Device capable of rasping cylindrical surface of bar at low speed

A technology for filing and bar grinding, which is applied in the field of devices for low-speed filing and grinding bar cylindrical surfaces. It can solve the problems of poor filing efficiency and effect, and achieve the effects of improving labor intensity, avoiding distortion of results, and improving filing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

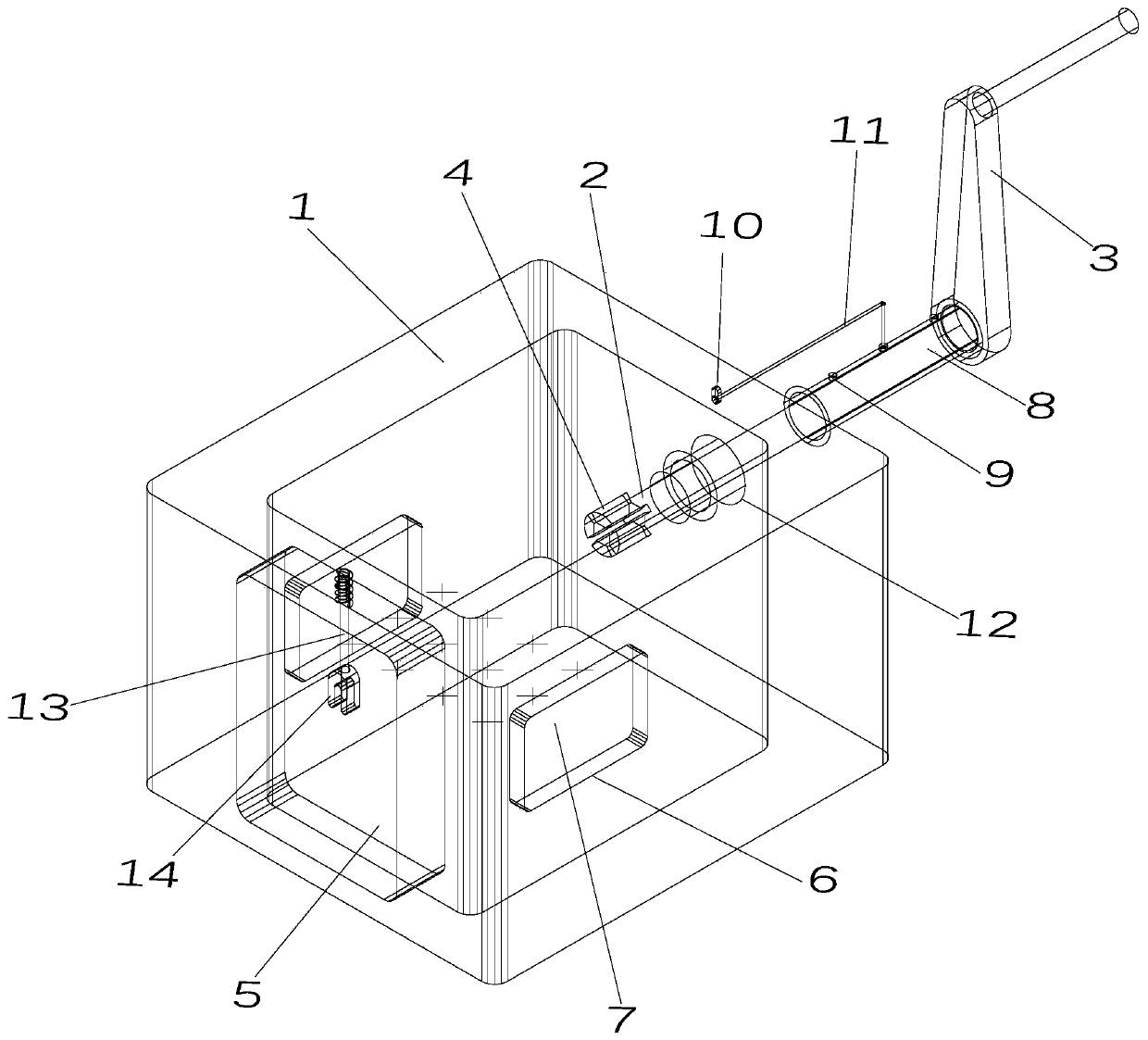

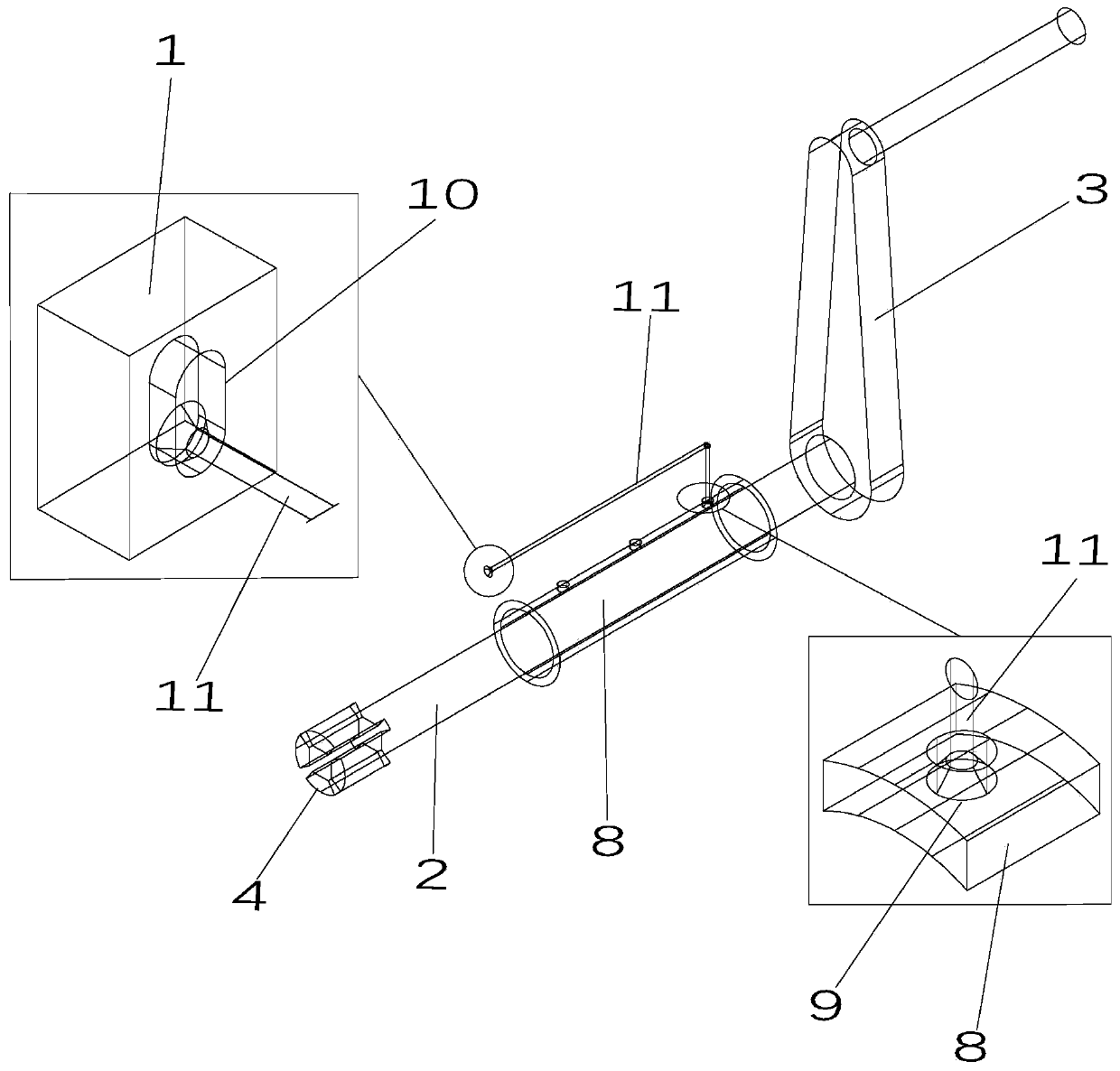

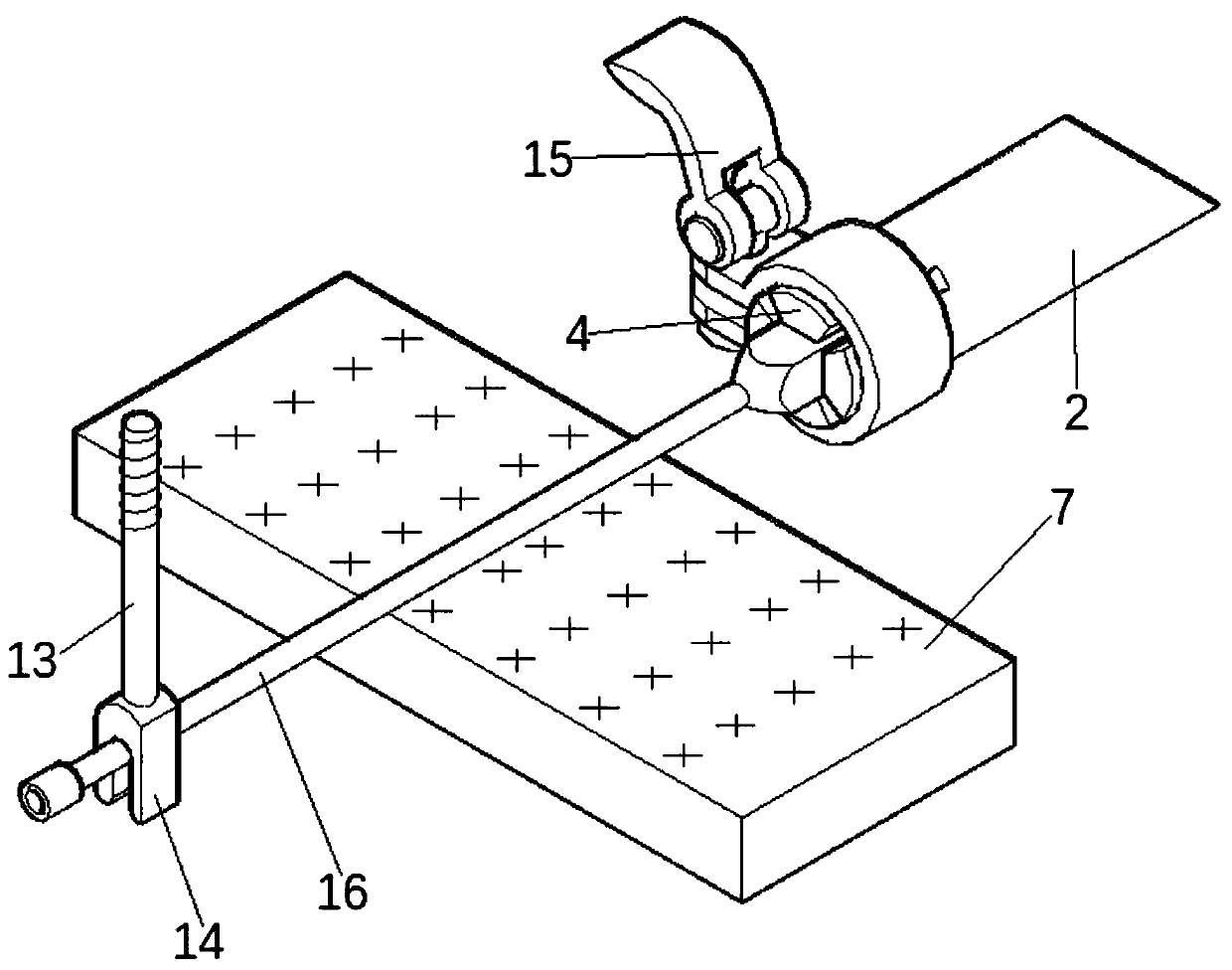

[0019] The invention provides a device capable of filing the cylindrical surface of a bar at low speed, such as Figure 1 to Figure 3 As shown, a box body 1 with an opening at the top is included, and a rotating shaft 2 with one end protruding outward is arranged horizontally in the box body 1. One end of the rotating shaft 2 located outside the box body 1 is connected with a handrail 3, and the handrail 3 is connected to the outer wall of the box body 1. The rotating shaft 2 between them is provided with a positioning mechanism, and one end of the rotating shaft 2 located in the box body 1 is coaxially connected with a four-jaw ferrule 4. In order to improve the filing efficiency of the bar 16, the contact between the bar 16 and the The action time of the device in the non-filing stage, by setting the lock 15 on the outside of the four-jaw f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com