Magnetic abrasive finishing process machine

A magnetic abrasive and finishing technology, which is applied to grinding racks, machine tools suitable for grinding the edge of workpieces, metal processing equipment, etc., can solve the problem of low button finishing precision, reduce the amount of waste, The effect of avoiding grinding dead angle and reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

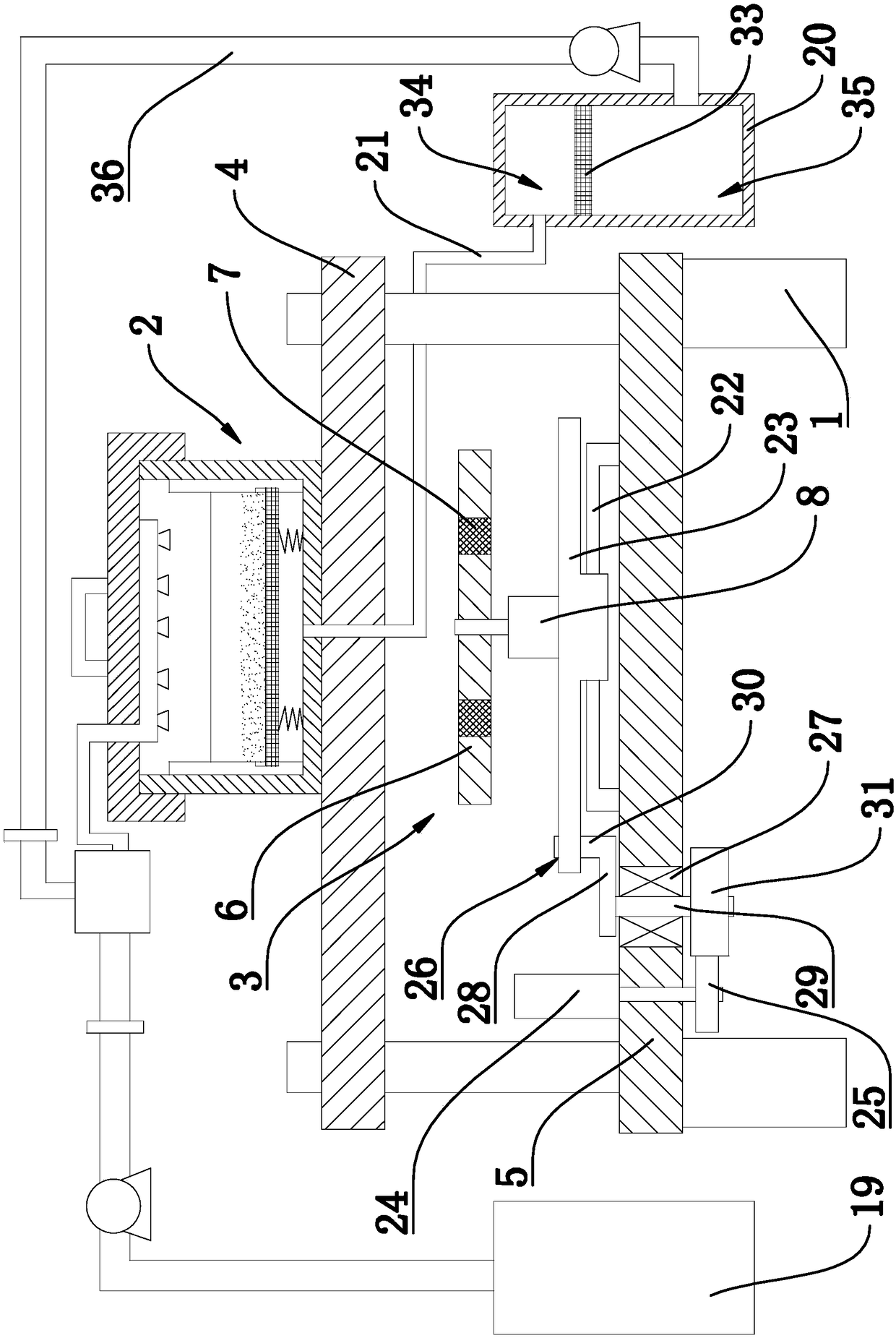

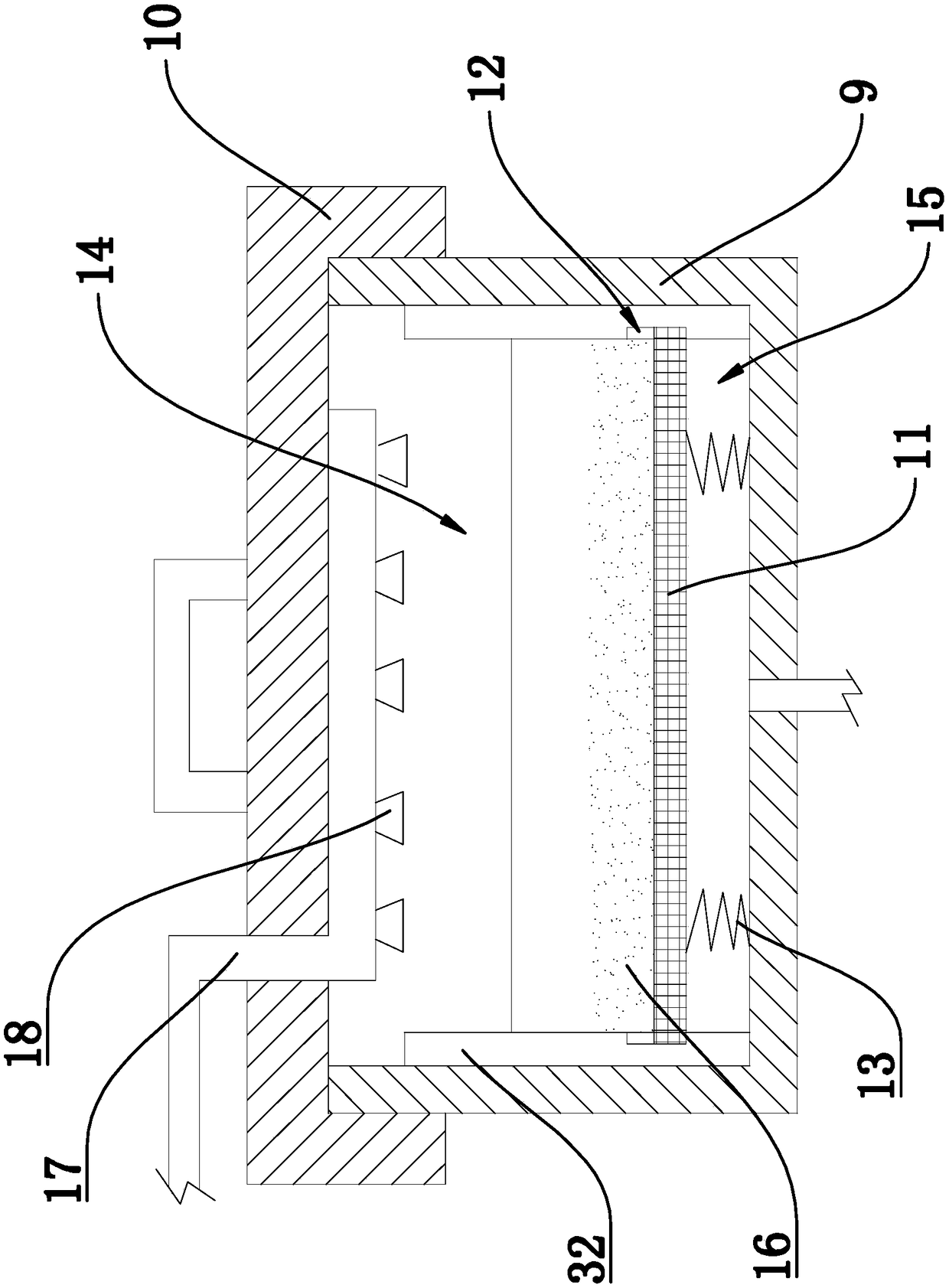

[0021] Such as figure 1 and figure 2 As shown, the present invention provides a magnetic abrasive finishing machine, which is used for finishing the surface of metal buttons, including a base 1, a processing box 2 and a rotating magnetic disk 3, and the base 1 includes a support table-4 and Support platform two 5, support platform one 4 are above the support platform two 5, and the processing box 2 is placed on the support platform one 4. The rotating disk 3 is used to provide a magnetic field. The rotating disk 3 is between the supporting platform one 4 and the supporting platform two 5. The rotating disk 3 includes a rotating disk 6 and a magnet 7. The rotating disk 6 is provided with a magnet mounting groove, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com