Hanging bracket supporting workpiece centerless grinding machine

A technology of centerless grinding machine and support parts, which is applied in the field of parts processing, and can solve the problems of workpiece processing influence, easy accumulation, and difficult discharge of grinding debris, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

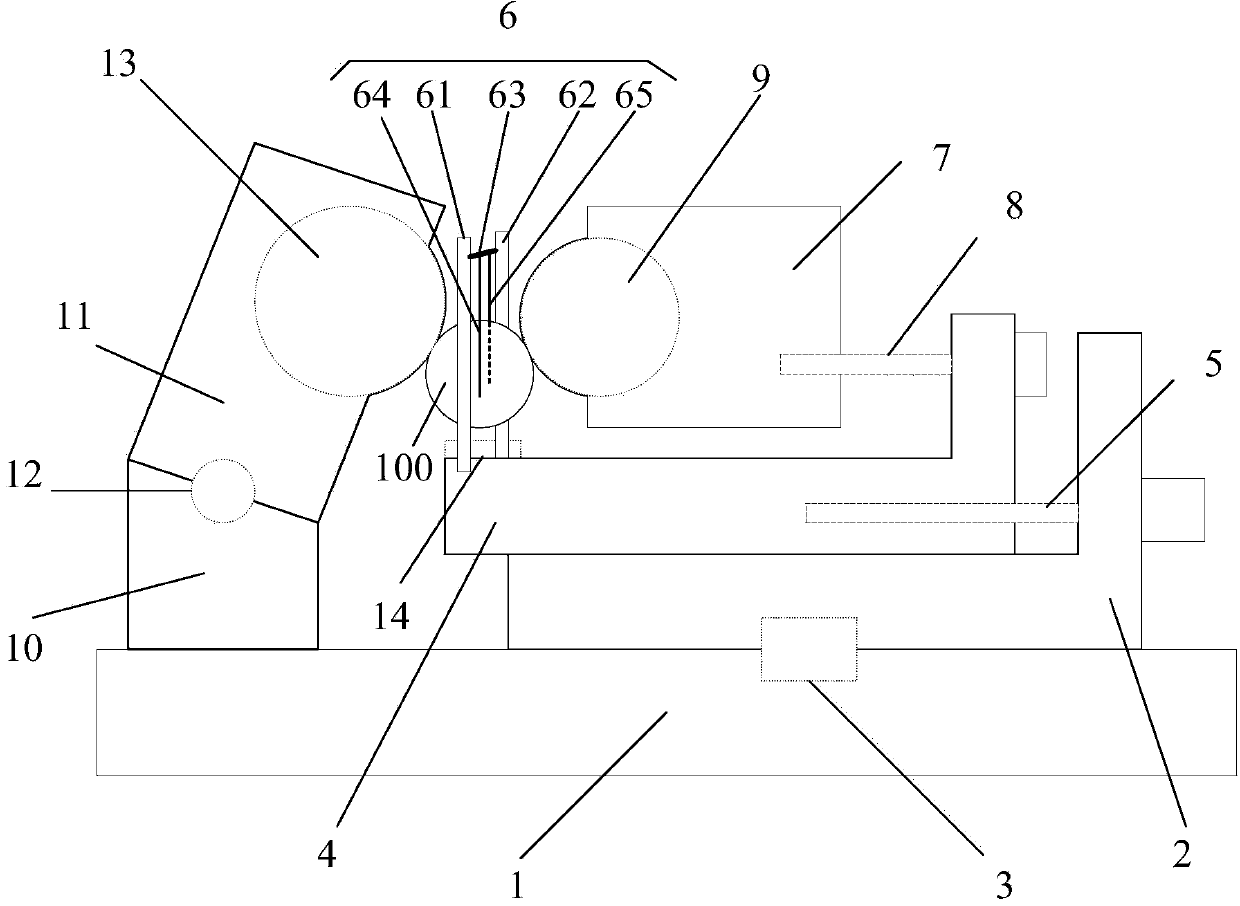

[0021] The present invention proposes a hanger supporting workpiece centerless grinder, such as figure 1 As shown, it includes: base 1, horizontal machine table 2, rotating shaft 3, sliding machine table 4, first screw rod 5, workpiece support frame 6, first tool rest 7, second screw rod 8, adjustment wheel 9, support member 10 , the second knife rest 11, the third screw rod 12, the grinding wheel 13 and the accommodation groove 14.

[0022] The horizontal platform 2 is horizontally rotatably mounted on the base 1 via a rotating shaft 3 . The support 10 is installed on the base 1 .

[0023] The sliding platform 4 is slidably installed on the horizontal platform 2 and can slide longitudinally on the horizontal platform 2 by adjusting the first screw rod 5 .

[0024] The workpiece supporting frame 6 is made up of a first pole 61 , a second pole 62 , a third pole 63 , a first boom 64 and a second boom 65 . The first support rod 61 and the second support rod 62 are installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com