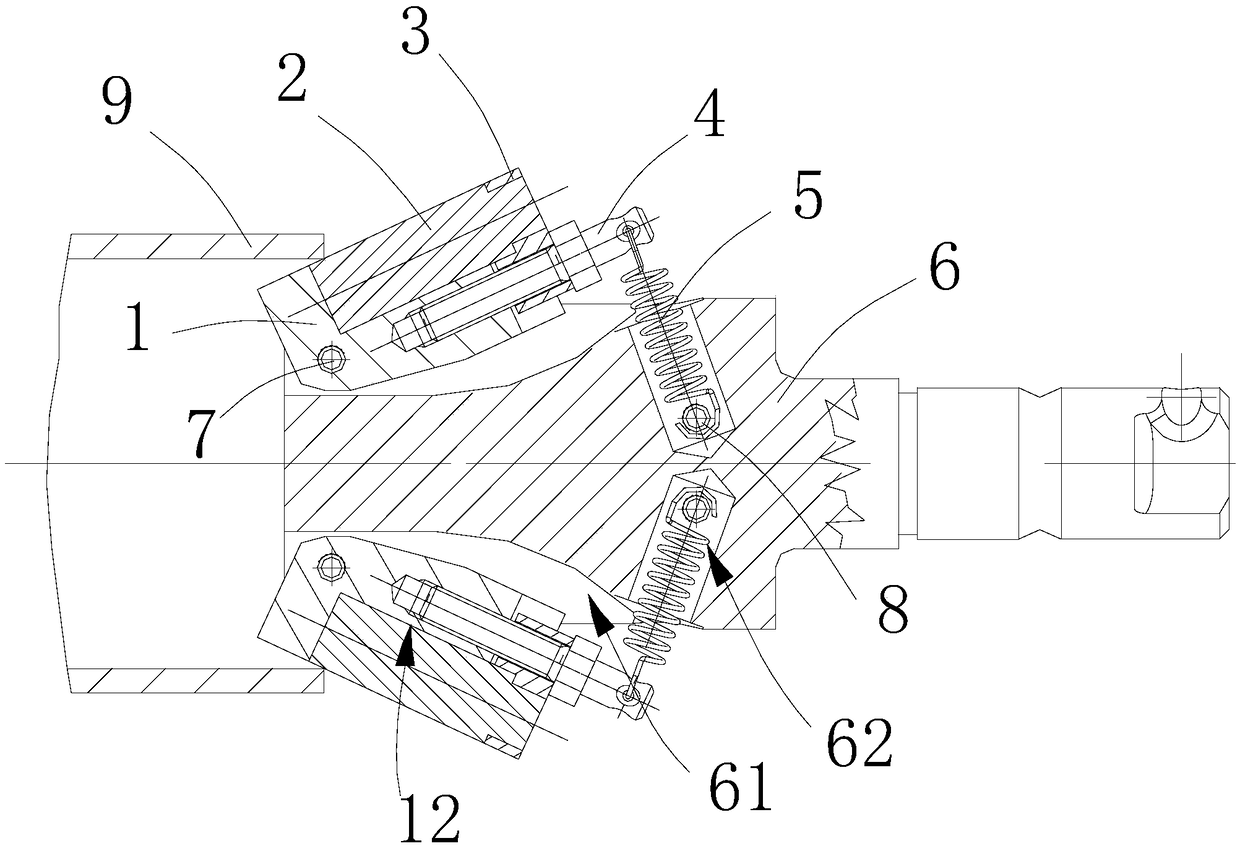

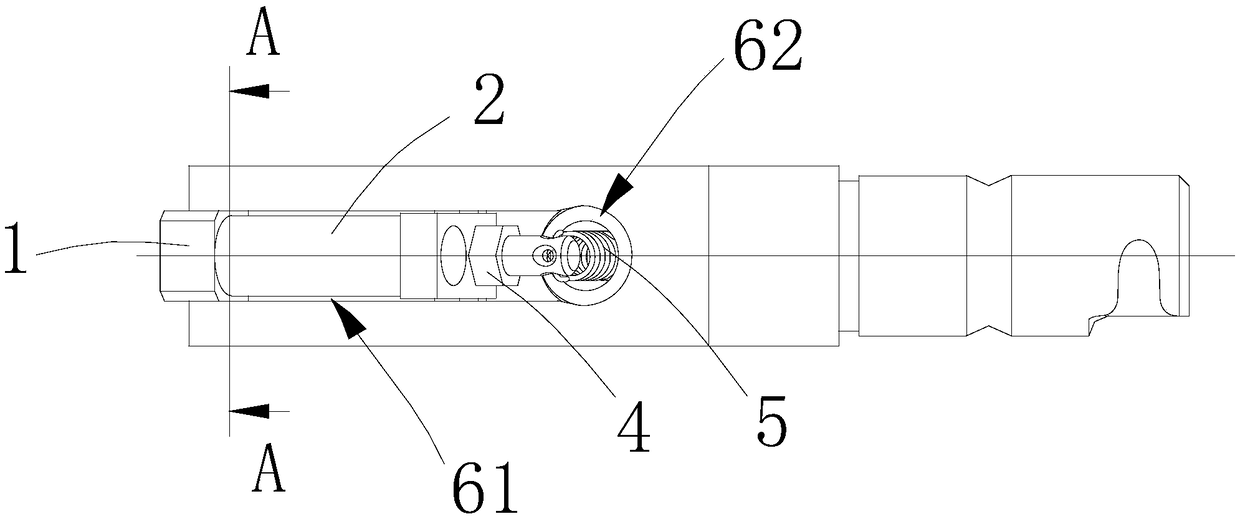

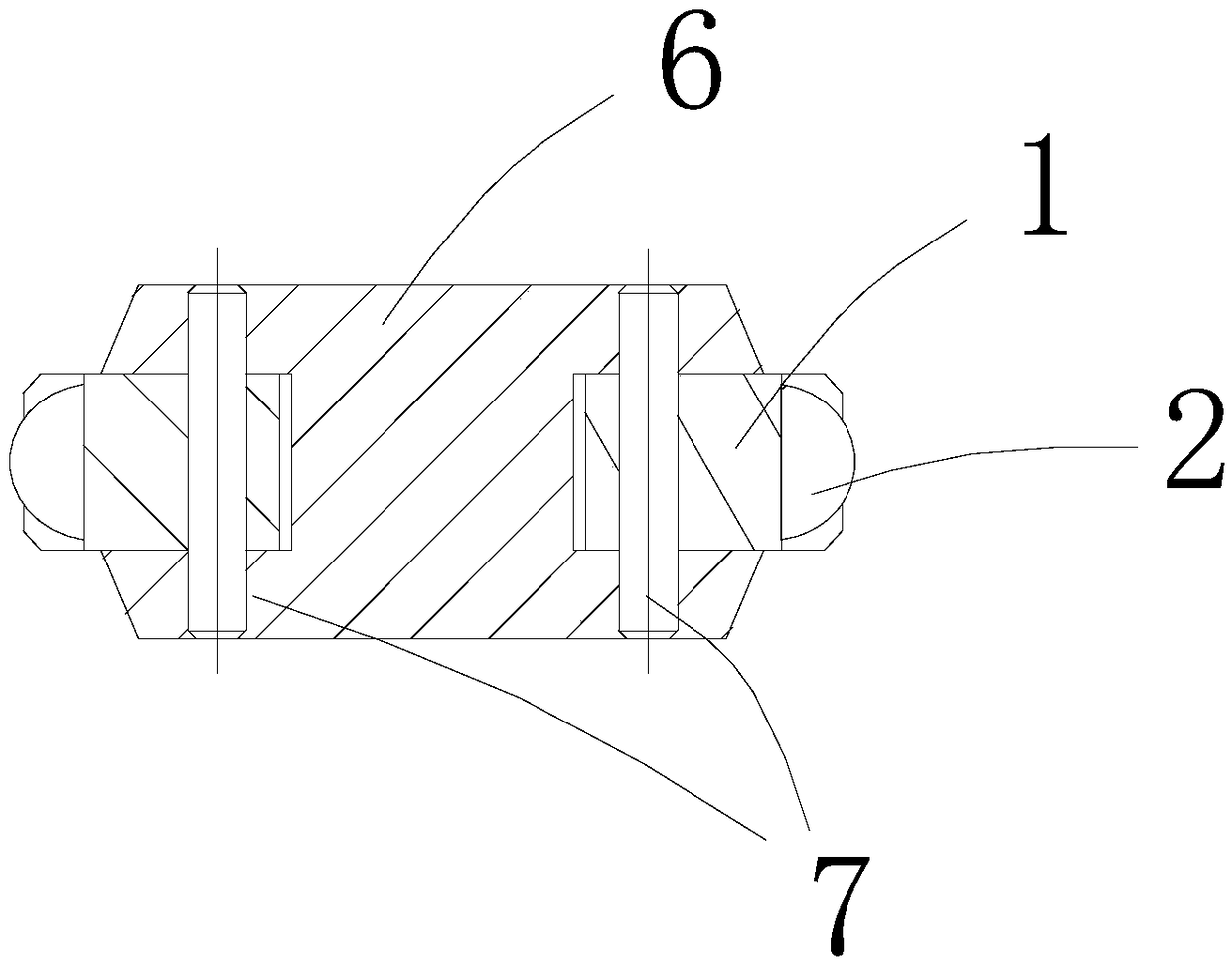

[0039] Such as Figure 1~3 As shown, the device for deburring the hole of the cylindrical part in this embodiment includes a file assembly, a spring 5 and a mounting part 6 that can rotate around the axis of the cylindrical part 9 .

[0040] Such as Figure 4 As shown, the end surface of the mounting part 6 facing the opening of the cylindrical part 9 is provided with a knife groove 61 extending along the axial direction of the cylindrical part 9 .

[0041] The end of the file assembly facing the opening of the cylindrical part 9 extends into the knife groove 61 and is hinged with the mounting part 6 through the first pin 7, and the end of the file assembly facing away from the opening of the cylindrical part 9 extends out of the knife groove 61 and connects with the spring One end of 5 is fixedly connected, and a second hole 62 for accommodating the spring 5 is opened on the mounting part 6 , and the other end of the spring 5 extends into the second hole 62 and is fixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com