Adjustable suction and application anticorrosion device for internal surface of oil exploitation pipe

A technology for oil extraction and anti-corrosion device, which is applied in the direction of pipeline anti-corrosion/anti-rust protection, special pipes and pipe components, etc. It can solve the problems of inconvenient pressure, inconvenient blowing, and inconvenient height adjustment of dust, and increase the adjustment work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

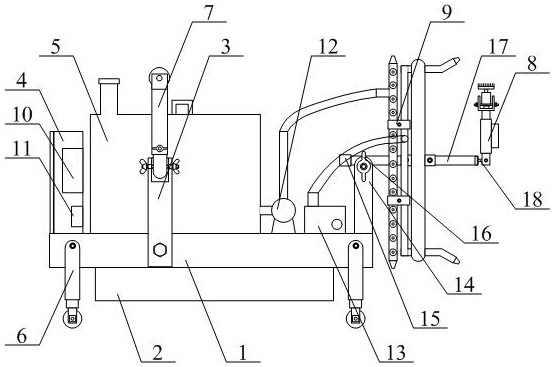

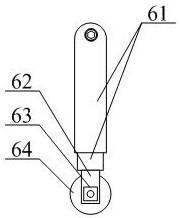

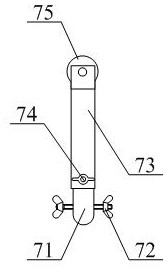

[0038] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, an adjustable anti-corrosion device for absorbing the inner surface of oil production pipes includes a chassis 1, a power supply box 2, a first support plate 3, a control box 4, a paint box 5, and a telescopic power push frame structure 6. Rotating telescopic support tube structure 7, detectable rotating cleaning brush structure 8, cleaning spraying frame structure 9, PLC10, wireless transmission module 11, spraying pump 12, micro air pump 13, second support plate 14, rotating motor 15, fixing bolts 16 , the support tube 17 and the support rotation tube 18, the power box 2 is bolted to the middle of the lower end of the chassis 1; the lower end of the first support plate 3 is bolted to the left side of the front surface and the rear surface of the chassis 1 respectively On the left side; the control box 4 is bolted to the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com