High-efficiency roller brush grinding mechanism

A technology of grinding mechanism and roller brush, which is applied to the parts of grinding machine tools, grinding machines, and machine tools suitable for grinding the edge of workpieces, etc., which can solve the problems of small grinding area, complex drive mechanism of the device, and large space occupation, so as to avoid Grinding the dead angle, improving the range of use, and the effect of compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

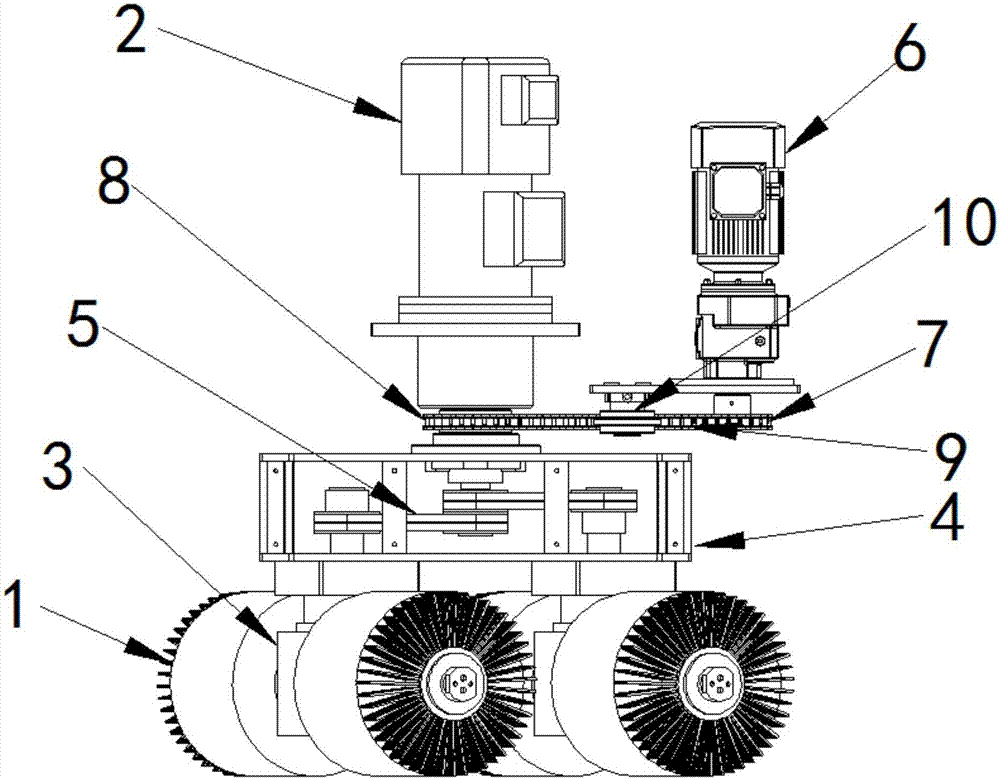

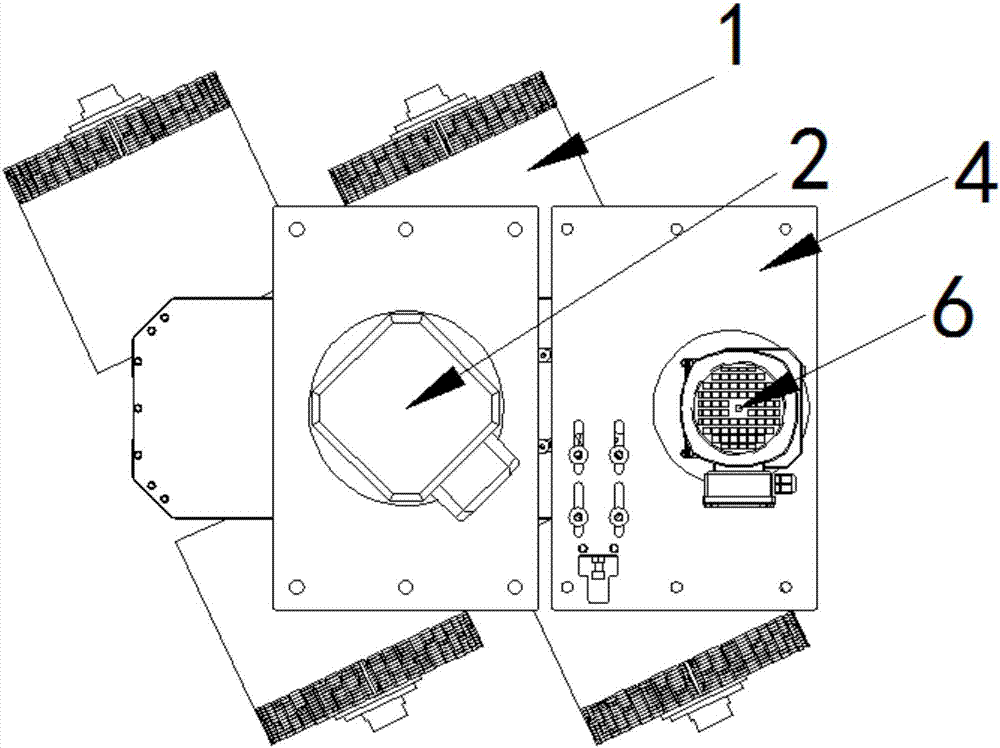

[0019] Embodiment 1: as Figure 1~2 The roller brush grinding mechanism shown includes a roller brush group, a roller brush rotation drive mechanism, a roller brush revolution drive mechanism, and a roller brush rotation drive mechanism including a rotation motor 2 , a steering gear 3 and a bracket 4 . The steering gear 3 is fixed on the support 4 . The output shaft of the self-rotating motor 2 is connected to the diverter 3, and the output shaft of the diverter 3 is parallel to the rotating shaft of the roller brush 1, and is connected to the rotating shaft of the roller brush 1 through the transmission belt 5. The roller brush revolution driving mechanism includes a revolution motor 6, and the revolution motor 6 is connected to drive the bracket 4 to rotate around the output shaft of the autorotation motor 2 through a transmission mechanism. The transmission mechanism described in this example is a chain transmission mechanism. A drive sprocket 7 is provided on the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com