Roll angle self-adaptive adjusting clamp

A technology of self-adaptive adjustment and roll angle, applied in the field of machinery, can solve the problems of different depths of the file pattern on the left and right, the reduction of the forming quality of the file, and the scrapping, etc., to achieve the effect of improving the processing efficiency and the adjustment quality, and the adjustment is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

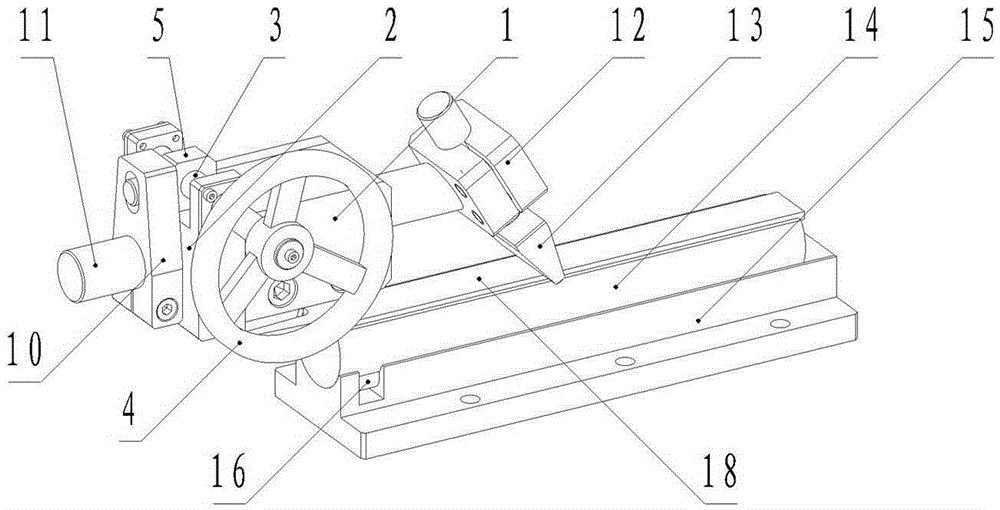

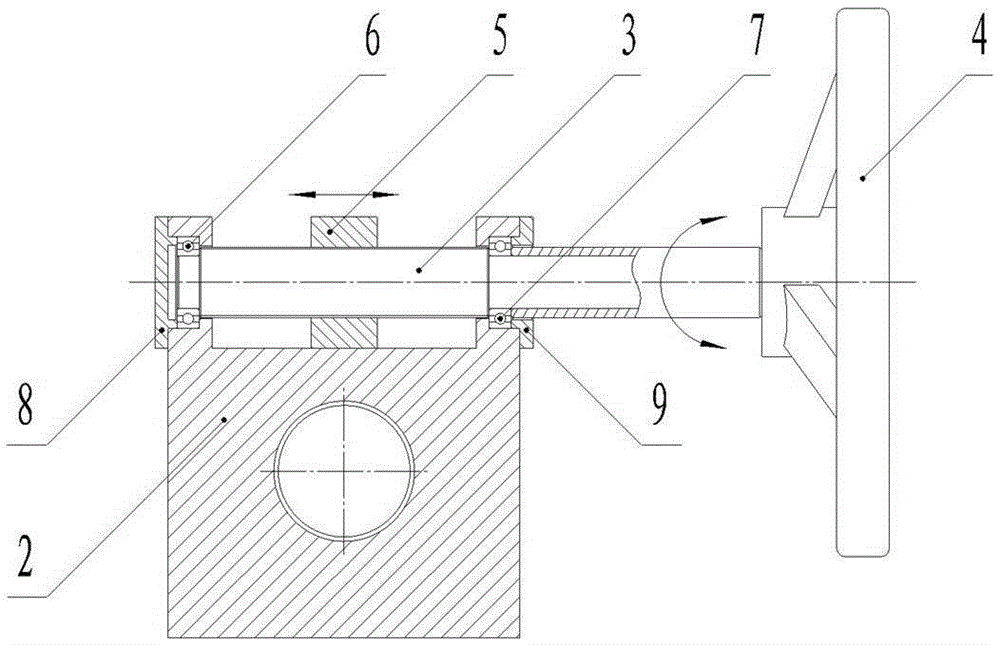

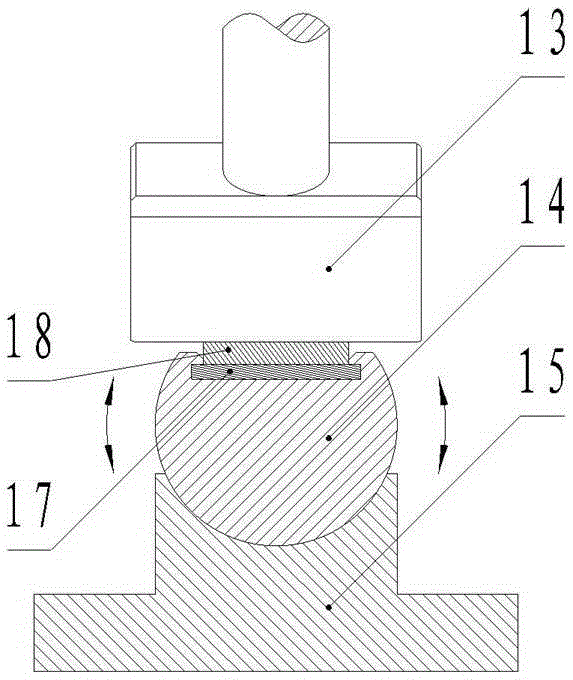

[0015] exist Figure 1 ~ Figure 3 Among them, the clamp for self-adaptive adjustment of the roll angle of the present invention includes a roll clamping block 1, an adjustment screw seat 2, an adjustment screw 3, a hand wheel 4, an adjustment nut 5, a screw bearing one 6, a screw bearing two 7, and a bearing gland 18. Bearing gland 29. Roll swing arm 10, roll shaft 11, presser foot clamp block 12, inverted T-shaped presser foot 13, clamp platform 14, clamp base 15, clamp key 16, backing plate 17, File 18. The roll clamping block 1 is fixedly connected to the machine bed, and the middle part is provided with a horizontal clamping hole, which is used to place the roll shaft 11 horizontally, and the roll shaft 11 with the adjusted roll angle can be clamped tight; the adjusting screw seat 2 is firmly connected to the roll clamping block 1, and there is a bearing mounting hole on both sides and a set of threaded holes for mounting the bearing cover correspondingly, for installing ...

Embodiment 2

[0018] The basic structure of this embodiment is the same as that of Embodiment 1, except that the manual rotation of the hand wheel to drive the rotation of the adjustment screw 3 is changed to the rotation of the motor to drive the rotation of the adjustment screw 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com